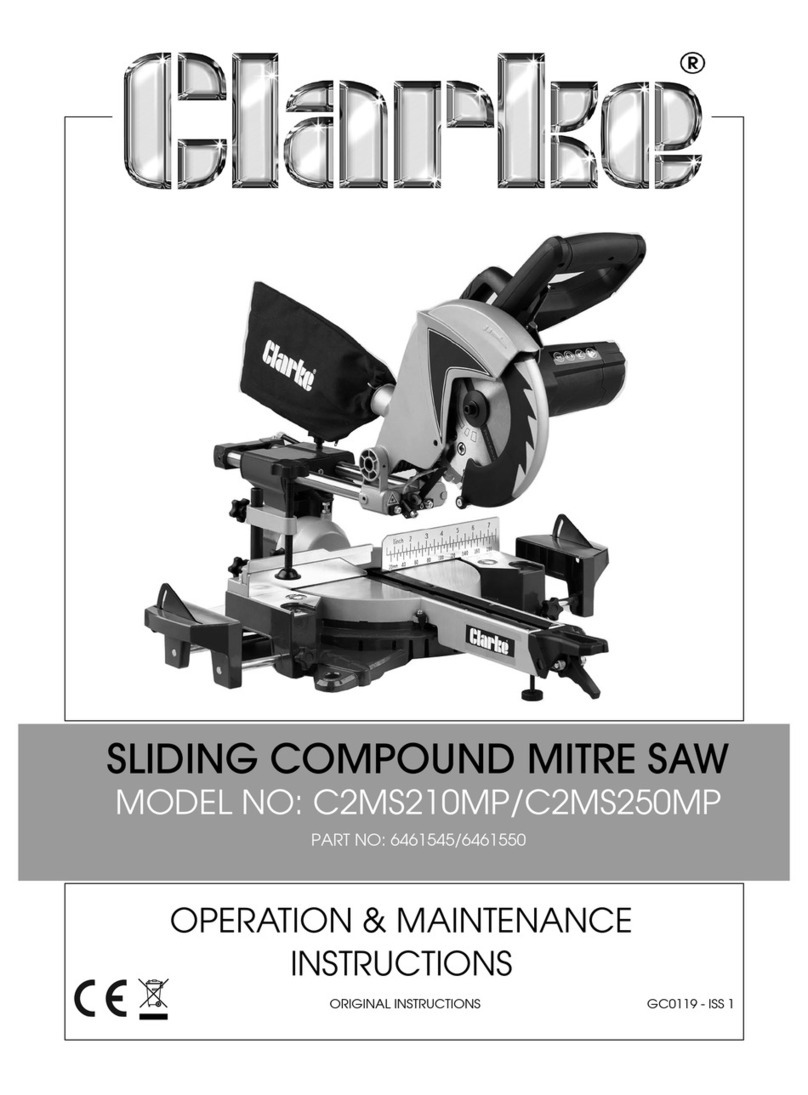

Thank you for purchasing this CLARKE Compound Mitre Saw, which is designed for

DIY, Hobby and Professional users alike.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt as proof of purchase.

This guarantee is invalid if the product is found to have been abused or tampered

with in any way, or not used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be

returned to us without prior permission.

This guarantee does not effect your statutory rights.

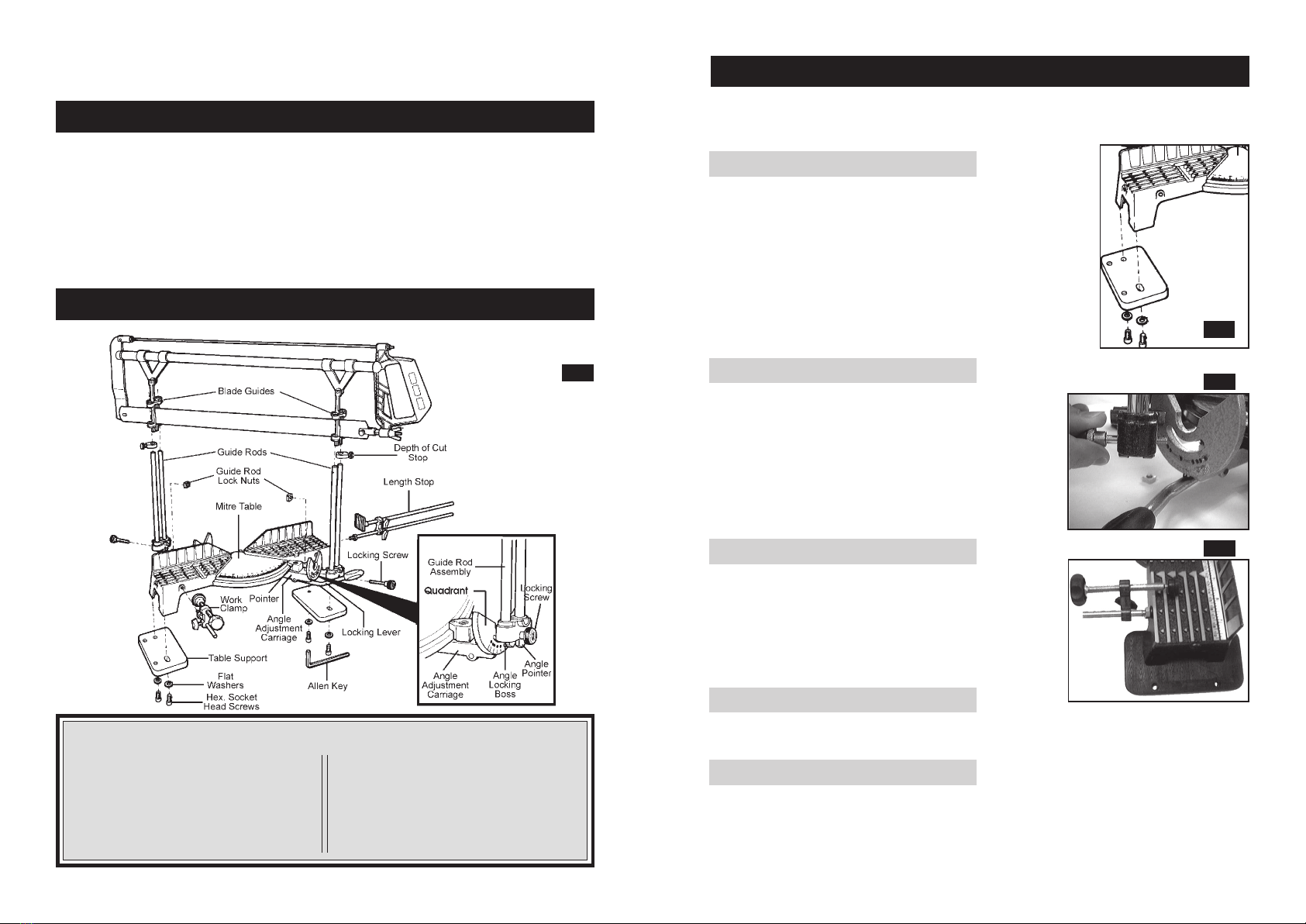

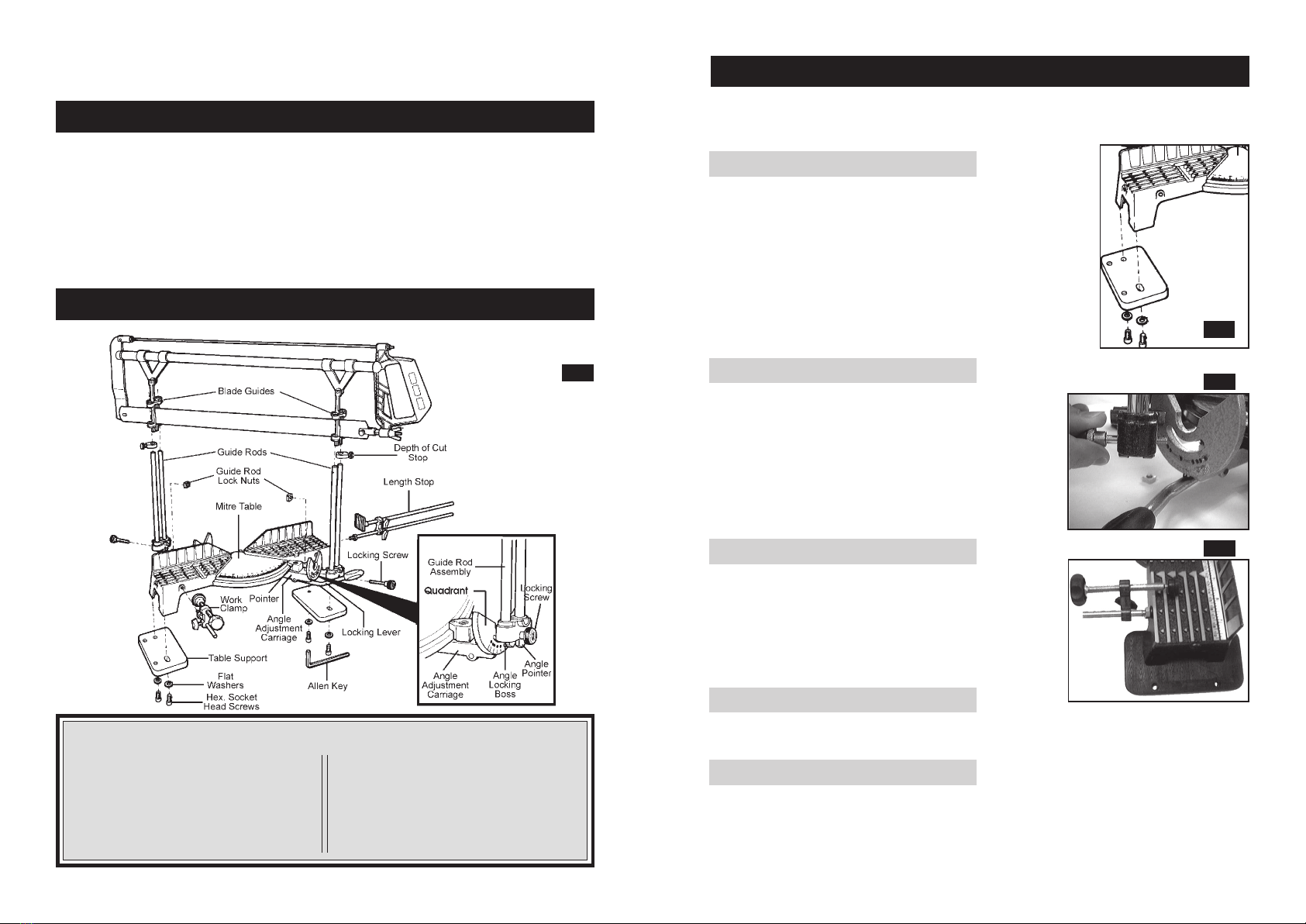

COMPONENT GUIDE

ASSEMBLY Ref. Fig.1

The Angle Adjustment Carriage is preassembled to the Mitre Table. It is necessary

to assemble the Guide Rod Assemblies, Table Supports, Work Clamp and Length

Stop as follows:

1. Table Supports

Screw the Supports to the Mitre Table using the Hex.

Socket Head screws with flat washers provided - two at

each side.

Refer to fig. 2, and note the manner in which they are

attached - the two holes nearer the edge of the

Support, are towards the outside of the Mitre Table and

are visible when correctly assembled (see also Fig. 4).

NOTE: These holes may be used to fix the Mitre Saw to a

workbench, for additional stability, if required.

2. Guide Rod Assemblies

Insert the locking screw through the hole in the base

of the Guide Rod as shown in Fig. 3, ensuring the

Locking Boss is facing inwards towards the Angle

Quadrant. Thread the screw through the slotted

hole in the Quadrant and secure with the square nut

provided.

The Locking Boss sits in one of the holes in the Angle

Quadrant to determine the saw blade angle.

3. Work Clamp

Screw the Clamp Support into one of the threaded

holes in the front face of the Mitre Table, (see fig. 4),

depending upon which side of the saw blade your

work is to be mounted, remembering NOT to clamp

the free end of the work.

Secure the Clamp Support with the nut provided

4. Work Stop

Screw the Stop Support rod into the threaded hole at the end of the Mitre table

and lock in place using the nut provided.

5. Saw Blade

Slide a Depth of Cut Stop on to one of the Guide Support Rods, before carefully

sliding the Blade Guides on to the Guide Rods. When this is accomplished, clip the

caps on to the top of each Guide Rod Assembly.

Your Mitre Saw is now fully assembled and ready for use.

SPECIFICATIONS

Cutting Width 90O................................ 120mm

Cutting Width 45O................................ 100mm

Cutting Width Compound .... 50mm

Cutting Depth ........................ 150mm

Table Length .......................... 400mm

Saw Blade Length .................. 600mm

Saw Blade Width ................... 45mm

Weight .................................... 3.95kg

Part No. ................................... 6461510

Dimensions ......... 626xs730x314mm

Fig.1

Fig.4

Fig.3

Fig.2