Thank you for purchasing this CLARKE Power Winch.

This versatile machine is designed for domestic, non-industrial use, and is ideal for

winching trailers, raising straw bales etc.

Before operating the machine, please read this leaflet thoroughly and follow the

instructions carefully. In doing so you will ensure the safety of yourself and that of

others around you, and you can look forward to the Power Winch giving you long

and satisfactory service.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of 12 months

from the date of purchase. Please keep your receipt as proof of purchase. This guarantee

is invalid if the product is found to have been abused or tampered with in any way, or not

used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be returned

to us without prior permission. This guarantee does not effect your statutory rights.

SAFETY PRECAUTIONS

1. This machine is designed for indoor, domestic use. Do not use outdoors unless

it is completely protected against the elements.

2. Keep children well away from the machine.

3. Do not service the machine in any way when it is plugged in to an electrical supply.

4. Protect the machine from extreme weather conditions, i.e. frost and/or high

temperatures.

5. The machine is not equipped with an overload cut-out. If the load exceeds

the capacity of the machine, do not persist in pushing the hoist button as this

will cause the motor to overheat and eventually damage will be inccurred.

6. NEVER stand beneath a raised load.

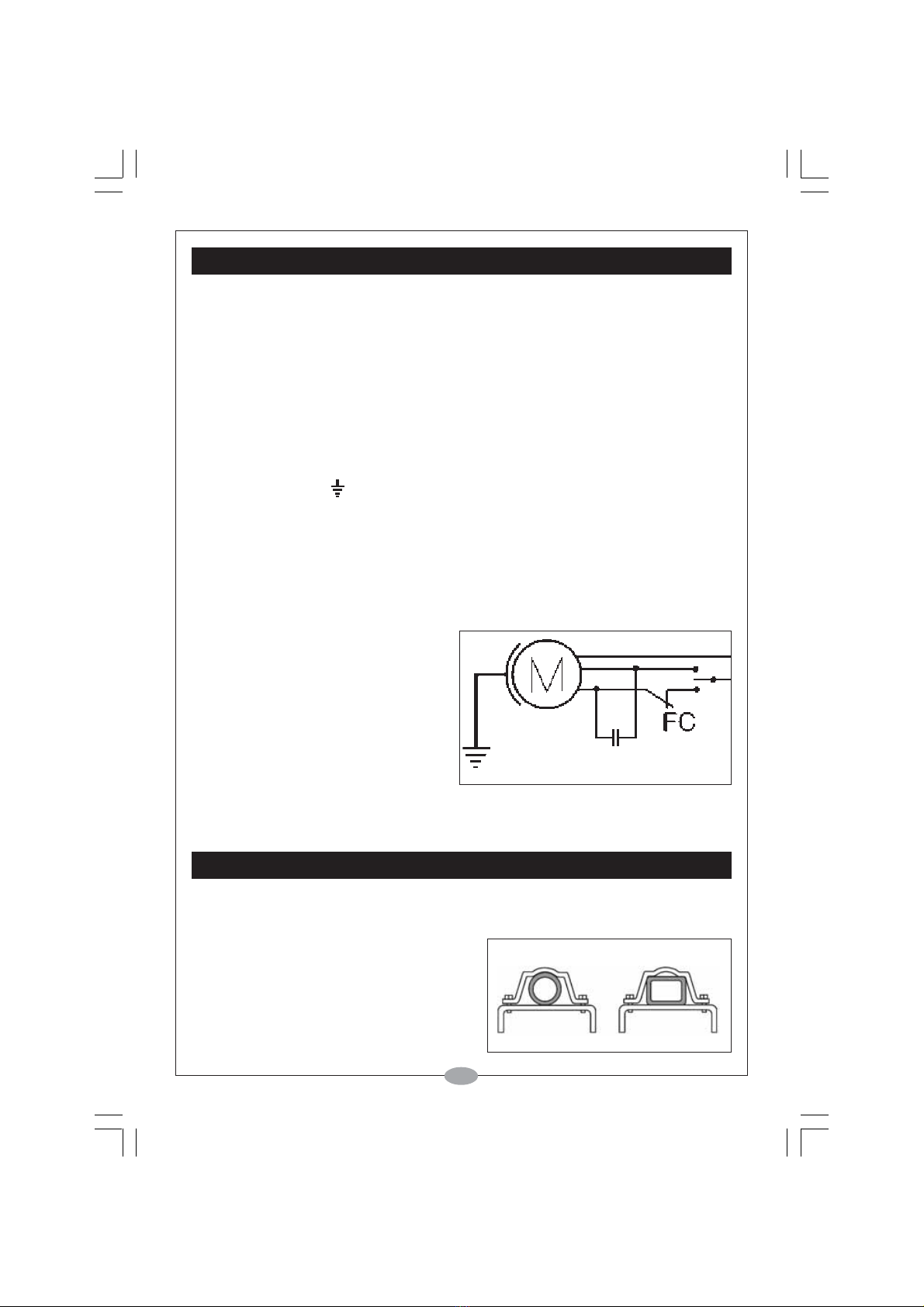

7. Before operating it is important to ensure that the steel cable is correctly wound

around the drum - see fig. 3, page 4.

8. Before operating ensure that at least THREE turns of the cable are wound

around the drum.

9. If the cable needs replacing, ensure it is replaced with one of identical

specification. Contact your CLARKE dealer or the CLARKE International Service

Department for advice.

10. Ensure that the switches are kept in good condition.

11. Before use, always inspect the machine and its’ mountings to ensure they are

in good condition. If any damaged or broken parts are found, the machine should

be removed from service and the parts renewed or repaired before further use.

12. Always wear industrial gloves when operating the machine.

13. When pulling or dragging a horizontal load, do not stand between the load

and the machine and keep others well away from the area.

2