MOUNTING INSTRUCTIONS

TECHNICAL SPECIFICATIONS

K1051/KX1051 Work Winch Owner’s Manual

Performance Products

FULTON

WARNING

!Read, understand and follow all instructions before installing and/or using product. NEVER allow anyone

unfamiliar with the operating instructions to use this product.

!Read, understand and follow all instructions provided by the manufacturer of the product(s) that this winch

will be installed on.

!Installation, use and maintenance of these Fulton winches must conform to the following instructions only.

!

!

!DO NOT use this winch as a human hoist. NEVER allow anyone to be positioned on, around or under the

load being lifted or moved.

!Never exceed the maximum rated capacities.

!Always inspect the cable and hook before each use to make sure that they are not damaged. If the cable or

hook breaks, the cable will whip violently and can inflict serious injury and/or property damage.

!Never use worn, kinked, or frayed cable. Replace the cable immediately.

!Always maintain a minimum of three complete wraps of cable on the drum.

!The cable on the winch must be strong enough to support the load to be moved.

!A loud clicking sound from the ratchet must be heard when lifting the load. If a loud clicking sound is not

heard do not use and replace ratchet components immediately.

!Never release the crank handle unless the ratchet pawl is fully engaged and the load is supported.

!Never operate with slippery, wet or oily hands and always maintain a firm grip on the winch handle.

!Never leave a weight hanging from the winch while the winch is unattended, as another person may attempt

to operate the winch, thereby creating an unsafe condition.

!Failure to follow these warnings and instructions will result in property damage, serious bodily injury and/or

death.

Fulton cannot be held liable for improper installation, use, or maintenance of this product.

Do not get oil or grease on the friction disks. This could allow the load to slip or fall.

Obey crank rotation decal and operating instructions. Disregard could cause bodily harm or property damage

and/or death.

50 Indianhead Dr., P.O. Box 8 Mosinee, WI 54455-0008

800/604-9466 715/693-1700 Fax 715/693-1799

www.fultonperformance.com

F1928 (D-7939) 3/02

FULTON

Performance Products, Inc.

READ, UNDERSTAND, AND SAVE THESE INSTRUCTIONS

OPERATING INSTRUCTIONS

Turning the handle counter-clockwise actuates the brake. The brake system is designed to hold the load

whenever the handle is released.

TO PULL CABLE IN OR RAISE LOAD

1) The cable must be securely fastened to the object being lifted and to the winch drum.

2) Always be sure that the cable and cable attachments are not damaged and are strong enough for the load.

Assure there is adequate safety factor, of at least three times the maximum load for all components used.

3) Referring to the "Cable In/Cable Out" decal on the winch, turn the handle clockwise to lift. The ratchet

MUST make a loud clicking sound.

TO LET CABLE OUT OR LOWER LOAD

1) Referring to the "Cable In/Cable Out" decal on the winch, turn the handle counter-clockwise to lower. No

clicking will be heard because the brake system is activated.

MAINTENANCE

Do not get oil or grease on the friction disks. This could allow the load to slip or fall.

1) Maintain a film of automotive type grease on all gear teeth and to the O.D. of drum bearing, item #17, at all

times.

2) Keep ratchet pawl pivot, bushings and pinion threads lubricated with automotive engine oil at all times.

3) Check brake friction disks for wear. If less than 1/16" thick, cracked, or broken, they must be replaced.

4) During each usage, check for proper ratchet operation. When cranking cable in, a loud clicking sound must

be heard from the ratchet. If a loud clicking sound is not heard, do not use and replace damaged components

immediately. When cranking cable out, there is no clicking and the ratchet pawl must be fully engaged into the

ratchet gear teeth.

5) Before each usage, inspect fasteners for proper tightness.

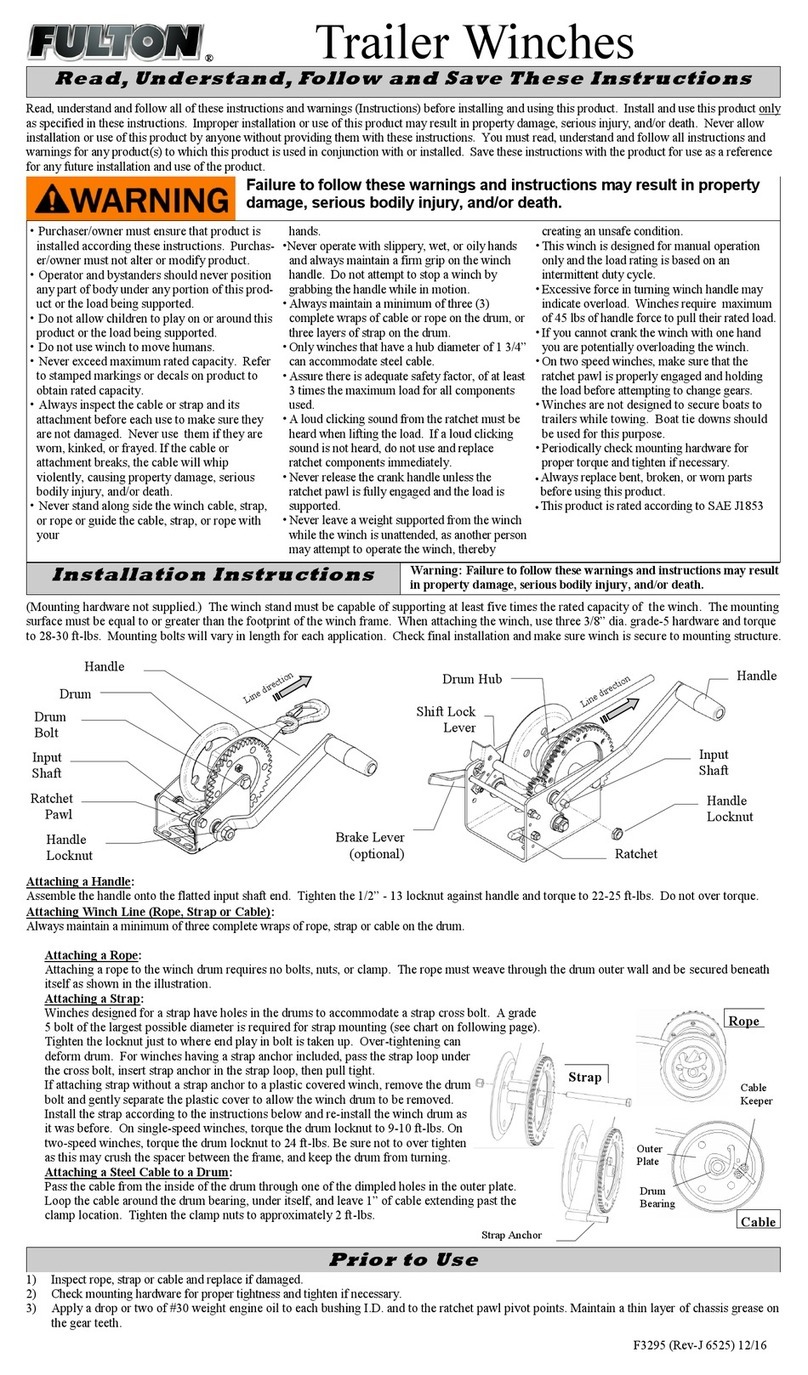

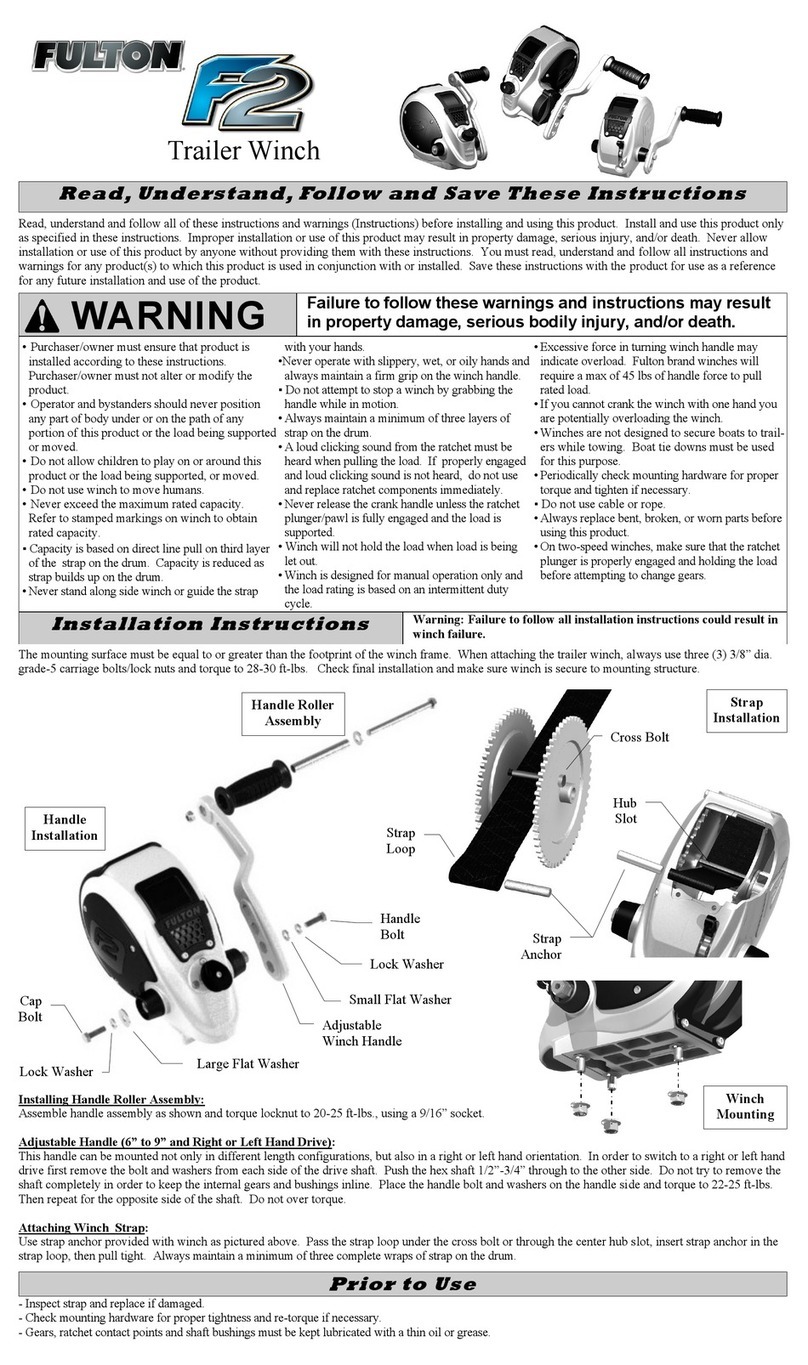

1) Assemble handle onto input shaft end.

Tighten the 1/2-13 locknut against handle.

Note: Do not remove or adjust the double

locknuts on long end of input shaft. They are

an important part of the braking system and

must be intact. See Fig.1

2) Mount the winch to a structure capable of

supporting at least 5 times the load the winch

will be pulling.

Note: When bolting the winch down, use three

grade 5, 3/8 diameter bolts, flat washers and

locknuts (not supplied).

Note: Always use outer most slots at the end

opposite the direction of line pull. Use large

flat washer if using center slot at opposite end.

CABLE ATTACHMENT TO DRUM

1) Feed the cable over the top of drum, through

drum side hole, and through cable clamp with

one inch extending past clamp.

2) With keeper nuts and lock washers outside the

drum side, tighten nuts snug until cable is

adequately clamped (approx. 20 - 30 lb-in).

3) Always be sure the cable is pulling straight off

the winch, not at an angle. This will prevent

the cable from rubbing against the sides of the

drum, which can damage the cable.

Warranty. Fulton Performance Products, Inc. ("We") warrants to the original consumer purchaser ("You") that the product will be free from defects

in material and workmanship for a period of three years under normal use and service, ordinary wear and tear excepted. If the product does not

comply with this warranty, We will replace the product without charge to You and within a reasonable time or, at Fulton's option, refund the purchase

price. This warranty is not transferable.

Limitations on the Warranty. The warranty does not cover the following: (a) normal wear and tear; (b) damage through abuse, neglect, misuse, or

as a result of any accident or in any other manner; (c) damage from misapplication, overloading, or improperly installed; (d) improper maintenance;

(e) a product altered in any manner by anyone other than us.

Obligations of Purchaser. To make a claim, contact us at 50 Indianhead Drive, Mosinee, WI, (715) 693-1700, identify the product, and follow the

instructions that will be provided. Any returned product that is replaced or refunded becomes the property of Fulton. You will be responsible for

shipping costs to us. Please retain your purchase receipt to verify date of purchase. This must be produced to honor warranty claim.

Remedy Limits. Repair or replacement is the purchaser's sole remedy under this or any other warranty on the product, whether express or implied.

We shall not be liable for service or labor charges incurred in removing or replacing a product or any incidental or consequential damages of any

kind. We expressly disclaim any implied warranty of merchantability or fitness for particular purpose after the three-year warranty period. Some

states do not allow the exclusion of incidental or consequential damages or limitation of an implied warranty so the above exclusion and limitation

may not apply to you.

Legal Rights. This warranty gives you specific legal rights, and You also may have other rights which vary from state to state. ANY IMPLIED

WARRANTY OFMERCHANTABILITY OR FITNESS FOR APARTICULAR PURPOSE ON ANYPRODUCT SHALL BE LIMITED TO

THREE YEARS FROM THE DATE OFRETAIL PURCHASE BYYOU. Some states do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to You.

This warranty is governed by the laws of the United States of America and is void where prohibited.

LIMITED THREE YEAR WARRANTY

HANDLE

INPUT SHAFT

1/2-13 LOCKNUT

DOUBLE

LOCKNUTS

FIG. 1

FIG. 2

CABLE KEEPER

KEEP 3 WRAPS

AROUND DRUM

TECHNICAL SPECIFICATIONS

K1051/KX1051 1,000

(4.5)

500

(2.2) 4.1:1 11"29:1 2-1/4" 50' x 7/32" Cable

(Max. 6 layers)

1st LAYER

LBS. (kN)

CAPACITY RATING (*1)FULTON

MODEL

NUMBER

MAXIMUM

MECHANICAL

ADVANTAGE (*2)

HANDLE DRUMHUB

GEAR

FULL DRUM

LBS. (kN)

FULTON

MODEL

NUMBER

MAXIMUM

MECHANICAL

ADVANTAGE (*2)

HANDLE

LENGTH

DRUM

STORAGE (*3)

HUB

SIZE

GEAR

RATIO

*1 - Capacity Rating - Based on direct line pull on first layer of line on the drum. Capacity is reduced as layers of line builds up on the drum.

*2 - Maximum Mechanical Advantage - Based on first layer of recommended line on the drum. For maximum efficiency use only the amount of line

required.

*3 - Breaking strength of cable must be greater than 3,035 lbs (13,5 kN).