wire rope.Do not operatethe winch until all defects

havebeencorrected.

2. AIR SYSTEM. Checkair lines, valvesandother

componentsfor leakage.Repairif necessary.

3. WIRE ROPE.Wire ropeis aconsumableitemwhich

mustbereplacedwhen worn. The following list is a

guide to theacceptedstandardsby which wire rope

mustbejudged andis not presentedasasubstitutefor

anexperiencedinspector:

a. Damage,suchasbird cages,kinking, core

protrusion, crushing, heatdamage,andmain

stranddisplacement.

b. Corrosionandnicking.

C.

Wearof crown wires.Replaceat l/3 wearof any

crown wire.

d. Brokenwires or strands,particularly at

connections.Replacementis necessaryif one

wire is broken ataconnection; six wiresbroken

within onelay; threewires broken in onestrand

within-one lay.

e. Lubrication.

Replacewire ropeif any doubtexistsasto wire rope

serviceability.

4. WIRE ROPEREEVING. Cheekreeving andensure

wire ropeis properly securedto thedrum.

5. CONTROLS. Seethat controls function properly and

control handlereturns to neutral centerwhenreleased.

Periodic Inspection

According to ASME B30.7, frequencyof periodic

inspection dependson theseverity of usage:NORMAL,

yearly; HEAVY, semi-annually; SEVERE,quarterly.

Disassemblymay,berequired for HEAVY or SEVERE

usage.Keepaccumulative recordsof periodic inspectionslo

provide abasisfor continuing evaluation. Inspectall the

itemsin afrequentinspectionplus the following:

1. FASTENERS.Check,capscrew,nuts,pins andother

fastenerson winch andair system.Replaceif missing

andtighten or secureif loose.

2. ALL COMPONENTS. Inspectfor wear,damage,

distortion, deformation andcleanliness.If external

evidenceindicates theneed,disassemble.Checkgears,

shafts,bearings,springs andcovers.Replaceworn or

damagedparts.Clean, lubricate andreassemble.

3. DRUM AND SHEAVES. Checkfor damageor

excessivewear.Replaceif necessary.

4. BRAKE. Perform functional load teston winch. Check

ability of thebraketo hold ratedload.

5. LABELS AND TAGS. Cheekfor presenceand

legibility. Replaceif necessary.

6. WIRE ROPE.Besidesthe itemsin afrequent

inspection,inspectfor the following :

a. Build-up of dirt andcorrosion.Cleanif

necessary.

b. Looseor damagedendconnection.Replaceif

looseor damaged.

C.

Cheekwire ropeanchoris secure.

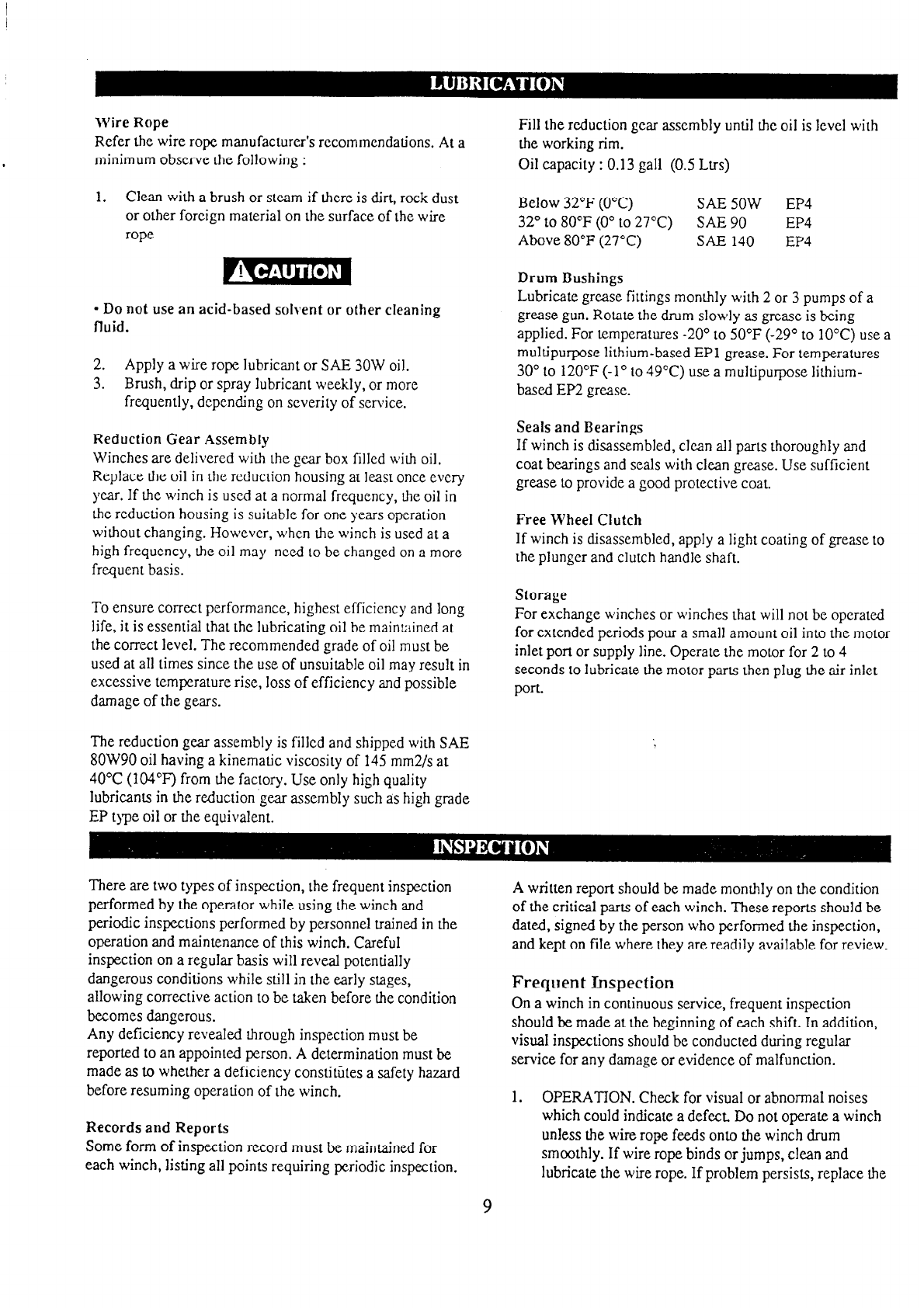

d. Changesin thesizeof thewire ropediameter.

Periodically measurethediameterof thewire

ropefrom crown-to-crown throughoutthelife of

thewire rope.The actualdiametershouldbe

recordedwhen thewire ropeis underequivalent

loading and in thesameoperatingsection.If the

actualdiameterof the wire ropehasdecreased

morethan 1/64in. (0.4 mm)athorough

examination of thewire ropeshouldbe

conductedby anexperiencedinspectorto

determinethe suitability of thewire ropeto

remain in service.

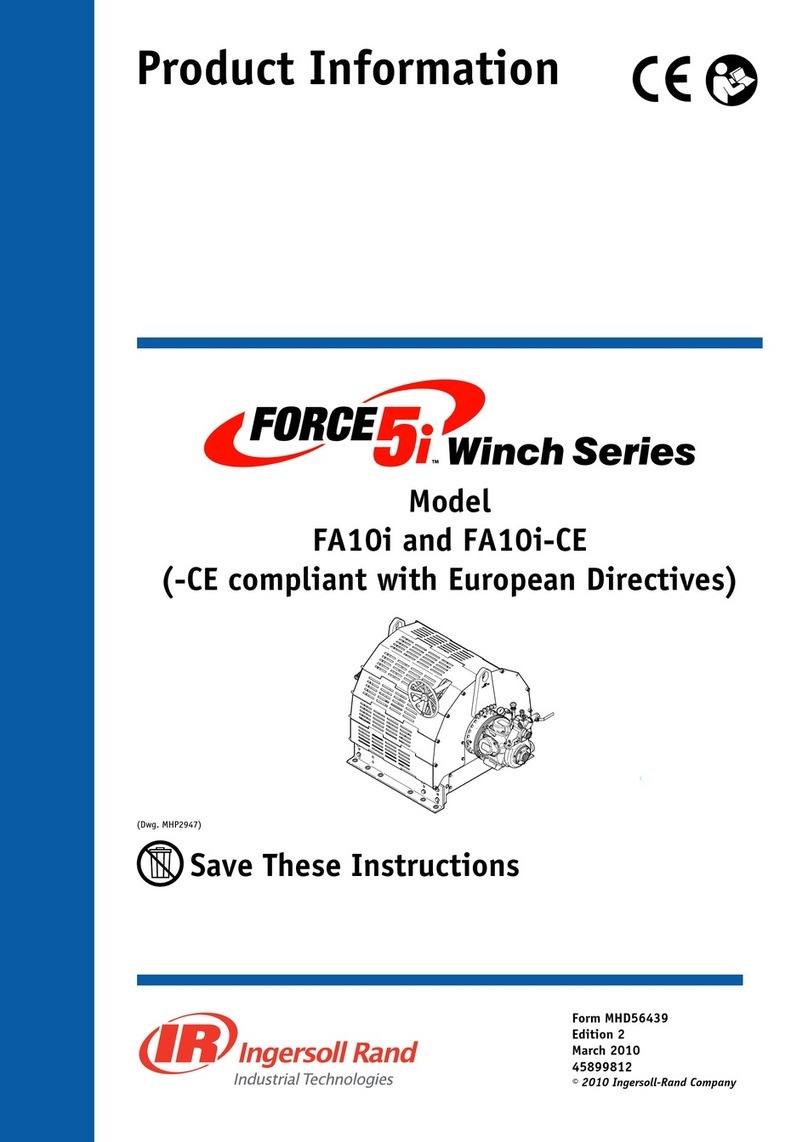

(ref. Dwg. D6310012)

i

CROWN

TO

CROWN

1

(Dwg. D6310012)

7. FOUNDATION. Check for thecontinuedability

lo

handlethe imposedloads.

Winches Not in Regular Use

A winch which hasbeenidle for aperiod of onemonthor

more,but lessthan six months,shall begiven aninspection

conforming with the requirementsof “FrequentInspection”

beforebeing placedinto service.

A winch which hasbeenidle for aperiod of over six

monthsshall begiven acompleteinspectionconforming

with therequirementsof “Periodic Inspection”. Standby

winchesshall be inspectedal leastsemi-annuallyin

accordancewith the requirementsof “FrequentInspection”.

If abnormaloperating conditions apply, winchesmay

require amorefrequent inspection.

10