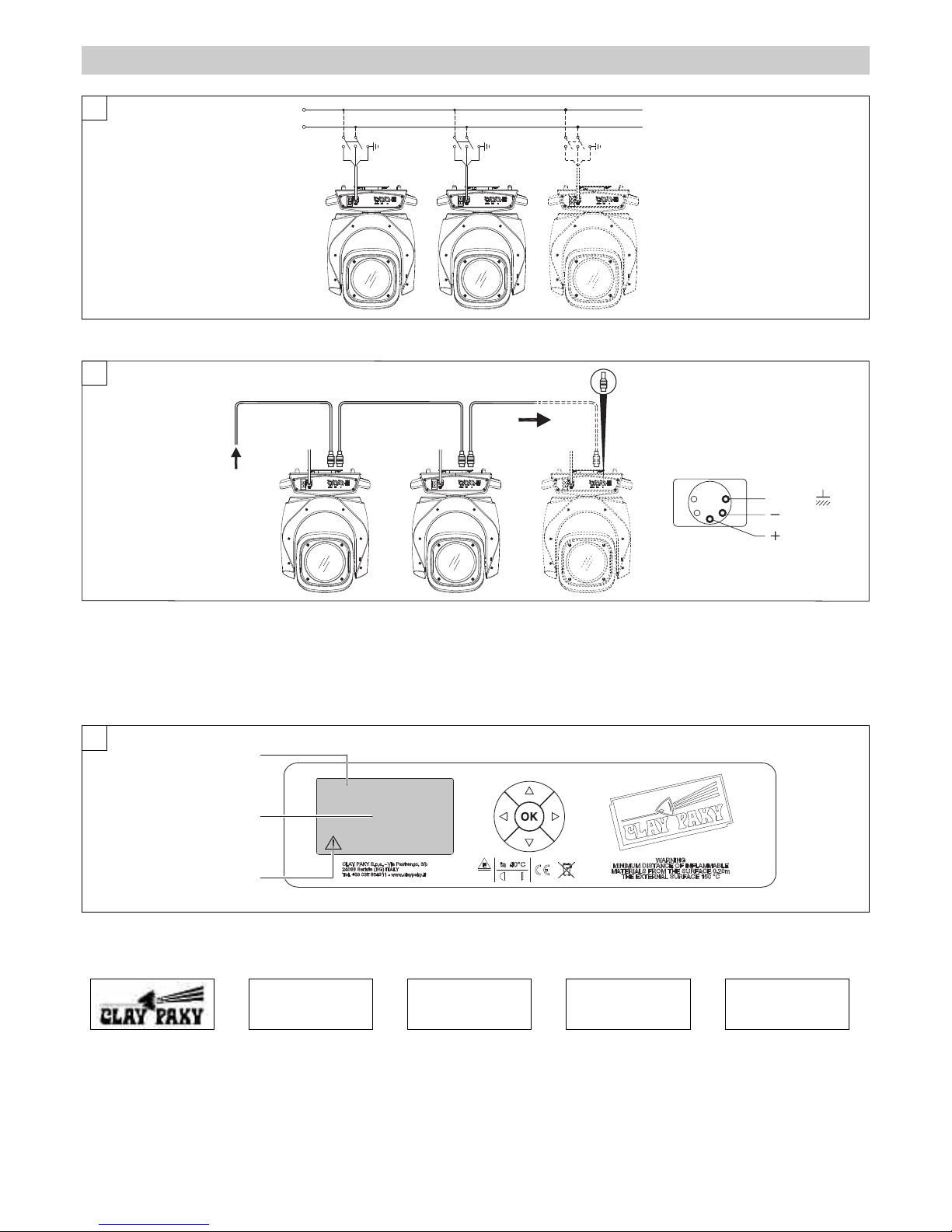

Reversal of the display - Fig. 9

To activate this function, press UP

B

and DOWN

C

keys simultaneously while the display is in the rest mode. This status will be memorised and

maintained even for the next time it will be switched on. To return to the initial state, repeat the operation all over again.

Setting the projector starting address

On each projector, the starting address must be set for the control signal (addresses from 1 to 512).

The address can also be set with the projector switched off.

Setting the projector Fixture ID

On each projector, the Fixture ID address must be set for an easy identification of the fixtures in an installation (ID from 1 to 255).

The Fixture ID address can be set with the projector switched off.

9

Functions of the buttons - Using the menu

Setting addresses and options with the projector disconnected

The projector’s DMX address, as well as other possible operating options, can also be set when the appliance is disconnected from the electricity supply.

All that is needed is to press

F

to momentarily activate the display and thus access the settings. Once the required operations have been carried out,

the display will switch off again after a wait time of 30 seconds.

USING HE MENU:

1) Press

F

once – “Main Menu” appears on the display.

2) Use the UP

B

and DOWN

C

keys to select the menu to be used:

• Setup (Setup Menu): To set the setting options.

• Option (Option Menu): To set the operating options

• Informations (Informations Menu): To read the counters, software version and other information.

• Manual Control (Manual control Menu): To trigger the test and manual control functions.

• Test (Test Menu): To check the proper functionning of effects

• Advanced (Advanced Menu): Access to the "Advanced menu" is recommended for a trained technical personnel.

3) Press

F

to display the first item in the selected menu.

4) Use the UP

B

and DOWN

C

keys to select the MENU items.

Confirms the displayed value, or activates the displayed function, or enters the successive

menu.

Decreases the value displayed (with auto-repetitions) or passes to the next item in the menu.

Increases the value displayed (with auto-repetitions) or passes to the previous item in a menu.

Return to the top level

Commute from units, tens, hundreds, in the "Address", "Fixture ID" and "Calibration" menù.

F

C

DOWN

B

UP

D

LEFT

E

RIGHT