Clean Logix SLX-PF User manual

USER

MANUAL

English (Original Instrucons)

Updated: 05/16/22

MODEL:

SLX-PF

PUMP FED FOAMER - SINGLE STATION

SLX-PF Pump Fed Foamer User Manual Page 2 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Table of Contents

System Requirements

General Use

Maintenance

Parts Call Out

03

04

05

07

09

10

12

PROTECT THE ENVIRONMENT

Please dispose of packaging materials, old machine

Safety Warning

General Precauons

• For proper performance do not

• Never

•

• Never

• Never

• Manufacturer assumes no liability for the use or misuse of

•

•

•

•

•

•

•

• WARNING: Severe damage to your facility, or

contaminaon of your pump supply, can occur without

proper backow prevenon.

SLX-PF Pump Fed Foamer User Manual Page 3 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

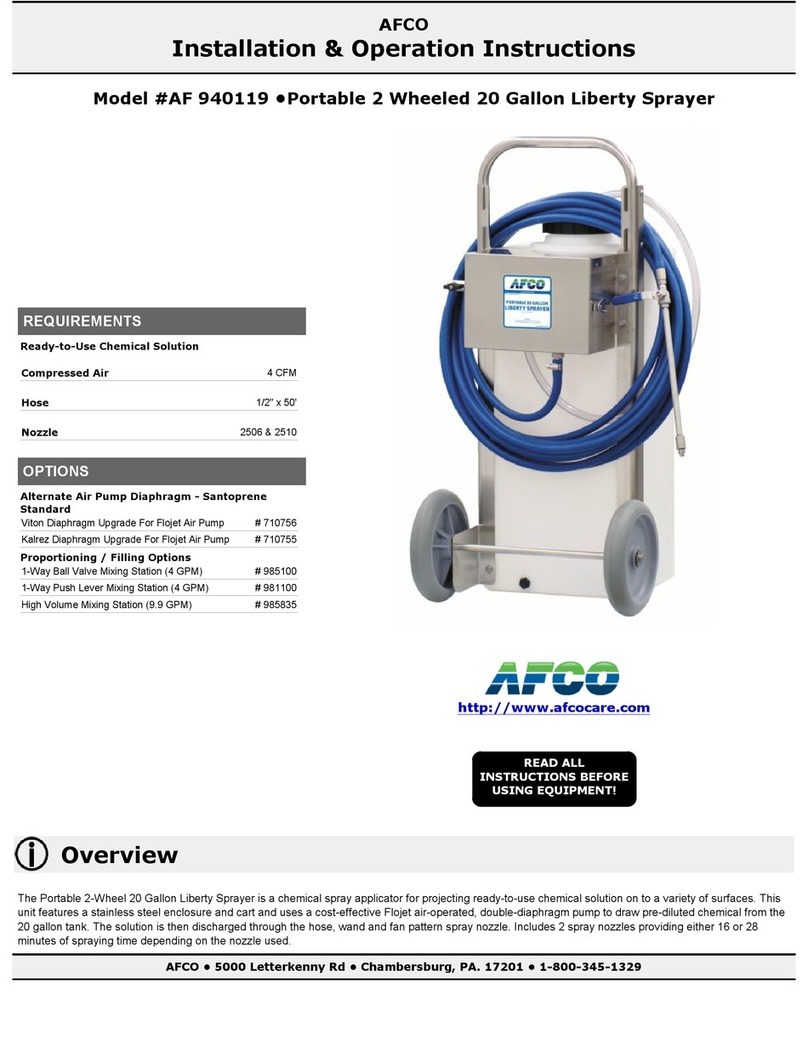

The SLX wall mounted pump fed foamer is a low to

and stainless steel Pump Fed Foamers regardless of insert

Overview

Enclosure: 304SS

Stainless Steel

Weight:

Dimensions: 8” x 111/” x 6”

Specicaons

Pressure: 35 - 125 PSI

Max Temperature: 160°F

Air Pressure: 40 PSI recommended

this equipment must be formulated for this type of

Requirements

NOTE:

NOTE:

Please contact Clean Logix at:

iMore Informaon

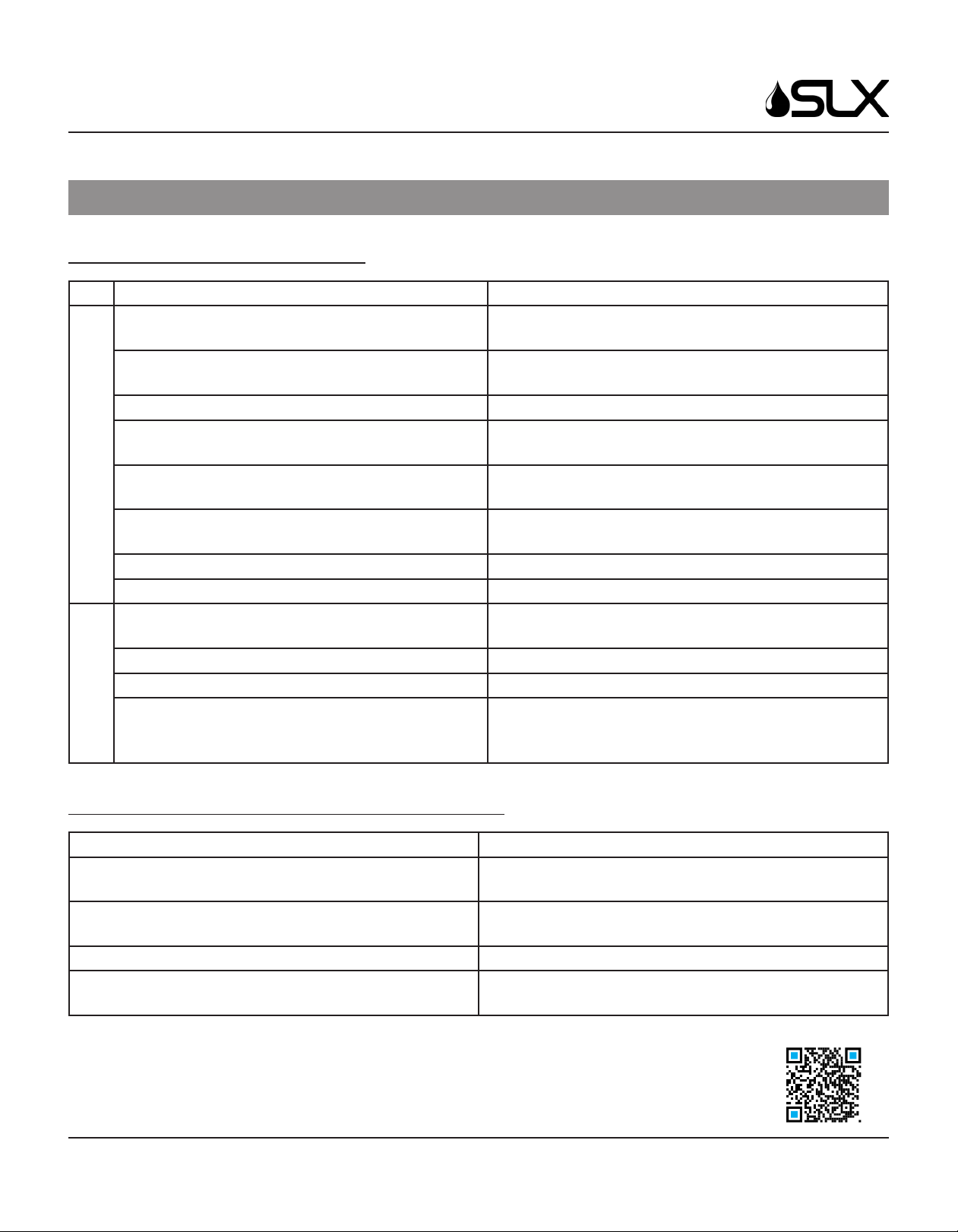

Insert #

Coverage Time

Foam Flow Rate

Water Flow Rate

Hose Size

Spray Nozzle

P08 110 4 - 8 3/4" x

50’ 80150

P21 250 3/4" x

50’ 50250

P46 500 23 - 46 1" x

50’

00400 or

50400

Flow rates and coverage me may vary depending on supply pressure,

metering p size, and chemical viscosity. Always test prior to normal

operaon to ensure facility requirements are met for cleaning

procedures.

NOTE:

SLX-PF Pump Fed Foamer User Manual Page 4 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

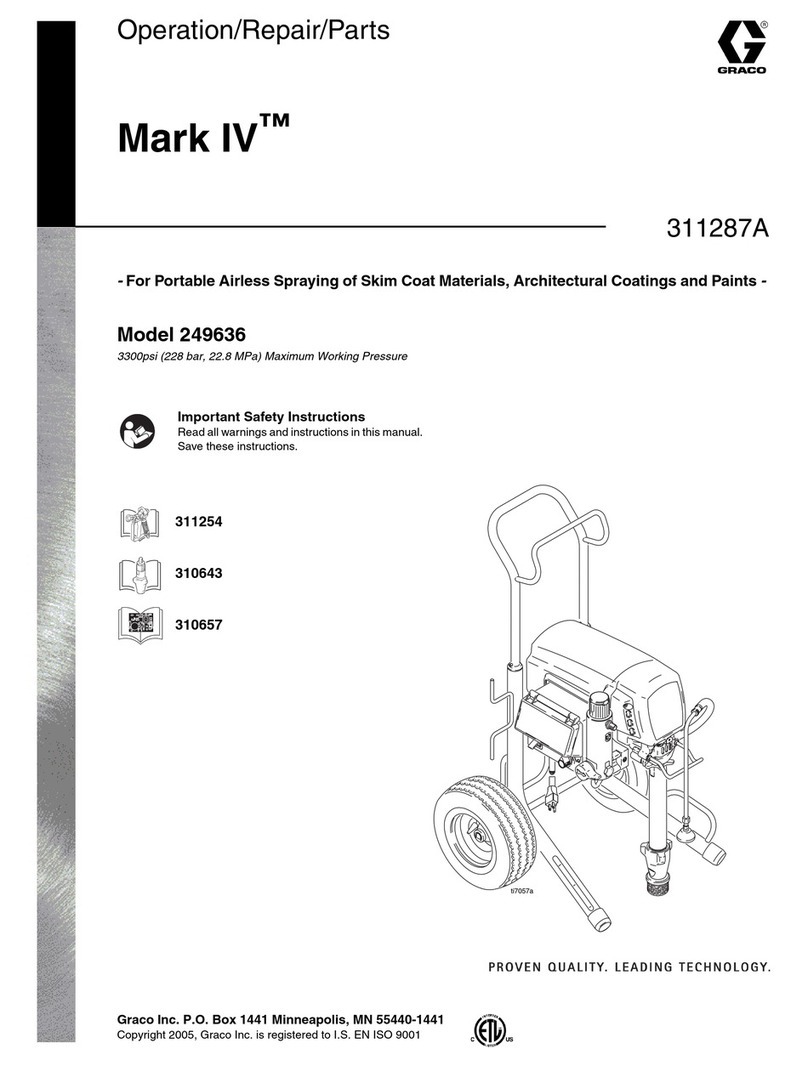

Installaon

11 1/2"

8 1/8"

7"

6"

4 5/8"

5 11/16"

1/4"

x4

2 3/4"

SHEET 3 OF 18

DATE CREATED:

10/21/2021

DRAWN BY:

A. ZIEGER

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:8

10.845

TITLE:

SLX EXAMPLE ASSEMBLIES - SINGLE STATION - For Renders

Material <not specified>

FINISH

MATERIAL

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

1/16"

ANGULAR: MACH

.5

BEND

2

TWO PLACE DECIMAL

.015"

THREE PLACE DECIMAL

.005"

PROPRIETARY AND CONFIDENTIAL!

THE INFORMATION CONTAINED

IN THIS DRAWING IS THE SOLE

PROPERTY OF CLEAN-LOGIX.

ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF

CLEAN-LOGIX IS PROHIBITED.

5

4

3

2

1

ITEM NUMBER:

SLX-PF21S

WEIGHT (LB.)

NOTE: DEBURR AND BREAK ALL

SHARP EDGES!

LAST SAVED:

2/22/2022

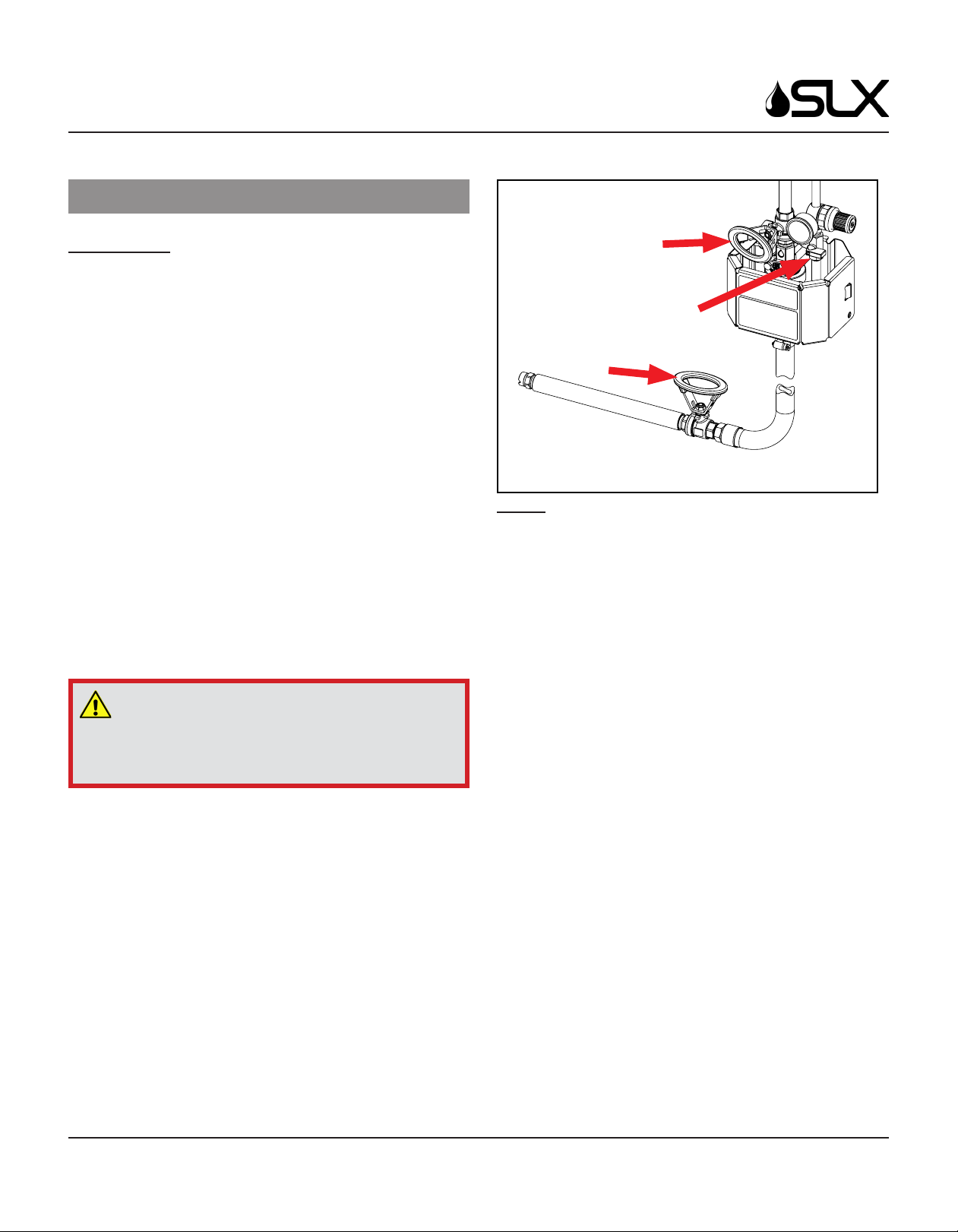

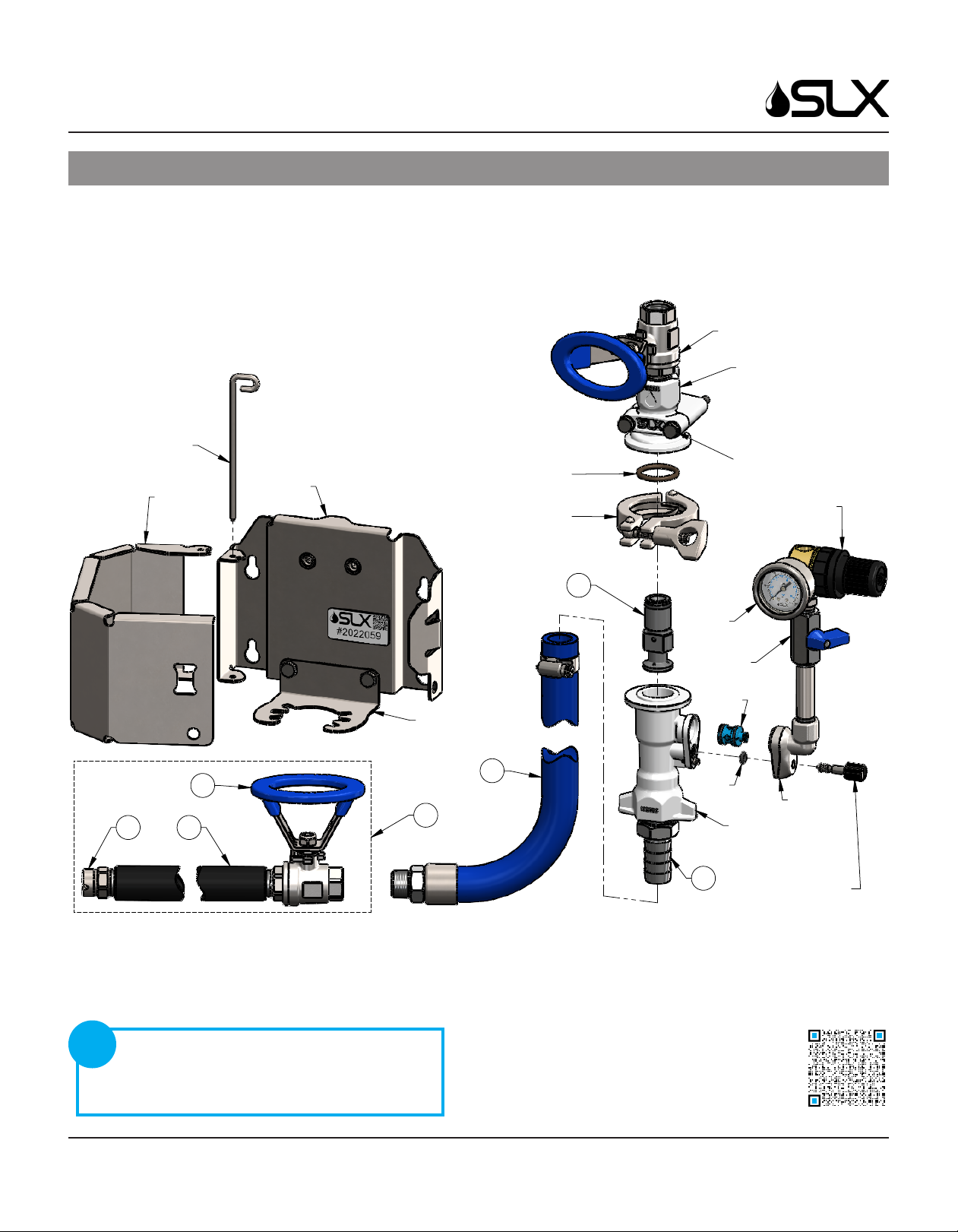

Flush air and pump supply lines to ensure they are

PUMP SUPPLY

(35 - 125psi)

AIR SUPPLY

(40psi RECOMMENDED)

DISCHARGE PORT

(3/4" - 1" HOSE BARB

DEPENDING ON MODEL)

STAINLESS STEEL

TRI-CLAMP

DOOR LOCK

FOAMER LOWER

BODY

PUMP FED

UPPER BODY

PUMP SUPPLY

BALL VALVE

AIR SUPPLY BALL

VALVE

AIR PRESSURE GAUGE

DISCHARGE BALL VALVE

HOSE WAND

POLYPROPYLENE (DEFAULT)

OPTIONAL STAINLESS STEEL UPGRADE AVAILABLE

SPRAY NOZZLE

DISCHARGE HOSE

(3/4" - 1" DEPENDING ON MODEL)

PUMP FED FOAMER - POLY

Notes:

• Air lter recommended.

• Backow prevenon required - consult local codes.

• System may vary depending on model and oponal upgrades.

AIR REGULATOR

SLX-PF Pump Fed Foamer User Manual Page 5 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Ensure foamer is properly connected and the pump

• The spray wand will slowly begin discharging liquid

• There will be a kick of pressure as the spray wand

•

water pressure stabilize the quality of the foam will

• Dryer Foam

• Weer Foam

Operaon

NOTE: Always keep air pressure BELOW pump

pressure!

+

Dry

-

Wet

SLX-PF Pump Fed Foamer User Manual Page 6 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Ensure foamer is properly connected and the pump

• The spray wand will slowly begin discharging

• There will be a kick of pressure as the spray wand

•

supply pressure stabilize the quality of the foam

Operaon (cont.)

Pump

OFF

WARNING

Air

OFF

Spray Wand

ON

SLX-PF Pump Fed Foamer User Manual Page 7 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Tri-clamp open

Pull the lower foamer body down, away from the

• For Polypropylene Models: Twist the lower foamer

body and align the winglets to release it from the

• Force may be required due to o-rings and/or

•

The insert can be cleaned using warm water or

General Use

Polypropylene lower support bracket

NOTE: Supply lines and discharge hose can remain

WARNING

WARNING

SLX-PF Pump Fed Foamer User Manual Page 8 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General Use (cont.)

Replacing Pump Fed insert and foamer body

Reconnect the lower foamer body to the upper Pump

Place the tri-clamp around the lip where the two

Open the enclosure door

Loosen the thumb screw on the elbow by hand or

WARNING

O-Ring

SLX-PF Pump Fed Foamer User Manual Page 9 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

The following maintenance procedures are recommended

Daily:

•

•

•

•

•

•

Weekly:

• Ensure tri-clamp is secure and bodies are sealed

•

•

Maintenance

WARNING

Monthly

•

•

•

•

•

•

•

Annually

•

•

Please contact Clean Logix at:

iMore Informaon

SLX-PF Pump Fed Foamer User Manual Page 10 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Troubleshoong

Foam surges, bucks, and/or recoils

Cause Soluon

Start-up

Air pressure too high Lower the air pressure using the included regulator

Improper chemical Ensure product is recommended for foaming and the

submerged

Discharge hose too long or wrong size or kinked Straighten the hose or replace hose with correct size and

Oil or lubricant is present in airline

Extended Use

Foamer insert is clogged

Improper air pressure

For Technical Support:

Foamer does not clean properly or Foam is too dry

Cause Soluon

Air pressure too high Lower the air pressure using the included regulator slowly

Improper chemical Ensure product is recommended for foaming and the

SLX-PF Pump Fed Foamer User Manual Page 11 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Troubleshoong

Foam is too wet

Cause Soluon

Start-up

small causing poor chemical pick up

Improper chemical Ensure product is recommended for foaming and the

submerged

Discharge hose too long or wrong size or kinked Straighten the hose or replace hose with correct size and

Oil or lubricant is present in airline

Improper air pressure

For Technical Support:

Chemistry is backing up into air supply line

Cause Soluon

Clean and replace as necessary

Close incoming supply lines and depressurize system when

Air is backing up into pump supply line

Cause Soluon

SLX-PF Pump Fed Foamer User Manual Page 12 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

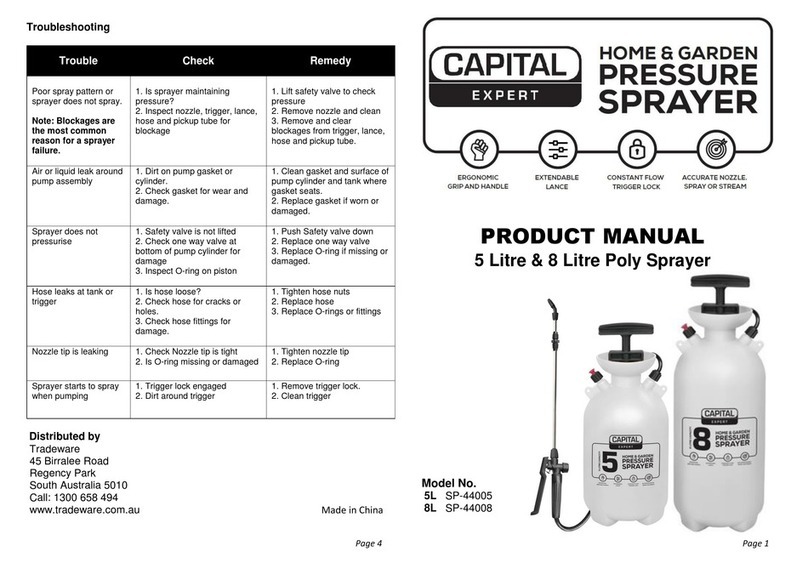

Parts Call-Out

(POLY BODIED

UNITS ONLY)

P2450

M2239

M2243

M2258

P2292

P2484

P2464

P2455

P2467

M2224

M2419

Poly: M2254 (Shown)

Stainless: M2221

4

M2441

1

2

3

Slotted Thumb: M2259

Socket Head: M2435

P2269

Poly: M2421

Stainless: M2420

5

67

F1252

GENERIC PF_ ASSEMBLIES

5

2

3

4

LAST SAVED:

2/23/2022

NOTE: DEBURR AND BREAK ALL

SHARP EDGES!

WEIGHT (LB.)

ITEM NUMBER:

GENERIC PF_ ASSEMBLIES

THE INFORMATION CONTAINED

IN THIS DRAWING IS THE SOLE

PROPERTY OF CLEAN-LOGIX.

ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF

CLEAN-LOGIX IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL!

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

1/16"

ANGULAR: MACH

.5

BEND

2

TWO PLACE DECIMAL

.015"

THREE PLACE DECIMAL

.005"

MATERIAL

FINISH

Material <not specified>

TITLE: SLX SINGLE STATION ASSEMBLIES REV100

8.294

SCALE: 2:5

UNLESS OTHERWISE SPECIFIED:

DRAWN BY:

A. ZIEGER

DATE CREATED:

9/9/2021

SHEET 12 OF 13

Please contact Clean Logix at:

iMore Informaon

Purchase Replacement Parts:

SLX-PF Pump Fed Foamer User Manual Page 13 of 13 Updated: 05/16/22

USER MANUAL: SLX-PF

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Parts Call-Out

NO. P08 P21 P46 DESCRIPTION

1 M2321 M2322 M2323

2 M2425 M2425 M2426 PIPE ADAPTER, HOSE BARB, 316SS

3 M2273 M2273 M2277

4

M2338 M2340 M2342

- - M2344

M2339 M2341 M2343

- - M2345

5 P2450 P2450 P2449

6M2218 M2218 M2264

M2263 M2263 M2265

7P2471 P2470 P2474

- - P2475

- P1339 P1339 P2488 HOSE CLAMP, WORM GEAR, SS

F1105 BOLT HHC 1/4-20 X 1/2 SS

F1128

F1212

F1252 BOLT HHC 1/4-20 X 3, 316SS

M2221

M2224

M2239

M2243

M2254

M2258

M2259 SLX THUMB SCREW

M2419

M2420

M2421

M2435

M2441

P2269

P2292

P2450

P2455

P2464

P2467

P2484

Table of contents

Popular Paint Sprayer manuals by other brands

SCAC

SCAC STS60-23BV Operator's manual

Hardi

Hardi COMMANDER Plus Series Operator's manual

Graco

Graco e-Xtreme Operation, repair, and parts

CookMax

CookMax MS1 Installation, operating and service instructions

Black & Decker

Black & Decker SmartSelect BDPH200 instruction manual

Graco

Graco AirPro EFX Instructions - parts