9

•With A/C power and compressed air attached to the expander, actuate the electric foot

switch which will activate the expander. Adjust the expander lower jaw to the position

you want using the Thumb Wheel Knob. Note that the jaws may be set to remain in the

“open” position using the toggle switch noted in Figure 3.3.1, and triggering the foot

pedal. Make sure the toggle switch is returned to the “off” position, or the jaws will

remain open.

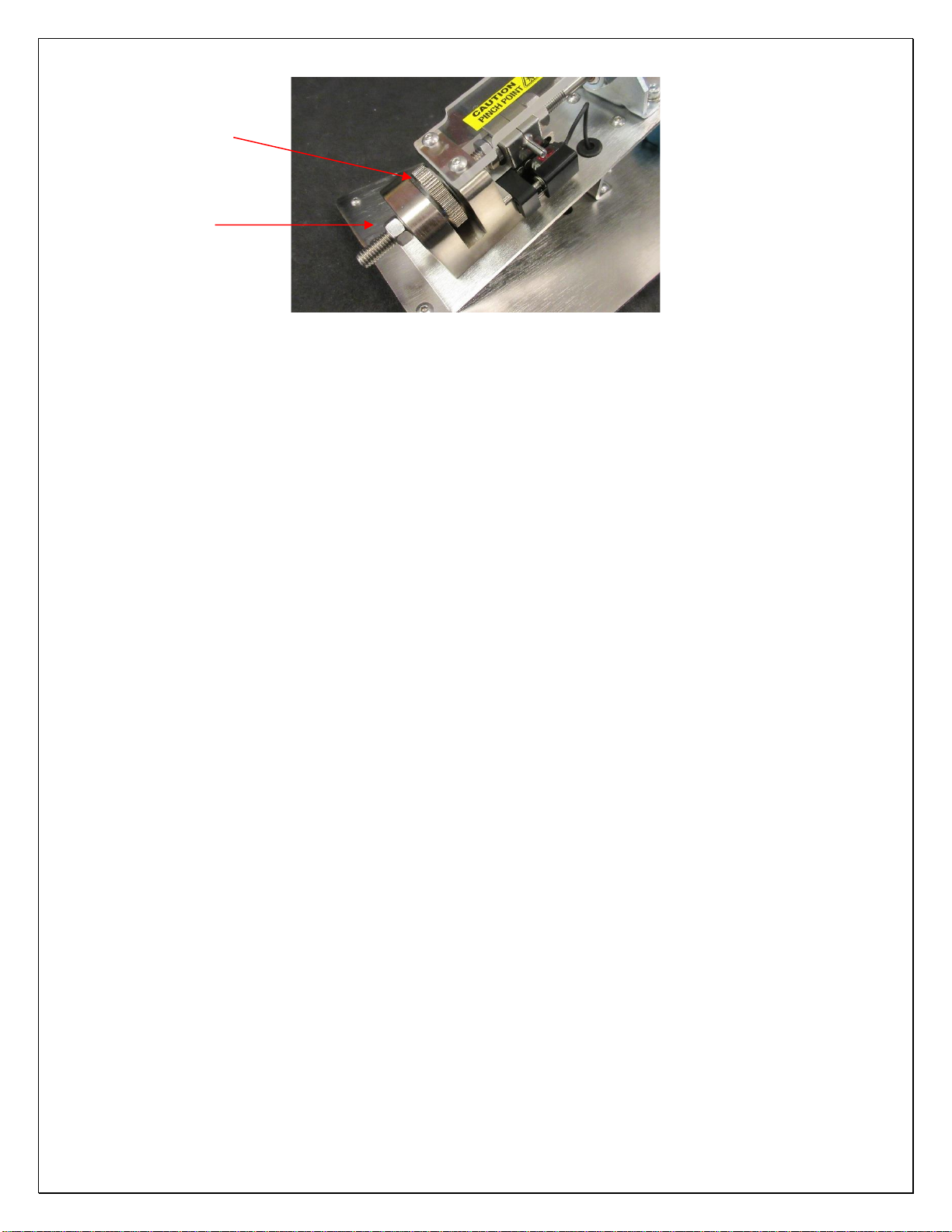

•Turning the Thumb Wheel clockwise will increase the jaw expansion size, counter

clockwise will decrease the jaw expansion size. This adjustment may require fine tuning

depending on your tubing I.D., O.D., durometer and/or material.

•Once you have the expansion size you want tighten the Lock Nut to secure the

adjustment.

•Place the desired tubing over the ends of both expander jaws and hold firmly in place.

•Once the tube is placed over the jaw, the jaws will expand at a rate determined by the

expansion time setting. Note: The unit may be operated with an optional electric foot

switch as well.

•The jaws will then close and the operator will rotate the tubing 90 degrees. Failure to do

so may result in uneven expansion and/or damaged tubing!

•After the interval time has expired, the jaws will then perform their second expansion

operation, again at the appropriate expansion time.

•The jaws will then close a second time, and the machine cycle will be complete.

Note: Several expanding actions may be necessary to effectively expand the end of

the tube for the fitting/connector to slide in. Each time you expand the tubing

remember to rotate the tubing 90 degrees on the jaws.

•Quickly insert the component or tube connector before the tubing regains its original size.

•If adjustment of sensor position is desired, use a 3mm hex wrench to turn the adjustment

screw shown below in figure 7. Turning the sensor adjustment screw clockwise will

move the sensor line closer to the jaws, while counterclockwise moves the sensor line

away from the jaws.