Clean Water 5900BT-AIR Operating and safety instructions

Other Clean Water Water Filtration System manuals

Clean Water

Clean Water 7500-REV2.5 User manual

Clean Water

Clean Water 7500-REV4 User manual

Clean Water

Clean Water 7500-REV2.5 User manual

Clean Water

Clean Water Living Water VORTEXer User manual

Clean Water

Clean Water 7500-REV2.5 User manual

Clean Water

Clean Water 7500-REV4 User manual

Clean Water

Clean Water Living Water VORTEXer User manual

Clean Water

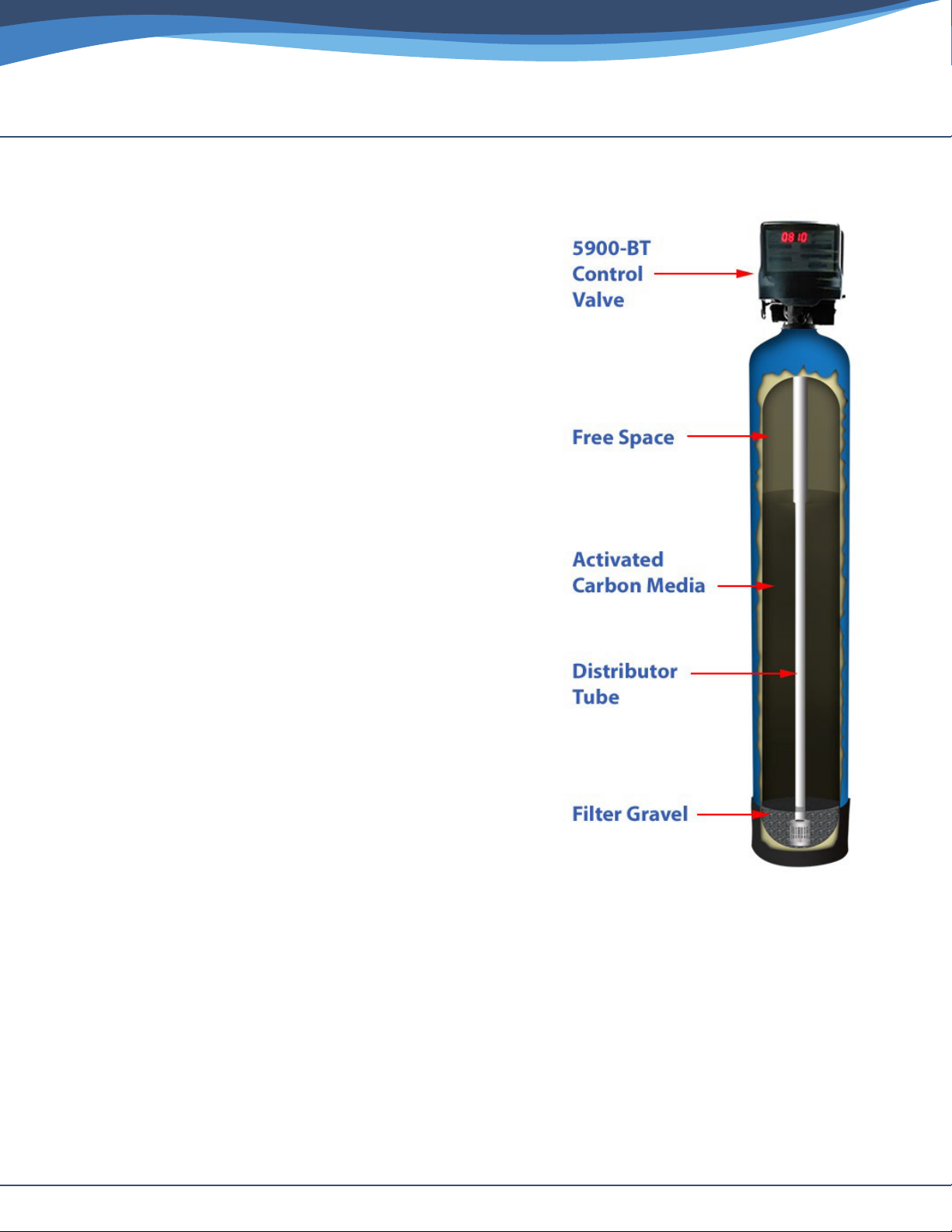

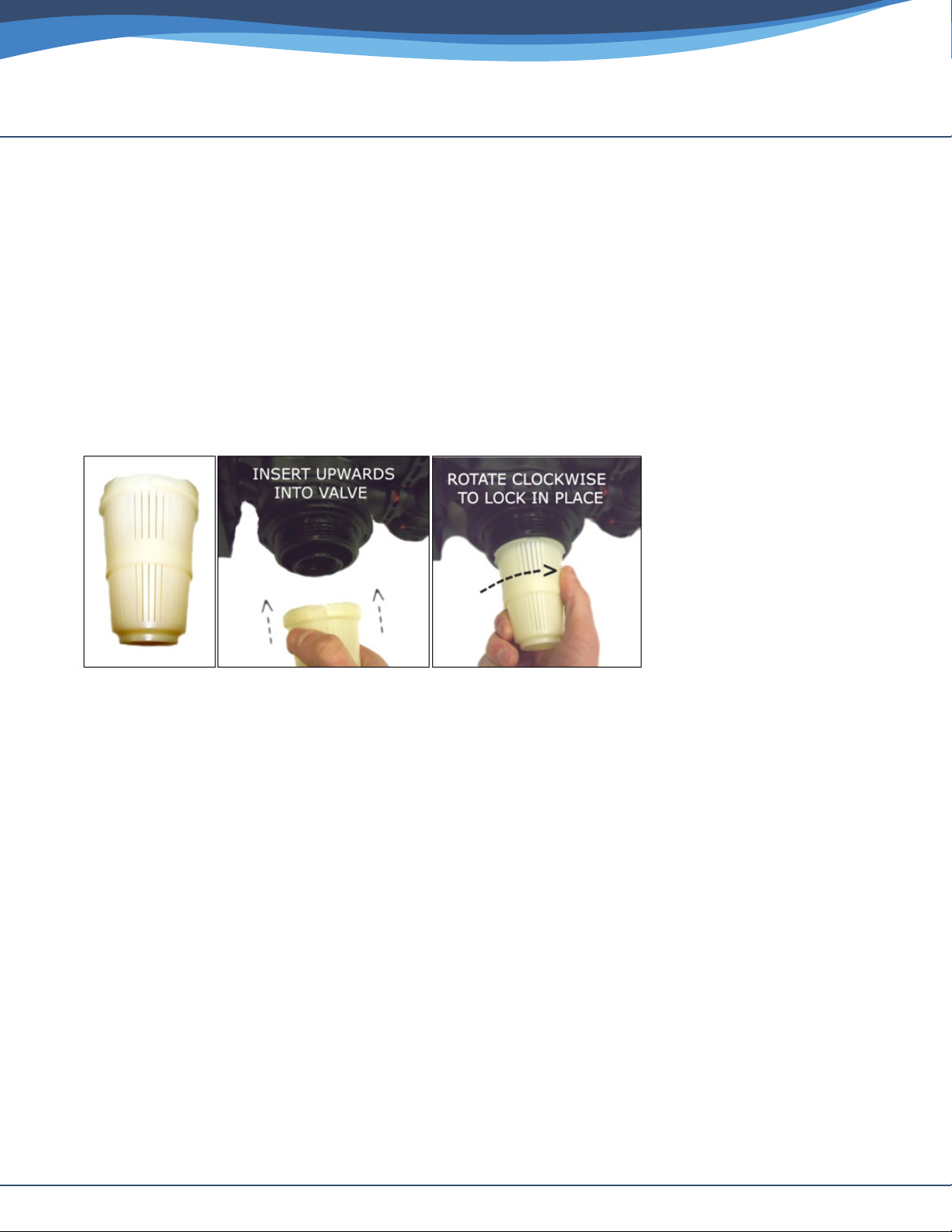

Clean Water 5900-BT Carbon Backwash Filter Operating and safety instructions

Popular Water Filtration System manuals by other brands

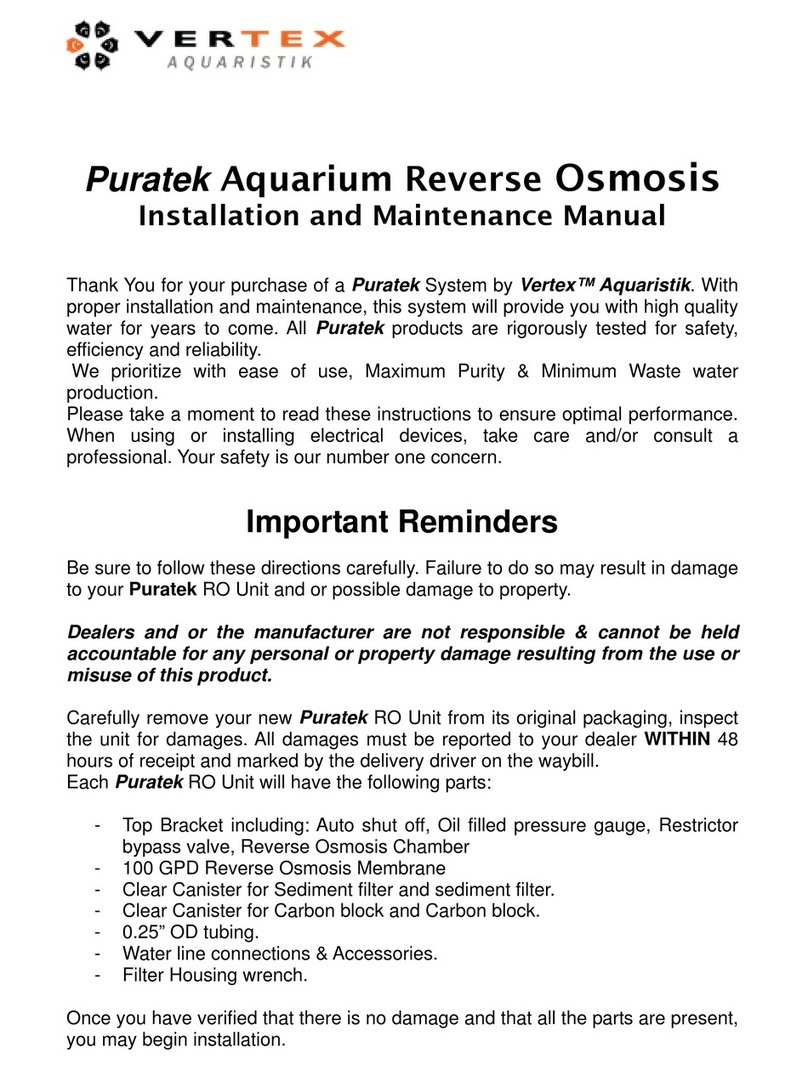

Vertex

Vertex Puratek Installation and maintenance manual

Philips

Philips AUT3234 user manual

Dustcontrol

Dustcontrol DC 50-W Original instructions

Ispring

Ispring UVF55FS Installation and maintenance manual

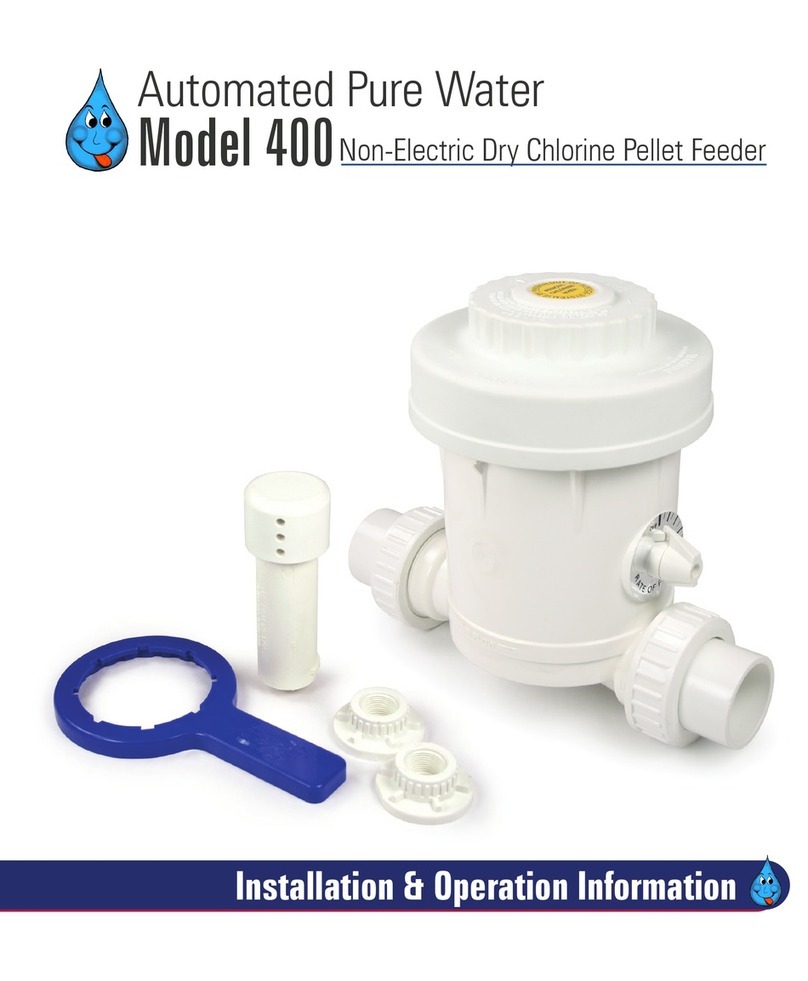

Automated Pure Water

Automated Pure Water 400 Installation & operation

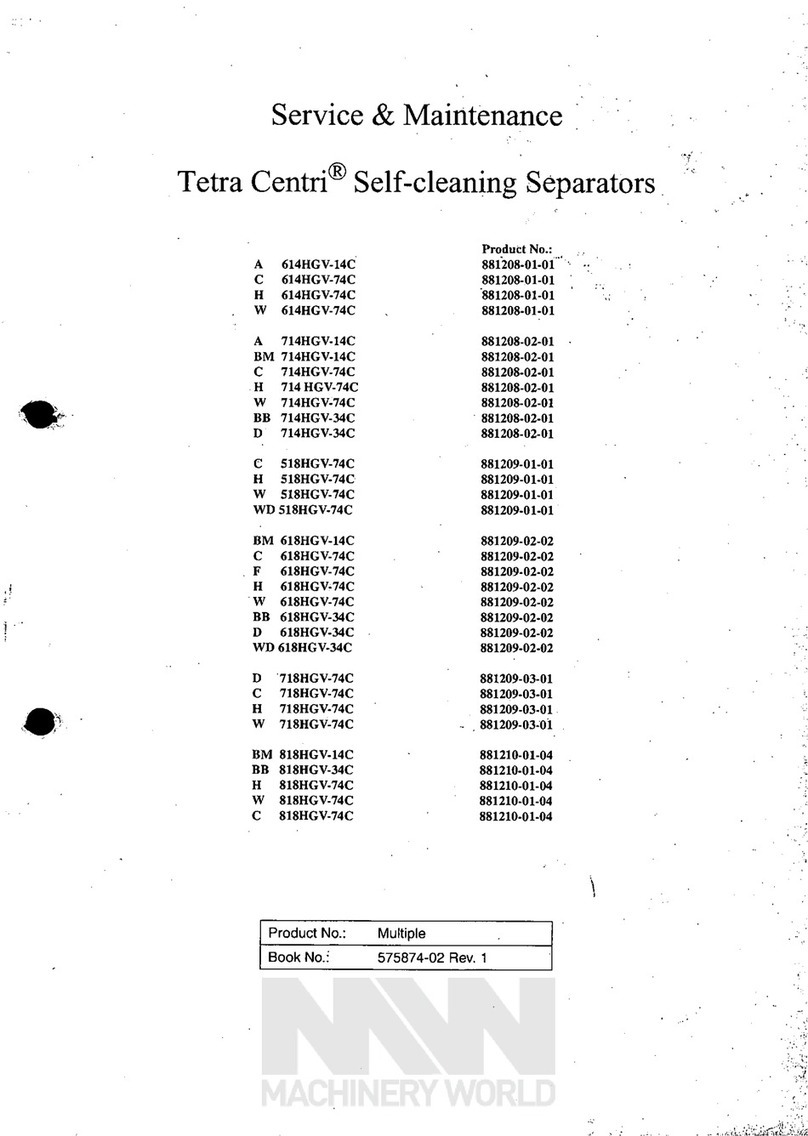

Machinery World

Machinery World Tetra Centri A 614HGV-14C Service & Maintenance

WilTec

WilTec 52367 user manual

Laica

Laica MikroPLASTIK-STOP Instructions and guarantee

Apec Water

Apec Water SOFTENER Series Installation instructions & owner's manual

Anetsberger Brothers

Anetsberger Brothers GoldenFRY FFM-150 Installation, user operation & maintenance manual

Sterilight

Sterilight S1Q-DWS Installation instructions & owner's manual

Aquascape Pro

Aquascape Pro Signature Series 1000 Instruction and maintenance manual

Oase

Oase Filtral UVC 1500 Commissioning

Theiling

Theiling ROLLERMAT XC Operation manual

Tetra

Tetra Tetratec EasyCrystal FilterBox 300 manual

OMOIKIRI

OMOIKIRI PURE DROP 1.0 manual

Premier

Premier RO-TFM-4SV/W50 Installation, operation and maintenance manual

Aquatec

Aquatec AquaPro All in One 2000 instruction manual