Cleanco Compact 45 User manual

VERSION AUG 2017

1

TABLE OF CONTENTS

OPERATIONS

Table of Contents 1

Machine Data Log 2

Safety Instructions 3

Technical Specifications 5

General Information 6

- Local Water Conditions

- Waste Water Disposal

- Cleaning Solutions & Cleaning

- Cleaning Wand Procedure

Operating Instructions 7

- Start up

- Shut down

De-flooding 8

Freeze Guard Procedure 8

Water Flow System 8

High Pressure Pump 8

Vacuum System 9

Electrical System 9

Heat Exchangers 9

PTO System 9

Front Instrument Panel 9

Recovery Tank 9

Maintenance 10

- Daily

- Weekly

- Monthly

- Quarterly

- Bi-Annual

- Coil Flush

Troubleshooting 11

Water Pumping & Heat Transfer System15

- Optional PTI

- PTI Maintenance

- PTI Operating System

- Jet Sizing

Chemical Injection System 19

Vacuum System 20

Vacuum Pump 21

- Water Pump

- Vacuum Inlet Filter

- Vacuum Relief Valve

- Drive Belts

- Pressure Regulator

- Hoses

- Optional Waste Pump-out

Engine Coolant Replacement 23

- Water Pump Drive Belt

- Waste Tank Lint Basket

- Waste Tank Float Valve

- Inline Water Filter

Troubleshooting 24

DRAWING & PARTS LIST

Front Panels 12

Water Pumping & Heat Transfer System17

- With PTI Option 18

Chemical Injection System 19

Vacuum System 20

Overhead View - Dual Heat Exchanger 27

Front Panel –Front View 29

Front Panel –Back View 30

Front Panel –Plumbing Assembly 32

Pressure Regulator 35

Recovery Tank 36

BasePlate 38

Pump Kits 43

Installation Kit 44

Dual Heat Exchanger 48

P.T.I. 50

Cover & Holder Kit 52

PTO Shaft 54

CAD Panel Mount Option 56

CAD External Option 57

Horizontal F/W Tank 60

Aqua Storage F/W Tank 62

Aqua Reel Tank 66

Wand 2 Jet 70

Wand Single Jet 71

Stair Tool 30” Swivel 72

Stair Tool 40” 73

Upholstery Tool 3” 74

Wand 1 ¾” S-Bend 4 Jet 75

Stair Tool 36” S-Bend 76

WIRING

Wiring Diagrams 77

WARRANTY

5 Year Extend-A-Care Warranty 80

2

MACHINE DATA LOG/OVERVIEW

MODEL

DATE OF PURCHASE

SERIAL NUMBER

COMPANY NAME

YOUR DEALER

NAME:

ADDRESS:

PHONE NUMBER:

Welcome…and congratulations on the purchase of your Cleanco Truckmount. This instruction

manual is a guide for operating and servicing your unit. Read this manual completely before

installing or operating this unit. This unit offers you personal convenience. All of your

instrumentation and controls have been positioned to give you easy access for operation and

daily maintenance.

Proper operation and service are essential to the efficient functioning of this unit. When

maintained correctly, this unit will have a long, trouble-free life.

The service methods described in this manual are explained in such a manner that servicing

may be performed accurately and safely. Proper service varies with the choice of procedure,

the skill of the mechanic, and the tools or parts available. Before attempting any repair, make

certain that you are thoroughly familiar with this equipment and are equipped with the proper

tools. Any questions pertaining to operating or servicing this unit should be directed to your

nearest dealer.

THIS UNIT MUST BE INSTALLED BY THE DEALER FROM WHOM YOU PURCHASED IT

IN ACCORDANCE WITH THE PRESCRIBED INSTALLATION PROCEDURES.

MAKE CERTAIN THAT THE WARRANTY FORM IS FILLED OUT AT THE TIME OF

INSTALLATION AND IS RETURNED TO YOUR DEALER.

ESTEAM MANUFACTURING LTD

3750 19TH ST. N.E

CALGARY, ALBERTA, CANADA T2E 6V2

Information in this document is subject to change without notice and does not represent a commitment

on the part of Esteam Manufacturing Ltd.

3

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic precautions must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE

These symbols mean WARNING or CAUTION. Failure to follow warnings and cautions

could result in fatality, personal injury to yourself and/or others, or property damage.

Follow these instructions carefully!

Read the operator’s manual before installing or starting this unit. Failure to adhere to instructions

could result in severe personal injury or could be fatal.

Operate this unit and equipment only in a well-ventilated area. Exhaust fumes contain carbon

monoxide which is an odorless and deadly poison that can cause severe injury or fatality. DO NOT run this

unit in an enclosed area. DO NOT operates this unit where the exhaust may enter any building doorway,

window, vent, or opening of any type.

DO NOT store any type of flammable material in the vehicle.

DO NOT operate engine if gasoline is spilled. Avoid creating any ignition until the gasoline has been

cleaned up. Never use gasoline as a cleaning agent.

DO NOT place hands, feet, hair, or clothing near rotating or moving parts. Avoid any contact with

moving parts! Rotating machinery can cause injury or fatality.

Never operate this unit without belt guards or hoods. The high speed moving parts, such as belts and

pulleys, should be avoided while this unit is running. Severe injury, damage or fatality may result.

DO NOT service this unit while it is running. The high-speed mechanical parts as well as high

temperature components may result in severe injury or severed limbs.

Never touch electrical wires or components while the engine is running. They can be sources of

electrical shock.

Before servicing this unit, allow it to “cool down.” This will prevent burns from occurring.

Water under high pressure at high temperature can cause burns, severe personal injury or fatality.

Shut down machine, allow to cool down, and relieve system of all pressure before removing valves,

caps, plugs, fittings, filters, and bolts.

Always wear hearing protection when unit is running. Always comply with local noise ordinance

when operating units.

4

Dangerous Acid, Explosive Gases! Batteries contain sulfuric acid. To prevent acid burns, avoid contact

with skin, eyes and clothing. Batteries produce explosive hydrogen gas while being charged. To prevent

a fire or explosion, charge batteries only in well ventilated areas. Keep sparks, open flames, and other

sources of ignition away from the battery at all times. Keep batteries out of the reach of children. Remove

all jewelry when servicing batteries.

Before disconnecting the negative (-) ground cable, make sure all switches are OFF. If ON, a spark will

occur at the ground cable terminal which could cause an explosion if hydrogen gas or gasoline vapors are

present. When disconnecting the battery, ALWAYS disconnect the negative (-) terminal FIRST.

DO NOT smoke around the unit. Gas fumes may accumulate and be ignited. The battery is also

extremely flammable. This will prevent possible explosions.

DO NOT damage the vehicle in any manner during installation. When routing fuel lines DO NOT

place the hose in any location where damage may occur to the hose or vehicle. Avoid any contact with

moving parts, areas of high temperature, brake lines, fuel lines, muffler, catalytic converter, or sharp

objects.

DO NOT exceed your vehicle’s weight limit. The console with waste tank and accessories weighs

approximately 800 lbs. Make certain to account for any additional accessories in your weight and balance

calculations. Make certain that the vehicle has the correct axle rating. This will prevent unsafe vehicle

driving conditions.

We require high-back seats on all vehicles in which units are to be installed for head and neck

protection. We recommend using a metal partition between the seats and equipment.

DO NOT operate this unit without the water supply attachment turned on. The water pump and other

vital components may be seriously damaged if this unit is permitted to operate dry without water.

DO NOT operate this unit without the filter installed in the waste tank.

Keep your vehicle work area clean. Wands, stair tools, and other accessories must be securely

fastened before driving the vehicle.

All high pressure hoses must be rated for 3000 PSI at 2500F. Thermoplastic hoses do not meet these

specifications and should not be used. Severe burns and injury may result if the hoses do not meet these

requirements.

Make certain that you receive complete training by the distributor from whom you purchased this

unit.

This unit uses high pressure and temperature. Improper or irresponsible use may result in serious

injury.

Do not modify this unit in any manner. Improper modification can cause severe personal injury or

fatality.

5

TECHNICAL SPECIFICATIONS

ITEM

DIMENSION/CAPACITY

Engine speed

1450 rpm (high speed) Water Pump ON

Water pump rpm

850 rpm

Vacuum pump rpm

2850 rpm

Water flow rate

4 GPM (maximum)

Water pump pressure

1200 PSI (maximum)

Vacuum relief valve

14" Hg/45 - 12” Hg/47

Waste tank capacity

100 gallons (optional 120 gallon)

Console weight (with waste tank)

500 lbs.

Pump Belt size

AX42

Blower Belt size

AX45

JET SIZING:

Recommended floor tool tip sizing should not exceed a total of “.045”. Using larger jet sizes on your

cleaning unit may reduce cleaning temperatures.

Example: Dual-jet wand uses two 11001.5 jets (110 deg spray angle w/ 01.5 orifice).

015 x 2 = 03

Three-jet wand uses three 11001 jets (110 deg spray w/1.0 orfice).

Quad-jet wand uses four 9501 jets (95 deg spray angle w/ 1.0 orifice)

01 x 4 = 04

Upholstery tool jet size: 80015

Stair tool jet size: 9502 or two 9501.5

6

GENERAL INFORMATION

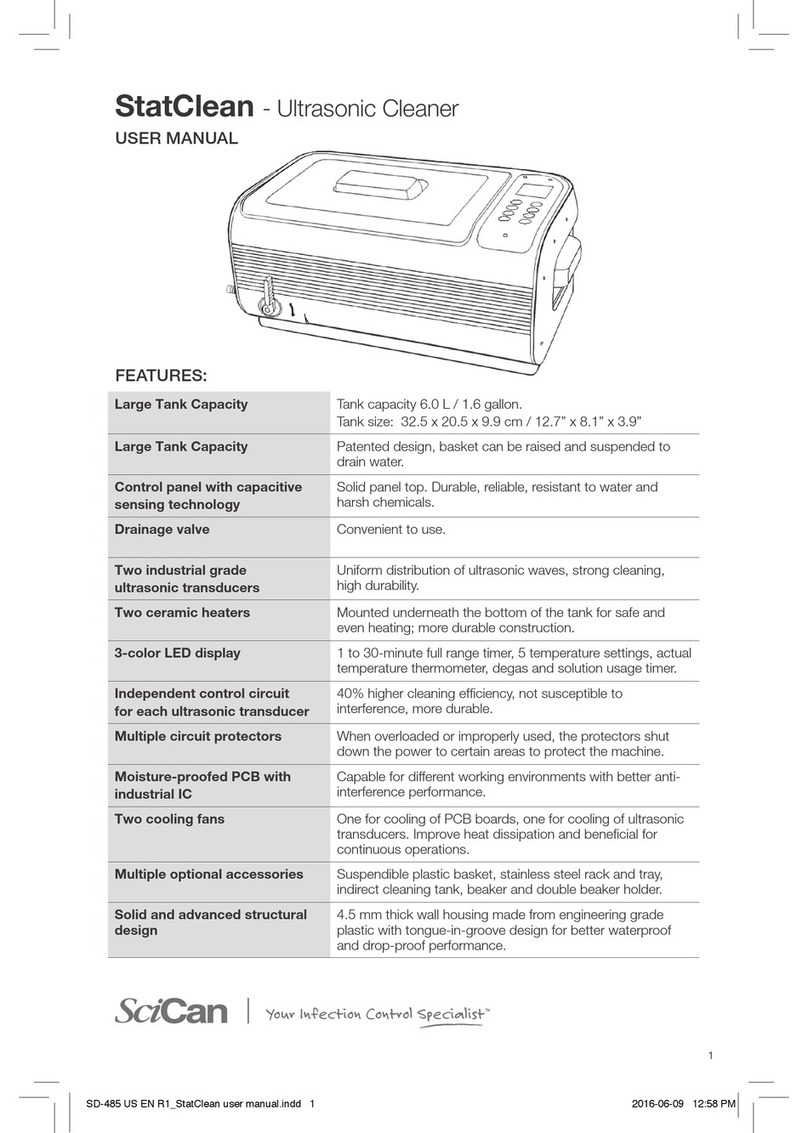

The Cleanco Compact Truckmount has been designed

for the professional cleaner who demands a high

performance cleaning unit. Dependable performance is

the guiding principal in the design and construction of

the Cleanco Compact. Although the Cleanco Compacts

are designed with simplicity in mind, this truckmounted

carpet cleaning plant has many functions that perform

simultaneously.

Engine has to run at a continuous RPM. (Van

Engine 1450 RPM)

High Pressure water pump provides steady pressure

at the proper flow for cleaning.

Vacuum Blower has to pull air and soiled water back

from the site.

Cleaning solution has to be injected into the water

flow at the right concentration.

Heating system must deliver and maintain proper

heat.

The vacuum recovery tank stores soiled water for

proper disposal.

This manual contains operation instructions as well as

information required for proper maintenance,

adjustments, and repair of this unit. To assist with proper

diagnosis of a problem, a general troubleshooting has

been included for your convenience.

LOCAL WATER CONDITIONS

The quality of water varies greatly throughout North

America. This can influence the reliability and efficiency

of your equipment. Many areas have an excess of

minerals in the water, which results in what is known as

hard water. These minerals tend to adhere to the inside

of heat exchangers and other parts of the machines

causing damage and loss of cleaning effectiveness.

Cleaning effectiveness and equipment life is increased

when water softeners are used in hard water areas. The

low cost of water softeners is more than made up for by

the increased life of machine parts and cleaning

efficiency.

WASTE WATER DISPOSAL

There are laws throughout North America that prohibit

the dumping of soiled water from carpet cleaning

equipment in any place but a sanitary treatment system.

The water recovered into your unit’s recovery tank

contains materials such as detergent residue and many

different soil contaminants removed from the carpet you

have cleaned. These materials must be processed

before they are safe to re-enter our streams, rivers and

reservoirs.

AS PER FEDERAL, STATE AND LOCAL LAWS, DO

NOT DISPOSE OF WASTE WATER INTO STORM

DRAINS, GUTTERS, STREAMS, RESERVOIRS, ETC.

CLEANING SOLUTIONS & CLEANING

Your Cleanco Compact has been designed with the

latest technology to produce the highest quality cleaning

results possible. However it is only one of many tools of

the carpet cleaning trade, and can produce only as good

as the person operating it. There are no short cuts to

quality. It takes time, cleaning knowledge, and the

proper use of quality cleaning solutions.

Cleanco recommends Esteam Cleaning Systems brand

name for use in your Cleanco Compact. Also be sure to

follow directions of all cleaning solutions, to obtain

quality results and for safety. The improper use of

cleaning solutions in your Cleanco Compact can cause

serious damage to the plumbing system, high-pressure

pump, and heat exchangers. (Cleanco does not

recommend running products through your unit such as

solvents, or grease removers with a high concentration

of solvents).

Cleanco endorses the IICRC Standards for Carpet

Cleaning, which outlines proper cleaning procedures for

all types of carpet and all kinds of cleaning systems. We

encourage Cleanco owners to acquire a copy of these

standards from your distributor and make yourself

familiar with them. In brief, the standards specify that all

carpet must be dry vacuumed, preconditioned, rinsed,

and dried, in order to be properly cleaned.

CLEANING WAND PROCEDURE

To have a quality cleaning result, correct wand

movement is of the utmost importance. Failure to take

time and extra care can result in an unhappy client.

Always move the cleaning wand in a smooth forward

and backward motion. Apply slight pressure on the

forward stroke while injecting cleaning solution onto the

carpet. Then on the backstroke towards yourself again

apply slight pressure on the wand and inject and vacuum

cleaning solution. Continue this method over-lapping

each forward and backstroke, for about a three to four

foot square area. Once the three square foot area has

been completed, return back over the same area-

utilizing vacuum only. Moving across then clean and

vacuum the next three to four square feet and again

7

repeating the extra vacuum pass. A good rule to

remember is for every one wet pass, two dry (vacuum)

passes are required. Failure to adopt good wanding

procedures can result in streaking, over wetting,

browning and longer drying times.

Over wetting not only leaves a bad impression with your

client but may also require an extra trip back to correct

annoying problems such as browning. There are several

things that could cause over wetting:

1. Not enough vacuum strokes, or incorrect wanding

procedures.

2. Clogged vacuum blower filter.

3. Clogged lint basket filter.

4. Vacuum tank not sealed properly.

5. Obstruction in the vacuum hose, or kink in the

vacuum hose.

6. Vacuum tank drain valve partially open.

7. Cleaning a heavily foam-saturated carpet without

defoamer.

OPERATING INSTRUCTIONS

NOTE: Before operating the unit, make sure you are in a

well-ventilated area. Exhaust fumes from the vehicle

contain carbon monoxide and are hazardous to your

health and your client’s health. Do not operate the unit or

the vehicle near any building doorways, windows, or

openings of any kind.

1. Check your fuel gauge to ensure you have enough

fuel for the job.

2. Check to make sure you have an adequate amount

of fresh water in your fresh water tank to complete

the entire job. If not, fill fresh water tank prior to

starting the job.

3. Check your chemical jug to ensure that you have

enough concentrated solution for the required job. If

not, mix and fill the chemical jug with the desired

cleaning solution.

4. Connect all hoses required. When connecting

hoses start from the furthest point to be cleaned

and work back towards the unit. This will ensure

that you have the proper length required. Once at

the Cleanco unit, connect the high-pressure hose to

the quick discount on the front panel. Then repeat

the same process with the vacuum hose and

connect it to the vacuum port on top of the recovery

tank.

START UP

1. Make sure the van is in the park position and the

emergency brake is set.

2. With the van engine running, turn the main power

switch to UPHOLSTERY or CARPET MODE

depending on the work you are about to do.

3. Connect the fill (primer) hose to the second high

pressure quick connect on the instrument panel, and

place the open end in the second vacuum port.

4. Turn on the high pressure pump switch to the “ON”

position. (Water will start to flow through the fill

(primer) hose into the recovery tank.)

5. Adjust the chemical metering system by turning the

chemical metering knob counter clock wise until the

float ball in the chemical meter sits at 2 or 3 GPH.

6. Turn the pump switch to the “OFF” position and

disconnect the fill (primer) hose.

7. Turn the pump switch to the “ON” position and check

the pressure setting on the high pressure gauge.

Standard carpet cleaning pressures should be

between 300 and 500 psi. Upholstery pressures

should be between 100 and 200 psi.

8. Connect the vacuum and the male end of the

pressure hose to the carpet wand or tool being used.

9. You are now ready to start cleaning.

NOTE: The machine will automatically shut down when

it reaches full capacity due to the high level float switch

located inside the recovery tank. When this occurs,

empty the recovery tank at an approved disposal site. To

save time on emptying recovery tanks Cleanco

recommends that you have a Cleanco C.A.D. (Cleanco

Auto Drain) installed on your recovery tank.

SHUT DOWN

1. Lay vacuum hoses out in order for all moisture to be

removed from hoses. This prevents spillage of any

soiled water in your vehicle when storing hoses.

2. Turn the MAIN POWER SWITCH to the “OFF”

position.

3. Turn the high pressure pump switch to the “OFF”

position.

4. Disconnect all vacuum and high pressure hose and

place them in the van. Also place the carpet wand

and any tools that were on the job site into the van.

5. Remove the lift out lint basket, clean, and replace

the lint basket back into the recovery tank.

6. Drain recovery tank at an approved disposal site.

8

DE-FLOODING OPERATIONS

De-flooding operations involve removal of water from

carpet and flooring. This differs from normal cleaning

operations in that no water or solution is required. A

Cleanco Auto Drain is recommended for all de-flooding

operations due to the large amount of water removal

often required.

1. Turn the MAIN POWER switch to the “CARPET

MODE”.

2. Leave pump switch “OFF” position.

FREEZE GUARD PROCEDURE

1. Drain recovery and fresh water tanks.

2. Remove chemical jug and store in a heated area.

3. Remove hose from fresh water tank and insert into

a container of window washer antifreeze along with

the chemical feed hose.

4. Turn chemical flow meter knob to the on position.

5. Attach the fill (primer) hose to the front panel high

pressure quick connect and place other end into

an empty pail.

6. Turn the unit switch and pump switch to the on

position.

7. Open the ball valve on the fill (primer) hose.

8. Chemical flow meter will begin to draw antifreeze

into the chemical injection system, continue until all

water is evacuated and antifreeze is present in the

flow being expelled into the pail.

9. Close the fill (primer) hose ball valve for approx. 10

seconds. This allows antifreeze to circulate through

the bypass system. Then open the fill (primer)

hose ball valve and evacuate the remainder of the

water until antifreeze is present.

10. Turn off unit and pump switch.

11. Replace hose on fresh water tank and remove fill

(primer) hose.

12. The use of a 12 volt air compressor for connecting

to all cleaning tools and high pressure hoses to

evacuate water from lines and valves.

13. Remember to reclaim the antifreeze upon start up.

COMPACT WATER FLOW SYSTEM

The Compact water flow system has been design to be

simple and trouble free. The incoming water flows from

the fresh water tank through the incoming water filter,

then through the chemical injector. As the water passes

through the chemical injector, it automatically picks up

the predetermined quantity of cleaning solution.

The predetermined quantity of cleaning solution is

determined by the chemical flow meter located on the

front panel. With this advanced chemical injector, the

chemical flow is injected only when there is a demand

for water.

Once the water has been injected with the correct

amount of chemical it then passes through the high

pressure pump, where it is pressurized. The pressure is

then control by the BPR (Balanced Pressure Regulator),

which is fully adjustable from the front panel.

After the water flow exits the BPR (Balanced Pressure

Regulator), it then passes through the dual reverse flow

heat exchanger where the water is heated to the preset

temperature, which is determined by the adjustable

temperature control knob on the front panel.

The water then exits the heat exchangers and continues

through the plumbing system to the high pressure quick

connects located on the front panel.

NOTE: The water flow plumbing system may need to be

flushed with vinegar periodically to prevent abnormal

chemical or hard water build-up. This can be done by

removing the clear hose from the chemical jug and

inserting it into a 1 liter (quart) container of vinegar. Then

open the chemical flow meter to the setting of 10. With

the unit running spray the wand until the 1 litre (quart) of

vinegar is empty. Then repeat the process with 1 litre

(quart) of water to flush the vinegar out of the lines.

If you are in an area with extreme hard water it is

suggested to use Coil Cleaner and flush entire water

system on a regular basis. For information on how to use

Coil Cleaner, contact your nearest Cleanco distributor.

HIGH PRESSURE PUMP

The Compact 45 & 47 are equipped with a state of the

art Cat plunger pump. Cat pumps are built to last, with

three ceramic plungers, stainless steel valves and oil-

cooled cam-shaft system.

With the Cat pump you have the ability of performing

carpet cleaning and power washing, with pressure

output ranging from 30 psi to 1200 psi. If 1200 psi is

exceeded this can cause damage to the packings and

retaining seals in the pump.

Your Cleanco Distributor will preset your Compact unit’s

pump at a pressure rating between 300 psi and 500 psi

during installation. Cleanco has found this pressure

range to be the optimal setting for carpet cleaning. When

cleaning upholstery a simple adjustment of the BPR

(Balanced Pressure Regulator) on the front panel will

lower your pressure to 200 psi, which is recommended

for upholstery cleaning.

When power washing you must remember that your

Cleanco Compact is set up for carpet cleaning. Even

though your Triplex pump has maximum rating of 2500

psi, this pump is set up for carpet cleaning will give you

maximum 1200 psi for power washing. With 1200 psi

and the high heat from the Cleanco heat exchangers it

makes power washing simple.

9

VACUUM SYSTEM

The vacuum system of the Compact is a Roots Whispair

Universal DSL 45 or 47 positive displacement rotary lobe

blower. This high performance blower provides

incredible air flow and water lift making sure carpets are

left as dry as possible. The blower is factory set for

maximum efficiency and longevity. The performance and

life of the blower greatly depends on the care and proper

maintenance it receives.

Due to the close tolerances of the internal lobes and the

housing of the blower, solid objects entering the inlet of

the blower can damage the interior.

To prevent this, Cleanco installs stainless steel filter

screens on the vacuum inlet inside the vacuum recovery

tank. This stainless steel filters should be removed daily

and cleaned. When reinstalling the filter only thread filter

on until finger tight. The lint basket should be removed

and cleaned after every job. If lint basket is not clean, it

will affect the performance of your machine.

For further information on the Roots Vacuum Blower

refer to the enclosed Roots Universal Blower Manual.

ELECTRICAL SYSTEM

The Cleanco Compact electrical system has been

specifically designed with simplicity in mind. There is one

complete wiring harness that connects all operations of

the unit. This harness is complete with specially

designed plug ends, which enable service centers easy

front panel removal if necessary. An inline fuse located

near the van battery protects the system. All wiring is

coated to protect against corrosion from moisture or

water spillage.

NOTE: Whenever working on wiring system power side

of van battery should be disconnected for safety.

COMPACT 45 & 47 HEAT EXCHANGERS

The Cleanco Compact “MAXI HEAT” heat exchangers

are custom built by Cleanco to meet our exacting

standards for performance. The heat transfer is quick

and efficient, with no potentially damaging heat swings

or peaks. The Cleanco Compact heat exchanger is

designed with a burst rating pressure of 9000 psi, and

operating pressures up to 3000 psi. The unique dual

reverse flow exchanger system gets the most heat from

the cooling system of your van, using a reverse flow

design to maximize heat transfer delivering the highest

heat to flow ratio in the industry. The exchangers require

little maintenance other than an occasional coil flush to

remove hard water residues and scale.

COMPACT 45 & 47 PTO SYSTEM

The power take off shaft (PTO), is a precision

engineered and balanced shaft that transfers power from

the van’s engine to the Compact unit, which drives the

vacuum and high pressure pump. An outer casing with

three bearings protects the shaft. These bearings are

designed to withstand extremes of heat and friction

without breaking down. The PTO shaft has two grease

jerk fittings one at the front of the PTO shaft and one at

the rear of the PTO shaft. These two bearings require

greasing every 250 hours of operation. The

recommended grease to be used to grease the bearings

is SKF LGMT 3/0.4 bearing grease. The PTO shaft is

activated by a single switch located on the front

instrument panel. The single switch engages an electric

clutch at the front of the shaft in the engine

compartment. The shaft is firmly mounted in the engine

compartment by the front PTO mounting bracket and at

the rear of the shaft by the rear PTO mounting bracket

which is mounted to the base plate of the unit.

COMPACT FRONT INSTRUMENT PANEL

The instrument panel of the Compact puts everything at

your fingertips. Complete with vacuum gauge, hour

meter, pressure gauge, water temperature gauge and

tachometer to monitor all internal workings of the

Compact. All electrical is controlled by rocker switches,

unit power, fast idle, high pressure pump clutch, interior

lights, C.A.D. (Cleanco Auto Drain) and the accessories

switch. The BPR (Balanced Pressure Regulator) and

Chemical Flow-Meter are both located at the center of

the front panel for easy access. To the right side of the

panel is the blower lube port and the oil level sight tubes.

At the lower left side of the panel are the two high

pressure quick disconnects and the C.A.D. (Cleanco

Auto Drain). The unique design feature of the Compact

front panel, allows complete removal in approximately 90

seconds giving you complete access to the major

components.

COMPACT RECOVERY TANK

The recovery tank of the Cleanco Compact incorporates

many unique features to protect your equipment, and

save you time. The tank is made from 3/16ths powdered

coated marine aluminum and contains several baffles to

insure strength and durability. The recovery tank holds

100 U.S. gallons (optional 120 gallons) of soiled water

solution, giving you longer cleaning intervals between

dumping. The safety and convenience features built into

the recovery tank include a high water shut-off switch, a

built-in lint basket, sloped tank bottom, stainless steel

blower protection filters, and an inline vacuum breaker.

The high water shut-off is located at the highest point in

the recovery tank, giving you full usage of the tanks

capacity. The high water shut-off cuts the power to the

unit when the tank is full, protecting the vacuum blower

from damage. The lint basket prolongs the life of the air

filtration system, and makes draining soiled water easier

with less clogging and debris. The stainless steel blower

protection filters guard against any small debris entering

10

into the blower chamber which could damage the blower

itself. The inline vacuum breaker adds years to the

vacuum blowers life by reducing stress caused plugged

filters and limited air intake. The recovery tank also has

two access lids for easy access to the lint basket and the

stainless steel blower protection filters. These filters

require regular cleaning on a daily basis as a minimum.

To finish off the recovery tank Cleanco added an

integrated storage shelf, giving the operator added

space for specialty tools that may be required at the

cleaning site.

MAINTENANCE

To avoid costly repairs and downtime, it is imperative to

develop and practice good maintenance procedures.

These procedures must be preformed on a daily, weekly,

monthly, quarterly and bi annual schedule.

As part of your Cleanco package you receive a Cleanco

Maintenance Booklet. This booklet provides you with a

convenient format for recording the required

maintenance of your Cleanco unit and van. You are

required to perform all maintenance items in the

Maintenance Schedule and record that you have done

so in this booklet as part of your Cleanco Warranty. It is

your responsibility to keep a copy of all repair orders and

receipts that relate to your Cleanco unit and Van. These

records of services and purchases will be required to

substantiate proper maintenance to your Cleanco unit

and Van for any warranty claim.

DAILY

Check van engine oil.

Check van engine coolant level.

Check high-pressure pump oil level.

Check vacuum blower oil level.

Clean vacuum tank lint basket. (Should be cleaned

after every job)

Clean the stainless steel blower protection filters.

Lubricate blower with LPS/TKX lubricant.

Winterize system if necessary.

WEEKLY

Check engine air cleaner filter. (clean as necessary)

Check Front drive belts. (adjust if necessary)

Check blower belts. (adjust if necessary)

Check high-pressure pump belt. (adjust if necessary)

Clean in-coming water filter.

Flush chemical system with 50/50 mixture of vinegar

and water.

Inspect unit for loose wires, oil leaks, and water

leaks.

Check engine RPM with unit running at fast idle.

(setting 1450 RPM under load )

Blower Speed. (actual reading)

Vacuum Gauge. (actual reading)

Temperature Gauge. (actual reading)

Hour Meter. (actual reading)

Clean wand and inspect for clogged jets.

Clean recovery tank thoroughly with high pressure

water.

MONTHLY

Change van engine oil.

Check van transmission oil level.

Check van coolant level.

Check engine air cleaner filter. (clean as necessary)

QUARTERLY SERVICE

Change oil in high-pressure pump.

Change oil in vacuum blower.

Flush entire water flow system. (coil flush if

necessary)

Check that all nuts and bolts are tight.

Check all hose clamps, tighten if necessary.

Grease front and rear PTO shaft bearings with SKF

LGMT 3/0.4 bearing grease.

BI - ANNUAL MAINTENANCE

Change the coolant and flush the

coolant system completely.

AS REQUIRED / COIL FLUSH

If your area has hard water you may see evidence of

hard water deposits form in the water system, or on the

quick connects. If scale is present, the water system

should be flushed with Coil Cleaner. This procedure may

have to be increased to a monthly interval if heavy built-

up is present. For information on flushing coils contact

your nearest Cleanco distributor.

Over all machine maintenance and appearance is very

important. It represents your company’s professional

appearance and is how you make your living. A clean

well maintained machine will give you years of reliable

performance. Maintenance, troubleshooting, and repair

is much easier on a clean well maintained unit. Regular

cleaning and maintenance will give you the opportunity

to spot any potential problems normally before they

occur.

It is important that you follow and record the

maintenance on your Cleanco unit and van according to

the Cleanco Maintenance Booklet to insure complete

warranty coverage.

11

TROUBLESHOOTING GUIDELINES

Loss of Vacuum:

Ensure recovery tank drain valve is closed.

Ensure recovery tank access lids are on properly.

Check recovery tank lid gaskets are in good

condition.

Check stainless steel blower protection filter, clean if

required.

Check vacuum tank lint basket, clean if required.

Check for blockage in cleaning tool or vacuum hose.

Check vacuum hoses for kinks, and good

connections.

Check vacuum hose between blower and recovery

tank.

Check belt tension between blower and pto shaft.

Check belt tension at front of pto shaft.

Loss of Water Pressure

Check fresh water tank for adequate water level, if

connected to direct feed water tap ensure tap is in

the on position.

Inlet water feed line collapsed or clogged.

Inline water filter strainer clogged or damaged.

Air leak on the inlet water line from water source to

high pressure pump.

Check BPR (Balanced Pressure Regulator) for

blockage and proper setting.

Check for lose pump belt.

Check chemical jug, ensure there is enough

chemical.

Water Pulsation

Foreign material in pump valves.

Air leak on the inlet water supply line.

Air leak on chemical metering line.

Inadequate water supply.

Foreign material in BPR (Balanced Pressure

Regulator).

No Hot Water

Check temperature control valve setting, ensure its

turned to hot.

Check engine coolant level, top up if required.

Flush heat exchangers with approved coil cleaner.

Possible air lock in water flow system, make sure

coolant level is at proper level then open pet-cock

valves located on the heat exchangers and bleed air

from heat exchangers, then close pet-cock valves.

If problems persist contact your nearest Cleanco

service center.

No Chemical Feed

Check chemical jug level and top up if necessary.

Check chemical feed hose for leaks or cracks.

Check chemical feed check valve located on the

end of the chemical feed hose in the chemical jug

for blockages.

Check chemical flow-meter for blockages.

Check chemical feed hose from front panel to

chemical injector tee for leaks or cracks.

No Unit Power

Check in-line fuse located at the vehicle battery or

fuse box accessory post.

Check to ensure recovery tank is not full.

Check recovery tank shut-off switch for proper

operation.

Check front pto clutch power and grounding wires.

Check unit power rocker switch for lose wires.

Check Hi-Temp shut-off connections on heat

exchanger and at wiring harness.

Unit Will Not Idle Up

Ensure vehicle is in park.

Ensure Park Brake is engaged.

Check which lights are flashing on E.T.M., all should

be on steady. IF no lights are on check fuse #30 on

GM’s.

If unsuccessful see your local authorized Cleanco

service center.

Unit Shuts Down Unexpectedly

Check recovery tanks level and drain if required.

Check in-line fuse located at the vehicle battery.

Check recovery tank shut-off switch to ensure proper

function.

Check Hi-Temp shut-down on heat exchangers.

Check pto clutch power and grounding wires.

Check Hi-Temp shut off on heat exchangers.

12

13

14

1. Tachometer

The Blower Speed shows the rpm of the

Blower.

2. Hour Meter

The hour meter records the number of

hours the unit has run. This serves as a

time recorder for servicing the machine

and van.

3. Solution Pressure Gauge

This gauge registers the amount of

pressure in the system.

4. Solution Temperature Gauge

This gauge measures the temperature of

the cleaning solution as it exits the

machine.

5. Vacuum Gauge

This gauge indicates in inches of mercury

how much the vacuum system is

producing at any given time.

6. Solution Temperature Control

This valve allows the operator to control

the solution temperature by adjusting the

valve from cold to hot.

7. Pressure Control Regulator

The pressure regulator sets the pressure

of the solution system. This spring loaded

valve can be adjusted up or down setting

the pressure of the unit by turning the

knob clockwise. The pressure is

increased or reduced by turning the valve

counter clockwise. This valve must be

maintained in accordance with this manual

maintenance table.

8. Main Power Switch

The switch serves to energize the

magnetic clutch to turn the P.T.O.

9. Pump Clutch Switch

This switch serves to energize the

magnetic clutch to turn the water pump on

or off.

10. Interior Light Switch

This switch controls the spot lights located

in the cargo area.

11. Auto Drain Switch

This switch controls the (Optional)

auxiliary pump to drain the waste

collection tank automatically. A float

switch located inside the tank

automatically turns on and off when the

solution level reaches a certain level.

12. High Pressure Outlets

The high pressure solution outlets are the

connecting point s for the high pressure

hoses. These outlets have quick connects

that allow hoses to be plugged into the

unit.

13. C.A.D. Port

This port is used when the (Optional) Auto

Drain is installed on the unit. It will accept

standard garden hoses. Waste tank

solution should only be dumped according

to Local, State, Provincial, and Federal

Laws.

14. Direct Feed

This port is used when the (Optional)

Water Box is being used instead of an “on

board tank”.

15. Flow Meter

The flow meter is a gauge to indicate how

much liquid detergent is being introduced

to the water system. Turning the knob on

the flow meter clockwise can increase the

quantity.

16. Blower Lube Port

The oil cup allows lubricant spray to reach

the lobes of the vacuum pump. USE

LPS/TKX LUBRICANT

17. Oil View lines

The oil view lines indicate levels of oil in

both the vacuum pump and water pump.

They are “indicators only”. Vehicle must

be on a level surface.

18. Detergent Bottle

The detergent bottle holds the

concentrated detergent used in the

operation of cleaning.

15

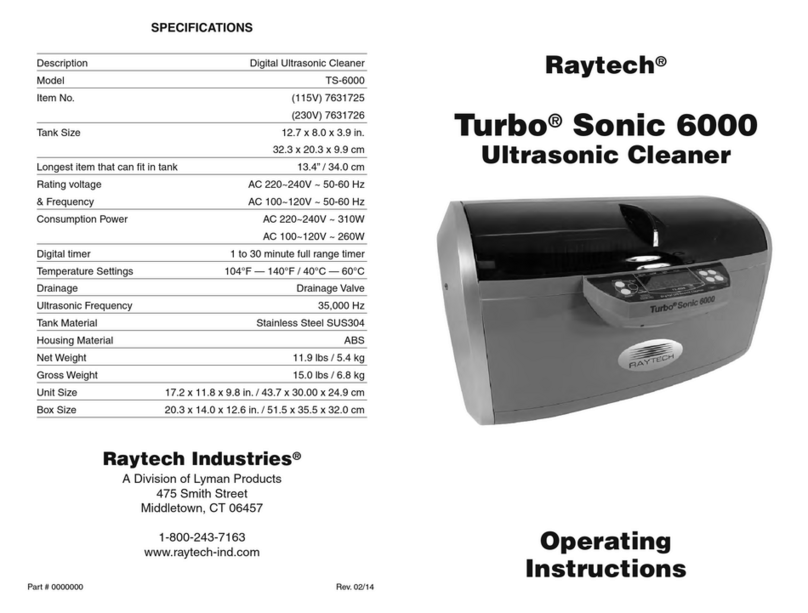

Water Pumping and Heat Transfer System:

Cold water enters the panel through the water

inlet. When the water tank is full the valve will

automatically shut off.

Water then flows from the water tank, through a

strainer, into the water pump where chemical is

introduced at this point. Then it is pumped to the

pressure regulator that provides and maintains the

desired pressure setting.

A certain amount of water is by-passed from the

pressure regulator due to over pumping capacity

of the water pump. Water that is not called for in

the cleaning process is channeled to the by-pass

coil in the recovery tank then flows to the inlet side

of the pump to be circulated again.

The heating stage occurs when the water leaving

the pressure regulator and directed to the first of

two heat exchangers. Heat from the vehicle

engine coolant is exchanged to the cleaning

solution spiraled copper tubing. This allows the

engine coolant to travel in a counter rotating

direction to the cleaning water during the

exchange process creating a very efficient transfer

of heat out of the engine and into the cleaning

solution.

The hot solution then exits the second heat

exchanger where it enters the outlet manifold.

The manifold serves as a sensing point and

connection for the high-pressure hoses.

Finally, the cleaning solution then passes through

pressure hoses and is distributed by the cleaning

tool to a surface that is being cleaned, completing

the water pumping and heating cycle of the

cleaning unit.

Optional P.T.I.

With the Optional Post Thermal Increase, the

cleaning solution goes to a second stage of

plumbing and heating which takes place in the

heater core located just after the vacuum pump.

This is the hottest point of exhaust air coming from

the vacuum pump. The hot exhaust air is forced

through the post heat core, creating the second

stage of heat transfer to the cleaning solution.

Required Maintenance of P.T.I.

Annual inspection of the fins inside the P.T.I. is a

requirement do to the potential folding over of the

fins or build up of debris, lint, dirt etc. This will

cause excessive stress on the drive line including

the blower, PTO shaft and PTO clutch. The blower

must be removed to see the possible results of the

wear and tear on the fins. Cleanco would

recommend this procedure be done by a Qualified

Service Center.

Heat Max P.T.I Operating Instructions:

Overview

The “Heat Max P.T.I.” is designed to transfer the

exhaust heat generated by the vacuum blower, to

the cleaning solution as the final heating stage. To

fully understand the heat transfer system of the

Cleanco Compact the following steps occur.

Before the P.T.I. will efficiently transfer heat to the

cleaning solution, the blower must be brought up

to temperature. This is accomplished when the

vehicle coolant system is first brought up to

operating temperature either through idling or

driving to the job site. Then the unit must be

turned on to high idle with the vacuum port of the

recovery tank closed off with the plug on the inlet

barb. The operating temperature of the P.T.I. will

be available in about ten minutes of running unit.

The P.T.I. will take much longer to reach operating

temperature if this procedure is not done and in

fact will cool the water until the blower can reach

the desired transfer heat rate.

Step 1

The water flows from the fresh water tank through

a strainer, into the water pump where it is pumped

to the pressure regulator providing constant

desired pressure.

Step 2

The next stage of water flow is to the heat

exchangers (Dual or Quad), when water is called

for in the cleaning process, it flows to the heat

exchangers under pressure. Heat from the engine

coolant is exchanged to the cleaning solution

through a series of spiraled copper tubing. This

allows the engine coolant to travel in a “reverse

flow” direction to the cleaning solution creating a

very efficient transfer of heat out of the engine and

into the cleaning solution.

Step 3

The last stage of the heat exchange takes place in

the “Heat Max P.T.I.” located under the baseplate.

This is the hottest point of the exhaust from the

vacuum blower which is forced through the “Heat

Max P.T.I.”. The cleaning solution travels from the

16

heat exchangers to the “Heat Max P.T.I” where it

is channeled through a series of stainless steel

tubing. The exhaust heat from the vacuum blower

is transferred to the stainless steel tubing,

boosting the temperature of the cleaning solution.

Step 4

The hot cleaning solution passes to the outlet

manifold, this manifold serves as a temperature

sensing point and connecting point for the high

pressure solution hoses. The cleaning solution

then passes through high pressure hoses and is

distributed by the cleaning tool to the surface that

is being cleaned.

Operating System

Step 1

Arriving at the job site, same routine applies: pre-

inspection, precondition, run hoses and tools

required into the site.

Step 2

Turn unit power on, then turn on pump, set

chemical meter and enter the site to begin

cleaning.

Step 3

Clean as normal using the recommended orifice

sizes listed below for the wand and stair tool.

Step 4

It will take approximately 15 minutes of normal

cleaning for the vacuum blower to generate

desired temperatures of 230ºF - 240ºF. As the

carpet wand vacuums the carpet it generates a

“load” on the vacuum blower, this in turn then

reaches and maintains optimum temperature for

maximizing the “HEAT MAX P.T.I.” heat transfer.

DO NOT FREEZE! UNIT IS IRREPARABLE IF

FROZEN.

HOTTER WATER TEMPERATURES WILL

CAUSE PREMATURE DETERIORATION OF

HIGH PRESSURE HOSE, VALVES, ORINGS,

ETC.

JET SIZING

For maximum heat and overall unit performance,

the recommended floor tool jet sizing not to

exceed a total of “.045”. Using larger jet sizes on

your cleaning unit may reduce cleaning

temperatures.

Example: Dual-jet wand uses two 110015 jets

(110º spray angle with 015 orifice).

015 x 2 = .03

Stair tool jet size: 11003

17

WATER PUMPING AND HEAT TRANSFER SYSTEM

18

WATER PUMPING AND HEAT TRANSFER SYSTEM

(DUAL HEAT EXCHANGER) WITH P.T.I. OPTION

19

CHEMICAL INJECTION SYSTEM

The chemical injection system utilizes the natural

inlet draw of the high-pressure pump to move the

chemical into the main pressure stream.

The chemical is picked up from the container

and fed through the flow meter at a desired

amount of chemical which is adjusted through

the metering valve.

The chemical and water are mixed in the high-

pressure pump and then forced through the heat

exchangers and outlet manifold where then it is

distributed to high-pressure hoses out to the

cleaning tool

This manual suits for next models

1

Table of contents