Skymen MECHANICAL Series User manual

MECHANICAL

SERIES

DIGITAL TIMER

S SERIES

DIGITAL TIMER

PLUS SERIES

Instruction Manual

Application:

Electronic factory, utensil, hardware, machinery, communication, biological,

medical instrument, glasses,Optical, Jewelry, clock, watch, chemical, Textile,

auto part, Ships, aviation, mining area, commercial cleaning.

ULTRASONIC CLEANER SKYMEN MANUFACTURE

Professional manufacturer focus on ultrasonic technology R&D

The pictures in this manual are for reference only.

Please refer to the real products.

01

Thanks for purchase ultrasonic cleaner,Please read the instruction manual

carefully before operation to avoid damage to the machine or any danger to personal

safty.And please keep it for reference.

Please make sure power supply is in rated range, before plug the machine.

Refitting is strictly prohibited! Attention that the control panel will be eroded by

organic solution, strong acid and strong alkali.

PREFACE OF USE

THE BASIC PRINCIPLE OF ULTRASONIC CLEANING

The cleaner uses ultrasonic energy (40 kHz) in the form of sound waves to create millions of tiny

microscopic bubbles in the solution that even works its way into holes and hidden cavities,

loosening dirt on all surfaces that the solution touches. This action called cavitation, occurs

thousands of times per second to gently yet thoroughly scrub contamination off the article being

cleaned. When you lift the item out of the cleaner, it’s microscopically clean.

1.Ensure the power supply is in rated range before power cable is connected.Refitting is strictly

prohibited! Attention that the control panel will be eroded by organic solution,strong acid and

strong alkali.

2.Ensure the earth wiring is well connected before starting.

3.Ensure the power switch should be placed in the “O” position before starting.

4.Do not operate if the tank is empty,or ultrasonic generator will be damaged.If heating is

needed,the water level shouldn,t be less than2/3.

6.Please close the lid to reauce noise and pay attention to water and steam in case of burning

skin while open the lid.

7.Do not relocate the machine when fluid in the tank in case of overflow.

8.Please choose the proper sizes or types of baskets according the object to be cleaned

9.Suggest using water-soluble liquid for bentchtop ultrasonic cleaners. Strong acid or flamma-

bility cleaner is forbidden.Donot heat when using flammable liquid such as alcohol, gasoline, etc.,

heating is strictly prohibited , ultrasonic vibration for a long time cause temperature of liquid

increase, caution fire!

10.Do not use the machine in severe environment:

The place where temperature changes fiercely; The place where humidity is too high and

is easy to produce dew; The place where vibration or impact is strong; The place where

exists corrosive gas or dust; The place where water, oil or chemicals splash; The place

where is filled with explosive and flammable gas;

NOTES BEFORE USE

www.skymen.cc

02

www.skymen.cc

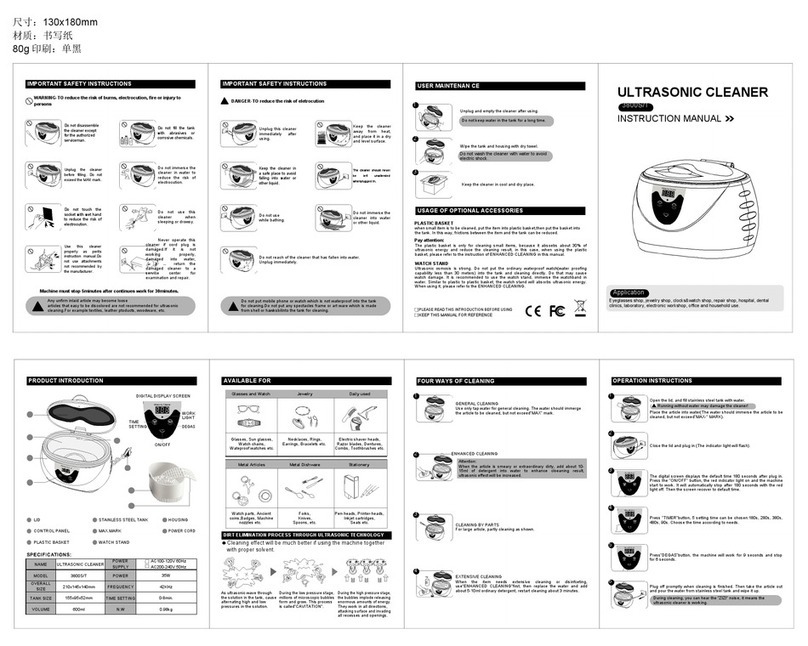

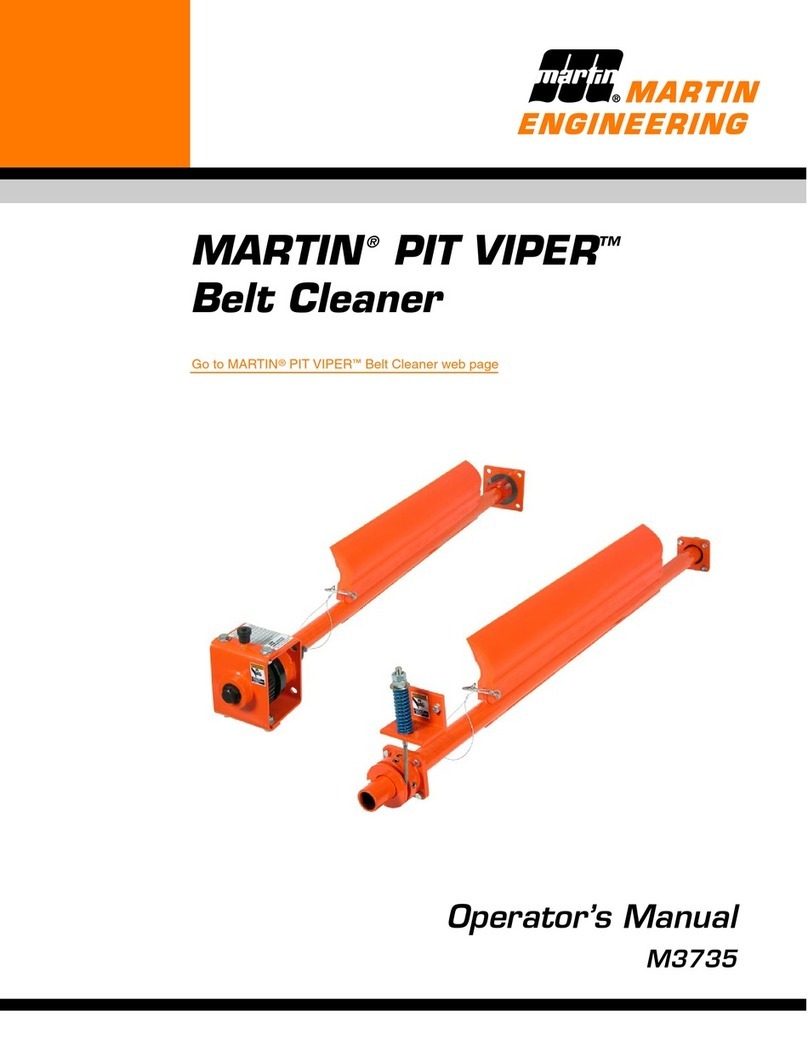

MECHANICAL MODEL

PRODUCT DRAWING&INDICATION

Ultrasonic

ON/OFF

Ultrasonic

indicator

Heater ON/OFF

Heater indicator

Lid

Control board Corner pad

Power switch

Handle

Drainage

Ventilation

holes

Fuse(a backup fuse)

The power plug

Tank

Back

03

SKYMEN ULTRASONIC

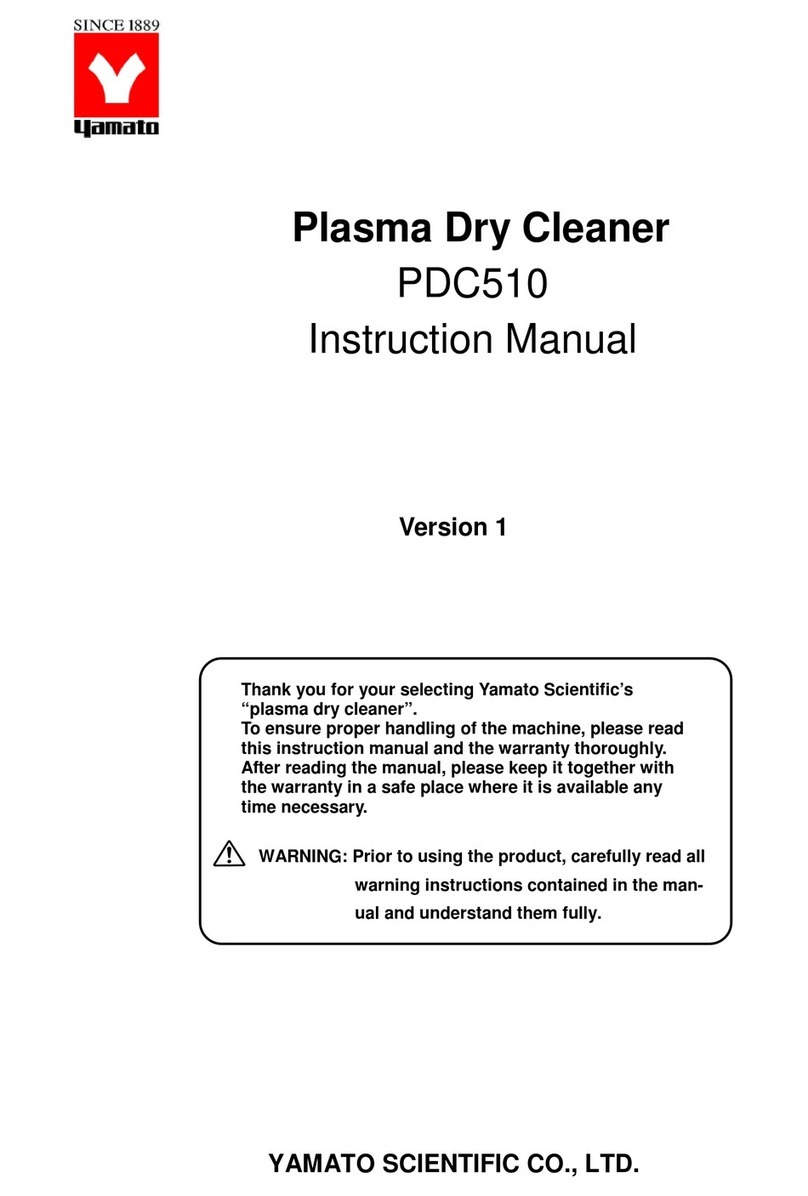

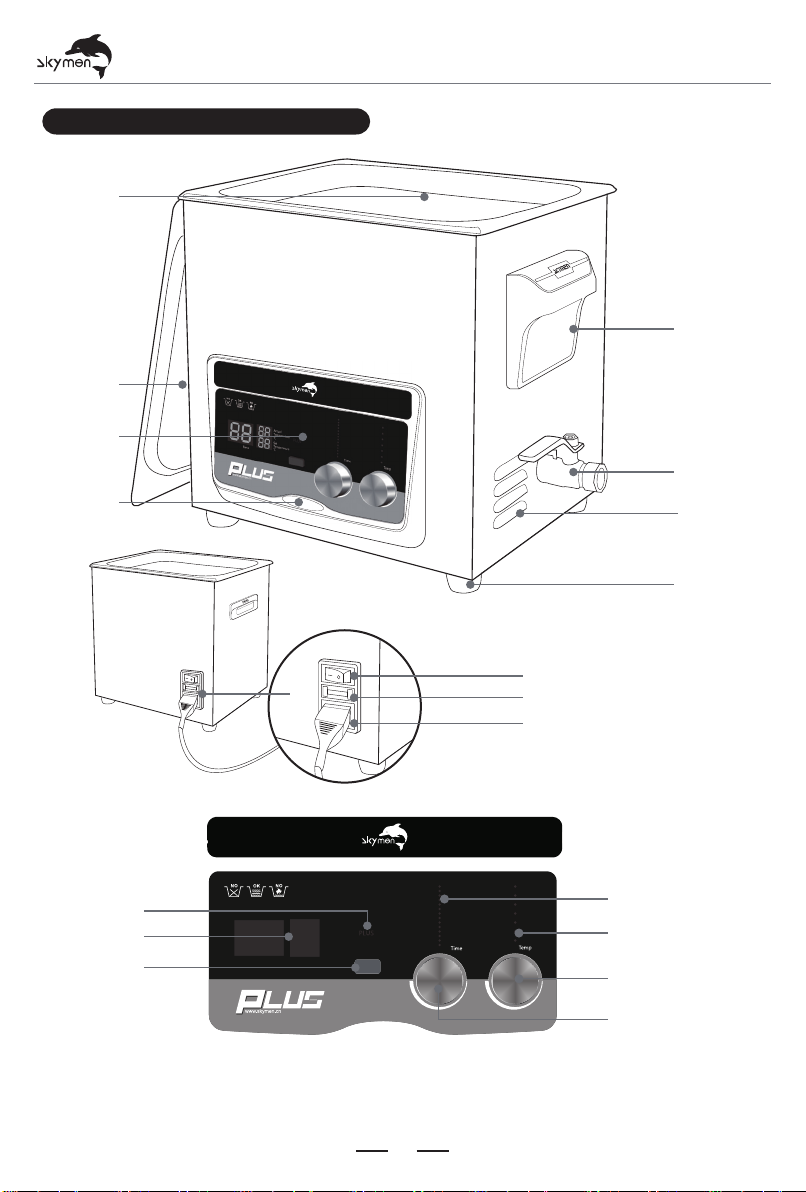

PRODUCT DRAWING&INDICATION

Digital timer heater adjustable with degas series

Lid

Control

board

Corner pad

Model

Handle

Drainage

Ventilation

holes

Degas

Heater indicator

Digital display

screen

Temp -

Tank

Ultrasonic indicator

Digital display screen

Degas indicator

Semi-wave indicator

Time -

Ultrasonic ON/OFF

Time +

Power

adjustable

Temp +

Heater ON/OFF

Power switch

Fuse(a backup fuse)

The power plug

Back

SKYMEN ULTRASONIC

www.skymen.cc

04

www.skymen.cc

Actual

Time

Temperature

Temperature

℃

℃

Set

Lid

Control

board

Corner pad

Model

Handle

Drainage

Ventilation

holes

Tank

Display

Time Progress bar

Temp Progress bar

Temp ON/OFF

Time ON/OFF

PLUS Key

PLUS

Indicator light

Digital timer heater adjustable plus series

Power switch

Fuse(a backup fuse)

The power plug

Back

05

www.skymen.cc

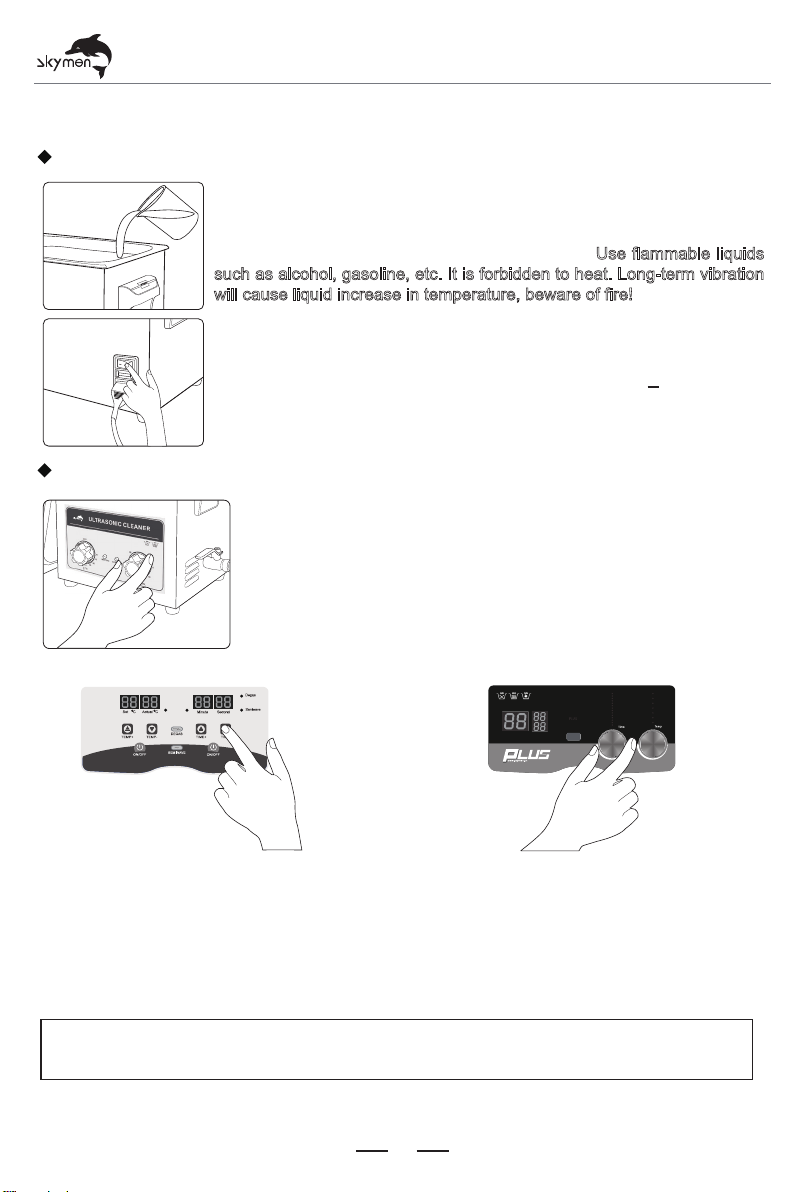

OPERATION STEPS

Before Operating Your Cleaner

Start ultrasonic cleaning

PLUS series: At first setting, the time is

random, progress bar light on, Turn the

rotary knob clockwise to increase time ;

Turn counterclockwise to decrease time.

Correspondingly the two digits on the left of

the display change accordingly, and the

time setting done well. Press the rotary

knob, ultrasonic start working.

Plus Series Description: Time starts to countdown in minutes. The progress bar indicator flashes to show that the ultrasound starts to work.

When the countdown is over, the ultrasound stops working, the progress bar indicator recover light, press the knob again during the work,

When ultrasound stops working, the progress bar indicates Light stops flashing. The next boot,display of timer will default last setting.

S series: At first setting, the time is random.

Touch “Time+” or “Time-“ to set time, press

“On/off” the ultrasonic active and the

machine start to countdown.

Start(ULTRASONIC), clockwise rotate to choose the time you

required between 0~30 min. When the indicator light is on and

make “ZIZI” sound,it shows ultrasonic operation work OK.

MECHANICAL SERIES

Actual

Time

Temperature

Temperature

℃

℃

Set

Plug the cleaner into a grounded outlet. Turn on the power switch at the

tank back, then machine is power on.("O" is closed, and " " is open)

Add appropriate amount of cleaning solution to the cleaning tank accord-

ing to the cleaning. Ensure that the liquid level is not lower than the inner

tank height by 2/3 when the heating is turned on. Use flammable liquids

such as alcohol, gasoline, etc. It is forbidden to heat. Long-term vibration

will cause liquid increase in temperature, beware of fire!

1. Add cleaning liquid

2. Open power

PLUS Series: Turn on the power ,in the LOGO breathing light standby

state, wake up by any operation

06

www.skymen.cc

Heat

Plus series: At first setting, the temperature

is random. Turn the rotary knob clockwise

or counterclockwise to increase or

decrease temperature. Press rotary knob

,heat will active before reaching the setup

temperature.

S series : At first setting, the temperature is

random. Touch “Temp+” or “Temp-“ to

increase or decrease temperature. Press”

on/Off” button ,heat will active before reach-

ing the setup temperature.

Degas:ultrasonic work for 9seconds,stop for 6seconds, work for 9seconds ets etc. till time is out.

(some cleaner do not have this function)

Semiwave: touch “Semiwave”to start half-wave Mode, ultrasonic power will cut in half. (some

cleaner do not have this function)

PLUS:The machine will work at 150-180% power (this will not affect the machine's performance

life) , which is used to clean object with stubborn stains. (Some machines do not have this

function)

Additional functions

Power OFF

Plus Series Description: Heating in degrees Celsius, the progress bar indicator light flashes, which say heater starts working, heat to the

specified temperature, When Heating Stop Working, the progress bar indicator recover light . Press the knob again during the work, the

heating stop working, the progress bar indicator light flashes. The next boot,display of heater will default last temperature setting.

If need heating, start(HEATING) to adjust required temperature, normally

40~60℃ is the best. (Heating is optional upon needs)

MECHANICAL SERIES

Turn the timer button to the location of “OFF”, the ultrasonic stops and the light is off. Turn the

heating button to the location of “OFF”, the heating stops and the light is off. And then cut off

the power, empty out the liquid, clean the tank and the unit with cloth for next use.

MECHANICAL SERIES

Presss the ultrasonic “ON/OFF” button, the ultrasonic stops and the light is off. Presss the

heater “ON/OFF” button, the heating stops and the light is off. And then cut off the power, empty

out the liquid, clean the tank and the unit with cloth for next use.

Digital timer heater adjustableS series

Actual

Time

Temperature

Temperature

℃

℃

Set

07

OPERATION PROCEDURE

>>>>>>Digital timer heater adjustable with degas series<<<<<<

JP-020S

JP-030S

JP-031S

JP-040S

JP-050S

JP-060S

JP070S

JP-080S

JP-100S

40

40

40

40

40

40

40

40

40

2

3

3

4

5

6

8

8

10

3.2

4.5

6.5

10

14.5

15

20

22

30

240x135x100

300x150x100

300x150x150

300x240x150

300x240x200

330x300x150

330x300x200

500x300x150

500x300x200

270x185x230

330x200x235

375x200x275

380x290x280

370x270x325

400x350x280

400x300x200

585x330x280

585x327x333

100

200

200

200

200

300

300

500

500

120/60

180/90

180/90

240/120

300/150

360/180

480/240

480/240

600/300

0~30

0~30

0~30

0~30

0~30

0~30

0~30

0~30

0~30

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

Model Frequency

(KHz)

Transducer

(Pcs)

Capacity

(L)Tank size(mm) Unit size(mm) Heating power

(W)

Utrasonic power

(W)Time(M) Temperature(℃)

>>>>>>MECHANICAL SERIES<<<<<<

Model Frequency

(KHz)

Transducer

(Pcs)

Capacity

(L)Tank size(mm) Unit size(mm) Heating power

(W)

Utrasonic power

(W)Time(M) Temperature(℃)

JP-010

JP-020

JP-030

JP-031

JP-040

JP-060

JP-080

JP-100

40

40

40

40

40

40

40

40

1

2

3

3

4

6

8

10

2

3.2

4.5

6.5

10

15

22

33

150x135x100

240x135x100

300x150x100

300x150x150

300x240x150

330x300x150

500x300x150

500x300x200

175x160x210

265x165x220

325x180x225

325x180x280

325x265x280

360x325x285

530x325x285

530x325x325

100

100

200

200

200

300

500

500

80

120

180

180

240

360

480

600

0~30

0~30

0~30

0~30

0~30

0~30

0~30

0~30

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

room temp~80

After the countdown is over (during the working, press the button again, the ultrasonic

operation stops).And then cut off the power, empty out the liquid, clean the tank and the unit with

cloth for next use.(If the PLUS series does not any operate for 3 minutes, the panel light will go

out in standby mode)

Digital timer heater adjustable PLUS series

0~30 room temp~80

JP-120S 40 12 38 500x300x250 800 720/360

595x345x385

www.skymen.cc

08

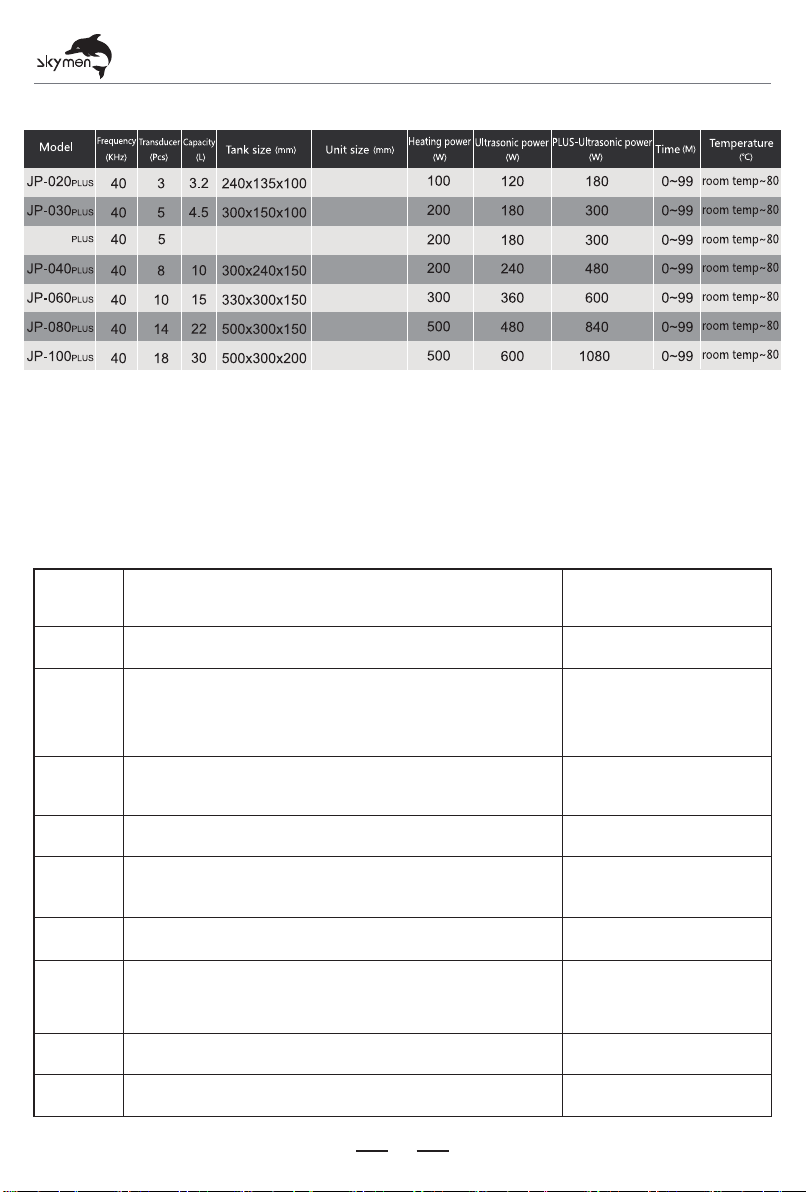

>>>>>>Digital timer heater adjustable plus series<<<<<<

APPLICATION

Industry

Semi-

conductor

Integrated circuit, power tube, slicon wafer, diode, lead frame,

capillary, tray, etc

Hards, etching oil,stamping oil,

pollshing wax, dust partides,etc

Electrical&

electronic

machine

Tube parts, cathode ray tube, printed circuit board, quartz parts,

electronic components, telephone switching equipment, speaker

components, power meter, LCD glass, core iron parts, computer

floppy disk, vido parts, hoop parts, head, photo die mask,etc

Fingerprint,powder,cutting oil,

stamping oil, iron filings,

polishing materials, wanut

powder, polishing wax, resin,

dust etc

Precision

machine

Bearing, sewing machine parts, typewriter, textile machine, optical

mechanical device, gas valve, watches, cameras, metal filter

element,etc.

Machine cutting oil,iron filngs,

polishing powder, finger print

oil, grease, dirt etc.

Optical

device

Glasses, lens prism, optical lens, filter lens, glass device, film, optical

fiber, etc.

Plastic, resin, paraffin, finger

printing, etc

Hardware &

machinery

parts

Bearing, gear,bal, metal shaft parts, tools, adjustable valve, and

cylinder parts,burner,copm pressors,hydraulic press, gun and

ultracentrifuge, city water faucet, etc.

Cutting oil, iron filings,grease

polishing powder, finger

printing, and so on.

Medical

instrument Medical instrument, denture, etc. Iron filings,polishing powder,

oil, stamping oil, dirt,etc.

The cleaning products materials Cleardirt

Electroplate Galvanized parts,mold,stamping parts,etc.

Car parts Iron filings,polishing powder,oil,

stamping oil,dirt,etc

Poston ring,carburetor,flow meter housing,compressor shell,electrical

components,etc

Chemical

fiber

Chemical colloid,glue,and other

solid material,dust,etc

Chemical or artificial fiber nozzle filter protector,chemical fiber texture,etc

Polishing scrap iron,oil,black

iron shell,rust,oxidation shell,

scrap iron,polishing powder,

stamping oil,dirt etc

JP-031 6.5 300x150x150

290x185x270

350x210x275

350x210x325

395x295x315

420x360x320

595x355x330

595x355x385

(The size is manual measurement, please refer to the actual product)

www.skymen.cc

Full series standard ultrasonic cleaners are made up of high quality stainless steel plate, which

is corrosion resistance and long lifespan, adopt with high quality ultrasonic transducer and

advanced adhesive technology, high electro-acoustic conversion efficiency and strong ultrasonic

power output. Equipped with automatic constant temperature heating device, heating range: room

temperature~80℃.Skymen ultrasonic cleaner widely applied to industry of precision electronics,

painting, filter system, watch-clocks, glass, metal, jewelry, and medical instruments deaning etc.

09

Donot operate when

tank is empty

Donot use flammable

solution

Caution pollution when

disposal this product.

Please use the ground

wire correctly

WARNINGS

MAINTENANCE

Regularly use high-pressure wind blown away dust for electrical parts Clean the tank at least

once a week

Maintenance

Troubleshooting

No Problems

No

Ultrasonic

Time control

failure

A.Timer failure

B.other reasons

Electricleakage

Scrap

According to the state related laws and designated

units for discarded medical equipment

Not repairable or discarded

A.Replace timer or digital control panel

B.Inquiry our after service engineer

Not well

cleaning

A.too high too low liquid surface

B.too high too low temperature

C.Not suitable cleaning liquid

D.Other reasons

A.Adjust liquid into the best surface

B.Adjust temperature into the most fitted

C.Stop and switch off power supply,replace

suitable liquid after the previous liquid cool down

D.Inquiry our after service engineer

Temperature

control

failure

A.Thermostant loosen

B.Thermostat tube broken

C.Digital display out of control

D.Other reasons

A.Fasten the thermostat header.

B.Replace thermostat.

C.Check the broken part and change it.

D.Inquiry our after service engineer

No heating Suggestion

50-60°C

Suggestion

50-60°C

A.Heater power switch bad

linkage

B.Fuse burn out

C.Heating pad burn out

D.Digital display board out of

control

E.Incorrect temperature setting

A.Check heating plug and connect well.check

outlet line with multimeter:if OK and resistance

value is few hundred OHMs.

B.Change the same specification fuse

C.Replace the bad heating pad if open circuit

D.Check the broken part and change it

E.The set temperature must be 3°C higher than

the actual temperature before heating can be

turned on. Please reset the temperature.

F.Other reasons F.Inquiry our after service engineer

A.Power supply not connect

B.Fuse broken

C.Cable short circult

D.Transducer short circult

E.PCB Board broken

F.Other reasons

A.Check and plug power switch

B.Check the fitted power supply and change the

same specification fuse

C.Connect fitted cable or replace a new

D.Inquiry our after service engineer

E.Check the broken part and change it

F.Inquiry our after service engineer

Possible causes Solutions Remarks

1

2

3

4

5

6

7

Other problems

Consult our after service:+86-755-297847256

8

A.The equipment ground wire is not

connected well.

A.Check whether the internal ground wire and power cable

grounding of the device are connected.

B.Check if the internal live wire or neutral wire of the

machine is fall off.

B.The internal live line or neutral line

of the equipment falls off

www.skymen.cc

10

MAINTENANCE CARD

Ultrasonic cleaner

Maintenance care records

EX factory date:

Machine number:

Work voltage

Work current

Rated power

01

02

03

04

05

06

07

08

09

10

11

12

Maintenance care solution replacement part contact person

Please contact supplier if trouble cannot be removed!

www.skymen.cc

It is sorry to that the design and specification of our products are subject tochange without

notice.

All information in this manual has been carefully proofread and made every effort to be

accurate. We reserve

the right to interpret any printing mistakes.

The copyright of this manual belongs to Skymen Cleaning Equipment Shenzhen Co., Ltd.

No copy or reprint is strictly prohibited without written authorization. The company will

pursue its legal responsibility.

Solemnly Declare

Please scan the code

for instructions

Tel:+86-755-27094405 FAX: +86-755-29784236

Production address: Skymen Ultrasonic,Wujiang Technology

Industrial Park,Wujiang District,Shaoguan City,Guangdong,China

Operation center: 3F, A1 Block, Fuhai Technology Park Building,

FuYong Steet, Baoan district, Shenzhen, Guangdong, China.

Skymen Cleaning Equipment Shenzhen Co., LTD

This manual suits for next models

27

Table of contents

Other Skymen Ultrasonic Jewelry Cleaner manuals

Popular Ultrasonic Jewelry Cleaner manuals by other brands

Hydro-Force

Hydro-Force AC040 Operator's manual

Makita

Makita DCL286F instruction manual

BubbleFlush

BubbleFlush BBF.275.62 user manual

Arch Environmental Equipment

Arch Environmental Equipment Saber Max Installation instructions manual

Dibo

Dibo SBH-E manual

Starmix

Starmix GS series Original operating instructions