CleanControlling CPS3 apex User manual

You must read these operating instructions and all relevant documents before using the system.

Document Particle suction extraction system C|PS³

Item no.: 6006100

Operating instructions –English translation

Version V 1 / Date 06.12.2023

Other documents relevant for this product:

EC Declaration of Conformity for C|PS³ particle suction extraction system

EC Declaration of Conformity for FESTOOL mobile dust extractors

Original operating instructions –FESTOOL mobile dust extractor CTL MINI I, CTL MIDI I, CTL

MINI, CTL MIDI

CleanControlling GmbH

Gehrenstrasse 11 a

D-78576 Emmingen-Liptingen

Tel.: +49 (0)7465 929678-0 Fax: +49 (0)7465/929678-10

Website: www.cleancontrolling.com/en/ Email: info@cleancontrolling.de

Copyright © 2019 CleanControlling GmbH

Contents

Particle suction extraction system / Item no.: 6006100 3 / 85 Date 06.12.2023 / Version 1

Table of contents

1. Basic safety instructions 5

1.1. Obligation to instruct 5

1.2. Conformity, guidelines and directives 6

1.3. Safety symbols and representations used 6

1.3.1. Warnings and warning signs 6

1.3.2. Signal words 6

1.3.3. Other symbols 7

1.3.4. Mandatory symbols 7

1.4. Operating instructions 7

1.5. Designated use 7

1.5.1. Obligation and liability 8

1.5.2. Foreseeable misuse 9

1.6. Risks involved in handling the system 9

1.6.1. Electrical hazards 10

1.6.2. Mechanical hazards 10

1.6.3. Hazard due to noise 11

1.6.4. Remaining hazards 11

1.6.5. Fire fighting, preventive fire protection 11

1.6.6. How to behave in case of danger and accidents 11

1.6.7. Organizational measures 12

1.6.8. Informal safety measure 12

1.6.9. Training of staff 12

1.6.10. Maintenance, servicing and fault repair 12

1.6.11. Structural changes to the device 13

1.6.12. Cleaning the device 13

1.6.13. Noise from the device 13

1.6.14. Decommissioning and disposing of the device 13

1.6.15. Change of owner 14

1.6.16. Guidelines for a safe work area 14

1.7. Defective device 14

1.8. Further use of components after suction extraction 15

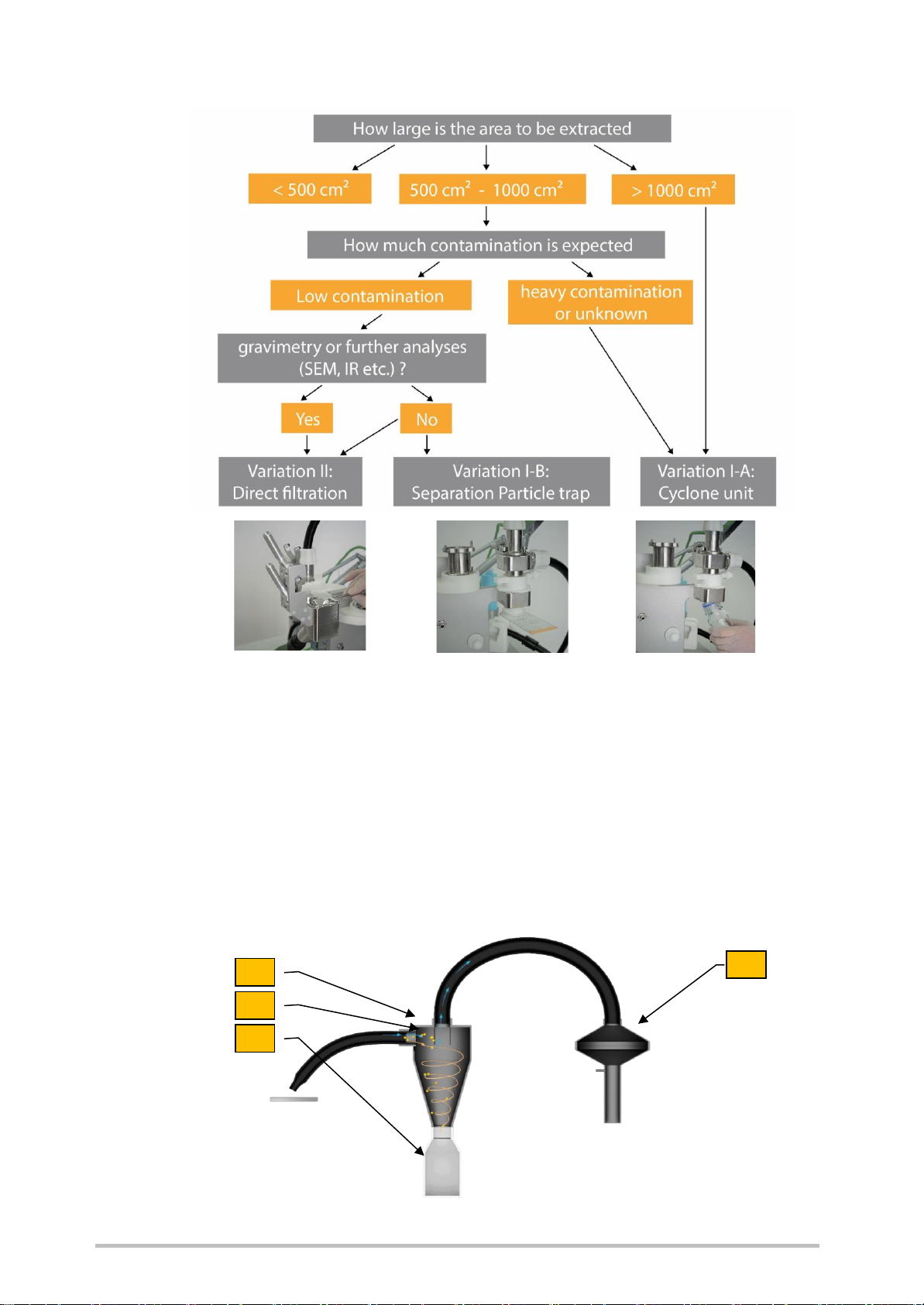

2. Description of the extraction principle 16

2.1. Particle suction extraction with cyclone and filter unit (variant I) 17

2.2. Particle suction extraction without cyclone unit, directly onto the filter unit

(variant II) 18

3. Structure 19

3.1. Mobile trolley 19

3.2. Mobile extractor REAR 20

3.3. Particle suction extraction system without cyclone unit 21

3.4. Particle suction extraction system with cyclone unit 22

4. Device transport 23

5. Initial operation 24

5.1. Mobile trolley 24

5.2. Suction unit 25

5.3. Extraction system 29

5.3.1. Initial operation with cyclone unit 30

5.3.2. Initial operation without cyclone unit 32

Contents

Particle suction extraction system / Item no.: 6006100 4 / 85 Date 06.12.2023 / Version 1

5.4. Switching on the device 33

5.4.1. Connecting the remote control to the suction unit 33

5.5. Reset on the remote control 34

5.6. Deleting all saved Bluetooth connections of the suction unit 35

6. Particle suction extraction process 36

6.1. Screwing on or replacing the particle collection jar 36

6.2. Attaching or replacing the particle trap 37

6.3. Replacing or inserting the mesh filter 37

6.4. Flushing the mesh filter 38

6.5. Carrying out the particle suction extraction procedure 40

6.6. Selecting the correct suction level 41

6.7. Instructions on using the suction and brush nozzles 42

6.8. Operating parameters 45

7. Cleaning 46

7.1. Cleaning with cleaning wire –dry cleaning 46

7.1.1. Preparing cleaning equipment and cleaning 46

7.1.2. Cleaning hoses 49

7.1.3. Cleaning the nozzles 51

7.1.4. Cleaning the system 52

7.1.5. Wet cleaning 55

7.2. Determining the blank value after cleaning 57

7.2.1. Determining the blank value with or without the prefilter 58

7.2.2. Determining the blank value 59

8. Operation with control system 60

8.1. Function keys 60

8.2. F1 –Settings menu 61

8.3. F3 –Suction unit control panel 63

8.4. F2 –Blank value 64

8.5. F4 –Qualification test 65

8.6. F6 –Analysis 69

8.7. Fault messages 72

8.7.1. Fault message 1 –Select power level 72

8.7.2. Fault message 2 –Failure to maintain the operating point 73

8.7.3. Fault message 3 –Empty suction unit liquid container 74

9. Maintenance 75

9.1. Changing the suction unit filter and emptying the dirt (water) container 75

9.2. Software update 76

9.2.1. Preparing the installation media 76

9.2.2. Preparing the installation medium for the control system 76

9.2.3. Preparing the installation medium for the HMI panel 77

9.2.4. Installing the firmware updates 77

9.2.5. Installing the firmware update for the HMI panel 77

9.3. Installing the firmware update for the control system 81

10. Scope of delivery/equipment 83

Particle suction extraction system / Item no.: 6006100 5 / 85 Date 06.12.2023 / Version 1

1. Basic safety instructions

These operating instructions contain important information on the safe and proper use of the

device. Observance of these instructions helps to

•avoid hazards,

•reduce repair costs,

•minimize downtimes, and

•increase the reliability and service life of the device.

CleanControlling GmbH accepts no liability if errors, damage, operational breakdowns and

resulting production downtimes occur due to non-observance of these operating instructions. The

operating instructions comply with the European Machinery Directive 2006/42/EC and DIN EN

ISO 12100 Parts 1 and 2. The operating instructions are part of the device and are included in the

scope of delivery of the device documentation. At the time of handover, the documentation

corresponds to the latest device version at the time of delivery.

The contents of the operating instructions must be read, understood, and observed in every

respect by every person responsible. This applies in particular to safety instructions that are

specially marked in the operating instructions.

In addition to the operating instructions and the local obligatory regulations for accident prevention

at the place of use, the generally recognized technical rules for safety-conscious and professional

work must also be observed. CleanControlling GmbH reserves the right to make technical

modifications that are necessary to improve the device. Therefore, deviations from the contents

or the illustrations in the operating instructions are possible.

1.1. Obligation to instruct

All persons who work on and with the device and are responsible for the device must read and

understand these operating instructions and must comply with all points in the instructions.

CleanControlling GmbH does not accept any liability or warranty for any damage caused by staff

who have received inadequate instructions or who have not received any instructions, as well as

in case of changes to the system that do not comply with the specified requirements.

Particle suction extraction system / Item no.: 6006100 6 / 85 Date 06.12.2023 / Version 1

1.2. Conformity, guidelines and directives

The device and its components, modules and assembly groupscomply individually and as a whole

with the current applicable safety standards as specified in European Union CE Directives (see

the enclosed EC Declaration of Conformity).

1.3. Safety symbols and representations used

The symbols used, if standardized, comply with the accident prevention regulation BGV A8 and

DIN 4844-2.

1.3.1. Warnings and warning signs

Warnings refer to an immediate danger and appear before an action at the beginning of each

chapter. In addition, warning signs are placed at various places on the device. They have the

following meanings:

Possible imminent danger to the life and health

of persons. Non-observance of these

instructions may result in severe adverse

health effects, including life-threatening injuries.

1.3.2. Signal words

Signal words are used in conjunction with safety warning symbolsto highlight warnings. The three

signal words WARNING, CAUTION and NOTICE used in these instructions indicate possible

injury or damage to equipment. The defined signal words indicate the risk level of the hazard. It is

absolutely necessary to observe the measures described to avoid the hazards. The signal words

may also precede the main text and have the following meanings:

A WARNING refers to a potential danger which can cause serious injuries or

even death if not avoided.

CAUTION refers to a potential danger which can cause slight injuries if not

avoided.

The word NOTICE indicates a potential danger which can cause damage to

the device.

Particle suction extraction system / Item no.: 6006100 7 / 85 Date 06.12.2023 / Version 1

1.3.3. Other symbols

The following symbols are also used:

The text next to this symbol provides additional important information.

This symbol requires you to take action.

•This symbol is a bullet point for lists.

1.3.4. Mandatory symbols

Mandatory instructions and symbols are used within warning symbols or precede highly important

points in the main text. They have the following meanings:

Obligation to behave in a certain way or to

perform an activity for the safe handling of the

device in order to avoid material damage.

“Observe instructions”

1.4. Operating instructions

Information on the operation of the system consists of an info pictogram and a verbal

instruction

Only trained staffmay operatethe particle suction extraction system. Themanufacturer or persons

authorized by the manufacturer to provide training will give training on the device's use.

Persons whose ability toreact is affected bydrugs, alcohol, medicationor similar must not operate

the particle suction extraction system. Region-specific age regulations must be observed.

1.5. Designated use

The device is used to suction and extract particles in line with the requirements for particle suction

extraction.

Any other use other than the one described above is forbidden since improper use could cause a

threat to life and physical well-being.

Particle suction extraction system / Item no.: 6006100 8 / 85 Date 06.12.2023 / Version 1

The suction unit or its suction hose may only be used in combination with the

particle suction extraction system. To ensure the operational safety of the

system, it may only be operated in accordance with its intended use and in a

perfectly safe condition. Dangers may occur if the device is not used as

intended.

The components of the current system configuration are listed in Appendix IV Data sheets of the

installed components. The operating conditions and operating parameters defined in the appendix

must be strictly observed.

Intended use also includes:

•Observance of all information in these operating instructions and in the manufacturer's

documentation for the components

•Regular cleaning of the system

•Compliance with inspection & maintenance cycles Use of original parts only

1.5.1. Obligation and liability

This particle suction extraction system has been built to state-of-the-art standards and in line with

established safety regulations. However, using the device may possibly pose a threat to life and

physical well-being for the user or third parties or adversely affect the device or other assets.

The device must be used for its designatedpurpose only. Any faults which could jeopardize safety

must be rectified immediately.

Our General Terms and Conditions of Sale and Delivery apply to the warranty and liability.

Warranty and liability claims for personal injuries and material damage are excluded if they are

caused by one or more of the following:

•Use of the device not in accordance with its intended use.

•Improper installation, initial operation, operation, and maintenance of the device.

•Operation of the device with defective safety devices or improperly installed or non-

functioning safety and protective devices.

•Non-observance of the instructions in the operating instructions regarding transport,

installation, initial operation, operation, maintenance, and setup of the device.

Particle suction extraction system / Item no.: 6006100 9 / 85 Date 06.12.2023 / Version 1

•Unauthorized structural changes to the device.

•Unauthorized modification of the operating parameters.

•Insufficient monitoring of device parts that are subject to wear.

•Improperly performed repairs and force majeure.

1.5.2. Foreseeable misuse

Any use other than that specified under “Intended use” or which goes beyond this is considered

improper use and is prohibited.

The operator bears sole responsibility for damage resulting from improper use. The manufacturer

assumes no liability whatsoever. The risk is borne solely by the operator.

Non-intended uses include:

•Work with modified operating parameters

•Unauthorized retrofits or modifications

•Use of spare and wear parts or auxiliary materials not approved by the manufacturer

•Violations of wastewater and environmental regulations at the operating site of the system

•Use of media and water qualities other than those defined

•Processing explosive materials

•Operating the system in an explosive atmosphere

1.6. Risks involved in handling the system

The C|PS³ has been built according to the current state-of-the-art standards and in line with

established safety regulations. Nevertheless, risks and impairments to life and limb of the

operators or third parties, to the system itself or to other material assets may occur during the use

of the system.

The prerequisite for safe handling and trouble-free operation is knowledge of the safety

instructions and safety regulations.

Particle suction extraction system / Item no.: 6006100 10 / 85 Date 06.12.2023 / Version 1

1.6.1. Electrical hazards

When working on the electrical equipment, danger to life exists due to electrical

voltage.

Caution –ESD-protected area: Observe preventive measures when handling

components susceptible to damage from electrostatic discharge.

Risk of damage to ESDS. Do not place any electronic components or assembly

groups on this surface! This warning symbol warns against damage to ESDS if they

are placed on labeled surfaces.

Work on the electrical equipment may only be carried out by qualified electricians.

The qualified electricians working on the system must be informed about the

power supply to the system, its disconnection options and about the procedural

instructions in accordance with the DGUV Regulation 3.

The integrity of the system's electrical equipment must be checked regularly; if

necessary, damaged parts must be replaced immediately and professionally.

Switch cabinets and control units must always be locked. Access is only allowed

to authorized personnel with a key or tool.

1.6.2. Mechanical hazards

The sharp edges of the sheets pose a risk of injury.

Cut-resistant protective gloves must be worn during cleaning work.

Wear the prescribed protective equipment, consisting of safety shoes, at all times

when working on the system.

Particle suction extraction system / Item no.: 6006100 11 / 85 Date 06.12.2023 / Version 1

1.6.3. Hazard due to noise

Depending on local conditions, a higher sound

pressure level may occur, causing noise-

induced hearing loss. For these areas, the

operator must provide the operating personnel

with appropriate protective equipment and take

protective measures in accordance with the

Worker Noise Protection Directive 2003/10/EC.

1.6.4. Remaining hazards

“Warning of obstacles in the head area”

1.6.5. Fire fighting, preventive fire protection

Risk of fire if motors and valves overheat.

The operator ofthe system must ensure thatthe applicable fire protection regulations arecomplied

with. He must regularly instruct the personnel on how to behave in the case of fire and document

the instructions that have been given.

Escape routes, emergency exits, and safety equipment must be marked in accordance with

ASR A1.3.

1.6.6. How to behave in case of danger and accidents

The operator of the system must regularly instruct the personnel on how to behave in case of

danger and accidents. General procedure in case of danger:

•Shut down the machine or trigger an emergency stop, secure the danger area

•Dial emergency number

•Inform first-aiders and supervisor

•Provide first aid

Particle suction extraction system / Item no.: 6006100 12 / 85 Date 06.12.2023 / Version 1

1.6.7. Organizational measures

The operator must provide the required personal protective equipment. All safety systems must

be checked on a regular basis.

The operator is obliged to appoint a person in charge who is responsible for safe operation of the

device and for coordination of all work on the device.

1.6.8. Informal safety measure

The operating instructions must be kept on the device at all times. In addition to the operating

instructions, general regulations and other binding regulations on accident prevention and

environmental protection must be observed.

You must keep all safety instructions and hazard warnings in a legible condition and replace if

necessary.

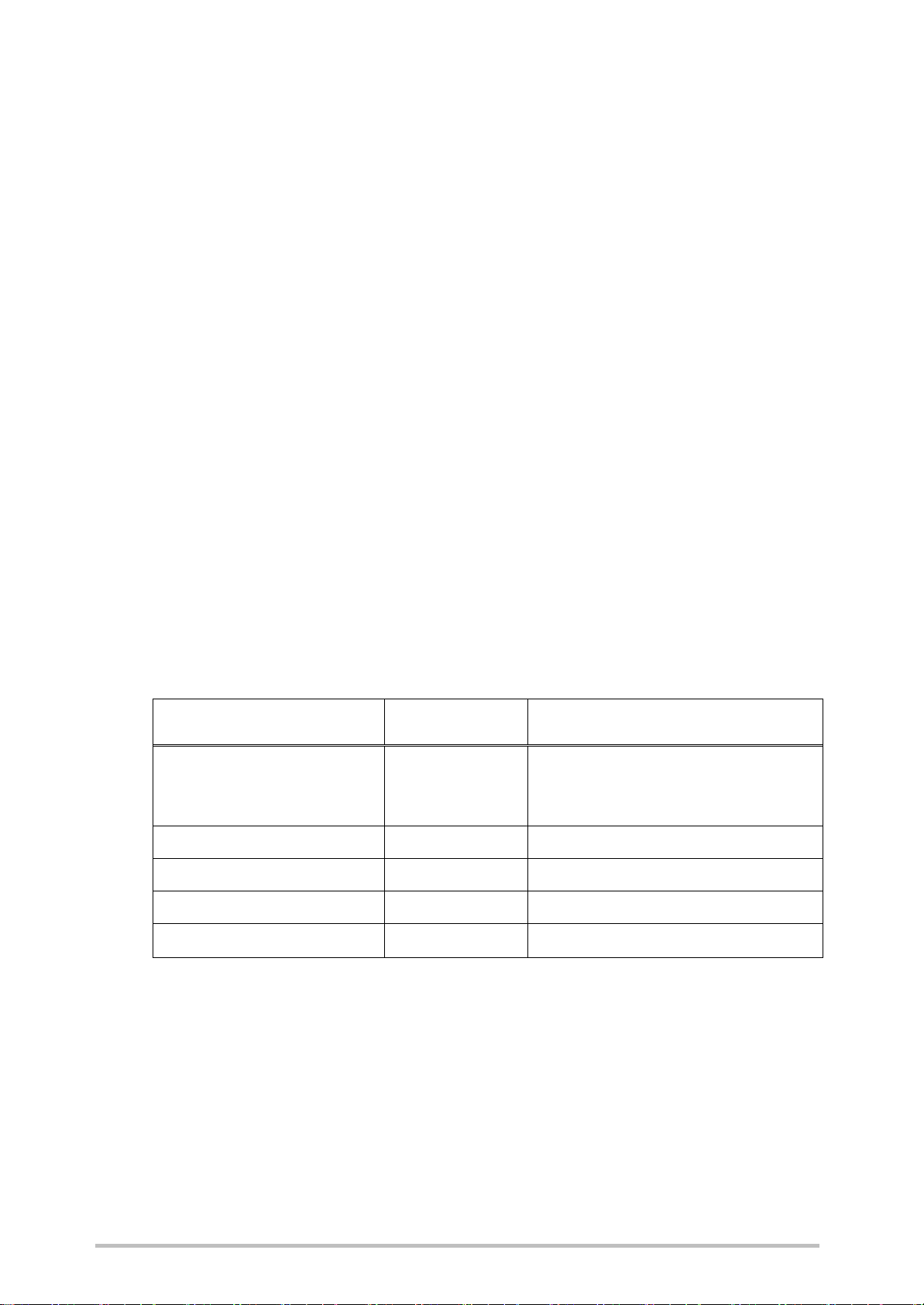

1.6.9. Training of staff

Only trained and briefed staff are permitted to work with and on the device. The staff's different

responsibilities are specified in the following table:

Task

Briefed

technical staff

Specialist

Operation

➔Parameterization

➔Extraction

x

Fault finding

x

Fault repair

Authorized service technician

Maintenance

x

Repair

Authorized service technician

1.6.10. Maintenance, servicing and fault repair

Do not perform work on the device until the device has been disconnected from the mains power

supply. Before putting it back into operation, check that all covers, screw connections and safety

systems have been fittedas per regulations and check that they work correctly. Perform all setting,

servicing and inspection work correctly within the required periods.

Particle suction extraction system / Item no.: 6006100 13 / 85 Date 06.12.2023 / Version 1

1.6.11. Structural changes to the device

Authorization from the manufacturer is required for any modifications or retrofits.

1.6.12. Cleaning the device

Correct functioning of the device can only be guaranteed for a longer period of time if the device

is kept spotless and is cleaned on a regular basis using customary methods. Clean with mild, non-

scouring, non-scratching products only. Never use aggressive cleaning agents such as solvents.

Properly handle materials and substances used, such as solvents and lubricants, and dispose of

them in an environmentally friendly way.

1.6.13. Noise from the device

1.6.14. Decommissioning and disposing of the device

This device is labeled in accordance with the European Directive on waste electrical

and electronic equipment –WEEE.

You must comply with applicable local regulations on health, safety and the

environment at all times when decommissioning the device or disposing of parts of

the device.

•You must dispose of the device as electronic waste once its service life has come to an end.

Ask your local waste management company or CleanControlling where your particular

collection point is.

•Sort different materials such as plastic, metal and electronic components and dispose of

them separately.

•Dispose of used liquids safely and correctly, so that they do not cause damage to health or

the environment.

Particle suction extraction system / Item no.: 6006100 14 / 85 Date 06.12.2023 / Version 1

•Dispose of all components safely and correctly as per applicable local regulations on health,

safety and the environment.

1.6.15. Change of owner

Ensure that all components, including spare parts and accessories, are also given to the new

owner if you sell the device. These components include all operating instructions, manuals,

maintenance instructions, other instructions, modifications and additions that you have received

as an owner.

1.6.16. Guidelines for a safe work area

Ensure that work areas and surrounding areas are clean and very tidy and do not contain any

potential hazards. The work area must comply with local and national safety regulations.

There must be enough room around the device to work with the system safely and comfortably

and perform adjustment and maintenance work.

Ensure that cables and hoses are not deformed and cannot be damaged.

Ensure that the ambient conditions are within the indicated ranges.

Ensure that no cables or hoses pose a tripping hazard.

1.7. Defective device

A defective device poses a serious risk of injury for operators and other persons. If the device is

not free from defects when in operation and cannot be repaired immediately, the person in charge

must switch off the device and put it out of service. The device can be defective if:

•The device shows signs of damage

•Electrical components and wires are damaged

•The device does not perform its required function correctly, even after it has been adjusted

•The device has been stored or not operated for a long time under unfavorable conditions,

such as high humidity or excessively high or low temperatures.

Particle suction extraction system / Item no.: 6006100 15 / 85 Date 06.12.2023 / Version 1

1.8. Further use of components after suction extraction

If the components sampled by the particle suction extraction system are reused, the operator is

responsible for carrying out subsequent tests to ensure their integrity.

Particle suction extraction system / Item no.: 6006100 16 / 85 Date 06.12.2023 / Version 1

2. Description of the extraction principle

The mobile particle suction extraction system is used to extract dry, adherent particles from large

surfaces and from specific control areas on workpiece carriers and in process environments. The

particles are released from the surface by suction using nozzles and brush and then sucked in by

means of a mobile extractor. The mobile trolley provides easy, safe set-up and transportation of

the particle suction extraction system and its associated equipment. The extraction by means of

the mobile extractor can be carried out with the help of the integrated control system in accordance

with VDA 19.1.

Particle suction extraction system –front view

Particle suction extraction is possible with or without the cyclone unit. The most suitable

process depends on different factors, primarily the specific application and the degree of

contamination.

Particle suction extraction system / Item no.: 6006100 17 / 85 Date 06.12.2023 / Version 1

Selecting the appropriate method according to the degree of contamination

2.1. Particle suction extraction with cyclone and filter unit (variant I)

Variant I-A: The extracted particles (2) are separated in a clean laboratory bottle (3) via the

cyclone unit (1). The filter unit (4) provides overload protection using a special analysis filter (> 5

µm) to protect against an excessively high particle load. The particles collected in the particle

collection jar are transferred to analysis filters for the subsequent microscopic analysis using

secondary extraction (with an aqueous medium) and then analyzed under a microscope.

Variant I-A operating principle: Particle suction extraction with cyclone unit and laboratory bottle

1

2

3

4

Particle suction extraction system / Item no.: 6006100 18 / 85 Date 06.12.2023 / Version 1

Suction extraction via the cyclone unit is particularly suitable for large component surfaces with

greater particle loads. This dry particle extraction system is very economical compared to wet

extraction due to the absence of liquid extraction media, the reduced logistics workload and the

easily delimited control areas.

Variant I-B: Via the cyclone unit, the extracted particles can also be deposited directly onto a

particle trap instead of the laboratory bottle. The filter unit provides overload protection using a

special analysis filter (> 5 µm) to protect against an excessively high particle load. For subsequent

microscopic analysis, the particles collected in the particle trap are analyzed under a microscope.

2.2. Particle suction extraction without cyclone unit, directly onto the filter unit

(variant II)

The particles are extracted directly via the filter unit and separated from the air stream using a

special analysis filter (> 5µm). Theanalysis filter can be analyzed usinga microscope directly after

suction extraction and any downstream flushing. The flushing unit can be used to prepare

particulates on the filter for microscopic analysis (see chapter 6.4)

Variant II operating principle: Particle suction extraction without cyclone unit

Direct suction extraction via the filter unit is suitable for small surfaces with a light particle load,

such as on workpiece carriers or printed circuit boards in the process environment. Particles are

quickly collected, meaning interruptions to processes are kept to a minimum.

The specially developed flushing unit allows homogeneous filter loading to be optimized. Manual

flushing (see chapter 6.4) is performed with an aqueous medium after suction extraction. The

analysis filter can be taken for microscopic analysis immediately after drying.

The flushing can also be used as a filter cascade (e.g. 5 µm/60 µm) if a higher particle volume is

extracted.

Particle suction extraction system / Item no.: 6006100 19 / 85 Date 06.12.2023 / Version 1

3. Structure

3.1. Mobile trolley

ESD-capable fixed

castors

Control unit

Drawer inserts with

extraction equipment

Operating panel

Extraction system

ESD-capable worktop

Main switch

Power button

Particle suction extraction system / Item no.: 6006100 20 / 85 Date 06.12.2023 / Version 1

3.2. Mobile extractor REAR

Suction hose

Suction unit flap

Adjustable panel

holder

Laboratory spray

bottle

Power connection

cable

Harting connector

Table of contents

Other CleanControlling Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Astell

Astell AMB220 instruction manual

Thermo Scientific

Thermo Scientific TSQ 8000 Evo Preinstallation manual

VERDER

VERDER Carbolite Gero CR/180 Installation, operation and maintenance instructions

Sutter Instrument

Sutter Instrument LAMBDA 10-B Operation manual

Fluke

Fluke 7008 user guide

caron

caron 2050 Operation manual