IC10/20FRLCD Page 8

Do not remove or change placement of BI once

the reading process has begun. If this occurs,

results may be invalidated.

Use a non-sterilized biological indicator as a

positive control every time a processed indica-

tor is incubated. For more information refer to

the Positive Control section of this user guide.

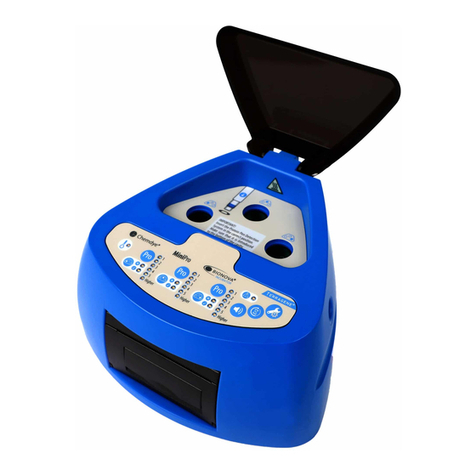

6-Place the rapid BI in a reading position and wait for

the result. Reading will start automatically. Immedia-

tely after placing the BI in a position, the auto-reader

IC10/20FRLCD will emit an audible alarm to indicate

that the readout started and will show the informa-

tion screen of the initiated position. Status position

light will turn violet and will blink until the result is

informed.

NOTE: If the auto-reader does not run automatically,

it might indicate that the auto-reader temperature is

not steady yet (check the temperature indicating li-

ght to remain steady) or that the incubation position

is disabled due to an error in the initial autotest.

When a BI is removed from it's position du-

ring incubation process, an audible alarm will

sound to indicate the tube should be returned

to the corresponding position.

If the indicator isn’t re-introduced into the rea-

ding position after 10 seconds of being with-

drawn, the reading will be cancelled and the

cancelation will be informed through the prin-

ting of a ticket.

7-When a positive result is detected, the red light and

the audible alarm will turn on, this will indicate that

the sterilization process to which the BI was subject,

has failed. 30 seconds after removing the IB from the

incubation position, the alarm and the red light will

turn o automatically and the position will be availa-

ble to start a new reading.

The negative BIs will be informed with a green light

in the corresponding position, this will indicate that

the sterilization process to which it was subject has

been successful. The green light will remain on for

up to 30 seconds after the BI is withdrawn from the

reading position. The auto-reader will inform results

within 20 min. (60 °C), 30 min. (60 ºC), 1 h. (60 ºC), 2 hs.

(60 °C), 3 hs. (60 ºC) or 4 hs. (37 ºC) , according to the

program selected.

These periods of incubation are the time-limits used by

the equipment to inform the uorescence nal readout.

8-Every time a positive result is detected, it will be

informed through the printing of the corresponding

ticket and with an audible alarm. The alarm can be

cancelled by pressing the button .

9-To register the tickets, press the button for paper

traction, take the paper and pull to cut it with the se-

rrated edge of the printer.

Instructions for use

Positive control

Interpretation of results

The positive control should belong to the same

batch of the processed BI.

Use a non-sterilized biological indicator as a

positive control every time a processed indica-

tor is incubated.

Incubate the processed biological indicator

and the indicator used as positive control as

long as specied in the instructions.

Press the cap to seal the tube and crush the ampoule,

make sure the media completely wets the carrier. Wri-

te a C(for control) and the date on the label. The posi-

tive control can be placed in any well of the Bionova®

IC10/20FRLCD Auto-reader.

It is a good practice to use a positive control, this

helps ensuring:

- Correct temperature is reached

-Viability of spores has not been altered due to im-

proper storage temperature, humidity, or proximity

to chemicals.

-Capability of the media to promote rapid growth

and the generation of uorescence.

-Proper functioning of Bionova® IC10/20FRLCD Au-

to-reader.

Rapid Readout

The indicator used as positive control should show

a positive result (red light ). The processed BI

results are not valid until the biological indicator used

as positive control shows a positive result .

A processed BI with a positive result indicates a failure

in the sterilization process. A negative result (green

light ) after 20 min. (60 °C), 30 min. (60 ºC), 1 h.

(60 ºC), 2 hs. (60 °C), 3 hs. (60ºC) 4 hs. (37 ºC) according

to the used program, indicates that the sterilization

process was eective.

The presence of positive results indicates a steriliza-

tion process failure may have occurred and implies

that the load must be reprocessed immediately. Fa-

cing these results, verify good practices for load pre-

paration and usage of biological indicators. Check the

volume of the load to be sterilized as well as the BI’s

Make sure that the reading position you want to

use is congured with the incubation program

corresponding to the biological indicator you

want to analyze.

NOTE: If the paper runs out, the light of paper repla-

cement will start blinking (see Replacement of the pa-

per roll in the printer).