Clearfield FieldSmart FxMP User manual

FieldSmart®FxMP Panel & Standard Frame

Installation Manual ______________________________________________________

Manual 019807 REV A - June 2018

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

2

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Table of Contents

Application 3

Description 3

Technical Specications 3

Tools and Optional Materials 4

Standard Frame Floor Installation 5

Standard Frame Raised Floor Installation 7

Standard Frame Interbays and End Guards Installation 11

Standard Frame Grounding 11

FxMP Panel Mounting 12

Cable Mounting and Routing 16

Routing Ribbon Fiber 19

Cassette Removal/Installation 20

Splicing/Buffer Tube Storage 24

FxMP Tie Panels 30

FxMP Designation Card 32

Connector Cleaning Procedure 33

Standard Warranty 36

Proprietary Notice 37

Technical Support 37

3

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Application

Description

Technical Specications

FieldSmart FxMP Panel

Port Density 24 72 96 144 288

Dimensions 1.75” H (44.45mm) 3.5” H (88.90mm) 4” H (101.60mm) 6” H (152.40mm) 11” H (279.40mm)

Ratings Compliant to Telcordia GR-63, GR-449, GR-20 and GR-409

Cassette Types Supported Clearview®Blue

Connector Types SC/UPC, SC/APC, LC/UPC, LC/APC, FC/UPC, FC/APC, ST/UPC, MPO

Cable Types Indoor Riser, Indoor Plenum, Indoor/Outdoor, Outdoor (Riser/Non-Rated), Outdoor Armored (Riser/Non-Rated), FieldShield®

Splice Capacity 12 splices in each Clearview Cassette

Storage Capacity One meter of 250 μm ber

Front Protection 3.25” (82.6 mm) or 4.77” (121.16 mm) radius ngers

Color Almond or black

Material Steel and aluminum with almond powder coating

FieldSmart Standard Frame

Dimensions Available in 7’, 8’ or 9’ heights and in either 19” or 23” widths; depth is 10” (5” frame + 5” guard box)

Ratings Compliant to Telcordia GR-449

Cable Entry Clamp Location On-frame (Note: Cable clamps included with panels)

Material Steel

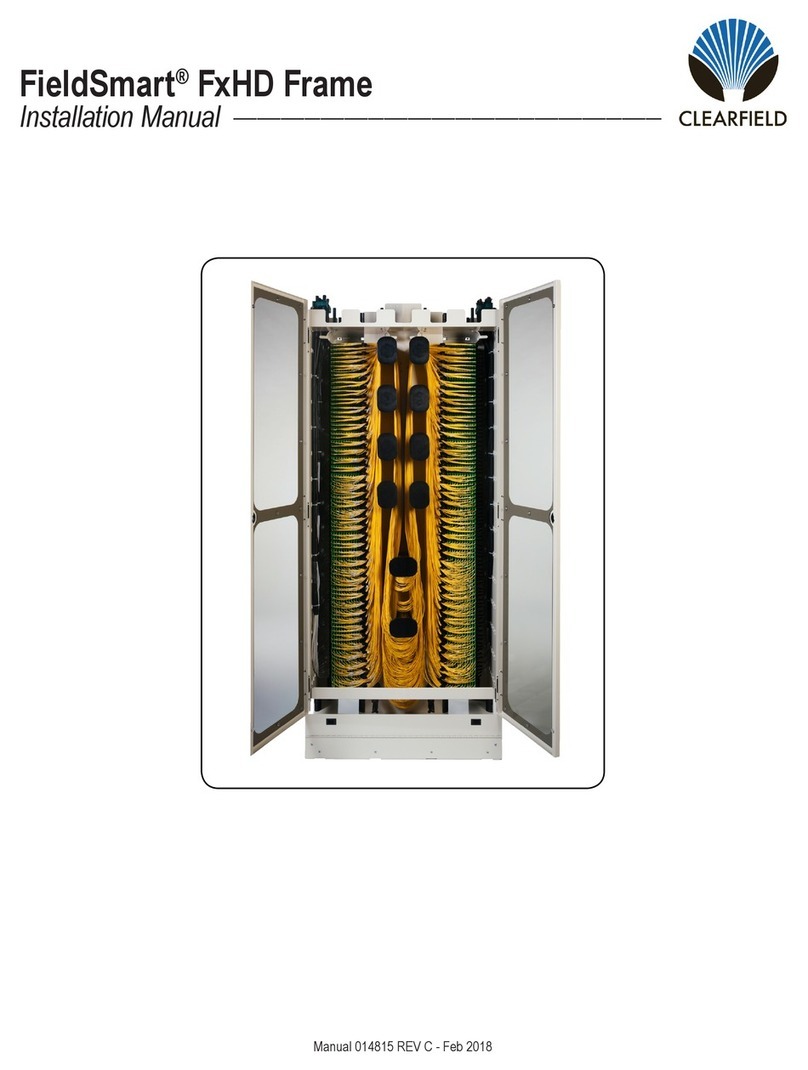

Standard Frame:

FieldSmart FxDS Standard Frames are available in 7’, 8’ or 9’ heights and in 19” or 23” widths. Frames are

seismic-rated and come with an unequal ange. When used with FieldSmart FxMP Panels, they provide the

highest port density in the industry - up to 1,728 ports in a 7’ frame.

FxMP Panel:

The FieldSmart FxMP Panel is a high density, low maintenance ber distribution panel for use in a data

style rack/cabinet, a 19” (482.60mm) or a 23” (584.20mm) frame. Utilizing the Clearview ®Cassette,

FieldSmart FxMP Panels are intelligently designed to provide the user with superior ber access and

craft-friendly, radius protected ber management for routing and deploying ber jumpers.

Standard Frame:

Frames are used for mounting equipment in a central ofce, head end or data

center applications.

FxMP Panel:

Provides an interconnect or cross-connect environment for up to 288 ports of high density ber

for inside plant and outside plant environments.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

4

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Tools and Optional Materials

Tools:

• Sockets (1/2”, 3/4” and 15/16”)

• Ratchet with Extension

• Phillips Screwdriver

• 1/8” Allen Wrench

• Hammer/Rotary Drill

• 5/8” Masonry Drill Bit

• Blowout Air Bulb or Vacuum with Small Diameter Tube

Materials (ordered separately):

Standard Frame:

• Isolation Pad (19” Frame P/N FMA-L1Z-SUB,

23” Frame P/N FMA-L2Z-SUB)

Floor Mounting:

• Floor Mounting Kit (P/N 009106)

Raised Floor Mounting:

• Raised Floor Mounting Kit (P/N 011236)

Patch and Splice Panels:

• Radius Limiter Brackets for Buffer Tube Slack Storage

(P/N 010600)

Ribbon Fiber Protection:

• High Density Ribbon Breakout Kit (P/N 010475)

• Ribbon Fanout Kit (P/N FMA-MZZ)

Radius Limiter Bracket

Breakout Kit Fanout Kit

Isolation Pad

5

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Standard Frame Floor Installation

Note: Floor mounting hardware is NOT included with the standard frame. Hardware is sold as a separate line item

(Cleareld P/N 009106).

IMPORTANT: If your frame is to be mounted next to a wall, or there are multiple frames in a line-up, you MUST

install the interbay management and end guards BEFORE mounting the frame to the oor.

Tools:

• Hammer (or rotary) drill (with depth gauge recommended)

• 5/8” masonry drill bit

• Socket wrench set

• Blowout air bulb or vacuum with small diameter tube

Using a 5/8” masonry bit, drill the four required holes to a

minimum depth of 2” (approx. 50mm).

Note: If for some reason you have trouble drilling the 5/8” hole,

Cleareld recommends rst drilling a ¼” pilot hole before drilling

out to 5/8”.

Thoroughly clean the dust from each hole, using a vacuum or

blowout air bulb.

Note: To not degrade the anchor’s installed performance, any unused anchor holes (or other nearby holes) in the

concrete within 3” must be lled with an epoxy ller (pour stone) or equivalent. Filled holes must be fully cured before

anchors are installed and torqued.

19” Frame

9 5/8”

22”

23” Frame

9 5/8”

26”

Determine where the frame is going to be installed. Using the isolation pad as a template, mark the 4 holes where

frame will be secured to the oor.

1.

2.

3.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

6

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Place the isolation pad in position over the predrilled holes and align as necessary. Lift the frame onto the isolation

pad and line up with holes.

Ensure that the anchor’s expansion shield is not expanded. Place the end of the anchor into the predrilled hole.

Repeat for the other drilled holes. Make sure the anchor is fully embedded in the concrete.

Align the edges of the 2” square washer parallel with the slots in the frame base to obtain the maximum material

overlap. Once aligned, tap each anchor/washer assembly until it is seated rmly in the hole and against the 2” square

washer.

Pre-tighten each anchor with a socket wrench or box-end wrench; do not use an open-end wrench (which could easily

slip off and cause injury). Before nal tightening, ensure that the frame is properly aligned (in the row and with any

adjacent frames). Torque each anchor to 60 ft-lbs.

Note: When using the break-off type anchor, a torque wrench is not required. The anchor’s (red) torque cap shears

off at a predetermined torque value (approximately 60 ft-lbs.), leaving a green seal on the bolt head, indicating proper

tightening.

The anchoring line up should look like this:

Note: Square

washers will be

packaged in base

of frames

Threaded Rod

4.

5.

6.

7.

8.

7

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Standard Frame Raised Floor Installation

Note: Raised oor mounting hardware is NOT included with the standard frame. Hardware is sold as a separate line item

(Cleareld P/N 011236).

IMPORTANT: If your frame is to be mounted next to a wall, or there are multiple frames in a line up, you MUST

install the interbay management and end guards BEFORE mounting the frame to the oor.

Tools:

• Hammer (or rotary) drill (depth gauge recommended)

• 5/8” masonry drill bit

• Socket wrench set

• Blowout air bulb or vacuum with small diameter tube

Also required is a raised oor mounting kit (Cleareld P/N 011236).

1. 1/2-13 Hex Nut (Qty 8)

2. 1/2 Lock Washer (Qty 4)

3. 1/2 Flat Washer (Qty 4)

4. 1/2-13 x 30 Threaded Rod (Qty 4)

5. Hilti HDI 1/2” Anchor (Qty 4)

6. 1/4 x 2” Flatwasher .515 Hole (Qty 8)

7. Split Tubing 30” (Qty 4)

Screw Sequence for Floor Screw Sequence for Frame

Note: Cleareld recommends installing the anchors directly into the concrete oor.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

8

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Using the isolation pad as a template, mark on the panel(s) of the raised oor the 4 holes where the frame will be se-

cured to the oor. Using a 5/8” drill bit, drill a hole through each of the oblong marks you made with the isolation pad.

Take the threaded rods from the raised oor mounting kit and slide one through each of the holes. Using a hammer

and holding them perpendicular to the oor, tap on the end rmly. The goal is to make a “mark” on the concrete oor

visible enough to see where the 4 holes should be drilled.

Once the concrete oor is marked, remove the threaded rods and oor panels. Using a 5/8” masonry bit, drill the four

required holes to a minimum depth of 2” (approx. 50mm).

Note: If for some reason you have trouble drilling the 5/8” hole, we

recommend rst drilling a 1/4” pilot hole before drilling out to 5/8”.

Thoroughly clean the dust from each hole, using a vacuum or

blowout air bulb.

Note: To not degrade the anchor’s installed performance, any unused

anchor holes (or other nearby holes) in the concrete within 3” must be

lled with an epoxy ller (pour stone) or equivalent. Filled holes must be fully cured before anchors are installed and

torqued.

19” Frame

9 5/8”

22”

23” Frame

9 5/8”

26”

1.

2.

3.

4.

9

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Install anchors into the oor. Replace raised oor panels and

insert threaded rods through the four holes.

Note: You are not installing the rods at this point. You are

measuring the rods to be cut to the appropriate length.

Measure the rods 2.5” above the oor and mark with a

permanent marker. Remove the rods and cut each rod at the

mark. Remove the oor panels.

Before installing rods back into the oor, place a nut and then

a washer on the threaded rods. Take the rod and install it into

the anchor installed in the oor.

Tighten the nut down to secure the rod into the oor. Tighten

each bolt to 65 ft-lbs., +10, -0 ft-lbs. The anchor will expand

and secure itself to the oor.

Once all four rods are secure, thread another hex nut, then

washer on each rod. Make sure the nut and washer are

approximately ½” below the raised oor level. This hardware

will be tightened down AFTER the frame is set into place but

BEFORE securely bolting the frame to the oor.

5.

6.

7.

8.

9.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

10

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Place the oor panels into position, and tighten the previously installed nuts below the raised panel until they make

contact with the panel. Put the isolation pad into place (isolation pad may look different than example).

Lift the frame into place.

Place the square washers onto each rod. Align the edges of the 2” square washer parallel with the slots in the frame

base to obtain the maximum material overlap. Install the isolation washers (packaged with the isolation pad) onto each

rod.

Install the remaining hardware (washers, nuts, etc) from the raised oor installation kit.

Note: Square

washers will be

packaged in base

of frames

Threaded Rod

10.

11.

12.

13.

11

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Standard Frame Interbays and

End Guards Installation

Attach the interbay to the front ange of

the frame with the hardware provided.

Next, install the end guard to the

interbay with the included hardware.

Note: The 9 foot interbay is shipped in

two pieces per side.

Note: End guards are only needed on

frames at the end of the frame line-up.

Repeat for the other side of the frame.

End Guard Interbay

1.

2.

3.

After

End Guard

Before

Interbay

Frame

Standard Frame Grounding

Cleareld provides a ground bar with the Standard Frame

which can be installed on the frame. Ground per your local

practices.

FrameInterbay

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

12

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

FxMP Panel Mounting

The FieldSmart FxMP Panel will arrive with reversible mounting brackets unattached. Depending on the size of the frame,

you will attach the mounting brackets in a 19 inch or 23 inch conguration.

The exception to this will be the 1RU panel, which has mounting brackets that are not reversible. These mounting brackets

will attach to a 19 inch frame. Extender brackets will be supplied with the panel, which can be attached to the mounting

brackets in order to mount the panel to a 23 inch frame.

Installing Mounting Brackets for 19 Inch Frame

If installing reversible mounting brackets for a 19 inch frame

conguration, the large side of the bracket will be mounted to the

panel. The smaller side will be used to mount the panel to the

frame.

Note: Mounting brackets for the left and right sides of the panel

are identical, interchangeable parts.

1.

Align the reversible mounting bracket so that the holes in the bracket and the panel body match up. Using the

provided screws (three per bracket) secure the bracket into place. Repeat for the other side.

Note: There are four bracket-to-panel screw holes on each side of the bracket and panel. One of the holes will be a

smaller size, used for a bonding screw with the NEBS panel.

2.

13

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Installing Mounting Brackets for 23 Inch Frame

If installing reversible mounting brackets for a 23 inch frame

conguration, the small side of the bracket will be mounted to

the panel. The large side will be used to mount the panel to the

frame.

Note: Mounting brackets for the left and right sides of the panel

are identical, interchangeable parts.

1.

Align the reversible mounting bracket so that the holes in the bracket and the panel body match up. Using the

provided screws, three per bracket, secure the bracket into place. Repeat for the other side.

Note: There are four bracket-to-panel screw holes on each side of the bracket and panel. One of the holes will be a

smaller size, used for a bonding screw with the NEBS panel.

2.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

14

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Installing Mounting/Extender Brackets for 1RU Panel

Align the mounting bracket so that the holes in the bracket and panel body match up. Using the provided screws, two

per bracket, secure the bracket in place. Repeat for the other side.

Note: There are three bracket-to-panel screw holes on each bracket and side of the panel. One of the holes will be a

smaller size, used for a bonding screw with the NEBS panel.

1.

If mounting the 1RU panel in a 23 inch frame, extender brackets will need to be installed. These attach on each side

of the panel to the mounting brackets via the two 12-24 x ½” screws provided.

2.

15

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Mounting Panel Into Frame

While supporting the panels in the desired rack location, insert and tighten the four mounting screws (two 12-24 x ½” thread

cutting screws per side) to secure the panel to the frame. In order to help align the panel, it is also recommended that

vertical and horizontal holes are used on each side for mounting.

19 Inch Mounting 23 Inch Mounting

1RU Panel - 19 Inch Mounting 1RU Panel - 23 Inch Mounting

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

16

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Cable Mounting and Routing

Choose a green cable clamp that is close to the same size but

slightly bigger than the cable you plan to mount.

The difference in size can be made up by either wrapping the

cable with some of the provided grommet tape, or laying a small

strip of grommet tape in the bottom side of the cable clamp shell.

Each panel comes with two types of cable mounting brackets. One is used for applications where you have access to

pre-drilled and tapped holes in the back of the frame, and one is for instances where these holes are not available.

Note: The standard frame Cleareld offers already has rear mounting holes.

Frames with rear

mounting holes

Frames without rear

mounting holes

Patch Only panels have tails which may need to be routed through the frame and up to the appropriate ladder

racks or down into the raised oor before securing the cable to the frame.

1.

2.

3. Place one cable clamp on each side of the cable, and using the

two mounting screws provided, secure the cable to the cable

mounting bracket.

Note: The angle of cable mounting can be adjusted by pivoting

the bracket on one of the mounting holes and securing it down

with the other. A greater range of angles can be achieved by

ipping the bracket to the other side.

17

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Mount the cable to the bracket as previously shown. The angle of the

cable can be adjusted by using the different sets of threaded holes in

the bracket.

If no rear mounting holes are available, the other bracket can be used.

You will need to hold the bracket up to the frame and drill a pilot hole

into the frame as shown. Then, you can mount the bracket using the

self-tapping screw included with the panel.

4.

5.

Cleareld offers optional radius limiter assemblies (P/N 010600),

used in pairs for storing buffer tube slack on the frame, outside of

panels, shown here. This part number is ordered and shipped

separately from the frame or panels.

Note: Panels shown in images may not match product received.

Cable mounting will be performed in the same manner regardless.

6.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

18

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Once you’ve mounted the panel and the cable is attached to the frame, open up your cable. Cleareld recommends a

cable opening of 11 feet (up to 8ft of slack (depending upon panel size) and 3ft for splicing in the cassette). Proceed to

mounting the cable to the panel.

Use the included mounting screws to fasten the cable clamps and

cable to the rear cable bracket. The cable should be mounted so

that the breakout is slightly beyond the end of the clamp.

Note: Panels shown in images may not match product received.

Cable mounting will be performed in the same manner regardless.

Clamp the cable to the panel using the same method you used

to mount it to the frame, choosing the closest size pair of cable

clamps, and using grommet tape to make up the size difference.

If mounting the cable to the back of

a 1RU panel, a vinyl coated P-clip

(supplied as a ship-along) will need

to be used to secure the cable. Use

grommet tape around the cable as

needed to increase the size of the

cable for proper grip.

7.

8.

9.

10.

19

FieldSmart®FxMP Panel & Standard Frame

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 019807 REV A - June 2018

Routing Ribbon Fiber

The High Density Ribbon Breakout Kit and Ribbon Fanout Kit are both used to protect bare ribbon on a frame before the

bers enter the protection of a panel body or cassette. The High Density Ribbon Breakout Kit allows the user to breakout a

high ber count cable (864 bers max) into manageable 144 ber groups that can be further broken down with the use of

the Ribbon Fanout Kit. Each Ribbon Fanout Kit breaks out ribbon stacks (max 12 ribbons) of 250 um bers (max 12 bers

per ribbon) into color-coded breakout tubes. The breakout tubes with individual ribbons can then be routed to your cassettes

and secured into the tray like a buffer tube.

The High Density Ribbon Breakout Kit can also accommodate a breakout of a 1728 SpiderWeb Ribbon cable. This will be

used in conjunction with the round Ribbon Fanout Kit (P/N FMA-MZZ-ROUND) which can hold 24 bers (2 subunits of 12

bers) each.

Note: The installation manuals for both products are shipped with the kits. Examples shown below.

High Density Ribbon

Breakout Kit

Ribbon

Fanout Kit

Kits During

Installation

Completed

Installation

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

20

FieldSmart®FxMP Panel & Standard Frame

Installation Manual _________________________________________________________

Manual 019807 REV A - June 2018

Cassette Removal/Installation

In order to access the front of the panel where the cassettes

are located, rst remove the front protection door. Release

the push/pull plungers by pulling until you feel it disengage

with a click.

1.

Repeat for the other side and swing the door down.

If you wish to remove the door, this can be done by gently exing the door to create the space needed to pull the

hinges out of their sockets.

2.

3.

Table of contents

Other Clearfield Control Panel manuals

Popular Control Panel manuals by other brands

AERMEC

AERMEC MULTI CONTROL Booklet

CityGrow

CityGrow CG100HHB-SKY user manual

Carrier

Carrier Aritech Reliance XR Series Installation and programming guide

St. Croix

St. Croix DHC3000 instructions

Bosch

Bosch D7412G Installation & Troubleshooting Quick Reference Guide

HST

HST Addressable fire alarm MN-300 operating instructions