Clearfield FieldSmart Makwa FDH User manual

FieldSmart®Makwa FDH

Installation Manual ______________________________________________________

Manual 017526 REV E - April 2018

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

2

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

Table of Contents

Application 3

Description 3

Technical Specications 3

Product Packaging 4

Designation Cards 6

Below Grade Installation 7

Optional Step Rack and Manual Mounting Brackets 8

Vault Installation Procedure 9

Vault Access and Storage 11

Makwa Swing Arm 14

Above Grade Installation 20

Dome Removal 22

Designation Card Installation 23

Dome Installation 24

Schrader Valve 26

Patch and Splice 27

Clearview Black Cassette 32

Storing Buffer Tube After Splicing 35

PON Splitters 37

Cross-Connect Patch Cords 41

Connector Cleaning Procedure 43

Standard Warranty 46

Proprietary Notice 47

Technical Support 47

3

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

The FieldSmart Makwa, incorporates all of the features found in our above

ground cabinets and adds the ability to deploy the FieldSmart FSC Distribution

Hub in a below grade application. Roughly 50% smaller than existing above

grade cabinets, Makwa reduces real estate costs and improves density without

compromising critical design elements of accessibility, bend radius protection,

physical ber protection and route path diversity.

Cleareld’s FieldSmart Makwa consists of four basic elements; top over

(dome), base plate, internal backplane and Clearview Black Cassettes. All

components are pre-assembled and loaded into the Makwa – making it eld

ready for deployment. Scalable to meet customer requirements, Makwa can

be congured to accept 12-48 feeder ports and 12-288 distribution ports in a

PON application. It will accept up to nine (9) 1 x 32 ruggedized splitters and two

(2) staging plates for PON networks. For cross connect scenarios, Makwa can

accommodate 12-432 ports as required.

Providing 12-432 ports of connectivity for either PON or Cross-Connect, utilizing

patch and splice or patch only technology in any network environment. The

FieldSmart FSC Makwa is scalable to meet customer’s specic requirements

and has the ability to be mounted either above or below-ground, taking the

potential above grade aesthetics issue out of the deployment equation

Description

Application

Technical Specications

288 PON Makwa 432 Cross-Connect Makwa

Dimensions 22 3/8” H x 16” W x 16” D 22 3/8” H x 16” W x 16” D

Splicing Yes - Clearview Black Cassette Yes - Clearview Black Cassette

Feeder/Express Ports Up to 48 Up to 216

Distribution Ports Up to 288 Up to 216

Cable Entrances 4 4

Splitter Slots 9 N/A

Jumper Length N/A 1.2 meters

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

4

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

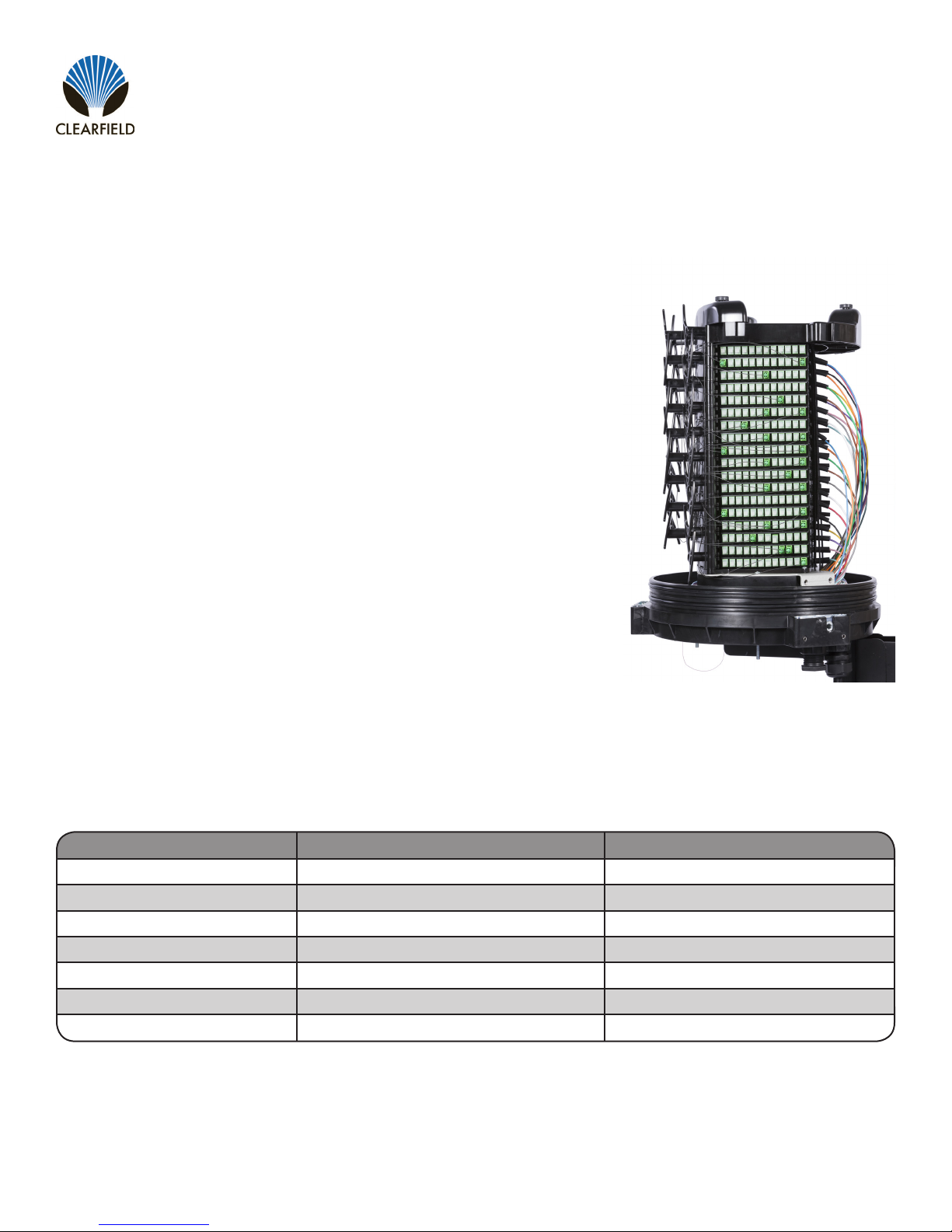

Product Packaging

Patch and Splice Packaging

Patch Only Packaging

Quantity Part Number Description

1 017271 Makwa Key, T-Handle 5/16 Hex Wrench - 9” Length

4 017466 1” Sealcon Fitting with Various Grommet Inserts

4 017468 1” Plug Fitting

1003042 30” Roll of 1” Wide Grommet Tape

1 016096 10 Feet of Snakeskin Sleeving (Patch and Splice)

Included Accessories List: (Some parts may already be installed for patch only congurations)

5

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

Packaging Removal

Open the enclosure following the dome removal procedure.

Remove the foam inserts holding the cassettes in place (Figure 1).

Note: The foam inserts can be saved and used as supports if desired.

Step 1:

Step 2:

Step 3:

Figure 1

Cut the zip ties holding the cassettes during shipping (Figure 2).

Figure 2

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

6

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

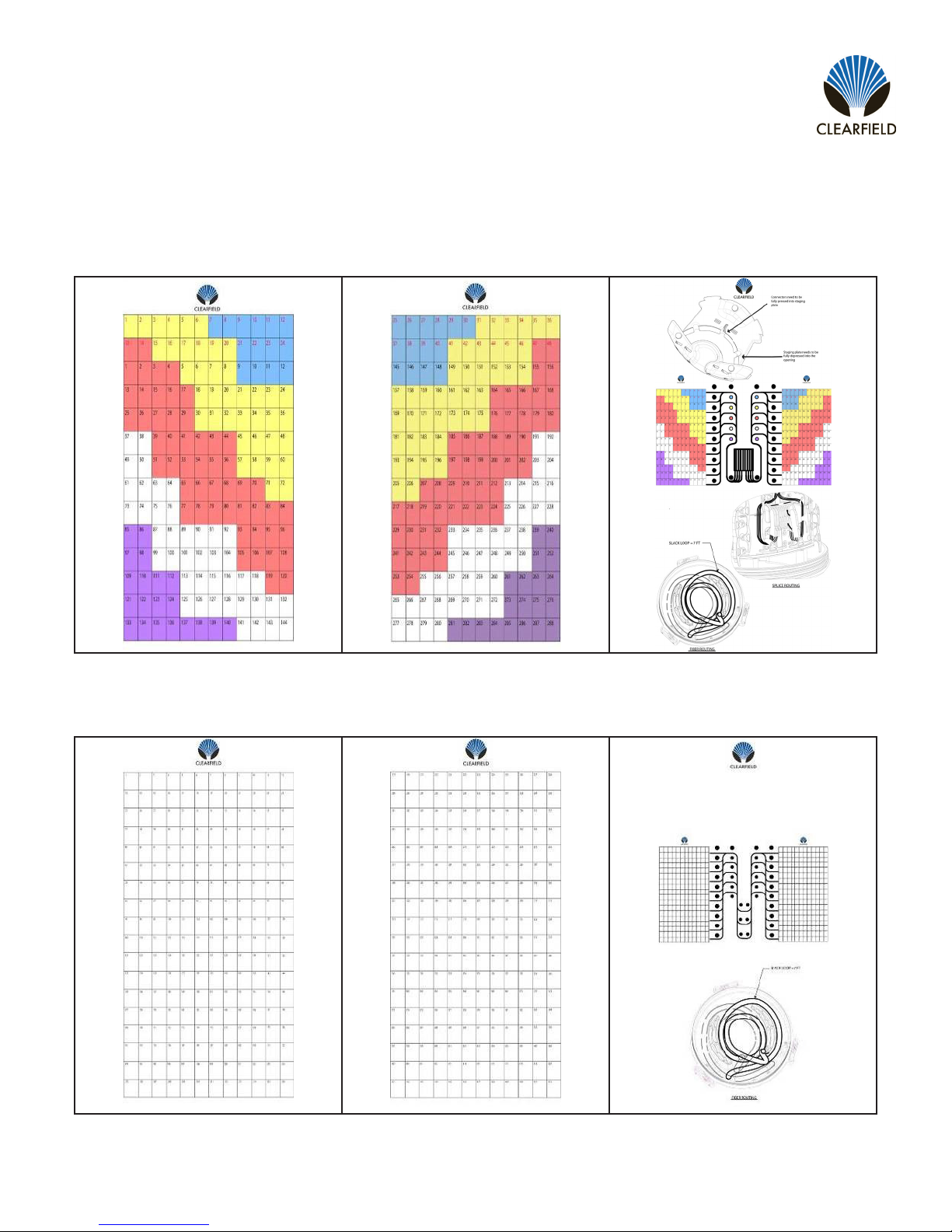

Designation Cards

The Makwa FDH is set up for either a PON or Cross-Connect application. Please refer to the appropriate designation and

application cards that will be utilized for ber protection when the dome lid is placed.

PON Designation Cards

Cross-Connect Designation Cards

Desi Card - Left Desi Card - Right Application Card - Center

Desi Card - Left Desi Card - Right Application Card - Center

7

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

Below Grade Installation

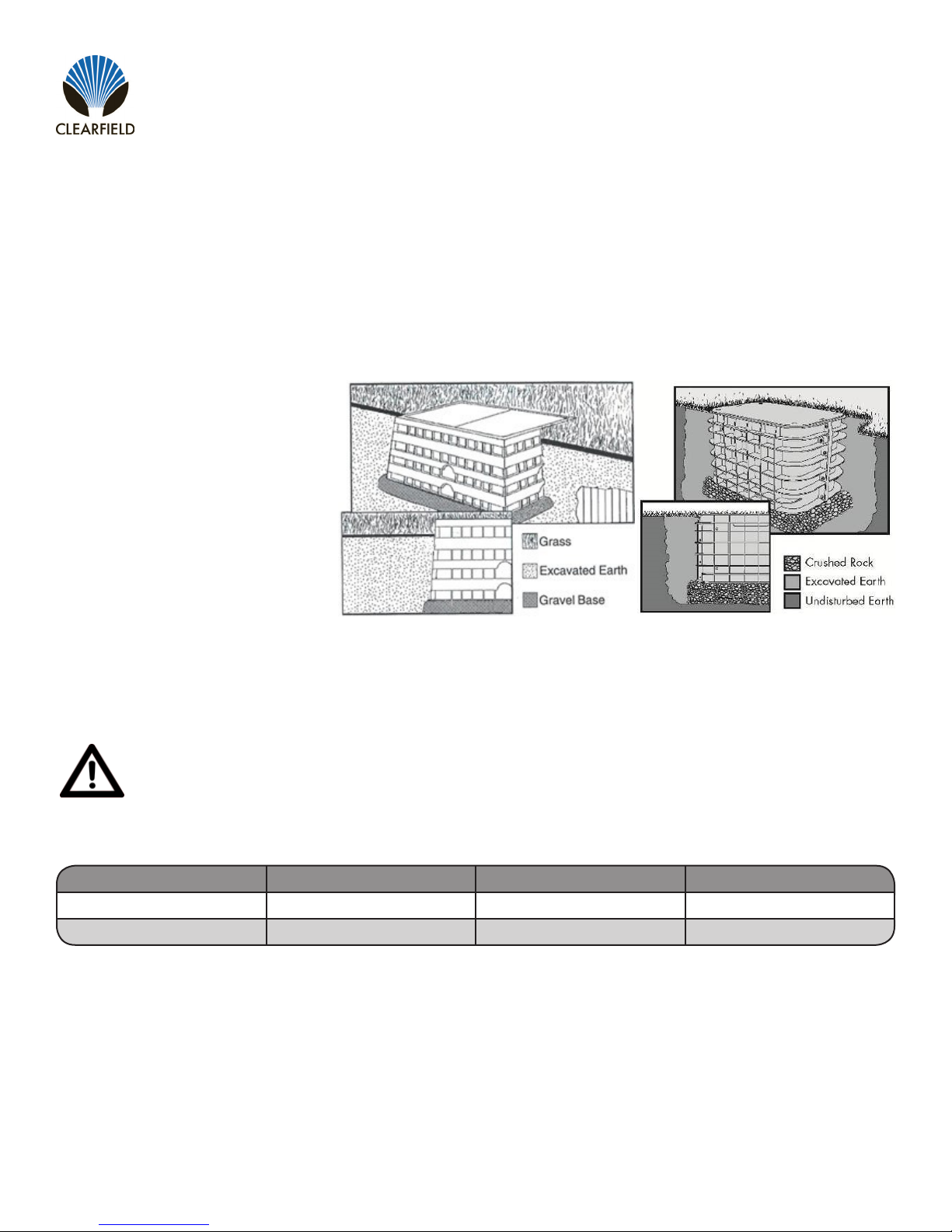

Parkway Vault Installation

Installation instructions provide general information useful for parkway placement in “grass surround”, grass, dirt, or

gravel applications. This guide cannot anticipate all situations that could develop in the eld. Rather, it represents

information applicable to common installation conditions.

Installation Location

Location alone should not dictate

product selection. “Pedestrian loading,”

sometimes referred to as “Greenbelt”,

denes our HDPE thermoplastic body

and covers vaults are intended for in-

stallation in landscape or grass surround

areas where they will not be exposed to

vehicular trafc. Exceptions to this rule

include residential or light commercial

mowers but do now include tractor/

mowers in highway easements.

Site Preparation

Ensure that national – local electrical and building codes, OSHA and company safety work rules are observed and

provisions made for street ags, barricades and cones. Secure permits as required by city and company.

Warning: Buried Telecommunications Cables. Be sure to call 811 at least 30 days in advance before digging.

Calling 811 will route to the local one-call center and ensure that utilities in the area of installation will be located

and marked.

Recommended Vault Sizes

Vault Size HDPE Solid Lid HDPE Split Lid Polymer Concrete

30” W x 48” L x 36” D V7B-AZP V7B-BZP V7B-EZP

36” W x 60” L x 36” D N/A V8B-BZP-F* V8B-EZP-F*

*Vaults must be straight walled to use brackets and step rack on swing arm. These vaults are ared walled so Makwa will

sit on bottom of vault (for vault with swing arm see page 17).

Note: Vault size is generally dened by the approximate cover dimensions. The vault actual measurements will differ. The

dimensions above for determining the size of excavation provide sufcient volume for accommodating the maximum recom-

mended select backll.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

8

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

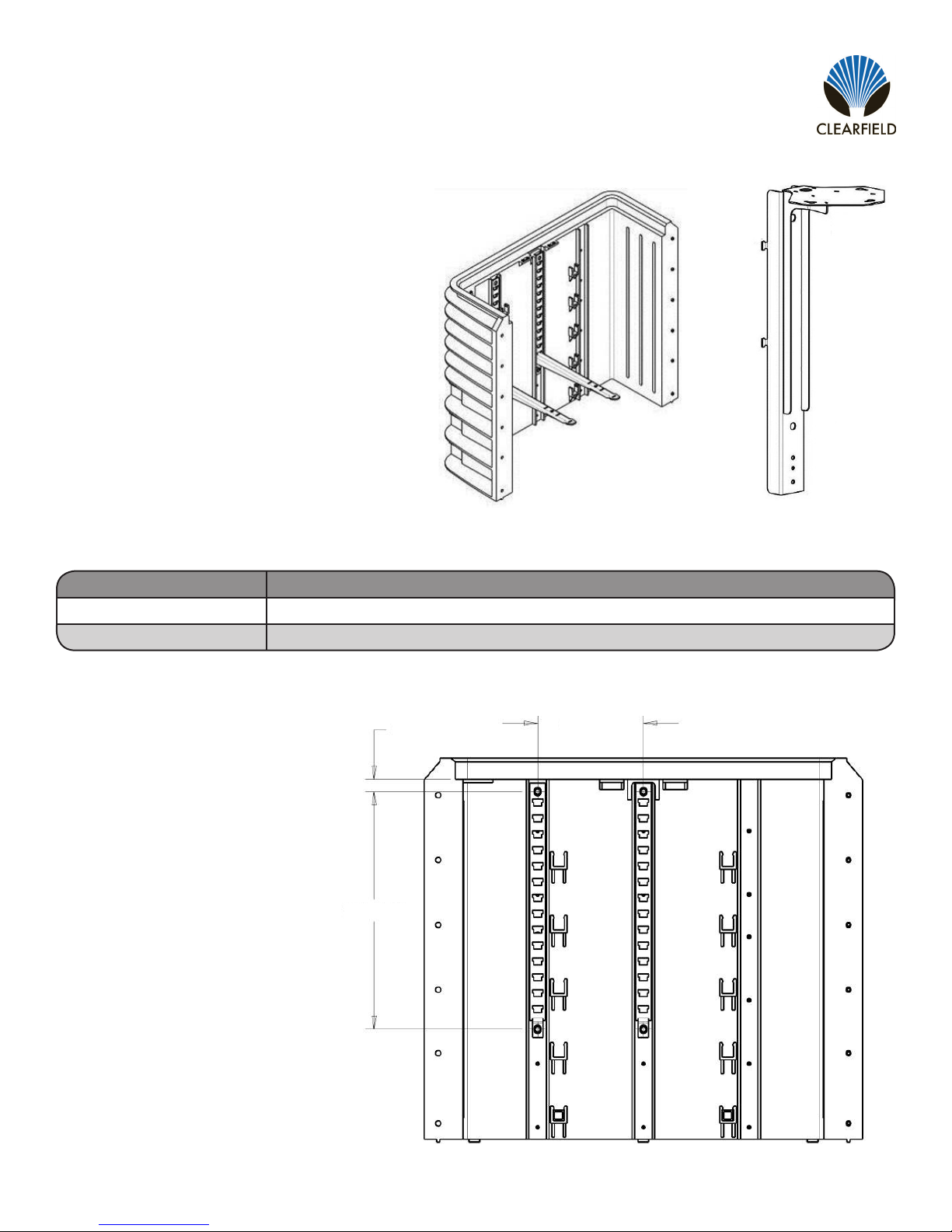

Optional Step Rack and Manual Mounting Brackets

Part Number Description

017202 Kit, In Vault Mounting Kit for Makwa, includes two 24” step racks and two 18” cable hooks *

016897 Bracket, In Vault Mounting Stand for Makwa *

If the Makwa Swing Arm (see page 20) is not used,

the optional Step Rack Mounting Bracket & Manual

Mounting Bracket may be deployed to install Makwa

inside of vault.

When using the optional step rack mounting bracket,

the step racks need to be installed onto the vault

before burying the vault in the ground.

Note: The step rack mounting bracket kit comes with

the required mounting hardware.

Makwa Mounting Kit (P/N 017202) Makwa Manual Mounting

Bracket (P/N 016897)

* Both items need to be ordered together

Step Rack Mounting Location

Note: The step rack arms should

be installed in one of the two bottom

steps to ensure the enclosure ts

with the vault lid installed.

1.17”

22.4”

10.0”

9

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

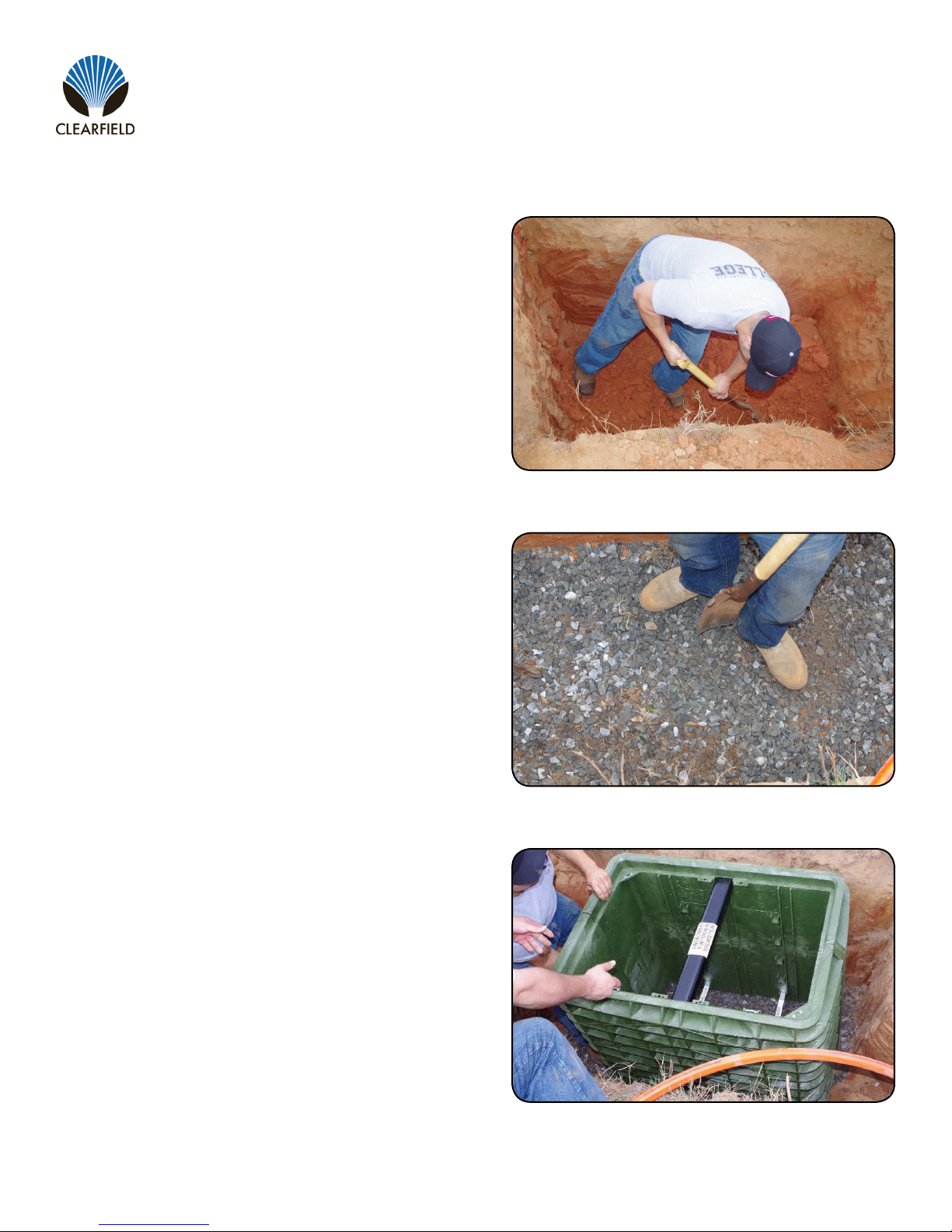

Vault Installation Procedure

Excavate hole to appropriate dimension with

mechanical excavator or hand dig as appropriate

(Figure 1).

Note: Plan excavation approximately twelve to

sixteen inches longer and wider than the actual

dimensions of the vault being installed. Similarly,

excavate six to eight inches deeper than the overall

dimensions of the vault with cover in place.

Step 1:

Figure 1

Figure 3

Figure 2

Use a minimum three to ve inches of crushed rock

to prevent subsidence over time (Figure 2).

Note: Base material shall be crushed rock 3/4”

and smaller, and not “river rock” or “round stone.”

Desired compaction and equivalent resistance to

lateral loading will not be achieved with round stone.

The rock should be free of soil and organic material.

Step 2:

Set vault on top of backll material and adjust height

to grade (Figure 3). Tamp base material to level with

a mechanical tamper or hand tamper. When a vault

must be installed on a hill, a retaining wall provision

shall be made. The cover of the enclosure shall be

at or to nal grade as specied by the Owner/

Operator. Soil in the immediate vicinity shall be

tamped and sloped away from the enclosure.

Step 3:

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

10

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

Center the vault in the excavation parallel with side-

walk or curb. Mark the vault for duct entry and step

rack locations. The vault may be cut with a hole saw

and drill (Figure 4). The duct may also come up

from underneath the vault, where-as no holes need

to be drilled

Note: Make sure to provide adequate clearance

for ovality in ducts. The small clearance between

the duct and vault may be sealed with expanding

polyurethane foam

Step 4:

Figure 6

Figure 5

Figure 4

Replace the cover on the vault before backlling

(Figure 5).

Note: Bolting the cover in place is recommended,

but not required during backll.

Begin the backlling operation by adding soil,

crushed rock or dry lean mix in eight inch (8”) lifts

or layers. A mechanical tamper may be used. The

tamped crushed rock supports the vault, preventing

subsidence and providing for drainage.

Note: Backll material can vary based on product

and installation location. It is customary and

acceptable in landscape installations where vehicles

are prevented from trafc on or around a vault to use

the soils removed during excavation for backll

(Figure 6). Make sure to remove stones three

inches and larger, prior to backll.

Take care not to damage vault during backll. Cover

may not t properly if vault is damaged.

Step 5:

Step 6:

11

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

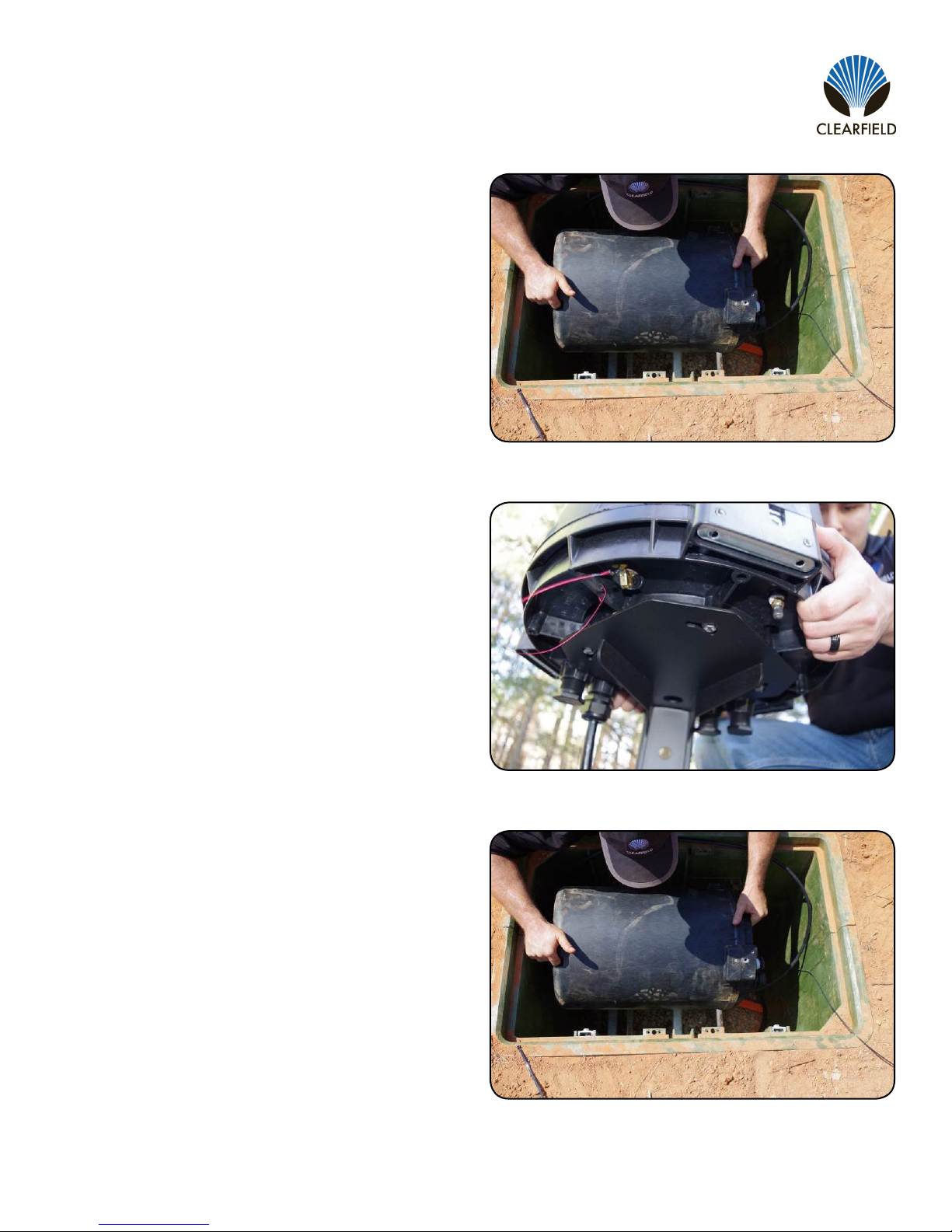

Vault Access and Storage

The following instructions apply only to Step Rack and Manual Bracket installation. Does not apply to Swing Arm installation.

Warning: : Make sure you read the warning labels before removing the enclosure. If there is water in the vault,

the water must be completely drained or pumped out of the vault prior to removing/reinstalling the Makwa.

Figure 1

Figure 2

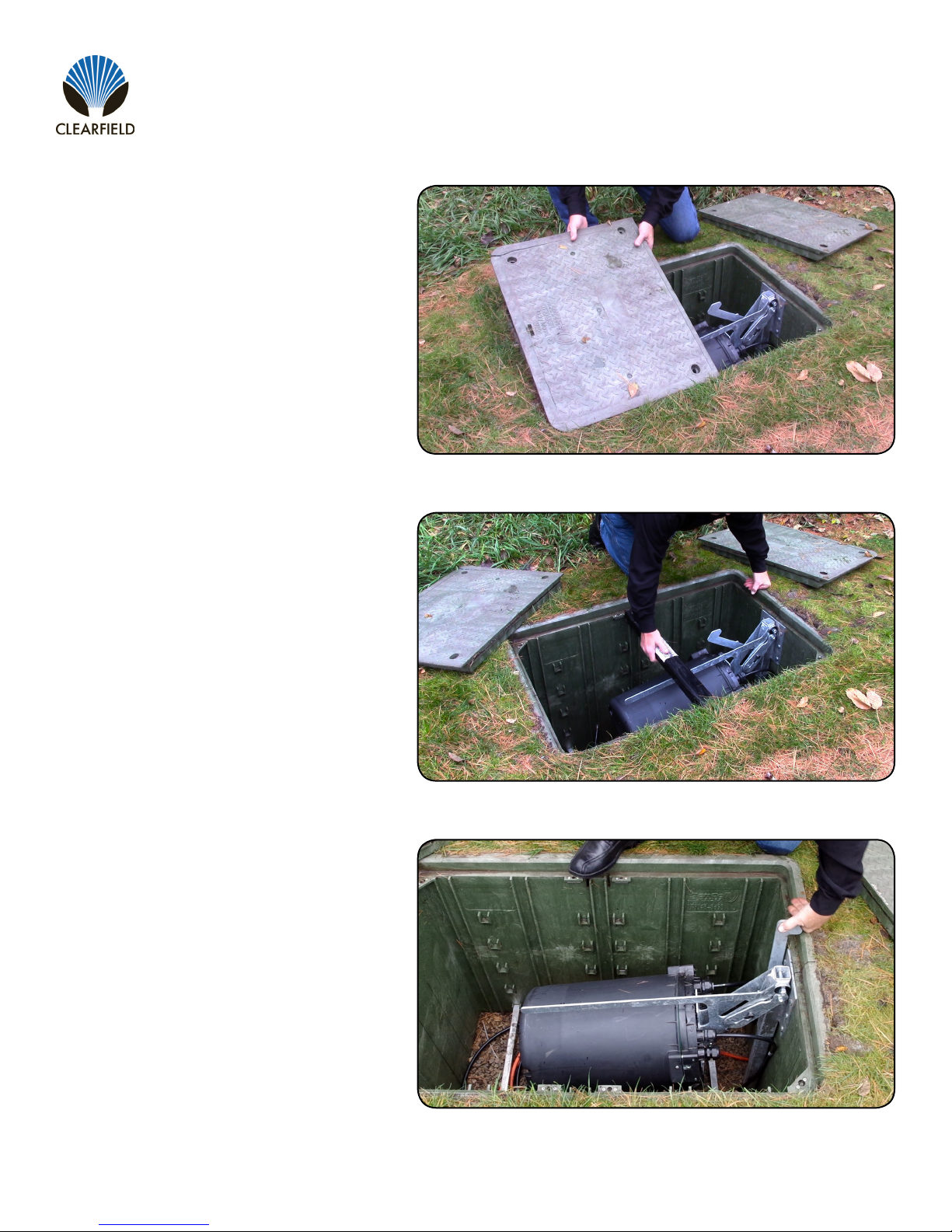

Remove vault lid support beam (Figure 2).Step 2:

Remove vault lid (Figure 1).Step 1:

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

12

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

Lift the Makwa out of the vault (Figure 3).Step 3:

Figure 5

Figure 4

Figure 3

Place Makwa on Mounting Bracket (P/N

016897) to perform maintenance (Figure 4).

When you have completed your maintenance,

follow the steps below to replace the Makwa

back in the vault.

Carefully lower the Makwa into the vault (Figure

5).

Note: Maintain proper cable bend radius when

lowering the enclosure into the vault.

Step 5:

Step 4:

13

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

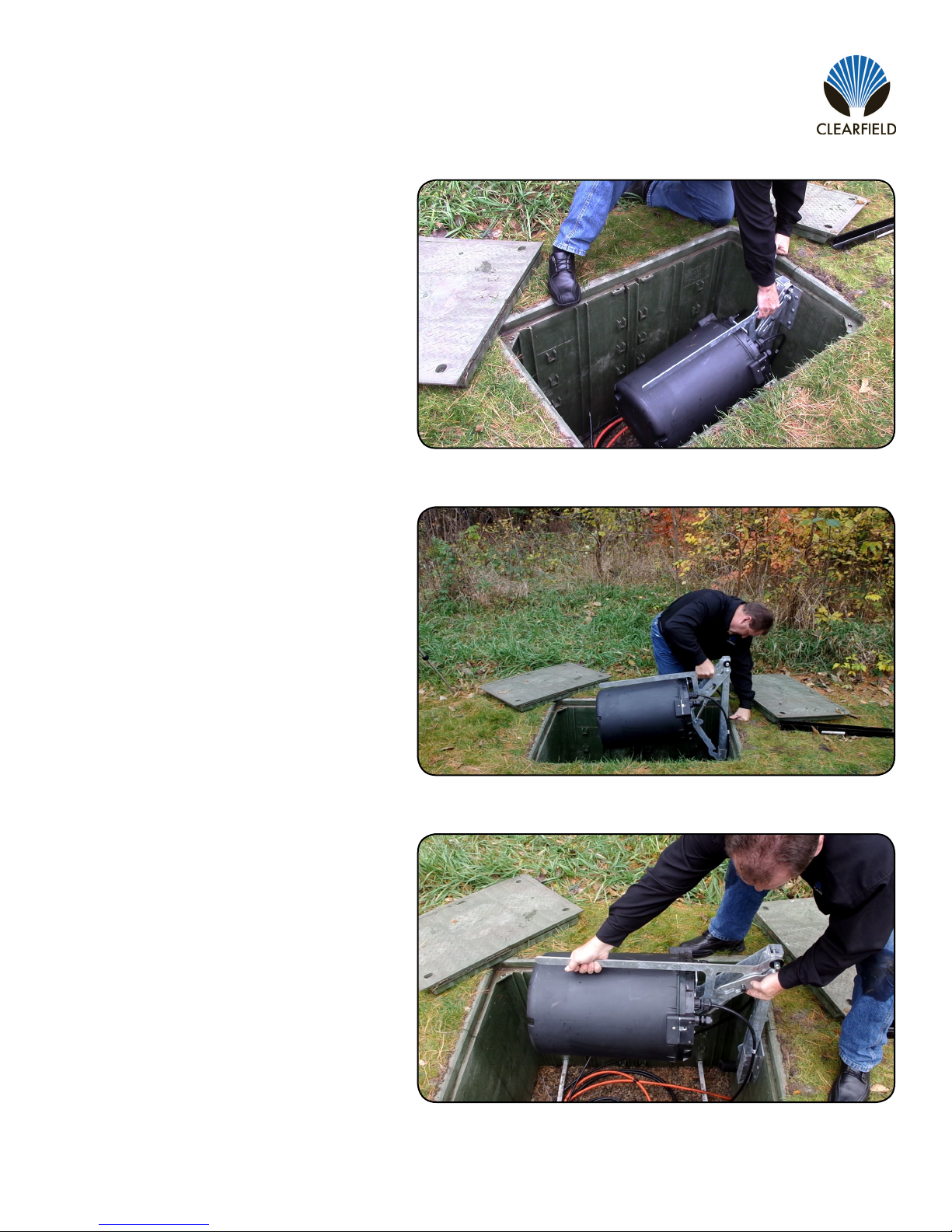

Secure the enclosure to the step rack using

zip ties (Figure 6).

Step 6:

Figure 8

Figure 7

Figure 6

Step 7:

Step 8:

Install vault lid support beam (Figure 7).

Install and secure the vault lid (Figure 8).

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

14

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

Makwa Swing Arm

When below grade mounting is required, the Makwa swing arm provides below grade vault protection, while allowing easy

access for ber maintenance. The swing arm is available preinstalled in approved vault sizes or as a stand alone accessory

that can be mounted into existing straight-sided vault.

Part Number Description

V7B-AZP-SARM Vault, below grade Pencell, 30 x 48 x 36”, solid HDPE lid, hex bolts, green, straight wall,

with swing arm

V7B-BZP-SARM Vault, below grade Pencell, 30 x 48 x 36”, split HDPE lid, hex bolts, green, straight wall,

with swing arm

V7B-EZP-SARM Vault, below grade Pencell, 30 x 48 x 36”, split polymer concrete lid, hex bolts, green,

straight wall, with swing arm

Installing Swing Arm in an Existing Vault

Part Number Description

016897 Bracket, In Vault Mounting Stand for Makwa *

017202 Kit, In Vault Mounting Kit for Makwa, includes two 24” step racks and two 18” cable hooks *

VA-SWING-ARM Swing arm for Makwa

* Both items need to be ordered together

The Makwa Swing Arm can be installed in any straight sided vault large enough

to accommodate the Makwa and swing arm (dims?) by using the hardware

provided in the vault mounting kit as shown below.

15

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

Raising the Makwa Swing Arm

Figure 3

Figure 2

Figure 1

Remove the vault lid (Figure 1).Step 1:

Step 2:

Step 3:

Remove vault lid support beam

(Figure 2).

Disengage kick bar by pressing it

away from central support beam

(Figure 3).

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

16

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

Figure 6

Figure 5

Figure 4

With kick bar depressed, grip the

swing arm near the base, between

the horizontal support beam and the

hinge, lift up on unit (Figure 4).

Step 4:

Step 5:

Step 6:

Continue lifting until unit locks into

place (Figure 5).

Now, gripping the swing arm near

the top, release the locking catch by

pressing upward (Figure 6).

Note: If the swing arm piston

becomes corroded, tap the arm

lightly with a mallet until piston

mechanism frees up.

17

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

Figure 1

Figure 8

Figure 7

With the catch released, lift up on

the swing arm until it locks in the

vertical position (Figures 7 & 8).

Step 7:

Step 1: Grip the swing arm near the top and

push the unit forward.

Lowering the Makwa Swing Arm

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

18

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

Figure 4

Figure 3

Figure 2

Pull back on locking catch to

partially lower the unit (Figure 2).

Step 2:

Step 3:

Step 4:

Locking catch will engage again at

the mid-point of descent. Lift up on

the locking catch to continue

descent to horizontal position.

(Figure 3).

Grip the swing arm near the base,

between the horizontal support

beam and the hinge, and disengage

kick bar by pressing it away from

central support beam (Figure 4).

19

FieldSmart®Makwa FDH

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 017526 REV E - April 2018

Figure 7

Figure 6

Figure 5

Lower unit into vault (Figure 5).Step 5:

Step 6:

Step 7:

Replace central strength member

arm (Figure 6).

Replace and secure vault cover

(Figure 7).

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

20

FieldSmart®Makwa FDH

Installation Manual _________________________________________________________

Manual 017526 REV E - April 2018

Above Grade Installation

Pole Mount Kit

The FieldSmart Makwa FDH is approximately half the size of a conventional Fiber Distribution Hub, allowing the broadband

service provider the choice of where to deploy the cabinet without sacricing performance or access. The Makwa FDH Pole

Mount Kit allows both the 288 port PON and 432 port cross-connect versions to be pole mounted, while providing access to

the FDH for moves, adds, and changes.

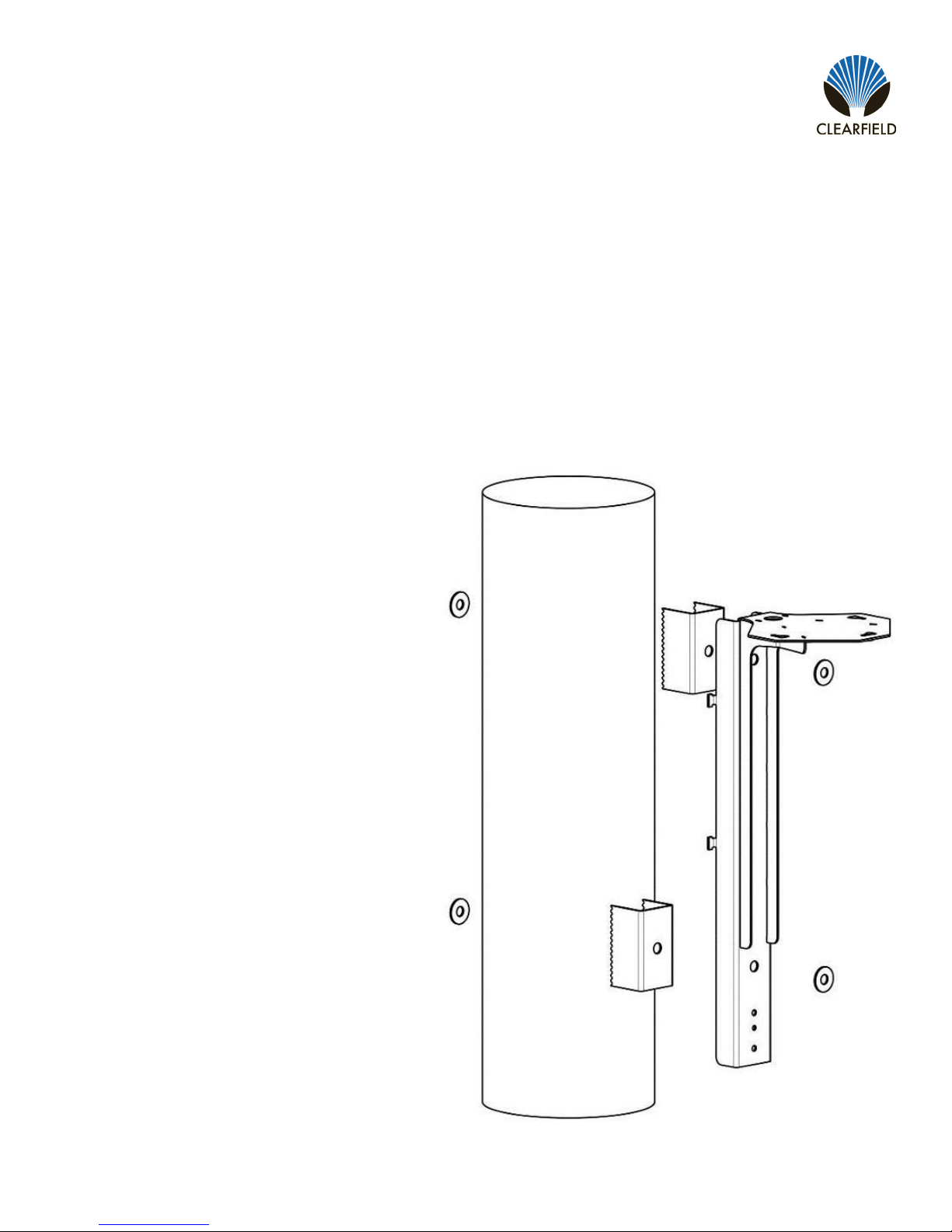

Required Items (Customer Supplied):

• Quantity 4 - Stainless Steel or Galvanized Washers and Nuts

• Quantity 2 - Stainless Steel or Galvanized 5/8” Threaded Rod (Minimum Diameter)

Note: Length determined by diameter of pole - It

is suggested to add 3” to the diameter of pole for

rod length. Cleareld does not recommend using

lag bolts to mount the bracket to the pole.

Assembly Diagram

FieldSmart Makwa Pole Mount Kit (P/N 016902)

This manual suits for next models

2

Table of contents

Other Clearfield Network Accessories manuals