VERIFICATION

Once the H4TU-R is installed, verify that it is operating properly by monitoring the Status

LEDs on the front panel.

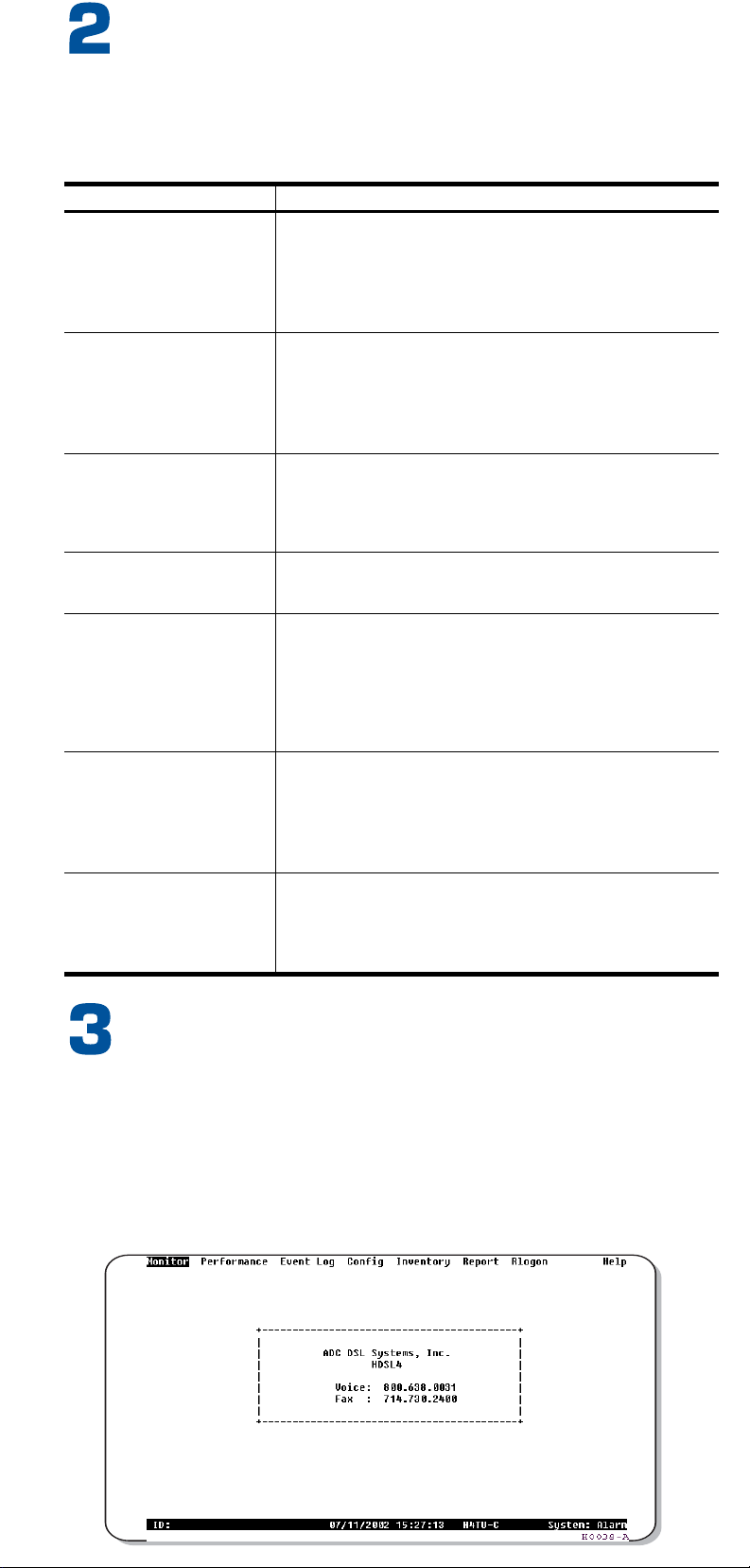

LOGGING ON TO THE MAIN MENU

The H4TU-R supports local and remote logon through a maintenance terminal (ASCII

terminal or a PC running terminal emulation software) connected to the craft port on the

H4TU-R front panel.

Logging on creates menus and screens for the H4TU-R that are replicationsof thoseviewed

at the H4TU-C. Once logged on, you can view system settings and inventory, initiate

loopbacks, monitor performance, and configure the circuit.

To log on using a maintenance terminal:

1Press + to refresh the Logon screen, if necessary.

2Press the first letter of the desired menu. Use the to cycle through menu

selections, and press to change a setting or display a menu.

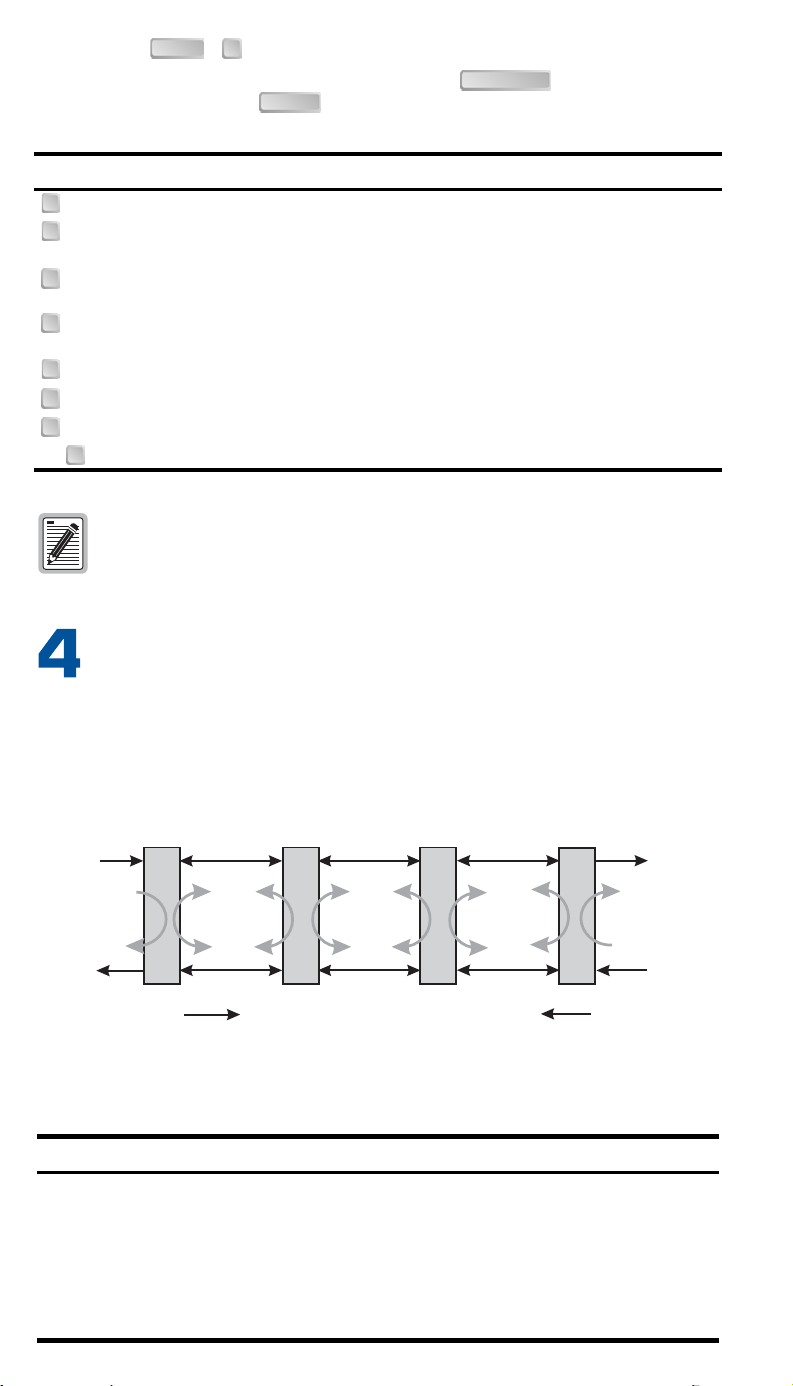

LOOPBACK TESTING

Initiate loopbacks with the H4TU-R loopback pushbuttons, the H4TU-C front-panel

display, the maintenance terminal monitor screen, or with inband codes. The inband codes

shown below can be sent by a test set. For more information on loopbacks, refer to the user

manual for the H4TU-C line unit.

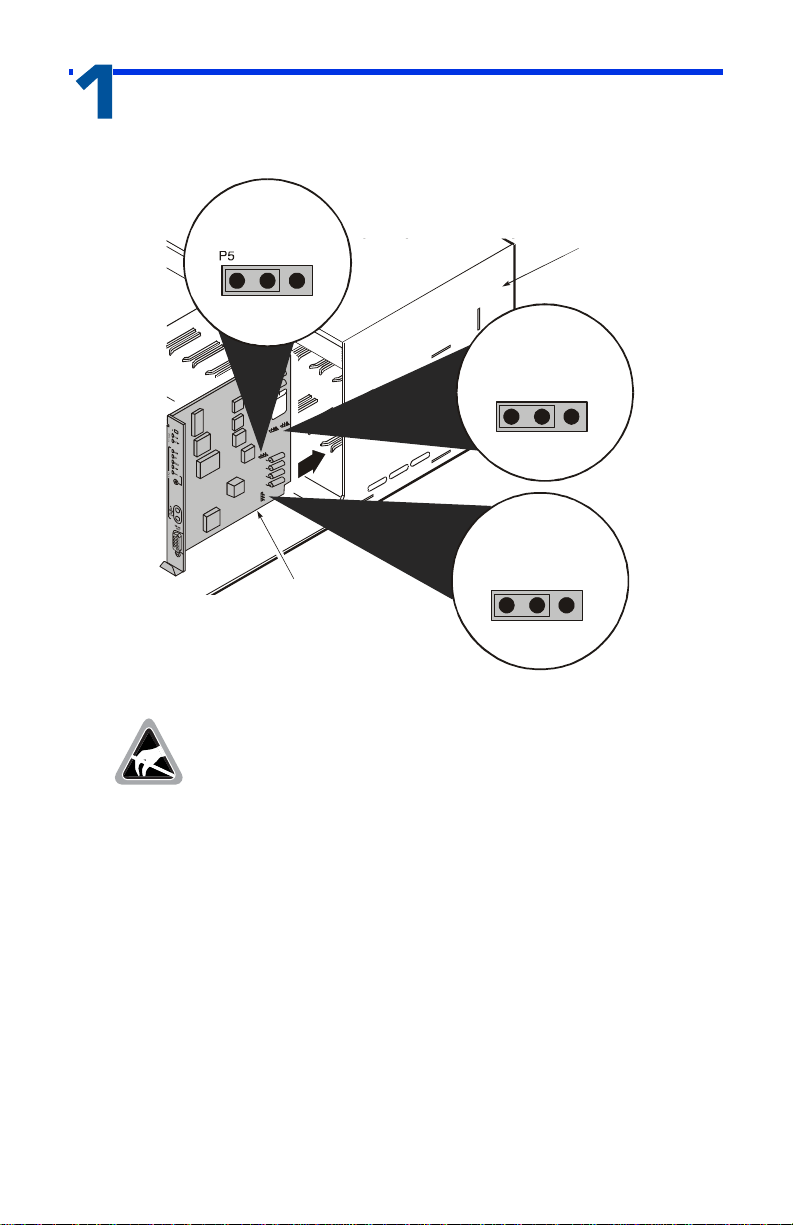

Table 1. LED Status and Functions

LED/Status Function

DSL1

OFF No power is applied to the H4TU-R.

Solid green Loop 1 connected to the H4TU-R has synchronized without error.

Flashing red once every second Loop 1 of the H4TU-R is in acquisition.

Solid red Loop 1 connected to the H4TU-R detects HBER or MARG alarms.

Flash red once every two seconds Download session in progress.

DSL2

OFF No power is applied to the H4TU-R.

Solid green Loop 2 connected to the H4TU-R has synchronized without error.

Flashing red once every second Loop 2 of the H4TU-R is in acquisition.

Solid red Loop 2 connected to the H4TU-R detects HBER or MARG alarms.

Flash red once every two seconds Download session in progress.

ALM

OFF Normal operation: the DS-1 signal is present at both the H4TU-R and

H4TU-C.

Solid yellow LLOS is present at the H4TU-C.

Solid red RLOS is present at the H4TU-R.

DS1

Solid green Normal operation: the DS1 signal at the H4TU-R is error free.

Solid red RLOS, BPV, frame error, or CRC is detected at the H4TU-R.

ESF/SF

OFF Unframed DS1 present at the H4TU-R or no DS1 is detected at the

H4TU-R.

Solid yellow ESF frame formatting is present at the H4TU-R.

Flashing yellow once per second ESF frame formatting and frame error/CRC are present at the H4TU-R.

Solid green SF frame formatting is present at the H4TU-R.

Flashing green once per second SF frame formatting and frame error are present at the H4TU-R.

B8ZS/AMI

OFF No DS-1 signal is present at H4TU-R.

Solid yellow B8ZS line code is provisioned at the H4TU-R.

Flashing yellow once per second B8ZS and excess zeros string are present at the H4TU-R.

Solid green AMI line code is provisioned at the H4TU-R.

Flashing green once per second AMI and BPV are present at the H4TU-R.

RLB/LLB

OFF H4TU-R is not ARMed or in loopback.

Solid yellow H4TU-C is looped back toward the network or customer.

Flashing yellow once per second System is ARMed.

Solid green H4TU-R is looped back toward the network or customer.

Type the first letter To view:

onitor A graphical representation of circuit activity and devices.

erformance Performance history statistics (current, 25-hour, 48-hour, 31-day, and blockage

indicator) at DS1 and HDSL4 interfaces. Also, displays alarm status and count.

vent log Sectionalized Event History for alarms and errors at all four legs of the DS1 signal at

the H4TU-R.

onfig Configuration options (standard, ADC, signal generation, date and time,

master clear, factory defaults).

nventory Product information, circuit and unit identifications.

logon Maintenance terminal screens at the H4TU-C.

elp Glossary, screen navigation keys, ADC contact information.

Rep rt Downloading status and performance monitoring data to file.

For more information about the HiGain HDSL4 maintenance screens,

refer to the user manual of the H4TU-C line unit. Copies of user

manuals can be downloaded from the ADC website at www.adc.com.

To order a hard copy, please contact your sales representative.

Loopback Commands

Loopback Inband Code Description

NLOC 1111000 DSX-1 signal is looped back to the network at the H4TU-C.

NREM 1110000 DSX-1 signal is looped back to the network at the H4TU-R.

SMJK 11000 DSX-1 signal is looped back to the network at the H4TU-R SmartJack module.

CREM 1111110 DS1 signal from customer is looped back to the customer at the H4TU-C.

CLOC 1111100 DS1 signal from customer is looped back to the customer at the H4TU-R.

Loopdown 11100 Deactivates any of the above loopbacks.

CTRL R

SPACEBAR

ENTER

M

P

E

C

I

R

H

O

Network Customer

Premises

NLOC NDU1 NDU2 CLOC

CDU1 CDU2CREM NREM

TLOS*

H4TU-C H4D1 H4D2 H4TU-R

SMJK

DS1

DSX-1

*

When enabled,TLOS is an automatic loopback

that occurs with an LOS at the remote DS1 input.

Span 1 Span 2 Span 3

Downstream Upstream

H0068-A

RS-232

DCE

DS1

R

U

ALM

DSL1

ESF/SF

B8ZS/AMI

RLB/LLB

OUT

2

0

4

T

4

H

.

L

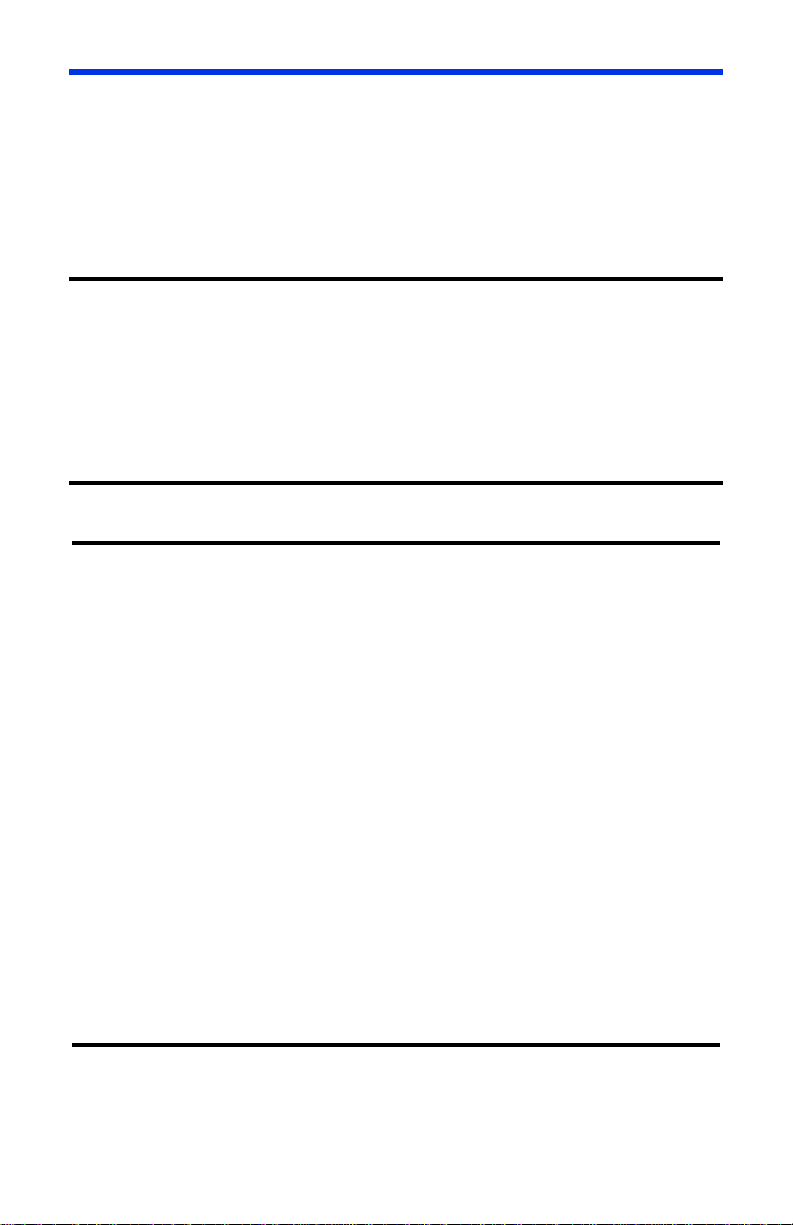

DSL Status LEDs

ALM LED

DS1 LED

Framing LED

Line code LED

Loopback LED

CLEI/ECI bar code label

Craft port provisioning

To access all system maintenance, provisioning,

and performance screens, connect a standard

9-pin terminal cable between the serial port on a

PC and the H4TU-R craft port.

Loopback control pushbuttons

Press pushbutton for 5 seconds to activate a dual loopback at the network (RLB) or at

the customer (LLB).

The unit can be looped down by pressing either pushbutton again for 5

seconds, by the standard loopdown inband messages, or by the maintenance terminal.

no active loopback in the system, will activate a bi-directional loopback at the Remote

Unit (loopback at RT towards NET and CPE using LLB) or (loopback at the CO towards

NET and CPE using RLB).

Press both pushbuttons together for more than 2 seconds on one- and two-span syste

(all LEDS on the front panel will reflect the corresponding LED states at the CO) or on a

3-span system (the DSL1 and 2 LEDs will reflect the DSL status of the span between th

1 and 2 repeater). All other LEDs at RT will reflect the LED status at the CO unit. All

LEDs at the RT will resume to the RT LED states when both LLB and RLB buttons are

released. This “Display CO” LED feature is invoked on either H4TU-C-L5A or H4TU-C-L

units.

st nd

Any existing loopback is terminated before these loopbacks are

activated.

Extraction handle

Use to remove the

H4TU-R-402 from

its slot.

DS1 input (OUT) and output (IN) bridging (BRG) jacks

Provides non-intrusive test access.

9600 baud

8 data bits

No parity

1 stop bit

Hardware flow control: OFF

Terminal emulation: VT100

Maintenance Terminal Modem Settings

List number

Indicates the list number of the H4TU-R-402.

BRG

IN

LBK

LLB

RLB

D

S

1

YEL/GRN

H0034-A

DSL2

27

25

23

21

19

17

15

13

11

9

7

3

5

1

DS1 Tip

Card-Edge Connector

DS1 Ring

HDSL4 Ring1

HDSL4 Tip 1

Factory Use Only Factory Use Only

Protection Switch Power

DS1 Ring1

Circuit Ground

( - )

( + )

HDSL4 Ring

IN

OUT

HDSL4 Tip

DS1 Tip1

Chassis Ground*

28

26

24

22

20

18

16

14

12

10

8

4

6

2

55

53

51

49

47

45

43

41

39

37

35

32 31

56

54

52

50

48

46

44

42

40

38

36

34

30

33

29

Note: Active pins are highlighted in black.

*Chassis Ground may be tied to earth ground per local practice.

rotection Switch Control

Chassis Ground* -48 Vdc Local Power

HDSL4

Loop1

HDSL4

Loop2

Front Panel