CLEARPATH HUSKY A200 User manual

Clearpath Robotics Inc. ©2011 All Rights Reserved.

2

Contents............................................................................................................................................2

Introduction ......................................................................................................................................4

What’s Included ........................................................................................................................................ 4

What’s Required ....................................................................................................................................... 4

Expansions ................................................................................................................................................ 4

The Basics..........................................................................................................................................5

Status Panel............................................................................................................................................... 6

Orientation References............................................................................................................................. 7

Pinout References..................................................................................................................................... 7

System Specifications................................................................................................................................ 8

Vehicle Equations...................................................................................................................................... 9

Control Modes .......................................................................................................................................... 9

Clearpath Robotics Inc. ©2011 All Rights Reserved.

3

Safety ..............................................................................................................................................10

General Warnings ...................................................................................................................................10

E-Stop and Lockout ................................................................................................................................. 10

Performance Recommendations ............................................................................................................11

Electrical System ..................................................................................................................................... 11

Lifting and Transport............................................................................................................................... 11

Getting Started ................................................................................................................................12

PC Setup ..................................................................................................................................................12

Connecting Computer............................................................................................................................. 12

Connecting Power................................................................................................................................... 12

Verification.............................................................................................................................................. 14

ROS-Based Teleoperation .......................................................................................................................15

Operation ........................................................................................................................................16

Control Protocol......................................................................................................................................16

Python.....................................................................................................................................................16

C++ .......................................................................................................................................................... 17

Battery & Maintenance....................................................................................................................19

Charging ..................................................................................................................................................19

Battery Care ............................................................................................................................................19

Wheels .................................................................................................................................................... 20

Chassis..................................................................................................................................................... 20

Tips and Troubleshooting .................................................................................................................21

Mechanical Tips ...................................................................................................................................... 21

Troubleshooting......................................................................................................................................21

A. PC Setup ......................................................................................................................................22

Python.....................................................................................................................................................22

ROS..........................................................................................................................................................23

C++ .......................................................................................................................................................... 23

B. Product Dimensions .....................................................................................................................24

C. Service and Support .....................................................................................................................25

Clearpath Robotics Inc. ©2011 All Rights Reserved.

4

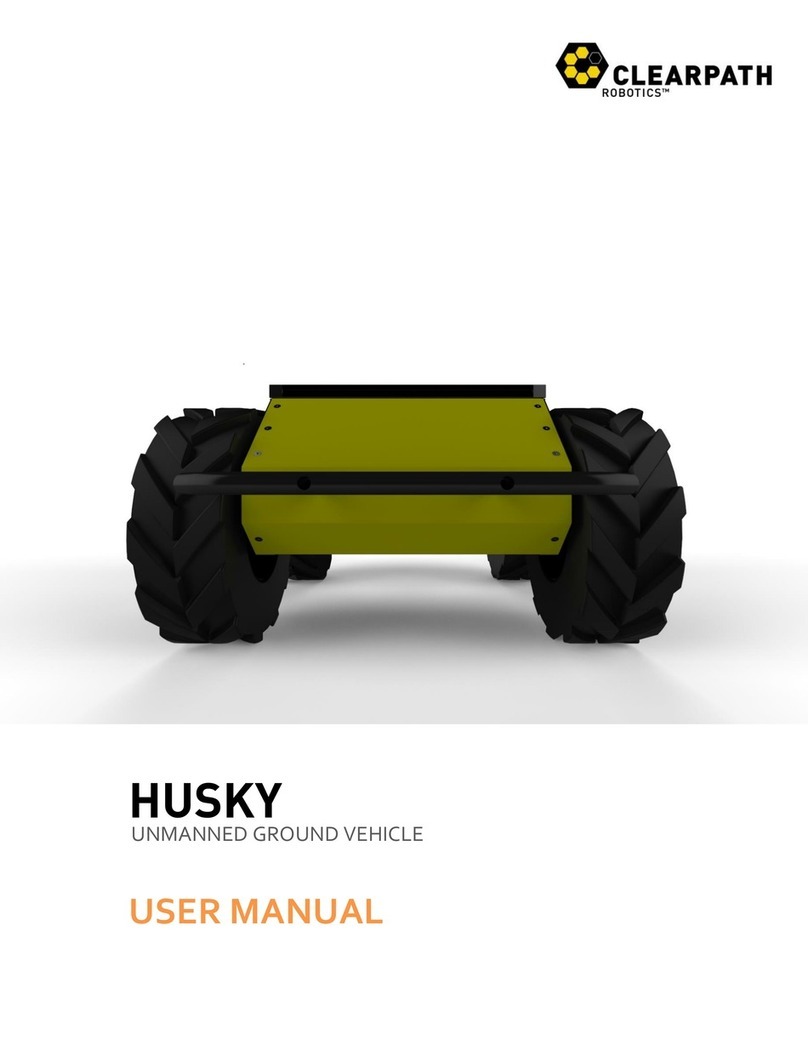

Husky A200 is a rugged and easy-to-use unmanned ground vehicle for rapid prototyping applications. In

this guide, you will find information about the setup, operation, and maintenance of your Husky A200.

Included with your Husky A200 kit are the following:

1x Clearpath Robotics Husky A200

1x 24V Sealed Lead-Acid Battery Pack

1x Battery Door Cover

1x Battery Charger

2x Lockout Keys

To use Husky A200, you will require a PC running Windows or Linux. Communication with Husky occurs

over standard RS232 serial, using the Clearpath Communication Protocol (CCP). Open-source software

interfaces for CCP are available in C++, Python, and National Instruments LabVIEW.

If you purchased a computer option from Clearpath Robotics with your Husky, then the laptop or

minicomputer you received has already been configured for use with CCP.

To expand the capabilities of Husky, consider the following additional sensor packages offered by

Clearpath Robotics:

LIDAR

Network Camera

GPS

Each sensor package ships from Clearpath Robotics with a custom mounting bracket and cabling, for

easy attachment to Husky’s extruded aluminum payload mounting rail.

Clearpath Robotics Inc. ©2011 All Rights Reserved.

5

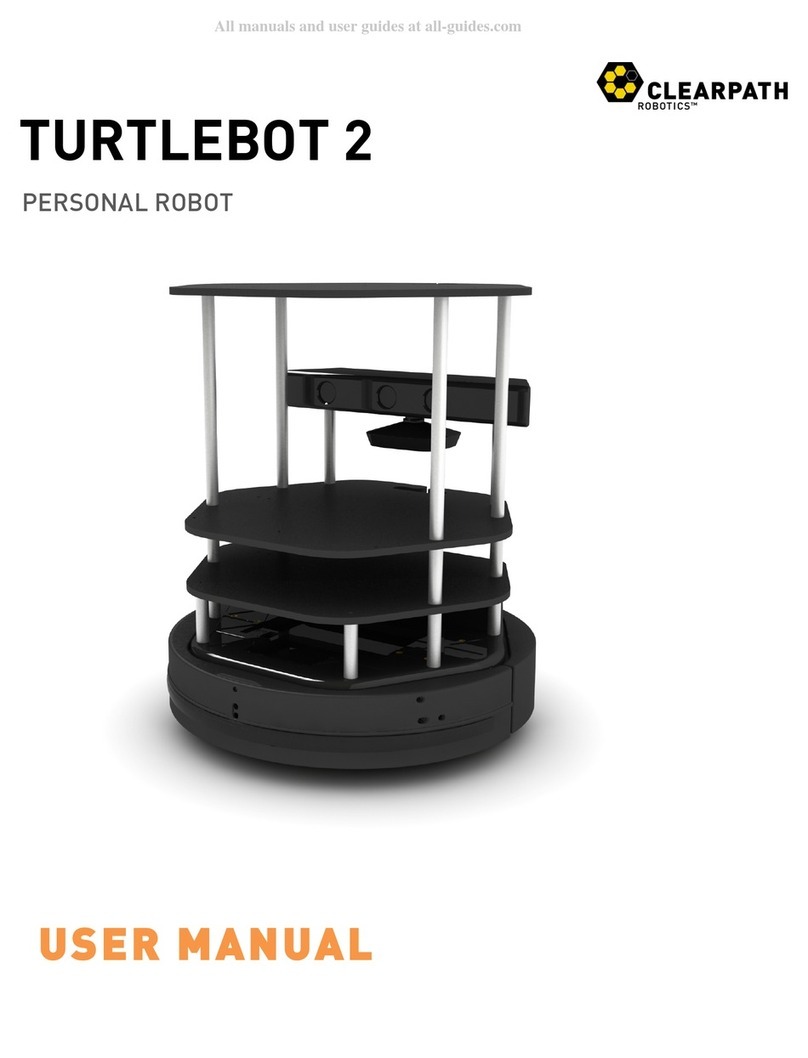

This section provides an overview of the key specifications of the Husky A200 platform. Figure 1 gives a

tour of key Husky A200 components.

Figure 1: Husky A200 at a Glance

Front Bumper Bar

Wheel

User Power Panel

Extruded Aluminum

Mounting Rail

User Payload Area

Lockout

Emergency Stop

Rear Bumper Bar

Power Button

Status Panel

Battery Area

Access Buttons

Clearpath Robotics Inc. ©2011 All Rights Reserved.

6

The status panel is an array of LED indicators which provide information about the current status of

Husky, located on the rear of the chassis. The indicators are described in Table 1.

Icon

Description

Battery status. The four LED segments provide an approximate indication as to

the relative lifetime remaining in the battery.

Communications status. When green, Husky is receiving a stream of correctly-

formatted motion commands, and is ready to drive. When yellow, Husky is

receiving commands but will not drive due to emergency stop or another error.

When red, serial communications are currently timed-out.

General error status. Illuminates red when Husky will not drive due to an error

state. Such states include emergency stop, insufficient battery power, or an

unspecified software error.

Emergency stop status. Illuminates red when Husky will not drive due to the

emergency stop being activated, either onboard or wireless (if available)

Charge indicator. Illuminates red when Husky user power is being supplied

externally.

Table 1: Husky A200 Status Panel Icons

Clearpath Robotics Inc. ©2011 All Rights Reserved.

7

The reference frame used by all Clearpath Robotics ground vehicles is based on ISO 8855, and is shown

in Figure 2. Husky is being viewed from the front; when commanded with a positive translational

velocity (forward), wheels travel in the positive x-direction.

The direction of the axes differs from those used for roll, pitch, and yaw in aircraft, and care should be

taken to ensure that data is interpreted correctly.

Husky A200 provides a female DE-9 connector, for communication with a host device. The pinout of this

connector is shown in Figure 3.

Pin

Name

Dir

Description

2

RX

IN

Data from Platform

3

TX

OUT

Data to Platform

5

GND

N/A

Common Ground

x

y

z

roll

pitch

yaw

Figure 2: Husky A200 Reference Frame

Figure 3: Husky A200 DE9 Pinout

Clearpath Robotics Inc. ©2011 All Rights Reserved.

8

Key specifications of Husky A200 are shown in Table 2.

Dimensions

990 mm length

670 mm width

390 mm height

39 in length

26.4 in width

14.6 in height

Track

555 mm

21.9 in

Wheelbase

512 mm

20.2 in

Weight

50 kg

110 lbs

Maximum payload1

75 kg

165 lbs

All-terrain payload2

20 kg

44 lbs

Speed (max)

1.0 m/s

3.3 ft/s

Ground clearance

130 mm

5 in

Climb grade

45°

100% slope

Traversal grade

30°

58% slope

Operating time

3 hours typical

8 hours standby (no motion)

Battery

24V 20 Ah

Sealed Lead Acid

Battery charger

Short-circuit, over-current, over-voltage,

and reverse voltage protection.

Charge time

10 hours

User Power

5V / 12V / 24V

Each fused at 5A

Communication

RS-232

115200 Baud

Wheel encoders

200,000 pulses/m

Internal sensing

Battery status

Wheel odometry

Motor currents

Table 2: Husky A200 System Specifications

1: Continuous operation on relatively flat terrain with wide turns

2: Vehicle climbing 30° grade with high-mounted payload, or turning in place in high-friction conditions

Clearpath Robotics Inc. ©2011 All Rights Reserved.

9

As a starting point, Clearpath Robotics recommends using the following relationship between wheel

velocity and platform velocity:

vrepresents the instantaneous translational speed of the platform and ωthe instantaneous rotational

speed. vrand vlare the right and left wheel velocities, respectively. wis the effective track of the vehicle

(0.555 m).

Husky A200 supports three distinct control modes: voltage control, speed control, and velocity control.

Voltage control, accessed via CCP message 0x0202, allows the direct control of motor voltage,

as a percentage of 24V.

Speed Control, accessed via CCP message 0x0200, activates a PID feedback control loop, and

allows the specifying of the left and right wheel speeds in m/s.

Current Control, accessed via CCP message 0x0220, activates a PID feedback control loop, and

allows the specifying of the left and right wheel currents in amperes.

Velocity Control, accessed via CCP message 0x0204, activates feedback control, and a basic

kinematic model, which allows the specifying of a target overall translational and rotational

velocity of the chassis.

For more details, please refer to the Clearpath Control Protocol documentation, and the documentation

specific to your chosen software API.

Navigate to http://clearpathrobotics.com/downloads to download the current release of the Clearpath

Control Protocol.

Clearpath Robotics Inc. ©2011 All Rights Reserved.

10

Clearpath Robotics is committed to high standards of safety. Husky A200 contains several features which

protects both the safety of users and the integrity of the vehicle.

Husky A200 is a rugged and high-performance vehicle. For the safety of yourself and others, always

conduct initial experiments and software development with the vehicle raised off the ground. Place a

wooden crate, a set of sawhorses, a sturdy storage tub, or any other solid flat structure having a height

greater than 6 inches under Husky to keep the wheels clear of the ground (“up on blocks”).

When starting out, favor slower wheel speeds. Husky’s control loops can accurately maintain velocities

as low as 0.1 m/s. Operating at such speeds will give you more time to react if things don’t go quite as

you expect.

When Husky is operating, keep clear of the wheels, paying particular attention to the pinch hazard

which exists between each wheel and the end of the corresponding bumper bar.

The red emergency stop button (e-stop) and lockout are located on the back of Husky, opposite the

status panel, shown in Figure 4. Power supply to Husky’s motor drivers is enabled by a normally-open

relay, which is closed in series with the e-stop switch. When in e-stop mode, the status panel e-stop light

will illuminate red, and Husky will not drive.

Always ensure the e-stop button is accessible at all times. Avoid mounting payloads which extend over

the rear of Husky and would occlude the e-stop.

Lockout

Emergency Stop

Figure 4: Husky A200 Emergency Stop and Lockout

Clearpath Robotics Inc. ©2011 All Rights Reserved.

11

The lockout provides a secondary e-stop for periods during which Husky will be left unattended. When

in lockout mode, the robot will still power on, but the motors will not drive.

Husky’s motors are rated to draw 4A continuous, but they will spike to several times this, particularly

when traversing rough terrain, and when turning on the spot. When you are ready to beginning running

Husky for continuous periods of longer than ten minutes, it is recommended that you monitor current.

In your software, use CCP message 0x4004 to request general system status. The three current fields

represent total draw, left motor current, and right motor current, respectively. Monitoring these fields

over longer periods of operation will allow you to ensure that you are not putting excessive wear on the

motors.

To reduce current draw, consider commanding wider-radius turns from your control software.

Husky is powered by a single 24V sealed lead-acid battery, similar to the type found in electric

wheelchairs, golf carts, and other devices. Husky’s battery is capable of delivering 1800W—similar to

wall mains. This gives Husky’s motors their great performance, but it is also enough power to cause

severe bodily harm. Please observe the following precautions:

Do not tamper with the plug attached to the battery.

Do not tamper with the fuse panel, except to check and change the fuses, and to connect and

disconnect the battery plug.

Do not operate Husky without the battery door in place. The battery is insufficiently restrained

without the door, and will come loose, damaging the fuse panel.

Charge the battery only with the charger provided by Clearpath Robotics.

Return the battery to Clearpath Robotics for proper disposal.

For the safety of users and to maximize the lifetime of Husky, please observe the following when

manually transporting the robot:

Husky should be lifted by two persons, firmly gripping the front and rear bumper-bars.

Ensure that Husky is e-stopped when transporting short distances and powered off when

transporting longer distances.

Clearpath Robotics Inc. ©2011 All Rights Reserved.

12

You are ready to go! This section details how to get the wheels rolling.

Before beginning, place Husky “up on blocks”, as described in the Safety section. You can use an

inverted storage tub or a wooden crate—anything, really, so long as the wheels are clear of the ground.

If you purchased a computer from Clearpath Robotics with Husky, it is set up and ready to go. Provided

on this machine are the officially-supported interfaces for Python and C++, as well as drivers for

Player/Stage and ROS, if requested.

For details on how to set up additional computers, please refer to Appendix A for details.

Husky’s serial port is located in the user power panel accessible from the user area, shown in Figure 5.

The connector is a female DE9, suitable for connection directly to a USB-serial adaptor, or to a PC serial

port via a straight-through modem cable (not a null modem cable). How you connect the PC to Husky

depends on whether the PC has a dedicated serial port:

If your PC contains a serial port, connect the male end of the provided serial cable to the female

DE9 on Husky, and the female end of the cable to the male DE9 on the PC.

If your PC contains only USB ports, connect the USB end of the USB-serial adaptor to the PC,

and connect the male DE9 to Husky’s serial port.

Husky A200 comes with the battery fully charged and installed, but disconnected for safety during

shipping. To reconnect the battery:

RS232 Connector

Figure 5: Husky A200 RS232 Connector

Clearpath Robotics Inc. ©2011 All Rights Reserved.

13

1. Ensure Husky’s main power button is in the outer “off” position and the e-stop is activated.

2. Using curled index fingers to grip the battery door latches, press with thumbs on the latch

buttons and lift the battery door free of the chassis.

3. Carefully connect the battery plug to the mating connector in the fuse panel, shown in Figure 6.

Ensure that it is firmly seated and clicks into place. It will be difficult to connect it in the

incorrect polarity.

4. Reseat the battery door cover, ensuring that it has clicked into place and is flush with the rear

panel.

To power on Husky, firmly press the power button located above the status panel. It will illuminate blue,

and the status panel lights will show a brief test pattern. The comm status light will show red, as the PC

is not yet communicating with Husky.

The stop status light will be red if the e-stop is pressed. If it is not, press the e-stop button and verify

that the stop light illuminates. Leave the platform in an e-stop state until it is successfully receiving

commands.

Fuse Panel

Battery

Figure 6: Husky A200 Battery Area

Clearpath Robotics Inc. ©2011 All Rights Reserved.

14

On the PC, attempt to communicate with Husky using the Python command-line interface (CLI). From a

terminal prompt, type:

$ python –m clearpath.cli

When the connection is made successfully, you should see a readout of information about your Husky

A200 platform, followed by a prompt where you may directly issue Clearpath Communication Protocol

commands. The comm light will still be illuminated red at this point, as the CLI does not issue commands

unless instructed to do so, and thus the connection times out.

At the prompt, issue a command to drive at 0.5 m/s:

clearpath:/dev/ttyUSB0$ set_velocity 0.5 0 2.0

The comm status light should momentarily switch to green. If you haven’t yet done so, release the e-

stop, and run the command a second time. This time, the comm light will flash green and the wheels

should turn also. After 200ms, Husky times out and reverts to the comm error status. To maintain the

commanded speed, use the repeat command to send the velocity command continuously at 20 Hz:

clearpath:/dev/ttyUSB0$ repeat 20 set_velocity 0.5 0 2.0

With the wheels spinning continuously, try using request_system_status to return some key data

from Husky:

clearpath:/dev/ttyUSB0$ request_system_status

You should see three voltages, representing the voltage level of the battery, and the input voltage of the

left and right motor drivers, three currents, representing the draw from the battery and the output

current at each motor driver, and two temperatures, representing the temperature of each motor

driver.

When finished, cease the repeated command and exit:

clearpath:/dev/ttyUSB0$ repeat off

clearpath:/dev/ttyUSB0$ exit

For a full list of all available commands, type help at the prompt. For help on a specific command, type

help <command>, for example help set_velocity.

Clearpath Robotics Inc. ©2011 All Rights Reserved.

15

Clearpath Robotics provides an officially-supported Robot Operating System (ROS) driver for Husky

A200, based on the Python interface. ROS is a flexible, distributed architecture for controlling robotic

systems, and is a recommend method for controlling Husky. Using ROS, you can quickly take joystick

control of Husky.

A simple ROS-based tele-operation network is shown in Figure 7. The joy_node is a device driver which

interfaces with the joystick and produces ROS Joy messages. The clearpath_teleop node consumes

these Joy messages, applies scale factors and produces Twist messages. The Twist messages are

received by clearpath_base, which uses CCP to forward them as velocity commands to Husky.

With a joystick connected directly to Husky’s PC, and available on /dev/js0, launch the teleop script:

roslaunch clearpath_teleop teleop_a200.launch

You should now be able to drive the robot from the connected joystick.

To drive remotely, set up a second ROS PC as the pilot’s computer. It is from here that you will launch

teleop_a200.launch, but you will need to specify that the clearpath_base node run remotely on the

Husky’s PC rather than locally on the pilot's computer. To do this, you must specify in the launch file a

<machine> tag giving the details of the Husky computer’s ROS installation. A typical configuration is as

follows:

<machine name="husky-pc" address="husky-pc" user="administrator"

ros-root="/opt/ros/cturtle/ros"

ros-package-path="/opt/ros/cturtle/stacks:

/home/administrator/ros-clearpath" />

Then add machine="husky-pc" to the <node> tag which launches clearpath_base, and run

roslaunch teleop_a200.launch from the pilot machine!

For more details, consult the following pages on the official ROS wiki:

http://www.ros.org/wiki/ROS/NetworkSetup

http://www.ros.org/wiki/roslaunch/XML/node

http://www.ros.org/wiki/roslaunch/XML/machine

joy_node

clearpath_teleop

clearpath_base

<Twist>

Joystick

RS232

Husky A200

USB

<Joy>

Figure 7: ROS Teleoperation Network

Clearpath Robotics Inc. ©2011 All Rights Reserved.

16

This section provides a guide to using the various available control methods on Husky.

The Clearpath Control Protocol (CCP) is a simple way for users to interface with Clearpath hardware

from a PC or other higher-level controller. All Clearpath Robotics hardware implements the subset of

messages relevant to the specific chassis configuration present. For example, Husky A200 provides

handlers for the differential drive messages, but not for the Ackermann messages.

CCP includes several features intended to increase communication reliability while keeping message

overhead and implementation complexity low. It is not intended for multiple devices to be

simultaneously connected to a single communication line, removing the need for addressing or bus

negotiation.

CCP is a binary serial protocol, documented in full in the CCP Guide. Provided by Clearpath Robotics are

implementations in Python, C++, and LabVIEW, as well as a driver for Robot Operating System (ROS)

built on the Python implementation. This section provides an overview and introduction to the two low-

level implementations.

The below code requests and prints a 1 Hz system status update and ramps the motor driver outputs

from 0 to 100% voltage.

#!/usr/bin/python

from clearpath import Interface

from clearpath.transports import Serial

import time

cpr = Interface(transport=Serial,

transport_args={'port':'/dev/ttyUSB1'})

cpr.open()

def status_handler(code, payload, timestamp):

print(payload)

cpr.add_handler(status_handler, request='request_system_status')

cpr.request_system_status(subscription=1)

for i in range(0, 10):

left_percent = right_percent = i * 10

cpr.set_differential_output(left_percent, right_percent)

time.sleep(0.5)

time.sleep(1)

cpr.close()

Clearpath Robotics Inc. ©2011 All Rights Reserved.

17

To use feedback speed control instead of direct voltage control, consider the

set_differential_speed or set_velocity messages. Also, if you would prefer to poll for received

messages rather than use callbacks, you may use the get_waiting method to receive a list of

unhandled messages. For more details on using the Python driver, see the included documentation and

examples.

This code is similar to the Python code, except that it uses the built in speed controller to implement a

velocity ramp as opposed to the Python demo’s use of the raw motor control functionality the protocol

also provides.

#include <iostream>

#include <cstdio> // want getchar()

#include <cstdlib>

#include <unistd.h>

#include <typeinfo>

#include "clearpath.h"

using namespace std;

int main(int argc, char *argv[]) {

/* Configure the serial port */

const char* port = (argc == 2) ? argv[1] : "/dev/ttyUSB0";

clearpath::Transport::instance().configure(port, 3 /* max retries*/);

/* Subscribe to some interesting data */

clearpath::DataSystemStatus::subscribe(1);

clearpath::DataSystemStatus * cur_status = NULL;

/* Ramp speed to 0.6m/s over 6 seconds.

* We use the 1Hz system status message for timing, so we want to

* begin by waiting for the first message, which is sent shortly

* after the beginning of the subscription */

cur_status = clearpath::DataSystemStatus::waitNext();

cout << *cur_status << endl;

delete cur_status;

for(int i=1; i<=6; ++i) {

// Set motor speed

clearpath::SetVelocity(0.1*i, 0.0, 1.0).send();

/* Wait for the next system status message to arrive */

while(!(cur_status = clearpath::DataSystemStatus::popNext()));

cout << *cur_status << endl;

delete cur_status;

}

/* Terminate subscriptions */

clearpath::DataSystemStatus::subscribe(0xffff);

return 0;

}

Clearpath Robotics Inc. ©2011 All Rights Reserved.

18

Distributed with the C++ API are three simple test programs:

botinfo.cpp: Requests four pieces of information from Husky A200 and exits

keyboard_ctrl.cpp/h: Allows the user to control the velocity of Husky A200 via the keyboard

dead_reckon.cpp/h: Allows the user to control the position of Husky A200 via the keyboard. The

position is estimated using the onboard encoders.

Clearpath Robotics Inc. ©2011 All Rights Reserved.

19

Husky A200 is built for rugged, long-term use. However, there are steps that can be taken to maintain

and extend the life of the platform even further.

The battery which ships with Husky A200 may be charged off-board, or while still inside of Husky. If

charging while installed, you will need to open the access door to the battery area, and disconnect the

battery from its connector in the fuse panel. From there:

5. Connect the DC output cable from the charger to the battery terminal connector.

6. Plug the charger power cord into into the charger, and then into a wall receptacle.

7. The POWER LED and CHARGING LED lights on the charger should both be illuminated.

8. When battery is fully charged, the CHARGING LED will turn off. Unplug the charger from the

wall, and then disconnect it from the battery.

The battery charger which ships with Clearpath Robotics lead-acid battery-powered products uses a

three-state charge cycle:

9. A fast, high current initial charge, until the battery voltage reaches 29.6 V.

10. A topping charge, during which the battery charges at 29.6 V constant voltage until the current

decreases to 500 mA.

11. A precision float charge, during which the battery voltage is held at 27.6 V. This mode allows the

charger to remain connected to the battery during periods of non-use, keeping it in a state of

full charge. When in this mode, the CHARGING LED will be off.

Husky’s power supply is a sealed 24 V lead acid battery pack (VRLA), providing 20 ampere-hours of

charge. To maximize the lifetime of the battery, recharge immediately after use, and keep charged to

prevent loss in capacity. Battery life expectancy is shown in Table 3 and shelf charge retention in Table

4.

Table 3: Battery Life Expectancy

Cycles

Depth of Discharge

200

100%

225

80%

500

50%

Table 4: Battery Shelf Life

Shelf Time

Battery Charge

None

100%

1 month

92%

3 month

90%

6 month

80%

Clearpath Robotics Inc. ©2011 All Rights Reserved.

20

Husky’s battery should never be used or stored in an environment exceeding 40 degrees Celsius (104 °F),

and should always be charged at temperatures above freezing. At the optimal operating temperature of

25 degrees Celsius, the discharge time of the battery may be seen in Figure 8.

Figure 8: Husky A200 Battery Voltage Characteristics

Tire pressure may change with temperature, and should be checked periodically with a pressure gauge.

Checking, releasing pressure and inflating a tire are all done through the tire’s inflation stem. Tire

pressure should not exceed 20 psi, and lower pressure may be desired based on terrain requirements.

If a tire must be removed, first unfasten the four M5 Socket Head Cap Screws that join the wheel to the

axle hub, and slide it off the axle. When replacing, these screws should be tightened to 3.7 ft-lb [5 N-m]

torque.

Husky is an all-weather robot, but it is not waterproof. Care should be taken that no part of the main

chassis is ever submerged in water. When the chassis becomes wet or dirty, wipe it down with a cloth

and warm water, and dry with a towel.

If water is suspected to have entered the Husky A200 chassis, remove the battery and allow Husky to

fully dry for a period of 24 hours.

Other CLEARPATH Robotics manuals

Popular Robotics manuals by other brands

Denso

Denso Faber HM-G Series General information

YASKAWA

YASKAWA MOTOMAN-VS100 Operator's manual

ABB

ABB IRB 6620 Product Manual, Spare Parts

Gilson

Gilson Quad-Z 215 user guide

TEACH TECH

TEACH TECH TTG-631 Assembly & instruction manual

Universal Robots

Universal Robots Log Viewer e Series Original instructions