ClearPlus Catalytic CP-CC-5800SXT Series Troubleshooting guide

OWNER’S MANUAL & INSTALLATION GUIDE

APPLICABLE MODELS: CP-CC-5800SXT Series

PLEASE READ THIS MANUAL CARE ULLY BE ORE

ATTEMPTING INSTALLATION. AILURE TO OLLOW THESE

INSTRUCTIONS MAY A ECT THE PER ORMANCE O YOUR

SYSTEM, VOID YOUR WARRANTY, AND RESULT IN

PROPERTY DAMAGE.

2

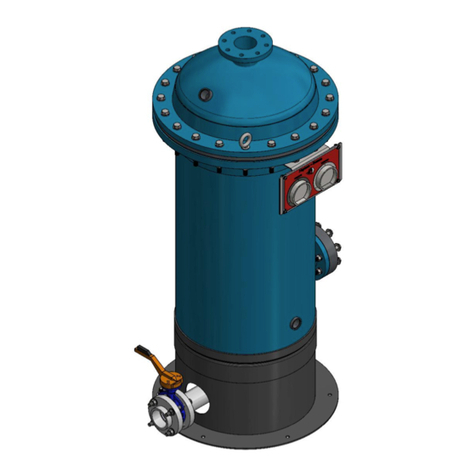

Congratulations on the purchase of your ClearPlus Catalytic™ Series filtration system.

You have purchased one of the finest catalytic carbon water treatment systems on the

market today.

All ClearPlus Catalytic™ Series water treatment systems utilize Calgon Centaur media, the

world's leading catalytic carbon for water treatment.

The brain of your ClearPlus Catalytic™ system is the Fleck 5800SXT control valve. It is

manufactured by one of the world’s premier water treatment companies. The Fleck 5800

control valve is well respected for its reliability, serviceability, simple operation, and value.

The integrated Fleck SXT digital valve controller offers unsurpassed simplicity of operation,

yet complete control over all important valve operations. The Pentair Fleck 5800SXT

Downflow/Upflow Service Manual is also included with your system. It includes additional

information regarding the operation of your valve, replacement parts lists, and more.

Your ClearPlus Catalytic™ water treatment system is designed to offer low maintenance

operation. The control valve will perform regular backwash functions automatically. For

your convenience, your system has been pre-programmed for you at our factory. Should

you need to change any of the settings, simply follow the instructions provided in this

manual.

This manual is designed to provide owners, installers, and service technicians with detailed

information about the installation, start-up, and operation of your new filter system.

IMPORTANT SA ETY SYMBOLS

Hazards or unsafe practices that may result in personal injury

and/or severe property damage.

Hazards or unsafe practices that may cause operational

problems with your water treatment system.

3

Table of Contents:

GENERAL WARNINGS ……………………………………………………………………………………………...….. …….. 4

OPERATING CONDITIONS …………………………………………………………………………………………….…... 5

INSTALLATION ………………………………………………………………………………………………………….…..…..….. 6

Step 1 – Pre-Installation Inspection ……………………………………………………………..……… 7

Step 2 – Selecting an Installation Location ………………………………………………..…..... 7

Step 3 – Prepare Treatment Tank ………………………………………………………………..……… 8

Step 4 – Turn off the Water & Electric Water Heaters ………………………………….… 11

Step 5 – Prepare and Install Inlet and Outlet Plumbing Connection …….…… 12

Step 6 – Drain Line Installation …………………………………………………………………………..… 14

Step 7 – Control Valve Set-up ………………………………………………….……………………….….. 16

Step 8 – Initial Start-up and Leak Testing …………………………………………………......…. 18

BACKWASH ………………………………………………………………………………………………………………….…..……. 19

CHANGING TIME OF DAY ………………………………………………………………..…………………………..…… 21

USER PROGRAMMING MODE ……………………………………………………………………………………..…. 21

MASTER PROGRAMMING MODE ………………………………………………………………………….……..… 22

RESETS ……………………………………………………….…………………………………………………………………….…… 23

OPERATION DURING A POWER FAILURE ………………………………………………………….…..…… 24

MAINTENANCE & TROUBLESHOOTING ……………………………………………………….…..….……. 24

WARRANTY INFORMATION ………………………………………………………………………………………..…… 27

4

GENERAL WARNINGS

Do not allow children or pets to play on or around the water filter.

Do not install or store this filter system where it will be exposed to freezing temperatures.

Do not tamper with controls.

Do not repair, replace, or attempt to service any part of the system unless specifically

instructed to in this manual and you have the understanding, tools, and skills necessary to

carry out the procedure.

Packing materials can be dangerous to children. Keep all packing material (plastic bags,

polystyrene, boxes, etc.) well out of children’s reach.

Individual components of this water treatment system, and the installed system, are heavy.

Precautions should be taken to prevent personal injury or strain. Do not move heavy

components without assistance if you are not physically capable of safely carrying out the

procedure.

If the water treatment system is to be left unattended for an extended period of time

(vacation, etc.), we strongly recommend that you turn off the water supply to the system, or

the whole house, while you are away.

If your water pipes are metal (galvanized or copper), they may be used to ground electrical

systems, appliances, or your phone line. If this is the case, be sure to install regulation

ground clamps to the metal pipe on each side of the control valve and connect a jumper

wire between the 2 clamps (#4 gauge solid copper wire recommended). Consult a certified

electrician or plumber if you are unsure.

5

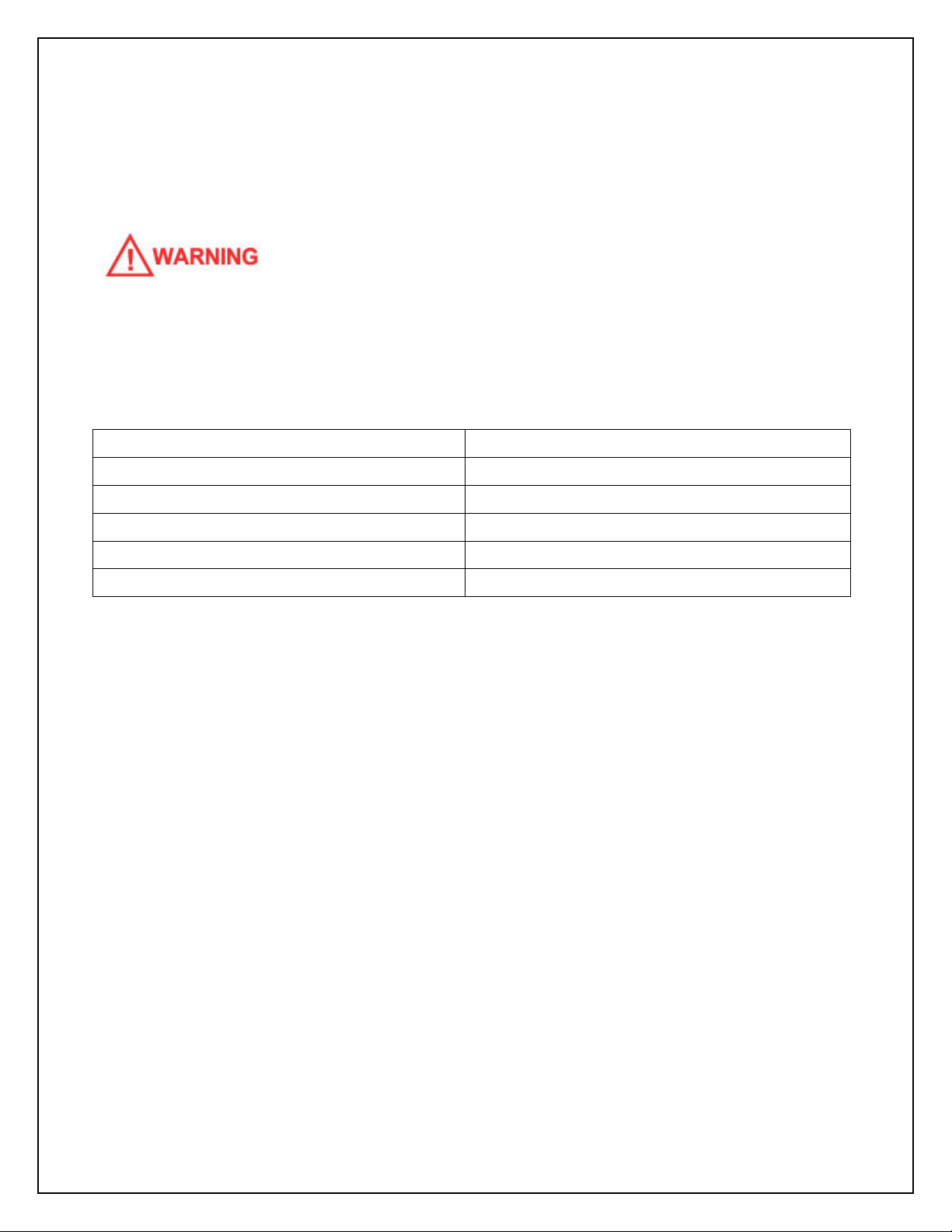

OPERATING CONDITIONS

The following chart provides guidance on the conditions required for successful operation of

your ClearPlus Catalytic™ system.

USE O THIS EQUIPMENT OUTSIDE O THESE OPERATING CONDITIONS MAY

ADVERSELY A ECT THE PER ORMANCE O YOUR SYSTEM, RESULT IN SYSTEM

DAMAGE INCLUDING WATER LEAKS AND CORRESPONDING PROPERTY DAMAGE, AND

MAY VOID YOUR WARRANTY.

Minimum Water Pressure 20 PSI

Maximum Water Pressure 90 PSI*

Recommended Water Pressure 40-70 PSI

Water Temperature 36F to 100F (2 to 38C)

Minimum Air Temperature 32°F (0°C)**

pH Range 5.0*** to 9.0

* While the ClearPlus Catalytic™ system is built to withstand pressures exceeding 90 PSI, if

your water pressure is greater than 70 PSI, we recommend that you have a certified plumber

install a pressure reducing valve ahead of the ClearPlus Catalytic™ system.

** The system cannot be subjected to freezing conditions or severe damage to the system

and your property could occur.

*** pH correction is strongly recommended where pH levels are less than 6.5 to prevent

damage to your control valve and plumbing system, and to prevent leaching of metals from

copper and brass plumbing components and solder in your home. Contact your dealer for

recommendations.

For best contaminant removal, the optimal service flow rate should not be exceeded.

Satisfactory to good filtration can generally be achieved up to the recommended maximum

service flow rate as long as this level of flow rate is not sustained continuously. See chart

below.

6

ClearPlus Catalytic™ Series low Rates & Backwash Requirements:

Model

Optimal

Service low

Rate* (GPM)

Maximum

Service low

Rate* (GPM)

Backwash low Rate

at 40 Water Temp

(GPM)

Backwash low Rate

at 70 Water Temp

(GPM)

CP-CC-5800SXT-8-44

2.5 3.5 3.5 4

CP-CC-5800SXT-9-48

3.5 4.5 4.5 5

CP-CC-5800SXT-10-54

4.0 5.5 6 6

CP-CC-5800SXT-12-52

5.5 8.0 8 9

CP-CC-5800SXT-13-54

6.5 9.0 9 10

CP-CC-5800SXT-14-65

7.5 10.0 10 12

CON IRM THAT YOUR WATER CONDITIONS, SERVICE LOW RATE NEEDS, AND

AVAILABLE BACKWASH LOW RATES MEET THE ABOVE SPECI ICATIONS OR THE

MODEL YOU ARE INSTALLING BE ORE COMMENCING THE INSTALLATION PROCESS.

I IN DOUBT, CALL YOUR DEALER OR ADVICE. INSTALLED UNITS CANNOT BE

RETURNED.

INSTALLATION

WE RECOMMEND THAT YOU READ THIS ENTIRE MANUAL BE ORE STARTING THE

ACTUAL INSTALLATION. WHILE WE STRONGLY RECOMMEND THAT A LICENSED

PLUMBER PER ORM ALL INSTALLATION WORK, A MECHANICALLY-INCLINED

HOMEOWNER WITH SUITABLE PLUMBING KNOWLEDGE CAN INSTALL THIS SYSTEM.

IN ALL CASES, IT IS CRITICAL THAT THE INSTALLATION BE DONE IN ACCORDANCE

WITH THESE INSTRUCTIONS AND ALL APPLICABLE PLUMBING AND ELECTRICAL

CODES. BE SURE TO OBTAIN ALL REQUIRED PERMITS. I THESE INSTRUCTIONS AND

THE APPLICABLE CODES ARE IN CON LICT, THE RELEVANT PLUMBING/ELECTRICAL

CODE SHALL BE OLLOWED. EQUIPMENT AILURE, PERSONAL INJURY, OR PROPERTY

DAMAGE CAN RESULT I THIS EQUIPMENT IS NOT INSTALLED PROPERLY.

7

Step 1. – Pre-Installation Inspection

Inspect all of the components that you received with

your unit. You should have received the following:

1. Fleck 5800 SXT Control Valve

2. Media Tank

3. Upper Screen

4. Bypass Assembly w/ 1” NPT Connector Yoke

5. Riser tube and lower distributor

6. Bag or box of gravel

7. Bag(s) or box(es) of Catalytic Carbon media

8. Funnel

9. Drain Line Flow Control - DLFC (attached to #1)

Step 2. – Selecting an Installation Location

While exterior installation in warm climate areas is possible, we strongly recommend interior

installation only. The system cannot be allowed to freeze or severe system damage could

occur. The system should not be exposed to rain and it should not be installed in direct

sunlight, as long-term exposure to UV light could damage components of the system.

Furthermore, direct sunlight could raise the internal water temperature in the treatment tank

and reduce backwash effectiveness.

In most cases, the system should be located AFTER your water pump and pressure tank(s)

and BEFORE all other water treatment equipment and your hot water heater.

I YOU HAVE OTHER WATER TREATMENT EQUIPMENT, YOU SHOULD DISCUSS THE

ORDER O YOUR TREATMENT EQUIPMENT WITH YOUR DEALER PRIOR TO

INSTALLATION.

8

Select a location for installation of your water filter that is within close proximity to the main

incoming water line of the home. The location should have a firm, level surface with enough

space for the unit itself and sufficient space surrounding the unit to facilitate maintenance.

WHILE WATER LEAKS ARE VERY RARE AND UNEXPECTED, YOUR WATER ILTER

SYSTEM SHOULD BE LOCATED NEXT TO A LOOR DRAIN OR PROTECTED BY A WATER

LEAK DETECTION SYSTEM WITH AUTOMATIC SHUT-O VALVE TO PREVENT WATER

DAMAGE TO YOUR PROPERTY IN THE UNLIKELY EVENT O A WATER LEAK.

RECOMMENDED WATER LEAK DETECTION SYSTEMS ARE AVAILABLE AT WWW.A-LEAK-

DETECTOR.COM.

You will also require a suitable drain to discharge waste water from the backwash cycle. A

drain standpipe for a washing machine, floor drain, or sump pump are excellent drain

options. We recommend that the drain line be connected to a minimum 1½" drain

standpipe or floor drain located ideally below the top of the head of your water filter. If

possible, the drain should be no farther than 20 feet from the system.

NOTE: NEVER CONNECT THE DRAIN LINE DIRECTLY INTO A DRAIN PIPE. ALLOW AN AIR

GAP BETWEEN THE DRAIN TUBING AND WASTE LINE TO PREVENT THE POSSIBILITY

O BACK-SIPHONING. WE DO NOT RECOMMEND USE O A CHECK VALVE AS IT MAY

BECOME CLOGGED WITH CONTAMINANTS EJECTED ROM THE SYSTEM DURING

BACKWASH.

You will also need access to a standard, non-switched, grounded 120 volt (60 Hz) electrical

outlet. An extension cord may be used to reach a suitable electrical outlet. If this option is

used, ensure that the extension cord is UL/CSA certified and of an appropriate wire gauge

for the application.

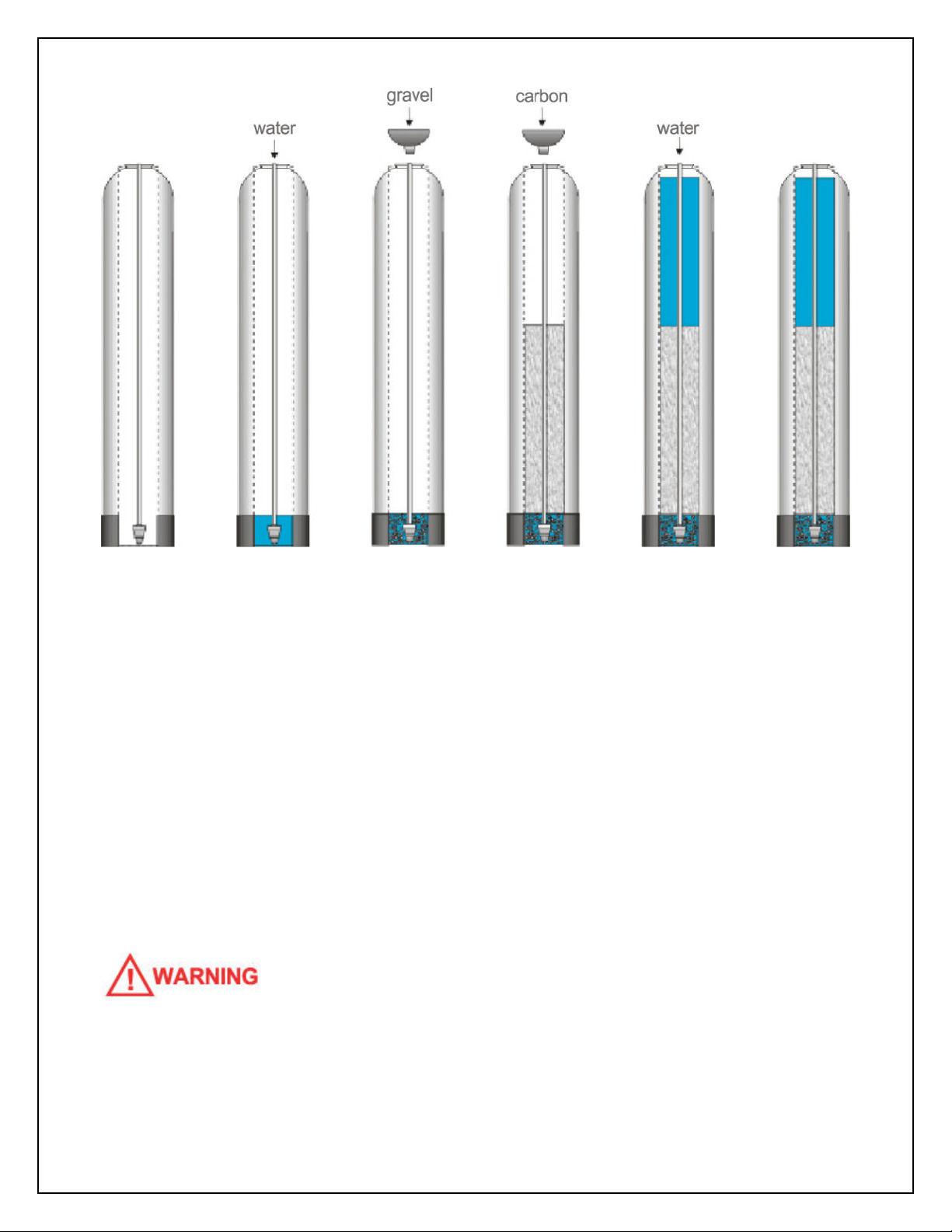

Step 3. – Prepare Treatment Tank

Two types of media are supplied with your ClearPlus Catalytic™ system: gravel which forms

the base layer (underbedding) in your treatment tank, and Centaur Catalytic Carbon.

9

Place the tank in the location where it will sit when the installation is complete. Note that the

black base of your tank is not permanently attached to the rest of the tank. If your tank

appears to be crooked, the base has likely been knocked out of alignment during shipping.

This can be correct by picking the tank up and tapping it on a hard surface while holding it

perpendicular to the floor. A few light taps will generally straighten it out.

Temporarily remove the distributor and riser tube assembly from the treatment tank. Hand

tighten the Fleck 5800SXT control valve on the tank and mark where the front of the tank will

be. Turn the tank so that the front of the tank is where you want it when it is full – once it is

full of media and water, it becomes very heavy and difficult to move!

Remove the control valve and re-insert the distributor and riser tube assembly into the tank.

The distributor, which looks like a cone-shaped plastic screen, is pre-connected to the end of

the long plastic riser tube which extends from the bottom of the tank to the top of the tank

where the control valve is attached. At the bottom of the tank, there is a recess in the center

of the tank to accept the distributor to keep it properly aligned. The riser tube has been pre-

cut to the correct height for you. When the distributor is correctly positioned, the top of the

riser tube will be approximately 1/8 to 1/4 of an inch below the top of the tank. If the tube is

flush or protruding above the top of the tank, the distributor tube is not nested correctly in the

recess at the bottom of the tank.

Add enough water to the tank to cover the lower distributor with a minimum of 6 inches of

water. This will prevent damage to the lower distributor as gravel is loaded. Place the funnel

into the tank so that the riser tube is in the middle. Place tape over the open end of the riser

tube. This will prevent gravel or media from accidentally going down the tube during the

following steps.

For the following steps, we recommend that you wear a dust mask. Take the bag/box of

gravel and, using a small scoop, add the gravel to the tank through the funnel to completely

cover the lower distributor. Use all of the gravel. Be sure to provide some downward

pressure on the riser tube while adding the gravel to ensure that the distributor does not shift

out of its recess or rise up. Ensure that you create an even layer of gravel across the bottom

of the tank. A rigid piece of thin wall tubing (conduit, copper pipe, etc.), approximately 1”

longer than the tank height works well as a leveling tool if you need it. Ensure that the riser

tube remains centered in the opening at the top of the tank.

10

Once this is complete, add the Catalytic Carbon media in the same manner. Use all of the

media provided. Depending on the capacity of the system, there will only be enough media

to fill the tank to about 1/2 to 3/4 full. This is normal. The media tank should never be filled

to the top of the tank as the remaining space, known as the “freeboard,” is necessary for the

media to have room to expand during the backwash cycle.

Once you have finished adding the media to the tank, remove the tape from the distributor

tube. Be careful not to pull upwards on the riser tube while doing this as it is important that

the distributor remain in its recess at the bottom of the tank.

Fill the media tank with water up to within a couple of inches of the top of the tank. This will

allow the media to pre-soak, thereby preventing media loss during the initial backwash.

DO NOT INITIATE A REGENERTION O THIS SYSTEM OR A MINIMUM O 2 HOURS

A TER ADDING THE WATER TO ALLOW ADEQUATE PRE-SOAKING. BACKWASHING

BE ORE THE MEDIA IS SATURATED MAY CAUSE A LOSS O MEDIA AND POTENTIAL

DAMAGE TO THE CONTROL VALVE.

11

Attach the upper screen to the underside of the control valve.

Be sure to twist clockwise and lock it into place.

Apply a small amount of lubricant to the top inch of the outside

of the riser tube and to the tank o-ring seal.

Note: Only use food-grade silicone lubricant. A small bag of

lubricant is provided in the small parts bag. Do NOT use

petroleum jelly.

The control valve can now be secured to the top of the tank.

Before attaching the valve, check to make sure that there is no

debris such as gravel or media in the tank threads. Screw the

control valve onto the tank – make sure that the riser tube inserts

into the center hole in the upper screen and the control valve as

you screw down the valve. The control valve should be hand-tightened

(clockwise). Do NOT use the control valve's timer assembly for leverage and do not use

tools. A firm grasp with both hands at the base of the valve will work. Do NOT use pipe

cement (“pipe dope”) or Teflon® tape on the threads.

Step 4. – Turn off the Water & Electric Water Heaters

AILURE TO OLLOW THIS PROCEDURE COULD RESULT IN SERIOUS, PERMANENT

DAMAGE TO THE HEATING ELEMENTS IN YOUR WATER HEATER.

If you have a conventional electric water heater or an on-demand (tankless) electric water

heater, we highly recommend that you turn off the power to the heater while installing any

water treatment equipment. Turn off power to your water heater now.

Turn off the household main water shutoff valve. Open several plumbing fixtures inside the

home as well as the outside faucets to drain as much water out of the plumbing system as

possible.

Following completion of the entire installation, restore the water flow by turning on the

household main water valve and allow all air to be purged from the plumbing system before

turning the power back on to your water heater.

12

Step 5. – Prepare and Install Inlet and Outlet Plumbing Connections

TE LON® TAPE IS THE ONLY SEALANT TO BE USED ON THE 1” NPT CONNECTOR YOKE

AND DRAIN ITTINGS.

I YOU WISH TO USE COPPER PIPING OR YOUR INSTALLATION AND WILL BE

SOLDERING THE JOINTS, DO NOT APPLY HEAT NEAR YOUR CONTROL VALVE, BYPASS

ASSEMBLY, 1” NPT CONNECTOR YOKE, OR THE DRAIN ITTINGS; OTHERWISE SERIOUS

DAMAGE TO THESE PARTS COULD OCCUR. ALWAYS SOLDER JOINTS WITH THESE

COMPONENTS DETACHED. I YOU ARE USING COPPER ADAPTERS TO CONNECT TO

THE 1” NPT CONNECTOR YOKE, IT IS RECOMMENDED THAT YOU SOLDER A 6" PIECE

O COPPER PIPE INTO EACH O THE CONNECTION ADAPTERS AWAY ROM THE

VALVE, THEN LET THEM COOL O BE ORE THREADING THEM ONTO THE 1” NPT

CONNECTOR YOKE.

Key Control Valve Components:

1. Control Valve Body

2. Bypass Assembly

3. 1” NPT (Male) Connector Yoke

4. Stainless Steel Clip w/ Screw

5. Drain Line Flow Control (DLFC)

6. Valve Cover

7. DLFC Retention Clip

The system’s control valve is

connected to your incoming and

outgoing water lines by way of a

bypass assembly with 1”NPT

threaded fittings. This assembly is

composed of the bypass valve and

the 1”NPT connector yoke. The 2 piece bypass assembly is secured to the control valve

using 2 stainless steel clips. Similarly, the 2 pieces of the bypass assembly, the bypass and

the 1” NPT connector yoke, are connected to each other in the same manner (they are

13

normally shipped to you pre-connected, but you can separate them to make plumbing

easier if you want). You will need to purchase the appropriate NPT threaded fittings to

connect the bypass assembly to the material and size of your main inlet and outlet water

lines.

Locate the inlet and outlet ports on the back of the control valve. Note that the inlet and

outlet are marked with arrows indicating the correct direction of water flow. When you are

looking at the back of the control valve, the inlet is on the left and the outlet is on the right.

Check the corresponding markings on the bypass to ensure the correct direction of water

flow and insert the bypass (do not secure the clips yet). The in and out arrows on the bypass

should be pointing the same direction as the in and out arrows on the outside of the control

valve.

BE VERY CARE UL TO MAKE SURE YOU PLUMB THE SYSTEM IN THE RIGHT DIRECTION.

Plumb your main incoming and outgoing water lines using suitable pipe, fittings, elbows, etc.

as necessary to create a tidy, secure installation up to the back of the bypass valve

(including the correct connection adapters to mate with the threaded fittings on bypass

assembly’s connection yoke. Be sure to follow all local plumbing codes.

WE HIGHLY RECOMMEND THAT YOU REMOVE THE BYPASS ASSEMBLY ROM THE

CONTROL VALVE BE ORE MAKING THESE INAL CONNECTIONS AS YOU MAY

INADVERTENTLY APPLY TOO MUCH PRESSURE ON THE VALVE WHILE SECURING THE

ADAPTERS, CAUSING DAMAGE TO THE VALVE BODY.

Once all plumbing to the bypass has been completed, you can connect the bypass

assembly to the control valve. Push the bypass onto the back of the control valve and

secure it using the two stainless steel clips with screws located on the back of the control

valve. Do not overtighten - it is normal for some “play” to exist when the bypass assembly is

properly seated. This allows for minor misalignment of the piping connections and relieves

stress on the valve.

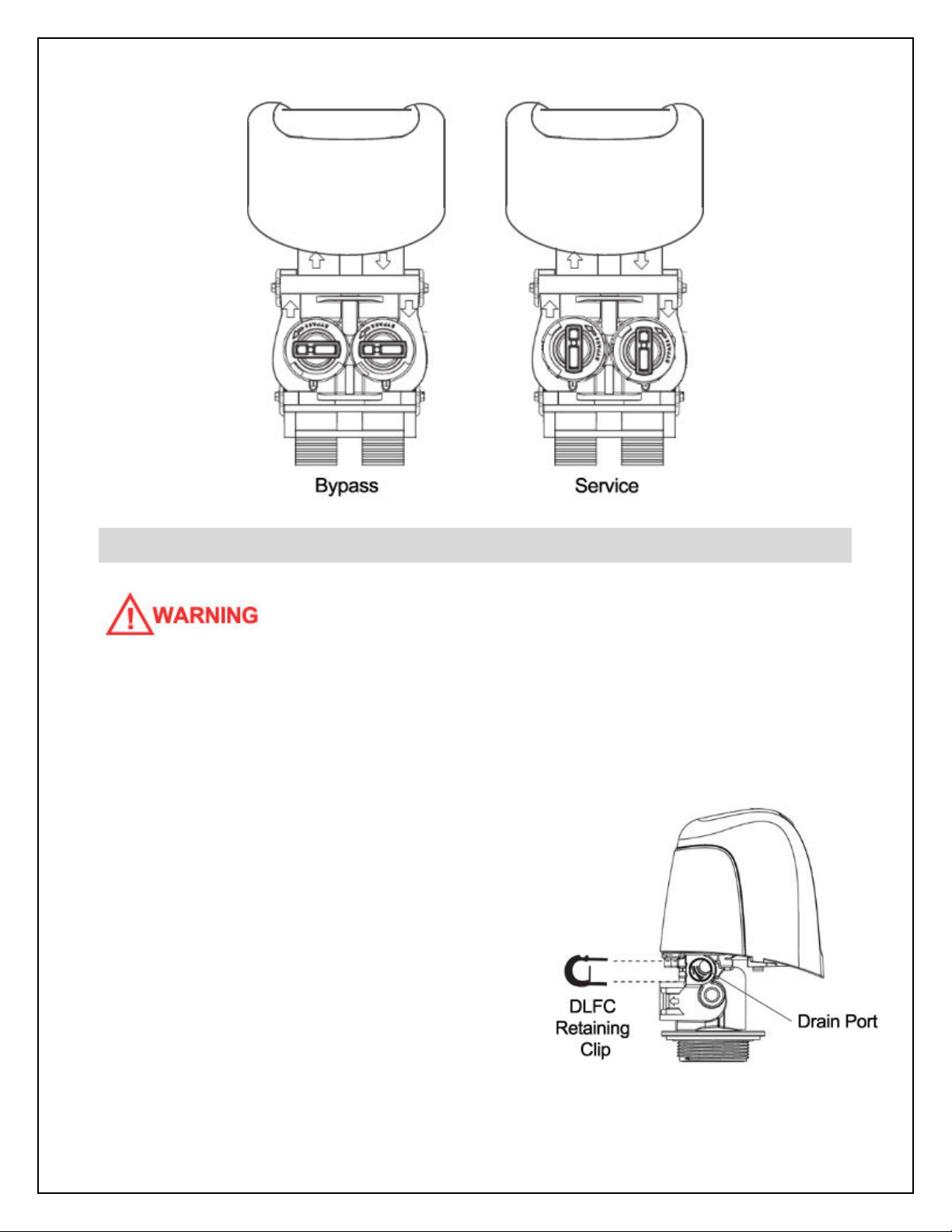

Place the bypass in the “bypass” position as pictured:

14

Step 6. – Drain Line Installation

NOTE: NEVER CONNECT THE DRAIN LINE DIRECTLY INTO A DRAIN. ALLOW AN AIR-GAP

O A MINIMUM O 1 INCH (CHECK LOCAL CODES) BETWEEN THE DRAIN LINE AND

WASTE LINE TO PREVENT THE POSSIBILITY O BACK-SIPHONING. ALWAYS OLLOW

LOCAL CODES. THE DRAIN LINE SHOULD NOT BE EXPOSED TO REEZING

TEMPERATURES.

During the backwash cycle, your system will

send captured contaminants out the drain port. This

port needs to be connected to a suitable household

drain, ideally within 20 feet of your media tank. A

nearby floor drain, sump pump, or a standpipe for a

washing machine is an excellent option. We

recommend that the drain line be connected to a

minimum 1 1/2 inch drain standpipe or floor drain

located ideally below the top of the head of your

water filter.

15

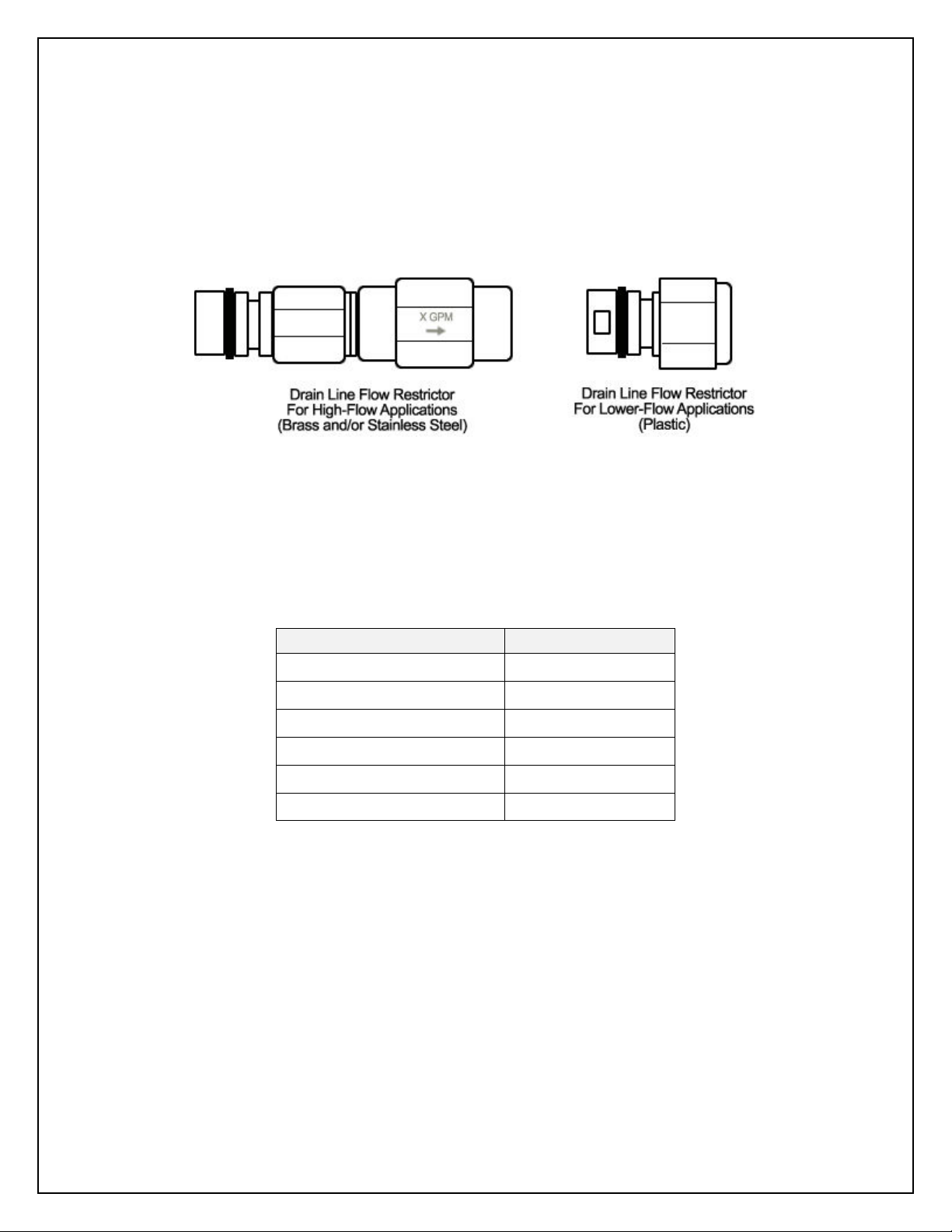

Locate the drain port on the back of your control valve. The drain line flow control assembly

(DLFC) is pre-attached to the control valve. For backwash flow rates of 7 GPM or less, the

DLFC will be a black plastic housing with 1/2 inch female NPT threads. This housing

contains a flow control washer that limits the backwash flow rate. For backwash flow rates

exceeding 7 GPM, the DLFC will be a brass adapter with a pre-attached external flow

restrictor with 3/4 inch female NPT threads.

You will need to purchase suitable pipe or tubing for the drain line, either 1/2 or 3/4 inch

diameter, to match the connection points on the drain line flow control assembly (DLFC). To

determine your MINIMUM drain line diameter, look up your model and incoming water

temperature using the chart below. If in doubt, use a 3/4 inch drain line.

MINIMUM Drain Line Diameter:

Model Min. Drain Line

CP-CC-5800SXT-8-44 1/2"

CP-CC-5800SXT-9-48 1/2"

CP-CC-5800SXT-10-54 1/2"

CP-CC-5800SXT-12-52 3/4"

CP-CC-5800SXT-13-54 3/4"

CP-CC-5800SXT-14-65 3/4"

Polyethylene tubing, PEX, PVC, CPVC, or copper pipe are all acceptable material choices for

the drain line. If you are using flexible tubing, be sure that there are no “kinks” or “crimps” in

the tubing after installation that may cause a flow restriction. If used, overhead drain lines

are not to exceed a height of 5 feet above the control valve and should be not more than 50

feet in length. Should an overhead drain line be utilized, it is recommended that the drain

line be increased in size (diameter), and that it not be fastened flush to the bottom of a floor

joist to minimize noise transfer to the upstairs of the building during regeneration.

Using an appropriate fitting, connect the drain line flow control to your drain line tubing/pipe.

The DLFC can be removed from the control valve to facilitate easier plumbing if desired. To

16

remove the drain line flow control, pull on the retaining clip to remove it and then grasp the

drain line flow control and pull outward. You may wish to dry-fit the fitting first to make sure

you line up the drain line properly with the drain port on the control valve if you are using

rigid pipe.

Re-insert the DLFC into the control valve and securely lock into place with the retaining clip

when done.

Ensure that the drain line is thoroughly secured along its route to the drain. The drain line

will be under pressure when the backwash cycle is working. If not adequately secured, the

drain line could vibrate during backwash causing excessive noise. If this is experienced, use

additional fixtures to better secure the drain line.

Step 7 – Control Valve Set-up

During cold weather, the installer should warm the control valve to room temperature before

operating. Note: All electrical connections must be done according to local codes.

Plug the control valve into a standard, grounded 120 volt (60 Hz) electrical outlet. Be certain

that the outlet is uninterrupted and not controlled by a switch. An extension cord may be

used to reach a suitable electrical outlet. Ensure that the extension cord is UL/CSA certified

and of an appropriate wire gauge for the application. Plug the other end of the power cord

into the electrical port on the control valve.

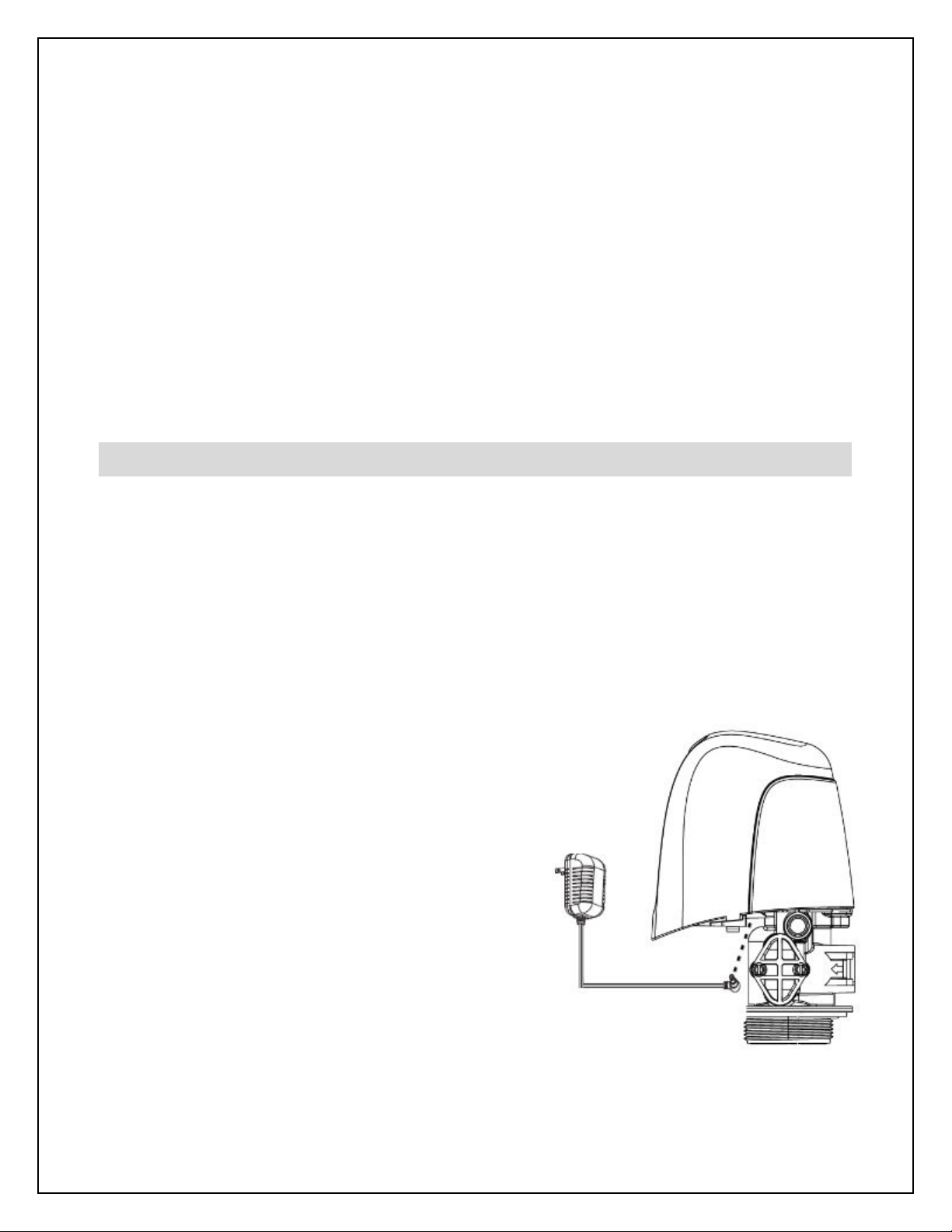

Note: The electrical port on the control valve is

located on the right side of the valve (when you

are facing the control panel), just behind the tab

used to remove the valve cover. It is a bit tricky

to find.

Once plugged in, the digital display on the control

valve will illuminate. The control valve may need

to reset to the home position when it is powered

up. If it does, the motor will run for a few seconds.

The digital display should be alternating between

17

the current time setting (which is probably incorrect), and the number “5” which indicates the

number of days remaining until the next backwash cycle. You will also see the “service” icon

which appears as a small faucet in the bottom left corner of the display window.

We will first set the time of day to the correct time. Press either the UP or DOWN button and

hold for a few seconds. The parameter display will read “TD” (Time of Day) and the

“programming” mode icon will appear (4 dots and a pencil). Use the UP and/or DOWN

buttons to change the time displayed to the correct time of day. Once the display shows the

correct time, press the EXTRA CYCLE button to save your changes.

Your ClearPlus Catalytic™ has been pre-programmed to backwash every 5 days and to

perform the backwash process at 12:30am in the morning when it is very unlikely that water

will be required in the building. If water is required during the backwash process, untreated

water will be permitted to flow to meet your service needs. You may edit the frequency and

duration of the backwash based on your water conditions. You may also alter the time of

day that the backwash process occurs if 12:30am is not ideal for you. If you have a water

softener or other automatic backwashing water treatment systems, make sure that they are

not set to backwash / regenerate at the same time. We recommend that they

18

backwash/regenerate at least 2 hours apart. Follow the instructions under “User

Programming Mode” to change the frequency or backwash time if desired. If you want to

change the duration of the backwash or final rinse cycles, these settings must be edited in

the “Master Programming Mode” – see below for details.

Step 8 – Initial Start-up and Leak Testing

Ensure that the bypass is in the bypass position. Turn on the main water supply. Open a

cold water tap nearby and let the water run for a few minutes or until the system is free of

foreign material (usually solder) and air that may have resulted from the installation. Once

the water is running clear and free of air, close the water tap.

INSPECT YOUR PLUMBING CONNECTIONS AND CONTROL VALVE OR LEAKS AND

REPAIR ANY LEAKS OUND BE ORE PROCEEDING.

DO NOT INITIATE A REGENERTION O THIS SYSTEM OR A MINIMUM O 2 HOURS

A TER ADDING WATER TO THE MEDIA TANK TO ALLOW ADEQUATE PRE-SOAKING.

BACKWASHING BE ORE THE MEDIA IS SATURATED COULD CAUSE A LOSS O MEDIA

AND POTENTIAL DAMAGE TO THE CONTROL VALVE.

Once the media has been adequately pre-soaked for 2 hours:

WITH THE BYPASS STILL IN THE BYPASS POSITION, press the EXTRA CYCLE button and

hold it down for about 5 seconds until you hear the valve change positions, the parameter

display changes to read “BW” (Backwash), and the time starts counting down. Once the

motor has stopped moving (no more noise), press the EXTRA CYCLE button again to

advance to the next stage of the backwash cycle – “RR” (Rapid Rinse).

Without delay, immediately begin to slowly open the bypass to the service position, allowing

water to flow into the system. Water and air will begin to flow to the drain line and will

continue for 3 minutes. At the end of this time, the valve will re-position and the filter will

return to normal service mode.

19

INSPECT YOUR DRAIN LINE PLUMBING CONNECTIONS AND REPAIR ANY LEAKS

IMMEDIATELY BE ORE PROCEEDING. I THE PLUMBING PIPE RATTLED OR VIBRATED

DURING THIS PROCESS CAUSING EXCESSIVE NOISE, USE ADDITIONAL ASTENERS TO

BETTER SECURE THE DRAIN LINE.

Press the EXTRA CYCLE button and hold it down for about 5 seconds to engage a full

backwash and rinse cycle. Allow the backwash and rinse to run their full cycles.

When the system returns to service mode, slowly open a nearby cold water tap (after the

ClearPlus Catalytic™ system) and let the water run for 5 to 10 minutes until the system is

purged of all air that may have resulted from the installation, and the water is running clear.

Repeat for other faucets in the building starting at the highest elevation and working down to

the lowest point until all air is purged. The initial flow of water may be slightly discolored.

This is normal and will go away quickly.

It is now safe to turn the electricity back on to your water heater.

Congratulations!

Your system is now ready to provide treated water to your home!

BACKWASH

The backwash process is automatically engaged and controlled by your Fleck 5800SXT

valve. Your system was pre-programmed at the factory. In most cases, your system will be

programmed to backwash every 5 days at 12:30am.

There are 2 steps to the backwash process:

Step 1: Backwash: factory pre-set for 10 minutes (parameter display code BW)

Step 2: Rapid Rinse: factory pre-set for 3 minutes (parameter display code RR)

Unless directed by a water treatment professional familiar with this system, we do not

generally recommend that you alter the duration of any cycles, however, you can adjust the

duration of both cycles based on your water conditions through the Master Programming

20

Mode (see below). If you experience reduced service flow rate and pressure loss due to

clogging, it is recommended that you increase the frequency and/or duration of your

backwash. If on the mornings after a backwash your water is often discolored or has

evidence of sediment, increase the duration of the rapid rinse cycle in 1 minute increments

until the problem is resolved.

During each step of backwash, the digital display on the control valve will indicate the cycle

currently underway and the amount of time remaining in that cycle.

There may be instances where more frequent backwash is required. For instance, if your

water consumption increases considerably, or if your feed water conditions temporarily

worsen, you may want to perform a manual backwash. You can choose to initiate a manual

backwash immediately or the next time the backwash time of day is reached:

To initiate a manual backwash the next time the backwash time of day is reached:

Press the EXTRA CYCLE button once. The “service” icon will begin to flash indicating that a

backwash is scheduled next time the backwash time of day is reached.

To cancel a queued backwash, press the EXTRA CYCLE button.

To initiate an immediate manual backwash:

Press the EXTRA CYCLE button and hold it down for 5 seconds until the backwash process

begins.

Skip through backwash steps:

There may be times that it may be desirable to skip through backwash steps without

allowing them to fully complete. This would be most typical during servicing. When a cycle

engages, always wait until the motor has stopped before skipping to the next cycle. You can

hear the valve motor while it is repositioning the valve at the beginning of each cycle.

During the backwash process, you can advance to the next step by pressing the EXTRA

CYCLE button.

The control valve will continue to keep time and the passage of days for a minimum of 48

hours in the event of power failure.

This manual suits for next models

6

Table of contents

Other ClearPlus Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Speedaire

Speedaire 4ZL96 Operating instructions & parts manual

Duramaxx

Duramaxx 10028064 manual

Siemens

Siemens SINAMICS G120P operating instructions

Pentair

Pentair FLECK 4600 SXT Installer manual

Bem

Bem Lora UF operation instruction

Evoqua

Evoqua Neptune Benson Defender FP Series Installation and operation manual

eSpring

eSpring Water Purifier owner's manual

Clean Water

Clean Water 7500-REV4 installation guide

Brita

Brita PURITY C iQ Quick installation guide

Vulcan-Hart

Vulcan-Hart SCALEBLOCKER SPS600V Installation & operation manual

ITT

ITT WEDECO Aquada Installation and maintenance instructions

Weh

Weh TSF2 H2 operating instructions