ClearPlus WH5B User manual

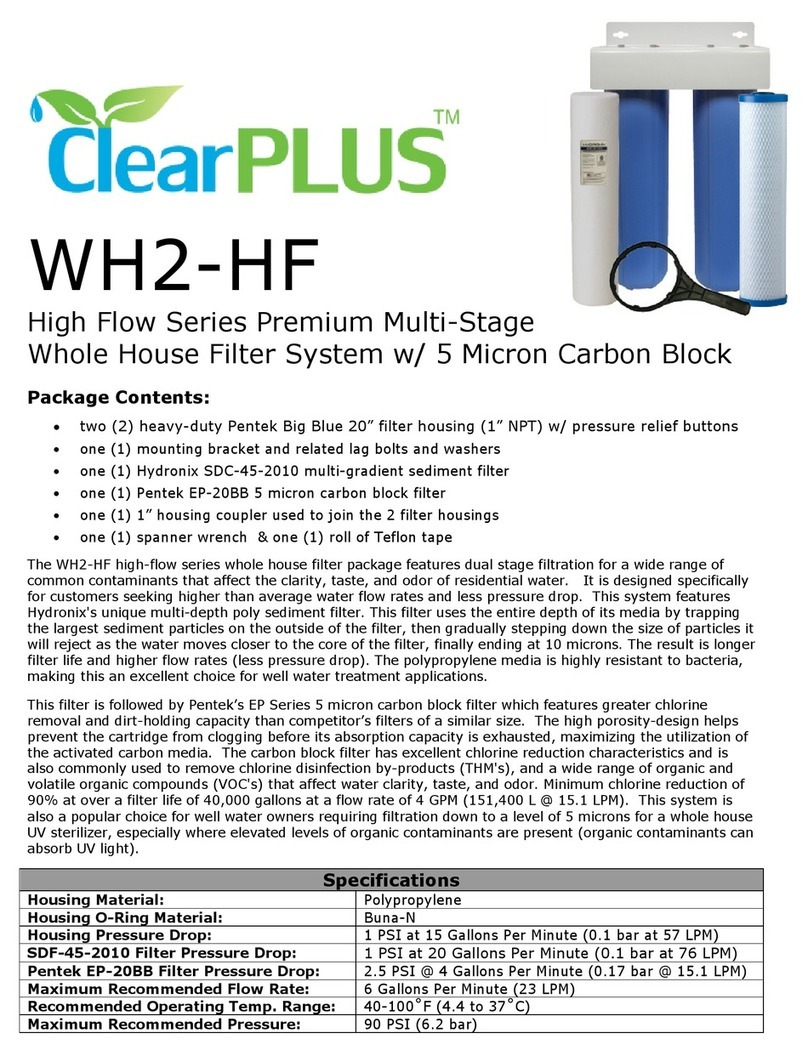

WH5B

Iron / Hydrogen Sulfide

Reduction Filter Package

w/ Sediment Pre-Filter

Package Contents:

• two (2 heavy-duty Pentek Big Blue 20” filter housings (1” NPT w/ pressure relief button

• one (1 powder-coated dual mounting bracket and related screws

• one (1 Pentek RFFE20-BB radial flow iron reduction filter cartridge

• one (1 Pentek DGD-5005-20 dual-gradient 5 micron sediment pre-filter

• one (1 spanner wrench

The WH5B iron / hydrogen sulfide reduction filter package contains manganese dioxide media

which reduces iron, manganese, and hydrogen sulfide through an oxidation / filtration process,

thereby substantially improving water clarity, taste, and odor, while at the same time protecting

your plumbing system including toilets, bath tubs and showers, and appliances such as clothes

washers and dishwashers, from unsightly staining. It does NOT add any harmful chemicals to the

water, making it completely safe for drinking water applications. A high-capacity 5 micron

sediment pre-filter extends the life of the primary iron filter by trapping sediments, debris, and

oxidized ferric iron particles to prevent pre-mature clogging.

This system should be employed where low to moderate ferrous (dissolved iron, manganese, or

hydrogen sulfide contamination is known or expected. This filter will also remove ferric iron

through mechanical filtration. This filter is most effective where iron contamination level is less

than 3 ppm (and no greater than 5 ppm or the hydrogen sulfide level is less than about 2 ppm. If

a combination of iron, manganese, and hydrogen sulfide are present, you must consider the "iron

equivalent" level when determining if this filter will work effectively in your circumstance (see

below . Best contaminant removal rates are achieved where the pH is 7.0 or higher, although

satisfactory contaminant removal can generally be achieved at slightly lower pH levels (6.8 to 6.9

under most conditions. This filter is not recommended where pH levels are less than 6.8. For best

results, pre-sediment and post-carbon treatment is recommended. A pH level of 8.0 is desirable

for optimal manganese reduction.

The life of the filter depends on the contamination level ("iron equivalent" and amount of water

consumed on a daily basis. You can get a good idea of how long a filter will last in your case by

using the chart below.

"Iron Equivalent" is calculated as follows:

(Iron level + (2 x Manganese level + (3 x Hydrogen sulfide level

If your level of Hydrogen sulfide is unknown (it is hard to accurately test for and you have a

noticeable "rotten egg" odor, assume a Hydrogen sulfide level of 0.5 ppm. If the rotten egg odor

is severe, assume a level of 1.0 ppm.

Example: Test results are 0.8 ppm iron, 0.05 ppm manganese,

and you have a rotten egg smell in your water. Iron Equivalent = (0.8 + (2 x 0.05 + (3 x 0.5 = 2.4

Approximately life of a R E20-BB filter cartridge:

Iron Equivalent

Level in Water

Total Gallons

Water Used

250 GPD

(four people)

125 GPD

(two people)

75 GPD

(one person)

5 ppm 16,000 gal 64 days 128 days 256 days

4 ppm 20,000 gal 80 days 160 days 320 days

3 ppm 26,000 gal 104 days 208 days 416 days

2 ppm 40,000 gal 160 days 320 days 640 days

1 ppm 80,000 gal 320 days 640 days 1280 days

0.5 ppm 160,000 gal 640 days 1280 days n/a

How it Works: Soluble iron (ferrous and manganese are oxidized and precipitated by contact

with higher oxides of manganese on the media granules. The hydrogen sulfide is reduced by

oxidation to an insoluble sulfur precipitate. The precipitates are then filtered. Ferric iron is

removed by mechanical filtration. No backwashing required!

Specifications

Housing Material: Polypropylene

Housing O-Ring Material: Buna-N

Housing Pressure Drop (each): 1 PSI at 15 Gallons Per Minute (0.1 bar at 57 LPM

ilter Pressure Drop: <3 PSI @ 6 Gallons Per Minute (<0.2 bar @ 23 LPM

Maximum Recommended low Rate: 6 Gallons Per Minute (23 LPM

Recommended Operating Temp. Range: 40-100˚F (4.4 to 37˚C

Maximum Recommended Pressure: 90 PSI (6.2 bar

Typical Installation:

Note: We recommend that this product be installed by a professional plumber. If you

install this product yourself, please ensure that your installation meets all local building

and plumbing codes. The following instructions are meant only as a general guide and

should not be considered a substitution for your local plumbing and / or building codes.

You will need the following plumbing supplies:

• two (2 shut-off valves with suitable sized unions to connect to your incoming and outgoing

water lines. You can select threaded, compression or sweat (soldered fittings on the shut-

off valves as desired.

• plumber’s cement or Teflon tape for all threaded fittings.

The plumbing connections on the inlet and outlet of the water filter housings are 1” inside

diameter (female NPT threaded fittings. You may require additional plumbing adapters to

connect to your selected shut-off valves. Your plumber will have all of these items, or they can be

purchased at your local hardware or plumbing supply store at minimal cost (take these

instructions to the store with you so the store clerk can make sure you get everything you need .

Note: In older homes with galvanized piping all fittings should be threaded.

STEP 1. Select an installation location. There are a variety of ways to install your filter system

into a main or branch water line. As a general recommendation, this system should be installed

on the main cold water line after the pressure tank or water meter. Select an installation

location with convenient access for regular filter replacements and maintenance.

STEP 2. Shut off the main water supply and drain the pipes. Opening the highest and lowest

fixtures in the house will help drain the pipes.

STEP 3. Using a pipe cutter, cut out a section of your main water line at the point where you

want to install your filter system. There will probably be some water remaining in the system, so

be sure to have a bucket and some rags handy to clean up any small spills. Make sure that the

section of water line you remove is appropriately sized such that all of the components of the

system including the shut-off-valves, adapters, and the black filter caps will fit snuggly when

assembled. If in doubt, cut a smaller section at first – you can always remove a slightly larger

section upon final assembly if necessary.

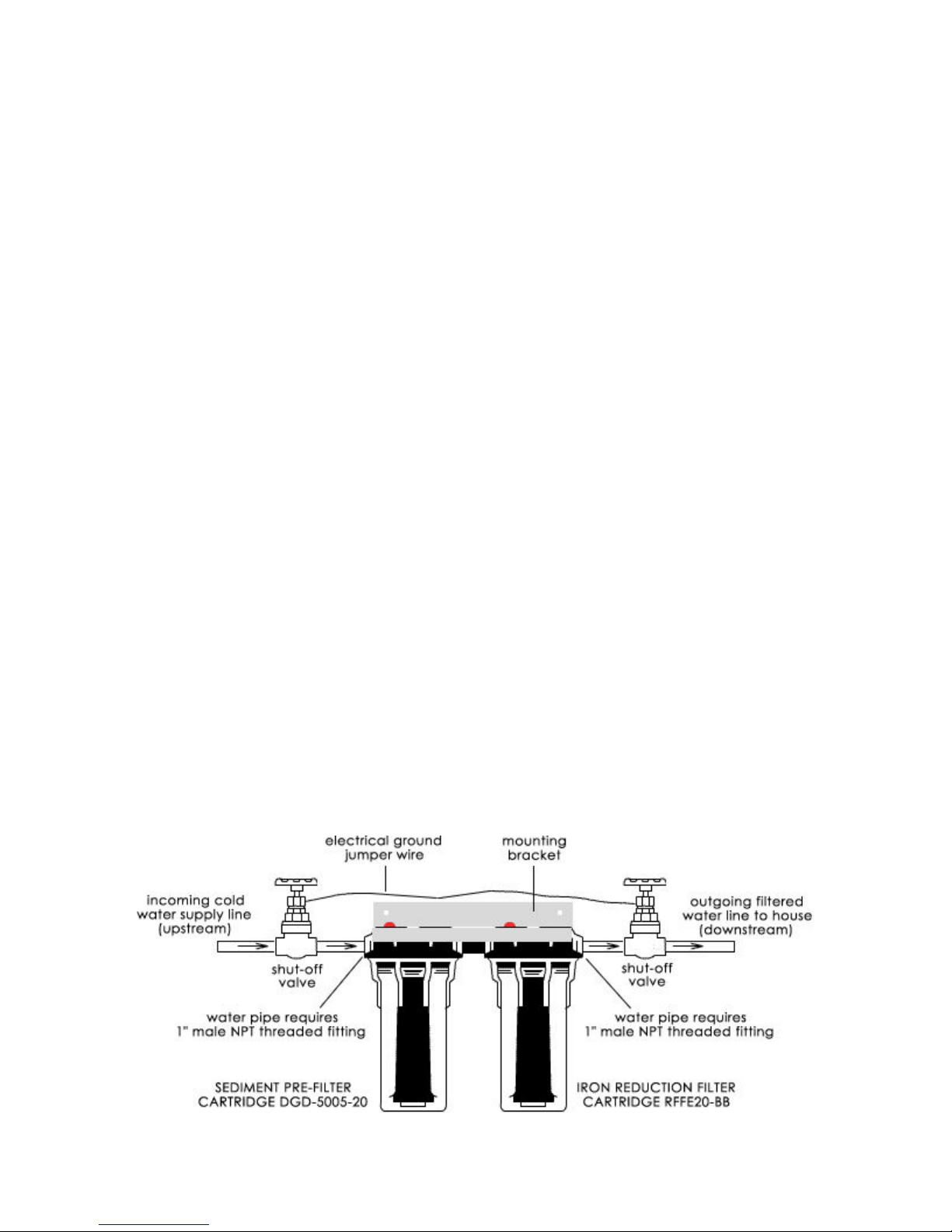

STEP 4. Assemble the components according to Diagram 1 below. Use the 1” housing coupler

provided with this package to connect the 2 black housing caps. We recommend installing shut-

off valves both upstream and downstream of the filter housings. A shut-off valve is not required

on the upstream side of the housing if the filter will be located within a couple of feet of the main

line shut-off valve. Plumber’s cement or Teflon tape should be used on all threaded

fittings. Use the mounting bracket and screws provided so secure the black filter housing caps to

the wall or other solid surface. Allow enough space below the black cap to accommodate the blue

housing sumps plus a minimum of an additional 3 inches of clearance.

IMPORTANT WARNINGS:

Use extreme caution when soldering any connections between the main water line and

the shut-off valve or between the shut-off valves & filter housings if your filter housings

are connected to the pipes, or serious damage to the filter housings could occur. If at

all possible, solder all connections before the pipe is connected to the filter housings.

If your water pipes are metal (galvanized or copper), they may be used to ground

electrical systems, appliances, or your phone line. If this is the case, be sure to install

regulation ground clamps to the metal pipe on each side of the plastic filter housing and

connect a jumper wire between the 2 clamps (#4 gauge solid copper wire

recommended). Alternatively, your plumbing code MAY allow you to connect the

jumper wire to the 2 shut-off valves (see diagram). Consult a certified electrician or

plumber if you are unsure.

Diagram #1

STEP 5. Remove the protective plastic wrap from one of the filter cartridges and place it in the

appropriate blue housing sump. At the bottom of the sump, there is a raised portion in the middle

(standpipe that will help center the filter in the housing. The standpipe will fit inside the hole

that runs through the middle of the filter cartridge. Check to make sure that the O-ring is seated

properly in the grove at the top of the blue housing sump, then screw the blue housing sump

containing the filter cartridge onto the black housing cap. Use the spanner wrench to tighten.

Repeat this step for the other filter. Store any spare filters in a cool dry place for future use.

STEP 6. Turn on the water and inspect all plumbing connections very carefully for leaks. Also

inspect the seal between the black housing caps and the blue housing sumps to ensure that the

O-ring has formed a good seal. Tighten this connections again using the spanner wrench if

necessary. If this connection still leaks, turn off the water supply and check to make sure that the

filter is aligned properly in the housing and repeat your test for leaks. When you are confident

that all connections are sound, run cold water for 5 minutes at any faucet to purge air out of your

system and flush the filter before use. New cartridges may release “fines” (very fine black

powder after installation. Wait one hour, and flush again for another 5 minutes prior to using the

water.

Important Notes:

1. The manufacturer recommends that the blue housing sumps be replaced every 10 years or if

you notice any cracks or damage.

2. This filter system should not be used with water that is microbiologically unsafe or of unknown

quality without adequate disinfection before and/or after the system.

3. Water filter systems should never be exposed to freezing temperatures - severe damage to the

filter and housings could result. Such damage is not covered under any warranty.

4. After prolonged periods of non-use (such as a vacation , it is recommended that the system be

flushed thoroughly for at least 5-10 minutes before using the water.

5. The contaminants or other substances removed or reduced by this water treatment device are

not necessarily in your water.

6. If you suspect that your water pressure will at any time exceed the maximum rating of 90 PSI

(6.2 bar , a pressure regulator must be installed before the system. It is recommended that the

pressure regulator be set at 75 PSI (5.2 bar or less.

Maintenance and ilter Replacement Information:

To maintain the optimal performance of your whole house water filter system, filters should

always be replaced in accordance with manufacturer specifications. Filters may need to be

replaced more frequently then specified, depending on the level of contaminants, particularly

sediments, in your water supply. If significant water pressure reduction is noticed, the filter may

have become clogged. We recommend that you keep a “Filter Replacement Log” attached to your

system where you can record the date of filter changes, and that you write a note on your

household calendar reminding you of filter replacement schedules.

Replacement ilters: Pentek R E20-BB & Pentek DGD-5005-20

Replacement ilters can be Obtained as ollows:

Phone Toll Free 1-866-376-2690 or

Order Online at: www.home-water-purifiers-and-filters.com

ilter Cartridge Replacement Procedure:

1. Turn off the water supply to the system using the shut-off valves you installed on the inlet

and outlet of the filter housing. Depress the red pressure release button on the top of the

filter housing cap to allow any pressure inside the housing to escape, thereby allowing the

blue filter sump to be removed easier.

2. Unscrew the blue sump (bottom of the housing from the cap using your spanner wrench

(included with original purchase of your system .

3. Locate and remove the large O-ring. Try not to remove any of the lubricant. The housing

O-ring should be replaced at least once annually or at each filter change if any damage to

the O-ring is noted (kinked, cracked, stretched, etc. , or if any leakage between the black

housing cap and the blue housing sump is detected and does not seal after tightened with

the spanner wrench. Put the O-ring in a safe place where it will not get dirty or otherwise

contaminated. Replacement O-Ring: Pentek Buna-N Big Blue O-Ring #151122

4. Take out the old filter cartridge and discard it.

5. Scrub the bottom of the housing and cap with dish soap and warm water using a sponge or

soft cloth. Fill 1/3 with water and add about 2 tablespoons of household bleach. Scrub to

disinfect (we recommend that you use rubber gloves . Rinse all parts thoroughly!

6. Lubricate the O-ring with food-grade silicon lubricant if needed. Insert O-ring in the

groove at the top of the blue sump and press into place. Make sure the O-ring is

seated level in the groove!

7. Remove the protective plastic wrapping from the new filter cartridge and insert the

cartridge into the housing sump, making sure that it slips over the standpipe in the bottom

of the housing.

8. Screw the blue sump onto the black housing cap tighten using the spanner wrench. Do

not over tighten.

9. Turn on the water supply slowly to allow the system to fill with water. Depress the red

pressure release button on top of the unit again to release any trapped air. Inspect

carefully for leaks. If a leak is found, first inspect the O-ring to ensure that it is seated

properly before tightening the sump more. Tighten using the spanner wrench as necessary

to achieve a good seal and stop leaks.

10. New cartridges may contain “fines” (very fine black powder after installation. Flush the

system by running water from a nearby faucet for 5 minutes. Wait one hour, and flush

again for another 5 minutes prior to using the water.

Table of contents

Other ClearPlus Water Filtration System manuals