CLEOPATRA Sedna Line Quick start guide

Steam Baths Professional

Sedna Line

A. 90548801 R01

2008/05

lnstallan and use

EN

Contents

For the installer:

For the user:

Section Page

Pos Article Description

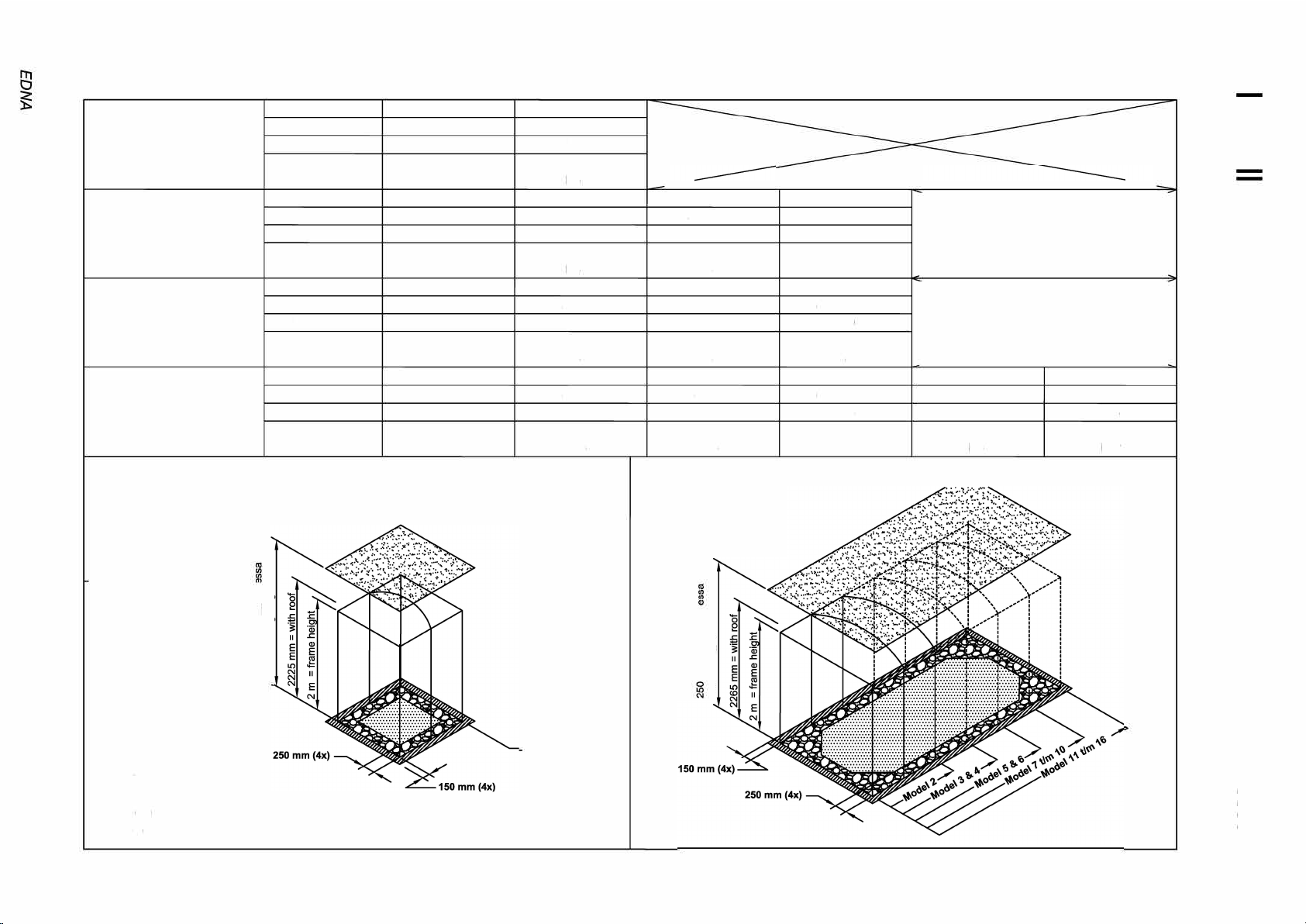

MODEL 1

MODEL 2

MODEL 3

MODEL 4

MODEL 5

MODEL 6

MODEL 7

MODEL 8

MODEL 9

MODEL 10

MODEL 11

MODEL 12

MODEL 13

MODEL 14

MODEL 15

MODEL 16

119337800 Corner element left 0 0 1 1 1 1 1 1 1 2 1 1 1 1 2 2

219337700 Corner element right 0 0 1 1 1 1 1 1 1 2 1 1 1 1 2 2

319338000 Seat element 1500mm 1 2 0 0 0 1 2 2 2 0 3 2 2 2 0 0

419337900 Seat element 750mm 0 0 0 1 2 1 0 1 1 0 1 2 3 3 2 2

519591000 Roof element Sloping 1500 x 750 2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

619509500 Roof element Sloping 2250 x 750 0 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

719509600 Roof element Concave 2250 x 750 0 0 1 1 2 2 3 3 3 3 4 4 4 4 4 4

830522610 Roof element with ventilating unit 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2

919576980 Frame Wall 6 8 10 10 12 12 14 14 14 14 16 16 16 16 16 16

10 19590480 Frame wall rarrow (with 1m door) 2 2 2 2 2 2 2 2 2 x x x

11 19576880 Frame seat element

12 19577980 Steam module with frame 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

13 Reducer ventilating unit 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2

14 19578210 Wall panel 12 14 15 14 17 16 19 18 18 17 20 21 20 24 18 18

15 19578220 Wall panel steam module 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

16 19337310 Corner glass plate 0 0 2 2 2 2 2 2 2 4 2 2 2 2 4 4

17 19579810 Steam glass plate 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

18 30949610 Wall fastening 4 4 12 12 12 12 12 12 12 20 12 12 12 12 20 20

19 19578680 Corner piece 35x35 0 0 12 6 12 6 12 6 6 12 6 12 6 6 12 12

20 19578780 Corner piece 35x57 6 6 0 3 0 3 0 3 3 0 3 0 3 3 0 0

21 19578880 Corner piece 57x35 6 6 0 3 0 3 0 3 3 0 3 0 3 3 0 0

22 90080682 Hexagonal socket bolt M8x12 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

23 90003780 Hexagonal tap bolt M8x30 50 50 70 70 90 90 110 110 110 110 130 130 130 130 130 130

24 19590800 Shims 1mm thick 5 5 10 10 15 15 15 20 20 20 20 20 20 20 20 20

25 19590900 Shims 3mm thick 5 5 10 10 15 15 15 20 20 20 20 20 20 20 20 20

26 90054082 Hexagonal nut M8 50 50 70 70 90 90 110 110 110 110 130 130 130 130 130 130

27 90056180 Bodywork ring M8 100 100 140 140 180 180 220 220 220 220 260 260 260 260 260 260

28 90040680 Coach screw 8 x 50 18 18 22 22 26 26 30 30 30 30 34 34 34 34 34 34

29 90014502 Plug D10 x 50 18 18 22 22 26 26 30 30 30 30 34 34 34 34 34 34

30 52860038 Polymer cement 3 6 7 7 9 9 10 10 10 10 12 12 12 12 12 12

31

32 90019210 Drill point screw D3.9 x 25 185 185 210 210 235 235 260 260 260 260 285 285 285 285 285 285

33 90011580 Drill point screw with hexagonal head D4.2 x 25 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

34 30930210 Door (M1) Left 750mm 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

35 30930211 Door (M1) Right 750mm 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

36 Door (M1) Left 1000mm 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

37 Door (M1) Right 1000mm 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

38 19578310 Top bar 750mm 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

39 19578320 Top bar 1000mm 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

40 30955700 Handle complete 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 Scope of delive

ACRYLIC

3

1

8

FMES

®

STEAM INLET

MFDU

WALL PANELS

2

1 Scope of delive

GLASS PLATE

17

\

CORNER ASSEMBLY

19

20

21

0

ASSEMBLY MATERIAL

22

21 �

© '

29

®

DOOR

®@

ten/ 1ooom

3

1 Scope of delive

40

$

I

@

DOOR

0 0

.

$

I

@

.

4

2 Installation dimensions

•

*minimum required fitting space

�

Vmln

f

�

f

r :

5

0

0

GROUP1

GROUP2

GROUP3

GROUP4

Model 1

"

E

II�

0

0

3 3

2 2

2 2

3 3

2 2

2 2

3 3

2 2

2 2

3 3

2 2

2 2

Model 1

3 3

2 2

2 2

3 3

2 2

2 2

3 3

2 2

2 2

Model 2 m 16

�

0

-

3 3

2 2

2 2

0

-·

3

0

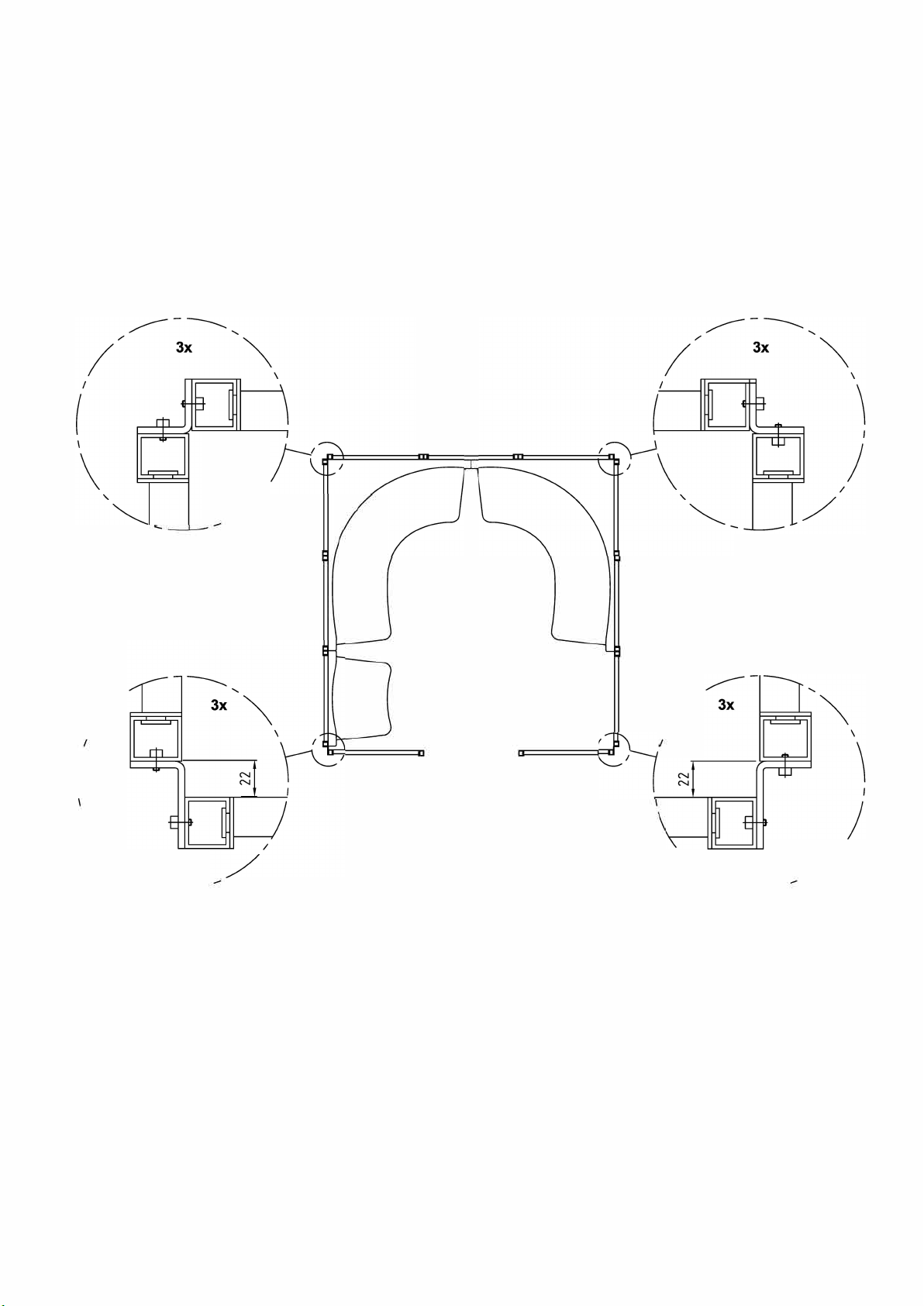

3 Basis

3.1 U-setup for the frames

Figure 1

-

Detail C

I

I

I

'

'

(

�

Side A

I

(

\

Side B

A-side B-side

3 Basis

3.1 U-setup for the frames

Corner pieces

(Cabin model 4 serves as example)

I

(

'

/

�

I

/

Corner piece 35x35

Corner piece 35x57 with

threaded hole on short side

/

I

'

Corner piece 35x35

I

� /

Corner piece 35x57 with

threaded hole on long side

2) Where frame parts are joined to each other with a corner piece care must be taken with the choice of corner piece.

This depends on the situation (fig.2). Details and show the situation at a corner seat In all other situations corner

pieces are used as shown in detail F and G.

Exceptions are models 3, 5, 7 and 12. Here the situation in all corners is the same as detail D and E.

The assembly of the corner pieces takes place with the same hexagon socket bolts M8x12 with which the frames are

connected to each other.

8

3 Basis

3.1 U-setup for the frames

Figure 3a

Figure 4

0

Figure 3b

Figure 3c

3)

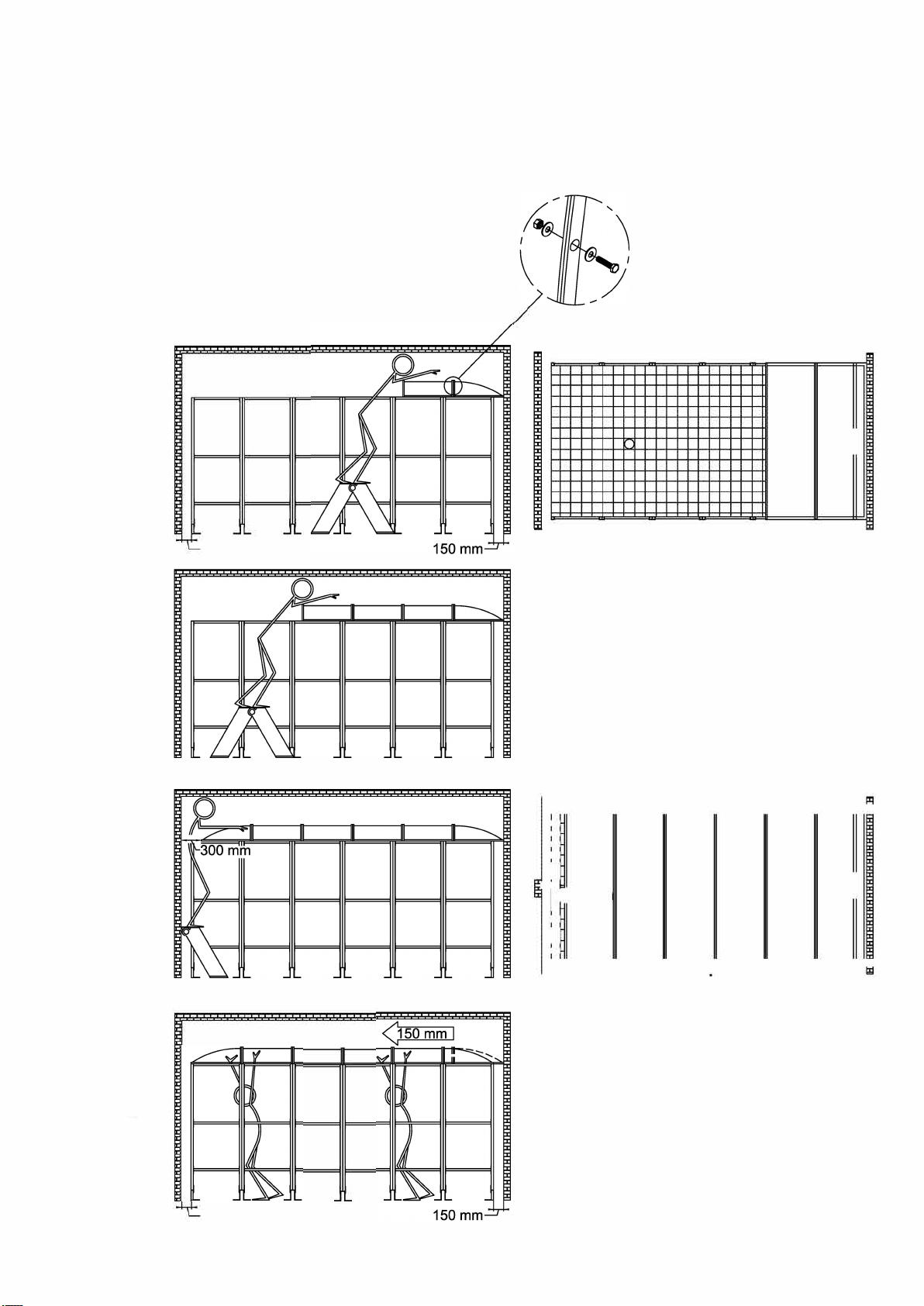

3 Basis

3.2 Aligning the U-setup

Figure 1

Aligning

Detail A

Fixing to the floor

(Cabin model 4 serves as example)

4)

5)

D

Chalk line

Check whether distances B, C and D are equal to distance A (fig. 1 ). The most accurate way is not to measure this

distance between the adjustable legs but between the bottoms of the frames (approx. 12 cm above floor level).

If necessary temporarily fix this distance with a wooden slat fixed to the frame using glueing clamps.

Now measure both diagonals E/F (approx. 12 cm above floor level). These must be equal (walls are then perpendicular

to each other).

Check the frame both horizontally and vertically with a long (min. 1 m) spirit level as described. If necessary adjust the

adjustable legs.

When the frame is aligned the legs can be screwed tight to the floor (detail A). To do this use a 10 mm bit to drill through

the holes in the legs through to the floor.

Note: there may be no undeloor heating in the area to be drilled!

Fit the plugs (diameter 1 0x50) and screw the legs tight to the floor with the coach bolt 8x50.

If the floor cannot be drilled into, the frame can be adhered to the floor with polymer cement.

Make sure that the frame parts are correctly positioned and that they cannot move during the drying time of at least 8

hours.

Use glueing clamps or other means to temporarily fix the frame as necessary.

With large cabins it is advisable when fitting the roof elements to use the slats and glueing clamps mentioned in point 4

to prevent the parallel sides of the U-setup from moving out of line while fitting the roof elements.

10

3 Basis

3.3 Connecting the roof elements to each other

Figure 1

I

I

I

'

Detail A

I

I

J

1)

2)

3)

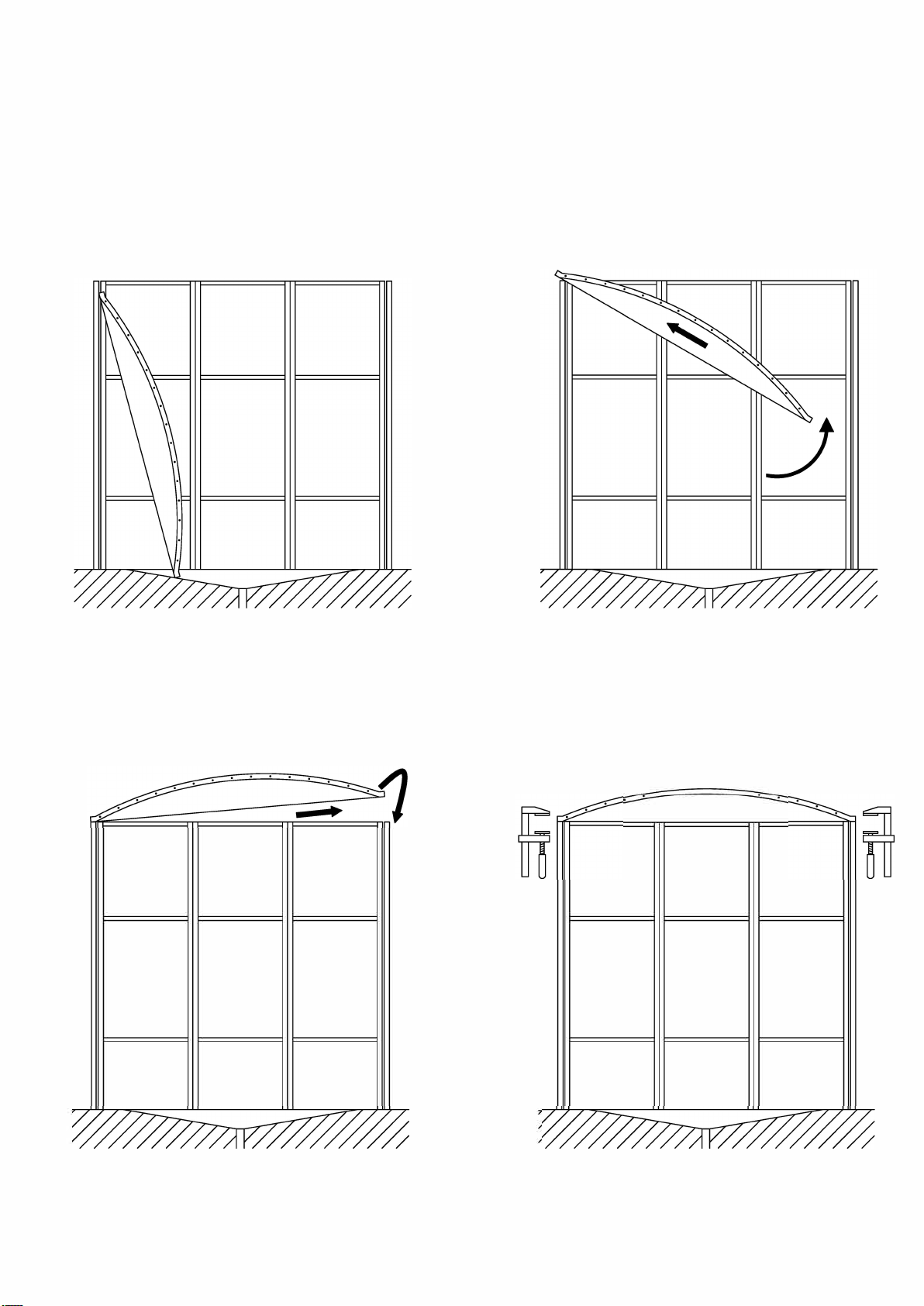

3 Basis

3.4.1 Fitting the roof on the U-setup

Figure 1

Staing position

Step 2.

Step 1.

. . . . .

Step 3.

3 Basis

3.4.2 Fitting te roof on the U-setup

Alternative method

Figure 2

======

-

l -

:

-

======

3 Basis

3.5 Fitting M1 door

\

Figure 1 Figure 2

Detail A

-

E

E

Detail B

Figure 3

1)

14

3 Basis

3.5 Fitting M1 door

Figure 4

Top view

Cabin model 1

Figure 5

Detail C

Detail D

\

' -Self-tapping screw

� /

-

Detail E

3)

Note! To prevent damage to casing and hinges the assembly of a door stopper is required. This is not

included in the delivery.

3 Basis

3.6 Finishing the roof

Figure 1

Figure 2

to outside air

-

Figure 3

1)

2)

3)

3 Basis

3.7 Assembly of bar with steam inlet

Figure 1

Figure 2

1)

2)

3)

4)

5)

6)

4 Seat elements

Figure 1

Figure 2

Detail A

'

10-20mm

Figure 3

1)

2)

3)

4)

5)

6)

18

Table of contents

Other CLEOPATRA Bathtub manuals

Popular Bathtub manuals by other brands

Kohler

Kohler Freewill K-12105-H installation instructions

Artweger

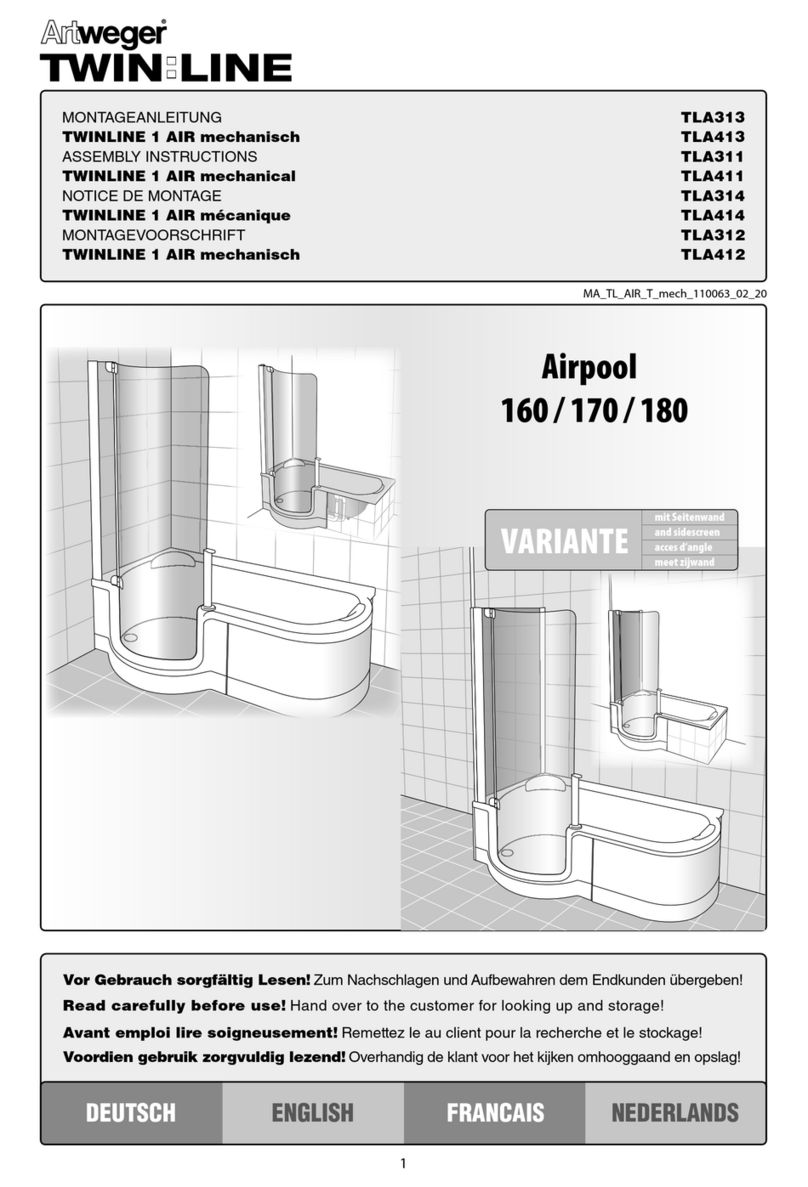

Artweger TWINLINE 1 AIR mechanical manual

American Standard

American Standard Cadet Whirlpool/Bathing Pool 2772.XXXW installation instructions

GALA

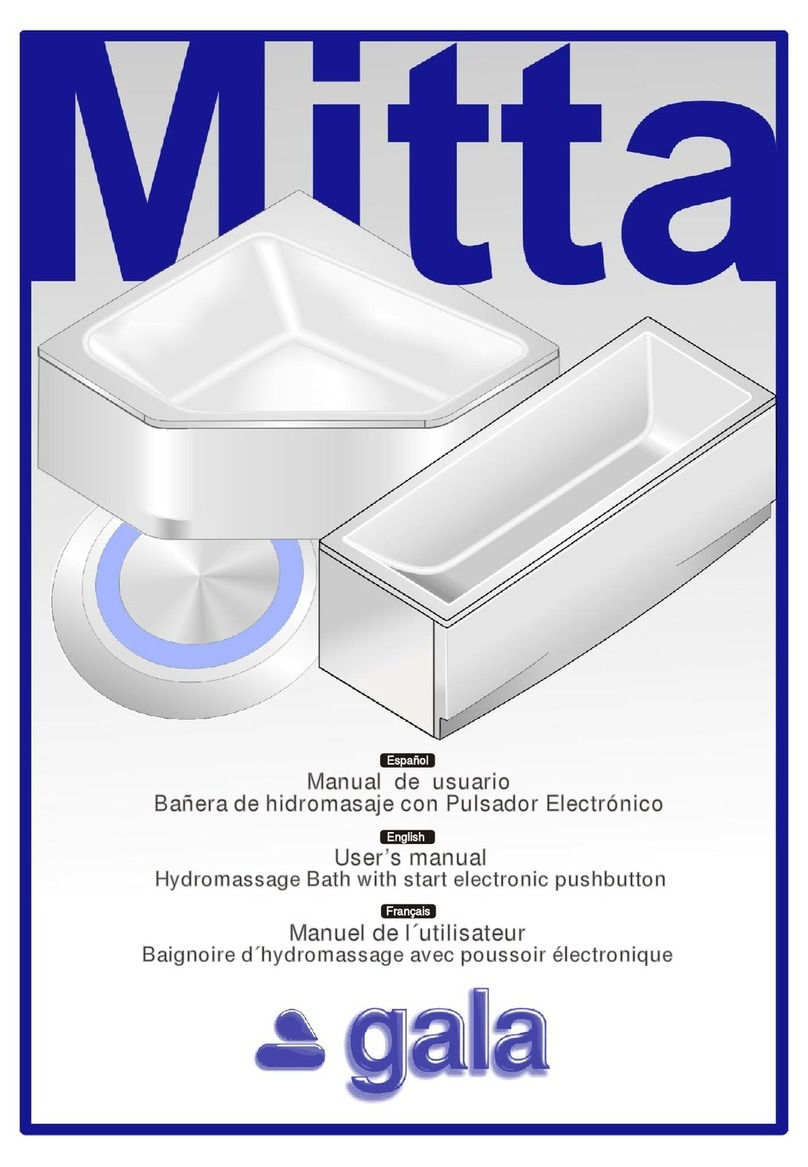

GALA mitta user manual

Kohler

Kohler K-1457-G Roughing-In Guide

Jacuzzi

Jacuzzi Arga Preinstallation manual

Jacuzzi

Jacuzzi ARGA 175x85 Instructions for preinstallation

Jacuzzi

Jacuzzi Stella Installation and operation instructions

Kohler

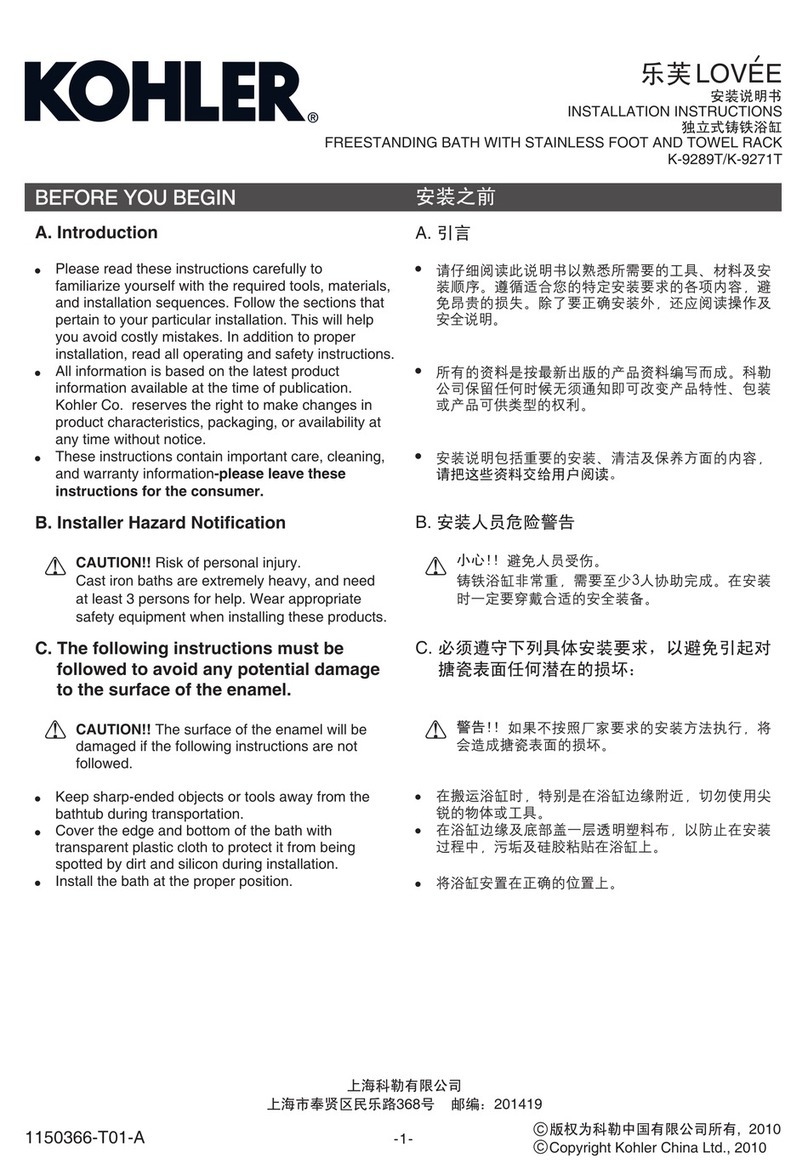

Kohler LOVEE K-9289T installation instructions

Casabath

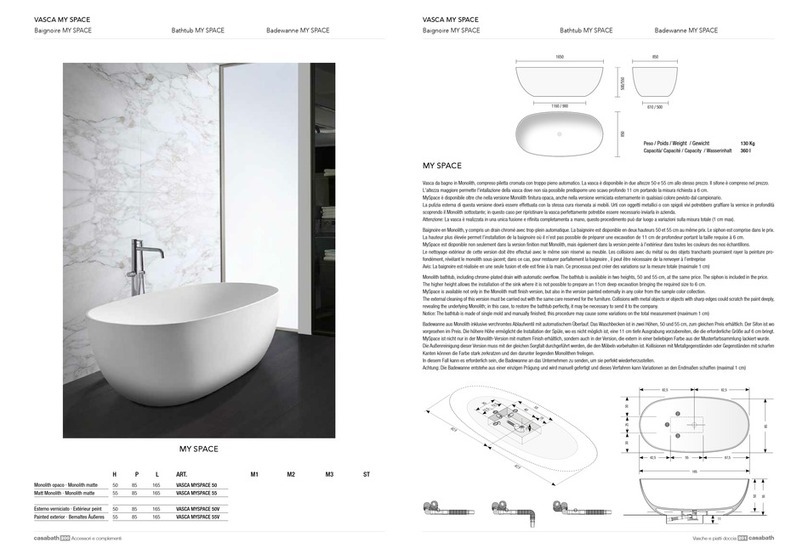

Casabath MY SPACE installation instructions

Porcelanosa

Porcelanosa KRION PURE installation guide

GoodHome

GoodHome 5059340060095 manual