Cleveland

™

Project ________________________________

Item __________________________________

Quantity _______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COO CHILL SYSTEMS Cook/Chill S stems

SECT. XIV PAGE 29

0907

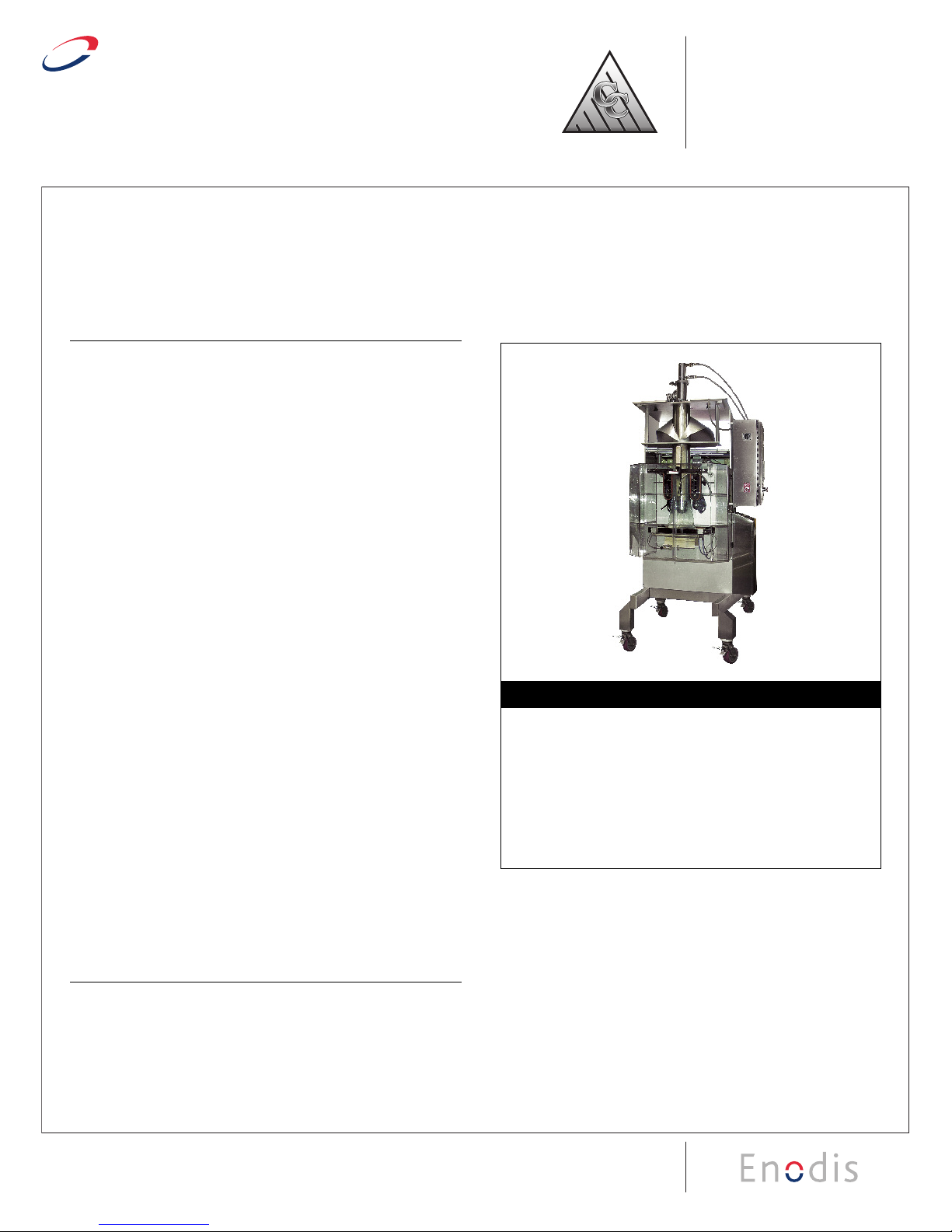

CYCLE-MATIC

VERTICAL FORM-FILL-SEAL MACHINE

MODEL:

AFF-1150

Cleveland Standard Features

I

Small footprint compact mobile design mounted on 5" lock-

ing casters

I

Fill speeds of up to 30 cycles per minute (speeds depend on

pouch size and length)

I

User friendly menu driven multi color touch screen controls

for selecting:

•

Pouch length

•

Film speed

•

Pouch count

•

Time and temperature heat-seal functions

•

Manual and automatic fill operation

•

Jog for film transport

•

Fill cycle start

•

Operation of the food transfer pump (AFF-1150-FTP)

I

Main power on/off switch with emergency safety stop

I

Standard pouch width of 11 1/2 inches with a selectable

pouch length of up to 30"

I

Feature to make a continuous tube for ease of cleaning

I

Base frame shafts and bearings are constructed of stainless

steel

I

Stainless steel teflon coated heating bars

I

Mechanically operated horizontal jaws

I

Pneumatically operated knife

I

Durable hinged Lexan safety guards with cut off safety

switches

I

Motorized film unwinding to eleminate drag and minimize belt

wearing

I

Air controlled dispensing valve with a drip proof seal

I

Factory mounted air regulator filter and lubricator

IAccepted for use in U.S.D.A. Inspected Facilities

Options & Accessories

ËFood transfer pump (AFF-1150-FTP) (required to operate

Cycle-Matic)

ËExiting conveyor for pouches (AFF-1150-EC)

ËIn-line thermal transfer printer (AFF-1150-TTP)

ËFilm transfer/loading cart (AFF-1150-FTC)

Ë3” diameter food transfer hoses (specify 3 6 or 9 foot long)

Shall be CLEVELAND Mo el AFF-1150 Cycle-Matic, VERTICAL

FORM-FILL-SEAL MACHINE; small footprint, compact, mobile

esign; Fill spee s of up to 30 cycles per minute; User frien ly, menu

riven, multi color touch screen controls; Stan ar pouch wi th of 9.5

inches with a selectable pouch length of up to 30"; Base frame, shafts,

bearings an heating bars are constructe of stainless steel; Stainless

steel serrate cutting knife; Hinge Lexan safety guar s with cut off

safety switches; Motorize film unwin ing; Air controlle ispensing

valve with a rip proof seal.

Short Form Specifications