Click RevoFit2 User manual

(MDD) - 93/42/EEC

harmonized & notified body

Click Medical, LLC

1205 Hilltop Parkway

Warehouse 101

Steamboat Springs, CO, USA

(970) 670-7012

RevoFit2™

Lamination Kit

PK2000-320-05

REF PK001

Advisory:

Do not use on patients with neuropathy, neuromas, or other nerve issues.

Fabrication only by a certied professional, trained in the RevoFit™ system.

Filament will wear, inspect and replace regularly.

Consultatif:

Ne pas utiliser chez les patients atteints de neuropathie, de névrome ou d'autres problèmes

nerveux. Fabrication uniquement par un professionnel certié, formé au système RevoFit. Le

lament sera porté, inspecté et remplacé régulièrement.

Beratend:

Nicht bei Patienten mit Neuropathie, Neuromen oder anderen Nervenproblemen anwenden.

Fertigung nur durch einen zertizierten Fachmann, der im RevoFit System geschult wurde.

Filament wird regelmäßig getragen, kontrolliert und ersetzt.

Consultivo:

No lo use en pacientes con neuropatía, neuromas u otros problemas nerviosos.

Fabricación solo por un profesional certicado, entrenado en el sistema RevoFit.

El lamento se desgastará, inspeccionará y reemplazará regularmente.

US PATENT# 8443501

WE ARE HERE TO HELP!

Tech Support: 970 670 7012

ClickMedical.co/RevoSupport

Help@clickmedical.co

RevoFit2™Lamination Kit Contents:

Recommended Designs:

T6

6ft RevoFit Tubing 7ft Lace

Lace Tool

RevoFit2

Lamination Dummy

High Power

Boa Dial

Below Knee:

3 Panel Design

or Symes Door

Above Knee:

2 System with

Medial/Lateral Panels +

Adjustable Strap

Recommended

Suspension System:

RevoLock™ Lanyard Kit

PN:3000-220-05

Patient Replacement

Lace Pack

+Additional Kit Required

Accedents happen, WE GET IT!

For any warranty or product failure please do not return to distributor,

simply contact CLICK MEDICAL DIRECTLY AT:

Help@ClickMedical.co Help Line: 970 670 7012

WARRANTY:

Design Overview:

Fabrication Overview:

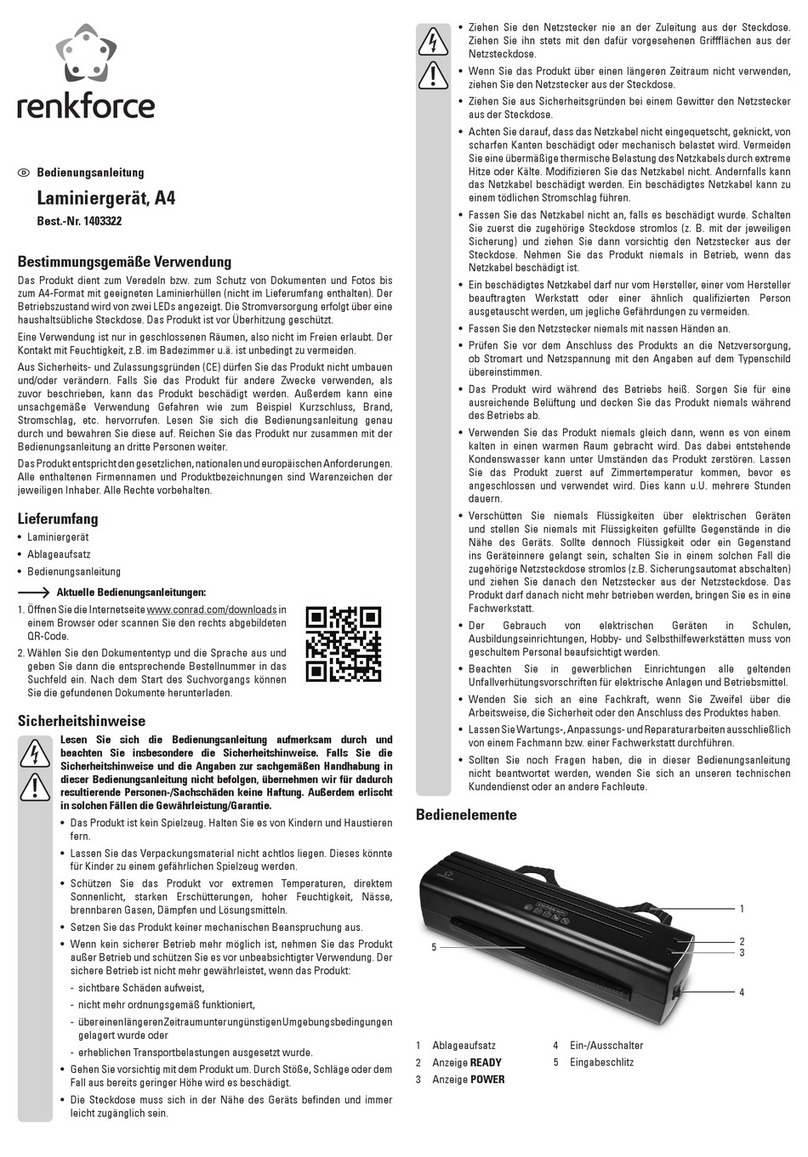

On frame

On panel

1

3

2

1

3

56

2

Determine location of panels or areas

of adjustment

Determine lace routing

For Inline Routing - Use port II and III For Remote Routing - Use port I and II

Inline - mounted on panel

Remote - mounted on socket frame

Inline - mounted on socket frame

Determine location of reel

Glue on RevoFit

Components Laminate

Cut Out

Windows

4

Install +

Shape Pads

Lace

Socket

Install

Reel +

Tune Pads

Lamination Instructions:

Prep the mold with a thin rst lamination layer:

Reinforce areas under the tubing and under

the panel cutout areas.

1a. Roughly sand socket.

b. Draw in trim lines.

c. Determine reel, panel and lace path location.

d. Roughly draw in lace path.

2

Draw tube guide lines:

3Reel mounting:

If mounting reel on frame, glue it into place now.

If mounting reel on panel refer to Step 3 before gluing.

4

Panel mount option:

Use port 2 and 3

Frame mount option:

Use port 1 and 2

Perpendicular crossings

1” or 2cm

Diameter:

1.25” or 3cm

Note: Indicate position of lace path

a. Ensure that lace path crosses all panels with the ¼spacing rule.

b. Ensure tubing crosses panels perpendicularly.

c. Don’t turn tubing until 1cm past any panel edge.

Do not kink tubing

1/2

1/4 1/41/41/4

Laminate again:

7

Glue on tubing:

5Trim one tube, pack with clay, insert into bayonet:

c. Insert Tube

Make sure tubing is

inserted

2cm into silicone.

6

b. Pack Clay

Cut otabs for lamination

a. Cut at an angle so tube

pierces into the silicone easily. Glue dots

NOTE: Take picture of socket for reference after second lamination.

HINT: Use photo from step 6 above.

a. Glue on tubing according to lace pattern.

b. Cut second end of tubing to length,

plug and insert second end into bayonet.

Do not displace tubing or

reel housing while laminating

Insert free end of tube.

Make sure tubing is

inserted 2cm into

silicone.

Mark with a pen the location of the panels to cut out:

8

Note of location of

the inner for the

future pilot hole

Lamination Instructions Continued:

Cut out the panels:

9

Sand edges

Clear tube holes

Prepare housing:

10

Finish sanding exit

holes by hand until extra smooth

1. Trim tube ends

to edge of housing

2. Clear all debris

Grind ush with top of reel housing.

Take care to not damage reel housing.

Use small end of blade for round corners

Scalloped blade

Drill pilot hole to access tab for reel removal:

11

Locate inner for

pilot hole.

Drill through

lamination at an

angle creating a

tunnel to access the

pilot hole & release

tab (2mm drill bit).

Test and clear hole

before installing

dial.

Fabricate and install pads:

12

Pad thickness, material and shape

are used to rene pressure and t.

Pad Material: Pads should be

dense enough to create pressure

and not compress under tension.

Pad Thickness: Average 3/16”

(4.75mm) Push shore: 35

Slight convex

shape allows

for better

application of

pressure.

Convex pad Skive edges

Panel

INCORRECT - Pad too thin when panel is ush with socket

CORRECT - Pad is the correct thickness when panel sits above socket when t is snug to patient

Good Closure Force

Weak Closure Force

5-10mm

Frame

Critical distance

Pad

Panel

Frame Pad

Panel

1cm

13 Attach lace to reel:

12

14

Feeder

Lace

Insert reel into socket - turn counter-clockwise to lock:

15

Wind up and test

Pull panel out to keep lace

from becoming pinched in the reel

Pilot hole

Insert laces into smallest end of pass through on

spool. Tie double overhand knots on each end.

Leave 8cm of lace

on both ends

8 cm

Feed lace:

How to remove dial:

Locate tab (see above)

Lock on to housing of dial with needle nose vise grips. Rotate clockwise to remove

Tab location:

Finished!

Push towards center of reel

1/4 turn - Turn the

housing not the dial itself

Pull dial to open

Inline

Depending on the location,

either at 4 o’clock or 11o’clock. Always at 8:30.

Remote

- Fit patient

- Tune in t, by rening pad shape... if necessary.

- Provide IFU's and replacement lace pack to patient

a. Open dial

b. Use tool to press inward on tab

c. Simultaneously turn housing clockwise

If you inserted the reel PRIOR to drilling an access hole use vise grip

instructions below. Once dial is removed, drill pilot hole.

Lamination Instructions Continued:

PEL, LLC

ph: 800-321-1264

www.pelservice.com

Distributed by:

Table of contents