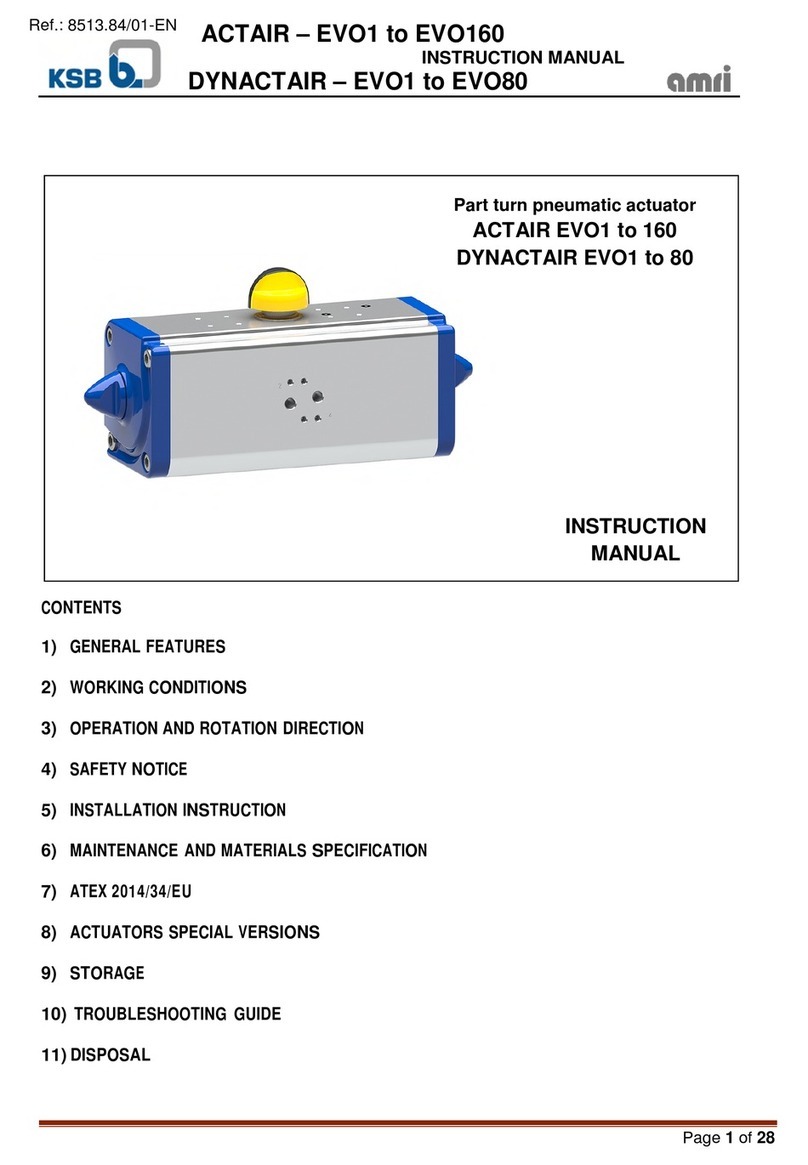

Climate Control DXM2.5 Installation guide

DXM2.5 Controls

DXM2.5 Digital

Heat Pump

Controller

Application, Operation

& Maintenance

97B0142N01

Created: October 18, 2022

Table of Contents

Overview 3

Legend and Glossary of Abbreviations 4

Layout and Connections 5

Physical Dimensions and Layout 6

DXM2.5 Controls 7

- Field Selectable Inputs 7

- Dip Switches 7

- Safety Features 9

- Fault Codes 9

- Unit Operation Descriptions 12

- Special DXM2.5 Application Notes/

Accessory Relays 15

- Other Outputs 18

Basic Troubleshooting Information/

Service & Application Notes 20

Conguration and Advanced

Troubleshooting Information 21

- General 21

- System Conguration 21

- Service Mode 22

- DXM2.5 Master/Slave Addressing 22

Functional Troubleshooting Flow Chart 23

Functional Troubleshooting 24

Performance Troubleshooting 27

Revision History 32

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

2

This Page Intentionally Left Blank

3

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Overview

The DXM2.5 electronic control is a robust, microprocessor

based heat pump controller that is advanced and feature-

laden for maximum application exibility. The DXM2.5

Control has relay outputs for Compressor, Compressor

Speed, Reversing Valve, Alarm Relay, and 2 congurable

relays for Fan, Fan Speed, HWG Pump, and Loop Pump,

and 2 congurable accessory relay outputs. The DXM2.5

can directly communicate and control a Constant Volume

(CV) ECM blower, internal variable speed water pump,

and modulating water valves. For on board diagnostics,

there are 2 LED’s to provide status indication.

There are inputs for safety pressure switches, low

temperature protection thermistors, condensate overow

sensor, DIP switch selection inputs, thermostat inputs,

night setback inputs, and emergency shutdown input.

Additional congurable temperature sensor inputs are

available that may be used for hot water, compressor

discharge, leaving air, leaving water, and entering water

temperature sensors (except for TRL and Water to Water

products, see product line submittals for details).

The DXM2.5 has an RS485 communications port to

interface with a communicating thermostat or other

communicating controls and tools.

General Operating Parameters: The following are

general operating parameters for the DXM2.5 Control:

• Operating Environment: -40°F to 176°F and up to

95% relative humidity, non-condensing.

• Storage Environment: -40°F to 185°F and up to 95%

relative humidity, non-condensing.

Power Requirements: DXM2.5 only power draw:

• Normally 8 VA draw at 24VAC

• Maximum 12 VA draw at 24VAC. A dedicated

24VAC, 50-60Hz, 1Ph, 40VA transformer minimum is

required for typical WSHP application.

Relay and Connection Contact Ratings: The following

relays are mounted on the DXM2.5 Control:

Compressor Relay: 40VA at 24VAC

• Compressor Speed Relay: 28VA at 24VAC

• Alarm Relay: 28VA at 24VAC

• Reversing Valve: 28VA at 24VAC

• Accessory Relay 1: 28VA at 24VAC

• Accessory Relay 2: 28VA at 24VAC

• Fan Enable / Loop Pump Relay: 1 HP at 240VAC

• Fan Speed / HWG Pump Relay: 1 HP at 240VAC

• Connection ratings on the DXM2.5 Control:

• ‘A’ terminal: 20VA at 24VAC. Larger solenoid valve

draw should be controlled with accessory relays.

Grounding: The control board must be grounded from

one of the C terminals.

Basic Control Features:

• Single or two–stage compressor control

• Anti-short cycle protection

• High pressure cut-out

• Loss of charge cut-out

• Over and under voltage cut-outs

• Water coil low temperature cut-out

• Air coil low temperature cut-out

• Random start

• Status LED and Fault LED

• Reset lockout at unit or disconnect

• Condensate overow sensor

• Intelligent fault retry

• Test Mode

• Multiple blower conguration options

• Electric heat outputs

• Accessory water valve connection

Advanced Control Features:

• Direct control of ECM blower

• Intelligent hot water generator control

• Two accessory relays congurable for multiple

applications

• Variable speed water pump output

• Modulating water valve output

• Night setback with override capability

• Emergency shutdown capability

• Removable thermostat connector for ease of

installation and service

• Accepts conventional heat pump (Y,O) or heat/cool

(Y,W) thermostat types

• RS–485 port to interface with a communicating

thermostat or other communicating controls and tools

• Boilerless electric heat

• Congurable inputs and outputs for advanced functions

• Stores operating conditions history during last 5 faults

and offers possible reasons for faults

• Master/Slave thermostat control of up to 3 units

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

4

Legend and Glossary of Abbreviations

Abbreviations Descriptions

BTUH BTU (British Thermal Unit) per hour

CDT Compressor discharge temperature

CFM Airow, cubic feet per minute

COP Coefcient of performance = BTUH output/BTUH input

CT ECM Electronic commutated constant torque fan motor

CV ECM Electronic commutated constant volume fan motor

DB Dry bulb temperature, °F

EAT Entering air temperature

EER Energy efcient ratio = BTUH output/Watt input

ESP External static pressure, inches w.g.

EWT Entering water temperature

FPT Female pipe thread

GPM Water ow in U.S., gallons per minute

HC Air heating capacity, BTUH

HE Total heat of extraction, BTUH

HR Total heat of rejection, BTUH

HWC Hot water generator (desuperheater) capacity, Mbtuh

KW Total power unit input, kilowatts

LAT Leaving air temperature, °F

LC Latent cooling capacity, BTUH

LOC Loss of charge

LW T Leaving water temperature, °F

MBTUH 1,000 BTU per hour

MPT Male pipe thread

MWV Motorized water valve

PSC Permanent split capacitor

SC Sensible cooling capacity, BTUH

S/T Sensible to total cooling ratio

TC Total cooling capacity, BTUH

TD or delta T Temperature differential

VFD Variable frequency drive

WB Wet bulb temperature, °F

WPD Waterside pressure drop, psi or feet of head

WSE Waterside economizer

5

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

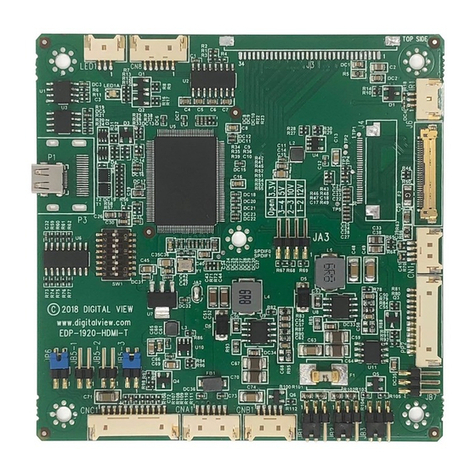

Layout and Connections

Communicating

Stat Connection

Relays for PSC Blower, CT

ECM Blower, Water Pump,

Hot Water Pump, and

Hot Water Generator

Service Tool

Connection

Conventional

Stat Connection

Communications

and HWG Settings

Accessory relays

refer to DXM2.5 AOM

for conguration

Test Button

to Speed up

Time Delays

Communicating

CV ECM Blower

Connection

Water Coil Low

Temp Limit Setting

JW3-LT1 jumper should

be clipped for low temp

(antifreeze) operation

Factory Low Voltage

Molex Connection

for Unit Harness

Electric Heat

Connection

Use 4 Mounting

Screws – #6 Sheet

Metal Screw 1” Long

24V to Compressor

Second-stage Solenoid

for Y2/Full Load Capacity

VFD or PWM CV ECM Blower

Modulating Valve or

Variable Speed Water Pump

Entering Water Temp

Leaving Water Temp

Leaving Air Temp

Entering Hot Water

Temperature

Compressor Discharge

Temperatrure

Congure Modulating

Valve or Variable

Speed Water Pump

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

6

Physical Dimensions and Layout

P1

Alarm

Relay

Comp

Relay

O

Y1

Y2

W

G

C

R

AL1

24Vdc

EH1

EH2

P6

R

C

Off On

JW3

A

OVR

ESD

C

R

NSB

AL2

JW1

Acc1

Relay

Acc2

Relay

H

COM

NC1

NO1

COM

NC2

NO2

P3

CO

RV

RV

LT1

LT1

LT2

LT2

LP

LP

HP

HP

P7

Status

Fault

R

R

CC

CCG

CO

S1

S2

1

12

1

4

Factory Use

(240Vac)

Com

N.O.

Fan Enable

5 1/2"

7" 6 1/2"

5"

Use 4 mounting screws

#6 sheet metal screw 1” long

1.5

3/8” standoff

Factory low

voltage Molex

connection for

unit harness

Factory low

voltage Molex

connection for

electric heat

harness

Micro

U1

Off On

P2

COH

COM

AO2

P11

Gnd T1

P10

T2 T2 T3 T3 T4 T4 T5

P9

T5

T6 T6

A0-1 A0-2

Off On

S3

RV

Relay

CCH

Relay

Test

P5

B-

Gnd

P4

A+ 24V

(240Vac)

Fan Speed

N.O.

N.C.

12V

OUT

Gnd

P8

IN

NC

P12

Note: There is only

one T1 connection

1 2 3 4

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

AO1

Gnd

1

7

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

FIELD SELECTABLE INPUTS

Test Mode: Test mode allows the service technician to

check the operation of the control in a timely manner.

By momentarily pressing the TEST pushbutton, the

DXM2.5 control enters a 20 minute test mode period

in which all time delays are sped up 15 times. Upon

entering test mode, the Status and Fault LED displays

will change. The Status LED will either ash rapidly

to indicate the control is in the test mode, or display a

numeric ash code representing the current airow if an

ECM blower is connected and operating. The Fault LED

will display the most recent fault condition in memory.

NOTE: A ash code of 1 indicates there have been no

faults stored in memory.

For diagnostic ease at conventional thermostats, the alarm

relay will also cycle during test mode. The alarm relay will

cycle on and off in sync with Fault LED to indicate a code

representing the last fault, at the thermostat.

The test mode can be exited by pressing the TEST

pushbutton for 3 seconds. The test mode can also be

entered and exited by cycling the G input, 3 times within

60 seconds.

During test mode, the control monitors to see if the

LT1 and LT2 thermistors are connected and operating

properly. If the control is in test mode, the control will

lockout, with Code 9, after 60 seconds if:

a) The compressor is On in Cooling Mode and the LT1

sensor is colder than the LT2 sensor. Or,

b) The compressor is On in Heating Mode and the LT2

sensor is colder than the LT1 sensor.

Retry Mode: If the control is attempting a retry of a fault,

the Fault LED will slow ash (slow ash = one ash

every 2 seconds) to indicate the control is in the process

of retrying.

Field Conguration Options: NOTE: In the following eld

conguration options, jumper wires should be clipped

ONLY when power is removed from the DXM2.5 control.

NOTE: Jumper 3 must not be clipped prior to adding

antifreeze to the water loop. Antifreeze protection to

10°F required. Clipping JW3 without antifreeze may

result in freeze damage and will void the unit warranty.

Water Coil Low Temperature Limit Setting: Jumper

3 (JW3-LT1 Low Temp) provides eld selection of

temperature limit setting for LT1 of 30°F or 10°F [-1°F or

-12°C] (refrigerant temperature).

Not Clipped = 30°F. Clipped = 10°F.

DXM2.5 Controls

Alarm Relay Setting: Jumper 1 (JW1-AL2 Dry) provides

eld selection of alarm function when Alarm Relay is

energized.

Not Clipped = AL1 connected to R (24VAC) with Alarm

Relay active.

Clipped = Dry contact connection between AL1 and AL2

with Alarm Relay active.

JUMPERS (Set at Factory)

A0-2: Congure Modulating Valve or Variable-Speed

Pump (vFlow®Models Only)

Set A0-2 jumper (see Figure on page 5) to “0 - 10v” if

using Internal Modulating Motorized Valve or “PWM” if

using Internal Variable-Speed Pump. This applies only to

vFlow®units with Internal Speed Water Flow Control.

DIP SWITCHES

NOTE: In the following eld conguration options,

DIP switches should only be moved when power is

removed from the DXM2.5 Control to ensure proper

operation.

DIP Package #1 (S1): DIP Package #1 is 8 position

and provides the following setup selections.

DIP 1.1 – Unit Performance Sentinel Disable: Provides

eld selection to disable the UPS feature.

On = Enabled. Off = Disabled.

DIP 1.2 – Compressor Relay Staging Operation:

Provides selection of Compressor Relay staging operation.

The Compressor Relay can be selected to turn on with

Stage 1 or Stage 2 call from the thermostat. This is used

with Dual Stage units (2 compressors where 2 DXM2.5

Controls are being used) or with master/slave applications.

In master/slave applications, each compressor and fan will

stage according to its appropriate DIP 1.2. If set to stage

2, the compressor will have a 3 second on-delay before

energizing during a Stage 2 demand. Also, if set for stage

2, the Alarm Relay will NOT cycle during test mode.

On = Stage 1. Off = Stage 2.

DIP 1.3 – Thermostat Type (Heat/Cool): Provides

selection of thermostat type. Heat Pump or Heat/Cool

thermostats can be selected. When in Heat/Cool Mode,

Y1 is input call for Cooling Stage 1, Y2 is input call for

Cooling Stage 2, W1 is input call for Heating Stage 1,

and O/W2 is input call for Heating Stage 2. In Heat Pump

Mode, Y1 is input call for Compressor Stage 1, Y2 is input

call for Compressor Stage 2, W1 is input call for Heating

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

8

DXM2.5 Controls, Cont’d.

Stage 3 or Emergency Heat, and O/W2 is the input call for

RV (heating or cooling dependent upon DIP 1.4).

On = Heat Pump. Off = Heat/Cool.

DIP 1.4 – Thermostat Type (O/B): Provides selection

of thermostat type. Heat pump thermostats with “O”

output on with Cooling or “B” output on with Heating

can be selected.

On = HP Stat with O output with cooling.

Off = HP Stat with B output with heating.

DIP 1.5 – Dehumidication Mode: Provides

selection of normal or Dehumidication Fan Mode. In

Dehumidication Mode, the fan speed will be adjusted

for Cooling. In Normal Mode, the fan speed will be

normal during Cooling.

On = Normal Fan Mode. Off = Dehumidication Mode.

DIP 1.6 – DDC Output at EH2: DIP Switch 1.6 provides

selection for DDC operation. If set to DDC Output at EH2,

the EH2 terminal will continuously output the last fault

code of the controller. If set to EH2 normal, then the EH2

will operate as standard electric heat output.

On = EH2 Normal. Off = DDC Output at EH2.

DIP 1.7 – Boilerless Operation: Provides selection

of Boilerless Operation. In Boilerless Mode, only the

compressor is used for Heating Mode when LT1 is

above the temperature specied by the setting of DIP

1.8. If DIP 1.8 is set for 50°F, then the compressor is

used for heating while LT1 is above 50°F. Below 50°F,

the compressor is not used and the control goes into

Emergency Heat Mode, staging on EH1 and EH2 to

provide heating.

On = normal. Off = Boilerless operation.

DIP 1.8 – Boilerless Changeover Temperature: Provides

selection of boilerless changeover temperature setpoint.

On = 50°F. Off = 40°F.

DIP Package #2 (S2): DIP Package #2 is 8 position

and provides the following setup selections.

DIP Package #2 (S2): A combination of dip switches 2.1,

2.2, 2.3, and 2.4, 2.5, 2.6 deliver conguration of ACC1

and ACC2 relay options respectively. See Tables 1 and 2

for description and functionality.

DIP 2.7 – Auto Dehumidication Fan Mode or High Fan

Mode: Provides selection of Auto Dehumidication Fan

Mode or High Fan Mode. In Auto Dehumidication Mode,

the Fan Speed will be adjusted during Cooling IF the H

input is active. In High Fan Mode, the Fan will operate on

high speed when the H input is active.

On = Auto Dehumidication Mode (default).

Off = High Fan Mode.

DIP 2.8 – Factory Setting: Normal position is On. Do not

change selection unless instructed to do so by the Factory.

DIP Package #3 (S3): DIP Package #3 is 4 position

and provides the following setup selections.

DIP 3.1 – Communications Conguration: Provides

selection of the DXM2.5 operation in a communicating

system. The DXM2.5 may operate as a communicating

master or slave device depending on the network

conguration. In most congurations, the DXM2.5 will

operate as a master device.

On = Communicating Master device (default).

Off = communicating Slave device.

DIP 3.2 – HWG Test Mode: Provides forced operation of

the HWG pump output, activating the HWG pump output

for up to ve minutes.

On = HWG test mode. Off = Normal HWG mode (default).

DIP 3.3 – HWG Temperature: Provides the selection of

the HWG operating setpoint.

On = 150°F [66°C]. Off = 125°F [52°C] (default).

DIP 3.4 – HWG Status: Provides HWG operation control.

On = HWG mode enabled.

Off = HWG mode disabled (default).

9

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

DXM2.5 Controls, Cont’d.

Fault Retry: In Fault Retry Mode, the Fault LED begins

slow ashing to signal that the control is trying to recover

from a fault input. The DXM2.5 Control will stage off the

outputs and then “try again” to satisfy the thermostat

call for compressor. Once the thermostat input calls are

satised, the control will continue as if no fault occurred.

If 3 consecutive faults occur without satisfying the

thermostat call for compressor, then the control will go

to Lockout Mode. The last fault causing the lockout will

be stored in memory and is displayed at the Fault LED by

entering the test mode.

NOTE: LT1 and LT2 faults are factory set for one try,

so there will be no “retries” for LT1 and LT2 faults. The

control is factory congured to enter lockout mode

after rst LT1 or LT2 fault.

FAULT CODES

Lockout: In Lockout Mode, the Fault LED will begin fast

ashing. The compressor relay is turned off immediately.

The fan output will be turned off after the current blower

off delay unless auxiliary heat is active. The Lockout Mode

can be “soft” reset via the thermostat by removing the

call for compressor, or by a “hard” reset (disconnecting

power to the control). The fault code will be stored in non-

volatile memory that can be displayed by the Fault LED by

entering the test mode, even if power was removed from

the control.

Lockout with Emergency Heat: If the DXM2.5 is

congured for Heat Pump thermostat mode (see DIP

1.3), the DXM2.5 is in Lockout Mode, and the W input

becomes active, then Emergency Heat Mode will occur

during Lockout. For Emergency Heat, the fan and auxiliary

heat outputs will be activated.

Fault Code 2 – High Pressure Switch: When the High

Pressure switch (HP) opens due to high refrigerant

pressures, the compressor relay is de–energized

immediately. The High Pressure fault recognition is

immediate (does not delay for 30 continuous seconds

before de–energizing the compressor). When the test

mode is activated, the Fault LED will display a fault code

of 2 for a High Pressure fault.

DIP 2.1 DIP 2.2 DIP 2.3 ACC1 Relay Option

ON ON ON Cycle with fan

OFF ON ON Digital night setback

ON OFF ON Water valve – Slow opening

ON ON OFF Outside air damper

OFF ON OFF Dedicated Dehumidication

Mode option – Dehumidistat

OFF OFF OFF Dedicated Dehumidication

Mode option – Humidistat

OFF OFF ON Hydronic Economizer – 1st Stage

ON OFF OFF Hydronic Economizer –

Both Stages

All other DIP combinations are invalid

DIP 2.4 DIP 2.5 DIP 2.6 ACC2 Relay Option

ON ON ON Cycle with compressor

OFF ON ON Digital night setback

ON OFF ON Water valve – Slow opening

OFF OFF ON Humidier

ON ON OFF Outside air damper

OFF OFF ON Hydronic Economizer

OFF ON OFF Hydronic Economizer – 1st Stage

All other DIP combinations are invalid

Table 1: Accessory Relay 1 Conguration

Table 2: Accessory Relay 2 Conguration

⚠

CAUTION!

⚠

CAUTION! Do not restart units without inspection and

remedy of faulting condition. Equipment damage may occur.

SAFETY FEATURES

The following safety features are provided to protect

the compressor, heat exchangers, wiring and other

components from damage caused by operation outside

of design conditions.

Anti-Short Cycle Protection: The control features a 5

minute anti-short cycle protection for the compressor.

NOTE: The 5 minute anti-short cycle also occurs at

power up.

Random Start: The control features a 5-80 second

random start upon power up. The random start delay will

be present after a control power up and after returning

from Night Setback or Emergency Shutdown modes.

Extended Compressor Operation Monitoring: If the

compressor relay has been on for 4 continuous hours,

then the control will automatically turn off the compressor

relay and wait the short cycle protection time. All

appropriate safeties will be monitored during the off time.

If all operation is normal, and if the compressor demand is

still present, the control will turn the compressor back on.

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

10

DXM2.5 Controls, Cont’d.

Fault Code 3 – Loss of Charge Switch: The Loss of

Charge Switch (LP) must be open and remain open for 30

continuous seconds during a compressor “on” cycle to be

recognized as a Loss of Charge fault. If the Loss of Charge

switch is open for 30 seconds prior to compressor power

up it will be considered a Loss of Charge fault. The Loss

of Charge Switch input is bypassed for the initial 120

seconds of a compressor run cycle. When the test mode

is active, the Fault LED will display a fault code of 3 for a

Loss of Charge fault.

Fault Code 4 – Water Coil Low Temperature Cut-Out

Limit (LT1): The control will recognize an LT1 fault, during

a compressor run cycle if:

a) The LT1 thermistor temperature is below the selected

low temperature protection limit setting for at least 50

seconds, AND

b) The LT1 thermistor temperature is rising (getting

warmer) at a rate LESS than 2°F every 30 seconds

The LT1 input is bypassed for the initial 120 seconds

of a compressor run cycle. When the test mode is

active, the Fault LED will display a fault code of 4 for a

LT1 fault.

DXM2.5 CONTROLLER FAULT CODES

DXM2.5 Fault and Status LED Operation with Test Mode Not Active Fault LED (Red) Status LED (Green) Alarm Relay

DXM2.5 is non-functional O O Open

Normal operation - No active communications On On Open

Normal operation - With active communications Very Slow Flash On Open

Control is currently in fault retry mode Slow Flash – Open

Control is currently locked out Fast Flash – Closed

Control is currently in an over / under voltage condition Slow Flash –Open

(Closed after 15 Min)

Hot water mode active –Slow Flash Open

(NSB) Night setback condition recognized –Flashing Code 2 –

(ESD) Emergency shutdown condition recognized –Flashing Code 3 –

Invalid thermostat input combination –Flashing Code 4 –

High hot water temperature lockout active –Flashing Code 5 –

Hot water mode sensor fault active –Flashing Code 6 –

DXM2.5 Fault LED and Status Operation with Test Mode Active Fault LED (Red) Status LED (Green) Alarm Relay

No fault since power up in memory Flashing Code 1 –Cycling Code 1

High pressure fault in memory Flashing Code 2 –Cycling Code 2

Low pressure fault in memory Flashing Code 3 –Cycling Code 3

Low temperature protection 1 fault in memory Flashing Code 4 –Cycling Code 4

Low temperature protection 2 fault in memory Flashing Code 5 –Cycling Code 5

Condensate overow fault in memory Flashing Code 6 –Cycling Code 6

Over / Under voltage shutdown in memory Flashing Code 7 –Cycling Code 7

UPS warning in memory Flashing Code 8 –Cycling Code 8

UPT fault in memory / swapped LT1 and LT2 thermistors Flashing Code 9 –Cycling Code 9

ECM airow fault in memory Flashing Code 10 –Cycling Code 10

Test mode active with no ECM connected or operating –Fast Flash –

Test mode active with ECM operating –

Flashing ECM Airow

–

– Fast Flash = 2 ashes every 1 second

– Slow Flash = 1 ash every 2 seconds

– Very Slow Flash = 1 ash every 5 seconds

– Numeric Codes = On pulse 1/3 second; Off pulse 1/3 second followed by a 10 second delay

– ECM Airow = 1 ash per 100 CFM; On pulse 1/3 second; Off pulse 1/3 second followed by a 10 second delay

– Alarm Relay Open = alarm signal off; Alarm Relay Closed = alarm signal on

Table 3: LED and Alarm Relay Output

11

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

DXM2.5 Controls, Cont’d.

Fault Code 5 – Air Coil Low Temperature Cut-Out

(LT2): The control will recognize an LT2 fault, during a

compressor run cycle if:

a) The LT2 thermistor temperature is below the low

temperature protection limit setting for at least 50

seconds, AND

b) The LT2 thermistor temperature is rising (getting

warmer) at a rate LESS than 2°F every 30 seconds

The LT2 input is bypassed for the initial 120 seconds

of a compressor run cycle. When the test mode is

active, the Fault LED will display a fault code of 5 for

a LT2 fault.

Fault Code 6 – Condensate Overow: The Condensate

Overow sensor must sense overow levels for 30

continuous seconds to be recognized as a CO fault.

Condensate Overow will be monitored continuously

during the compressor run cycle. When the test mode is

active, the Fault LED will display a fault code of 6 for a

Condensate Overow fault.

Fault Code 7 – Over/Under Voltage Shutdown: An Over/

Under Voltage condition exists when the control voltage

is outside the range of 18VAC to 31.5VAC. Over/Under

Voltage Shutdown is self-resetting in that if the voltage

comes back within range of 18.5VAC to 31VAC for at

least 0.5 seconds, then normal operation is restored.

This is not considered a fault or lockout. If the DXM2.5

is in over/under voltage shutdown for 15 minutes, the

Alarm Relay will close. When the test mode is active, the

Fault LED will display a fault code of 7 for an Over/Under

Voltage Shutdown.

Fault Code 8 – Unit Performance Sentinel - UPS: The

UPS feature warns when the heat pump is operating

inefciently. A UPS condition exists when:

a) In Heating Mode with compressor energized, if LT2 is

greater than 125°F for 30 continuous seconds. Or

b) In Cooling Mode with compressor energized, if LT1

is greater than 125°F for 30 continuous seconds, OR

LT2 is less than 40°F for 30 continuous seconds.

If a UPS condition occurs, the control will immediately go

to UPS warning. The status LED will remain on as if the

control is in Normal Mode. (see “LED and Alarm Relay

Operation Table”). Outputs of the control, excluding Fault

LED and Alarm Relay, will NOT be affected by UPS. The

UPS condition cannot occur during a compressor off cycle.

During UPS warning, the Alarm Relay will cycle on and

off. The cycle rate will be On for 5 seconds, Off for 25

seconds, On for 5 seconds, Off for 25 seconds, etc. When

the test mode is active, the Fault LED will display a fault

code of 8 for an UPS condition.

Fault Code 9 – Unit Performance Test-UPT/Swapped

LT1 & LT2 Thermistors: During test Mode, the control

monitors to see if the LT1 and LT2 thermistors are

connected and operating properly. If the control is in

test mode, the control will lockout, with Code 9, after 60

seconds if:

a) The compressor is On in Cooling Mode and the LT1

sensor is colder than the LT2 sensor. Or,

b) The compressor is On in Heating Mode and the LT2

sensor is colder than the LT1 sensor.

When the test mode is active, the Fault LED will display

a fault code of 9 for a Swapped Thermistor fault.

Fault Code 10 – ECM Blower Fault: When operating

an ECM blower, there are two types of ECM Blower fault

conditions that may be detected.

a) An ECM blower fault will be detected and the

control will lockout after 15 seconds of blower

operation with the blower feedback signal reading

less than 100 RPM.

b) An ECM blower fault will be detected when the ECM

conguration is incorrect or incomplete. For this fault

condition, the control will continue to operate using

default operating parameters.

When the test mode is active, the Fault LED will display

a fault code of 10 for an ECM Blower fault.

Fault Code 11 – Low Air Coil Pressure Switch

(Dedicated Dehumidication Mode Units Only):

When the Low Air Coil Pressure switch opens due

to low refrigerant pressure in the cooling or reheat

operating mode, the compressor relay is de–energized

immediately. The Low Air Coil Pressure fault recognition

is immediate (does not delay for 30 continuous seconds

before de–energizing the compressor). When the test

mode is activated, the Fault LED will display a fault code

of 11 for a Low Air Coil Pressure fault. Note: Low Air Coil

Pressure fault will keep the unit from operating in the

cooling or reheat modes, but heating operation will still

operate normally.

Fault Code 12 – Low Air Temperature (Dedicated

Dehumidication Mode Units Only): The control will

recognize a Low Air Temperature fault, during cooling,

reheat, or constant fan operation if the LAT thermistor

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

12

DXM2.5 Controls, Cont’d.

temperature is below 35 degrees for 30 continuous

seconds. When the test mode is activated, the Fault LED

will display a fault code of 12 for a Low Air Temperature

fault. NOTE: Low Air Temperature fault will keep the unit

from operating in the cooling, reheat, or constant fan

modes, but heating operation will still operate normally.

Fault Code 13 – Internal Flow Center Faults: When

operating an internal ow center, the DXM2.5 monitors

the pump feedback signal and may detect one of several

pump faults. The control may detect locked rotor, low

voltage, no ow, or bad pump sensor conditions that will

result in an internal ow center fault. When the test mode

is active, the Fault LED will display a fault code of 13 for

any of these ow center faults.

ESD: The ESD Mode can also be enabled from an

external common signal to terminal ESD (see “Thermostat

Inputs” section for details). For WSHP rooftop products,

ESD (Emergency Shut Down) Mode is utilized when the

ERV (Energy Recovery Ventilator) option is applied to an

TRE series rooftop unit to indicate an ERV fault. A contact

closure at the ERV unit will connect common to the ESD

terminal, which will shut down the rooftop/ERV units. The

green Status LED will ash code 3 when the unit is in

ESD Mode.

Diagnostic Features: The green Status LED and

red Fault LED on the DXM2.5 Control advise service

personnel of the current status of the DXM2.5 Control.

The LED’s will indicate the current operating status of the

DXM2.5, as well as the LAST fault in memory. If there is

no fault in memory and the fault display is selected, the

Fault LED will ash Code 1. See Table 3 for a complete

listing of codes.

UNIT OPERATION DESCRIPTIONS

Power Up: The unit will not operate until all the inputs

and safety controls are checked for normal conditions.

NOTE: The compressor will have a 5-minute anti-short

cycle delay at power-up.

Standby/Fan Only: In Standby Mode, the compressor

will be off. The selected fan output(s) and RV relay

may be on if appropriate inputs are present. If there is

demand for constant fan, the appropriate fan output(s)

will be activated for low speed operation, or constant fan

airow. If there is demand for constant high speed fan, the

appropriate fan output(s) will be activated for high speed

operation, or high speed constant fan airow.

NOTE: DIP1.5 (Dehum Fan Mode Select) has no effect

upon constant fan operation.

The RV relay will not directly track the input demands for

RV, the DXM2.5 Control will employ “smart RV” control.

This ensures that the RV will only switch positions if the

thermostat has called for a Heating/Cooling Mode change.

Heating Stage 1: In Heating Stage 1 Mode, the selected

Fan output(s) and the Compressor relay are turned on

immediately. If congured as Stage 2 (DIP1.2 = off),

then the Compressor and Fan will not turn on until there

is Stage 2 demand. The Compressor relay is turned

off immediately when the Heating Stage 1 demand is

removed. The selected Fan output(s) will turn off after

the selected heating blower off delay, and the control

then reverts to Standby Mode. If there is a Master/Slave

situation or a Dual Compressor situation, all Compressor

relays and related functions will track with their

associated DIP1.2.

Heating Stage 2: In Heating Stage 2 Mode, the selected

Fan output(s) and Compressor relays remain on. The

Compressor Speed relay is turned on, and multi–stage fan

congurations switch to the appropriate operating speed

for Heating Stage 2 immediately. The Compressor Speed

relay is turned off immediately when the Heating Stage 2

demand is removed, and multi–speed fan congurations

switch to the appropriate operating speed for Heating

Stage 1 immediately, and the control reverts to Heating

Stage 1 Mode. For Master/Slave or Dual Compressor

congurations, all Compressor relays and related

functions will track with their associated DIP1.2.

Heating Stage 3: In Heating Stage 3 Mode, the selected

Fan output, Compressor, and Compressor Speed relays

will remain on. The EH1 output will turn on immediately,

and if the control is operating an ECM Blower, the

airow will change to the appropriate Heating Stage 3

airow. With continuing Heating Stage 3 demand, EH2

will turn on after 10 minutes. EH1 and EH2 are turned

off immediately when the Heating Stage 3 demand is

removed, and the control reverts to Heating Stage 2

Mode. During Heating Stage 3 Mode, EH2 will be off

(or will turn off if already on) if LT1 is greater than 45°F

AND LT2 is greater than 110°F (LT2 greater than 110°F

includes the condition that LT2 is shorted). This condition

will have a 30-second recognition time.

13

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

DXM2.5 Controls, Cont’d.

Emergency Heat: In Emergency Heat Mode, the selected

fan output(s) will be activated at high speed or the

appropriate airow for Emergency Heat, and EH1 is

turned on immediately. With continuing Emergency Heat

demand, EH2 will turn on after 5 minutes. EH1 and EH2

are turned off immediately when the Emergency Heat

demand is removed. The selected fan output(s) will turn

off after the selected heating blower off delay and the

control reverts to Standby Mode.

Cooling Stage 1: In Cooling Stage 1 Mode, the selected

fan output(s), Compressor, and RV relays are turned

on immediately. If congured as Stage 2 (DIP1.2 = off),

then the compressor and fan will not turn on until there

is Stage 2 demand. The Compressor relay is turned

off immediately when the Cooling Stage 1 demand is

removed. The selected Fan output(s) will turn off after

the selected cooling blower off delay, and the control

then reverts to Standby Mode. The RV relay will remain

on until there is a Heating demand. If there is a Master/

Slave situation or a Dual Compressor situation, all

Compressor relays and related functions will track with

their associated DIP1.2.

Cooling Stage 2: In Cooling Stage 2 Mode, the selected

Fan output(s), Compressor, and RV relays remain on. The

Compressor Speed relay is turned on, and multi–stage

fan congurations switch to the appropriate operating

speed for Cooling Stage 2 immediately. The Compressor

Speed relay is turned off immediately when the Cooling

Stage 2 demand is removed, and multi–speed fan

congurations switch to the appropriate operating speed

for Cooling Stage 1 immediately, and the control reverts

to Cooling Stage 1 Mode. For Master/Slave situation or

dual compressor congurations, all compressor relays and

related functions will track with their associated DIP1.2.

Night Low Limit (NLL) Staged Heating: In NLL Staged

Heating Mode, the OVR input becomes active and is

recognized as a call for Heating (OVR is an alternate

means of calling for Heating Mode). In NLL Staged

Heating Mode, the control will immediately go into

Heating Stage 1 Mode with an additional 30 minutes of

NLL demand, the control will go into Heating Stage 2

Mode. With an additional 30 minutes of NLL demand, the

control will go into Heating Stage 3 Mode.

Blower Congurations: The DXM2.5 may be congured

to operate several different blowers and blower

congurations. The congurations include:

a) No Blower: If the DXM2.5 is congured for no blower

(split system compressor sections), the K1 relay

will become a loop pump relay and the K2 relay will

become a HWG pump relay.

b) 2 Speed PSC Blower: The default conguration of

the DXM2.5 is to operate for a 2 Speed PSC blower,

with the K1 relay operating as a blower enable relay,

and the K2 relay operating as a blower speed relay.

With this conguration, the blower enable relay is

momentarily de-activated when the blower speed

relay is switched. For low speed blower operation

(Constant Fan, Heating 1, Cooling 1, Cooling 2

with Dehumidication), K1 will be active and K2

will be inactive. For high speed blower operation

(High Speed Constant Fan, Heating 2, Heating 3,

Emergency Heat, Cooling 2), K1 and K2 will be active.

c) Constant Volume (CV) ECM Communicating Blower:

If the DXM2.5 is congured for a CV ECM blower, OR

a CV ECM blower is detected, the DXM2.5 will directly

control a CV ECM blower through communiations

using selected or default airows for each operating

mode. When operating a CV ECM blower, the K1

relay becomes a loop pump relay active anytime the

compressor relay is active, and the K2 relay becomes a

HWG pump relay.

d) Single Speed PSC Blower: If the DXM2.5 is congured

for a single speed PSC blower, the K1 relay will operate

as the blower relay, and the K2 relay becomes a HWG

pump relay.

e) 2 Speed Constant Torque (CT) ECM Blower: If the

DXM2.5 is congured for a CT ECM blower, the K1

relay will operate as a blower enable relay, and the

K2 relay will operate as a blower speed relay. The CT

ECM conguration operates like the 2 Speed PSC,

except the blower enable relay is not de-activated

when the blower speed relay is switched.

f) Constant Volume (CV) ECM (PWM) Blower: If the

DXM2.5 is congured for a CV ECM (PWM) blower,

the DXM2.5 will directly control a CV ECM (PWM)

blower through PWM output signal using selected

or default airows for each operating mode. When

operating a CV ECM (PWM) blower, the K1 relay

becomes a loop pump relay active anytime the

compressor relay is active, and the K2 relay becomes

a HWG pump relay.

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

14

DXM2.5 Controls, Cont’d.

g) VFD Blower: If the DXM2.5 control is congured for

VFD blower, the DXM2.5 will directly control a VFD

to achieve a target Leaving Air Temperature (LAT) or

at discrete speeds depending on the selected blower

control mode. When operating a VFD, the K1 relay

becomes the VFD enable relay. When the VFD is

off, the output will be set to 0 VDC. If congured for

xed speed blower control, there are maximum and

minimum operating speeds for each operating mode

unique to each unit size.

ECM Blower Operation: When the DXM2.5 is congured

to operate an ECM Blower, or an ECM Blower is

connected to the DXM2.5, the ECM blower will be directly

controlled by the DXM2.5, with advanced operating

features including:.

a) Airow Settings: The DXM2.5 allows the target

airow for each operating mode to be selected

individually, within the allowable operating range.

b) Soft Start Ramping: During the rst 2 minutes of

blower operation during a heating or cooling demand,

the ECM blower will ramp up to the selected target

airow for the current operating mode. For the rst 30

seconds of blower operation, the target airow will

be 50% of the normal target airow. For the next 90

seconds of blower operation, the target airow will

be 75% of the normal target airow. For Constant

Fan, Emergency Heat, and test mode operation, the

Soft Start Ramping prole is bypassed, and the ECM

immediately ramps up to the normal target airow.

c) Blower Off Delays: For ECM blower off delays, the

target airow will be adjusted to 50% of normal target

airow before the beginning of the blower off delay.

d) Default Blower Operation: If the DXM2.5

conguration is incorrect or incomplete with an ECM

Blower connected, the ECM blower will not operate;

an ECM conguration warning will be recognized

while unit is in standby but an airow fault will be

recognized if blower demand is present. Once the

heat pump family, unit size and blower type are

selected, the ECM blower will operate based on the

airow parameters for the current conguration for a

compatible ECM blower of any power level.

Hot Water Generator Operation: When the DXM2.5 is

congured to operate a hot water generator pump, the

pump will be directly controlled by the K2 relay, based

on the S3 DIP switch settings and the T5 (hot water

temperature) and T6 (compressor discharge temperature)

inputs. Hot water generator operating features include:

Thermostat Operating Modes

Mode

Input3Output

O G Y1 Y24W H / DH RV Fan 1st Stg

H/C

2nd Stg

H/C4AUX Reheat

No Demand ON/OFF OFF OFF OFF OFF OFF ON/OFF OFF OFF OFF OFF OFF

Fan Only ON/OFF ON OFF OFF OFF OFF ON/OFF ON OFF OFF OFF OFF

Cooling 1st Stage ON ON ON OFF OFF OFF ON ON ON OFF OFF OFF

Cooling 2nd Stage ON ON ON ON OFF OFF ON ON ON ON OFF OFF

Cooling & Dehumidistat1ON ON ON ON/OFF OFF ON ON ON ON ON/OFF OFF OFF

Dehumidistat Only ON/OFF OFF OFF OFF OFF ON ON ON ON ON OFF ON

Heating 1st Stage OFF ON ON OFF OFF OFF OFF ON ON OFF OFF OFF

Heating 2nd Stage OFF ON ON ON OFF OFF OFF ON ON ON OFF OFF

Heating 3rd Stage OFF ON ON ON ON OFF OFF ON ON ON ON OFF

Heating & Dehumidistat2OFF ON ON ON/OFF ON/OFF ON OFF ON ON ON/OFF ON/OFF OFF

Emergency Heat OFF ON OFF OFF ON OFF OFF ON OFF OFF ON OFF

1 Cooling input takes priority over dehumidication input.

2 DXM2.5 is programmed to ignore a dehumidication demand when the unit is in heating mode.

3 Above inputs assume DIP 1.3 is in the heat pump position, and DIP 1.4 is in the O position. When 1.3 is in the heat/cool position, Y1 and Y2 are used for cooling inputs; W and O are used for

heating inputs. When 1.4 is in the B position, the O column would be opposite logic.

4 N/A for single stage units; Full load operation for dual capacity units.

5 ON/OFF = Either ON or OFF; H/C = Either Heating or Cooling.

Table 4: Thermostat Inputs with Resulting Demands

15

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

a) HWG operating setpoint selection (S3–3)

b) Temperature offset verication for efcient HWG

operation

c) HWG test mode (S3–2)

Internal Flow Center [IFC] Operation: When the

DXM2.5 is congured to operate the variable speed

pump in the internal ow controller, the pump will be

directly controlled by the DXM2.5. For controlling the

variable speed pump, the DXM2.5 monitors the entering

water temperature, leaving water temperature, and

pump feedback signal. The pump is controlled in the

following way:

a) Maintain the appropriate temperature difference

across the water coil (EWT–LWT for heating, LWT–

EWT for cooling).

b) Maintain the leaving water temperature below the

appropriate Maximum Heating LWT and above the

Minimum Cooling LWT limits.

Proportional Valve Operation: When the DXM2.5 is

congured to operate a proportional valve, the valve will

be directly controlled by the DXM2.5. For controlling the

proportional valve, the DXM2.5 monitors the entering

water temperature and leaving water temperature. The

proportional valve output will be eneergized 60 seconds

before the compressor relay to establish ow before

the compressor starts. The valve is controlled in the

following way:

a) Maintain the appropriate temperature difference

across the water coil (EWT–LWT for heating, LWT–

EWT for cooling).

b) Maintain the leaving water temperature below the

appropriate Maximum Heating LWT and above the

Minimum Cooling LWT limits.

SPECIAL DXM2.5 APPLICATION NOTES/

ACCESSORY RELAYS

Generally the following applications are based upon

conguring the accessory relays.

Cycle with Fan: If Accessory relay 1 is congured to

“cycle with fan”, Accessory relay 1 will be on any time the

Fan Enable relay, or ECM Blower is on.

Cycle with Compressor: If Accessory relay 2 is

congured to “cycle with compressor”, Accessory relay 2

will be on any time the Compressor relay is on.

DXM2.5 Controls, Cont’d.

Digital Night Setback: If an Accessory relay is congured

for Digital NSB, the Accessory relay will be on any time

the NSB input is connected to Ground “C”.

NOTE: If there are no Accessory relays congured

for Digital NSB, and the DXM2.5 is not connected

to a communicating thermostat congured for

night setback, then the NSB and OVR inputs are

automatically congured for “mechanical” operation.

See Mechanical NSB operation below.

NOTE: Digital Night Setback feature requires a

compatible thermostat. Contact the manufacturer for

information on compatible thermostats.

Mechanical Night Setback: When the NSB input is

connected to Ground “C”, all thermostat inputs (G, Y1, Y2,

W, and O) are ignored. A thermostat setback Heating call

can then be connected to the OVR input. If the OVR input

becomes active, then the DXM2.5 will enter NLL Staged

Heating Mode. NLL Staged Heating Mode would then

provide heating during the NSB period.

Water Valve/Slow Opening: If an Accessory relay is

congured for Water Valve/Slow Opening, the accessory

relay will be energized 60 seconds before the compressor

relay to establish ow before the compressor starts.

Outside Air Damper: If an Accessory relay is congured

for OAD, the Accessory relay will normally turn on any

time the Fan Enable relay is on. But, following a return

from NSB (NSB input no longer connected to Ground “C”)

to Normal Mode, the Accessory Relay will not turn on for

30 minutes even if the Fan Enable Relay is on. After this

30-minute timer expires, the Accessory Relay will turn on

if the Fan Enable Relay is on.

Humidier: If Accessory relay 2 is congured for a

Humidier, the Accessory relay will be on any time the H

input is active.

Hydronic Economizer: If Accessory relay 1 is congured

to be used as a hydronic economizer, normal cooling

operation will be modied.

If Accessory relay 1 is congured as a single stage hydronic

economizer, when a rst stage cooling demand is present

and the H input is active, the accessory relay will be

activated instead of the compressor output. All other heat

pump operating modes will operate normally, and the

accessory relay will be off in all other operating modes.

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

16

DXM2.5 Controls, Cont’d.

If Accessory relay 1 is congured as a hydronic

economizer for both stages, when a rst stage cooling

demand is present and the H input is active, the accessory

relay will be activated instead of the compressor output.

When a second stage cooling demand is present with

the H input active, the accessory relay will be activated in

addition to the compressor output. All other heat pump

operating modes will operate normally, and the accessory

relay will be off in all other operating modes.

Dedicated Dehumidication Mode Operation: A heat

pump equipped with the Dedicated Dehumidication

Mode can operate in three modes, cooling, cooling

with condenser water reheat (CWR), and heating.

The cooling/heating modes are like any of our other

WSHP. The reversing valve (“O” signal) is energized

in cooling, along with the compressor contactor(s) and

the selected blower outputs. In the Heating Mode the

reversing valve is de-energized. Almost any thermostat

will activate the heat pump in heating or cooling modes.

The Reheat Mode requires either a separate humidistat/

dehumidistat or a thermostat that has an integrated

dehumidication function for activation. The DXM2.5

board may be congured to work with either a humidistat

or dehumidistat input to terminal “H” (DIP switch

settings for the DXM2.5 board are shown in table 2), or

the manufacturer’s communicating thermostat. Upon

receiving the appropriate “H” input or communicated

signal, the DXM2.5 board will activate the Cooling Mode a

nd engage CWR. Table 5 shows the relationship between

thermostat input signals and unit operation.

Units congured for Dedicated Dehumidication Mode

operation use two additional fault sensors not present

in other unit congurations. The OVR input is used to

monitor a Low Air Coil Pressure switch, and the T4 input

is used for a Leaving Air Temperature sensor, used for low

temperature detection.

Thermostat Inputs: Table 5 shows the resulting demand

from differing combinations of inputs.

Y1: Y1 is the input for compressor stage 1 if DIP1.3 = on.

Y1 is the input for Cooling Stage 1 if DIP1.3 = off.

Y2: Y2 is the input for compressor stage 2 if DIP1.3 = on.

Y2 is the input for Cooling Stage 2 if DIP1.3 = off.

W: If Y1 and Y2 are active and DIP1.3 = on, then W is the

input for Heating Stage 3. If Y1 and Y2 are not active and

DIP1.3 = on, then W is the input for Emergency Heat. If

DIP1.3 = off, then W is the input for Heating Stage 1.

O: O is the input for Reversing Valve Relay if DIP1.3 =

on and DIP1.4 = on. O is the input for Heating Stage 2 if

DIP1.3 = off. O is the input for “Heat Mode” if DIP1.3 = on

and DIP1.4 = off; this means that the thermostat outputs

a “B” call when in Heating Mode and does NOT have

an “O” output. The DXM2.5 Control will employ “Smart

RV” control. This ensures that the RV will only switch

positions if the thermostat has called for a Heating/

Cooling Mode change.

G: G is the input for Constant Fan Operation.

NSB and Override: NSB is the input for Night Setback

Mode. When Digital NSB is selected via the Accessory

Relays DIP switch inputs and the NSB input is connected

to Ground “C”, then the appropriately congured

Accessory Relay is turned on to signal the digital

thermostat to go to Night Setback Setpoints. Stated

differently, when congured for Digital NSB Mode, the

Accessory Relay directly tracks the NSB input.

NOTE: Digital Night Setback feature requires a

compatible thermostat. Contact the manufacturer for

information on compatible thermostats.

When Digital NSB is NOT selected via the Accessory

Relays DIP switch inputs and a communicating

thermostat congured for night setback is not connected,

when the NSB input is connected to Ground “C”, then

Y1, Y2, W, O, and G inputs are ignored. During this time

period, if OVR is momentarily connected to 24VAC, then

Y1, Y2, W, O, and G are once again monitored for 2 hours.

After the 2 hour override period, the DXM2.5 reverts back

to ignoring Y1, Y2, W1, O, and G, assuming the NSB input

is still connected to Ground “C”. There will be a random

start timer when coming back from NSB Mode.

NOTE: The maximum number of DXM2.5 controls

with daisy-chained “NSB” terminals is 75. Also, the

maximum total wire resistance of the “NSB” wiring is

500 Ohms.

OVR: OVR is the input for Night Setback Override or

Night Low Limit Staged Heating input (NLL). When

Digital NSB is NOT selected via the Accessory Relays DIP

switch inputs and a communicating thermostat congured

for night setback is not connected and NSB is connected

to Ground “C”, then if OVR is momentarily connected

to 24VAC (minimum 1 second) then the OVR input is

recognized as a Night Setback Override signal and the

DXM2.5 Control reverts from Night Setback and begins

monitoring thermostat inputs for heating and cooling calls

17

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

DXM2.5 Controls, Cont’d.

for a 2 hour override period. If NSB is connected to ground

“C”, then if OVR is continuously connected to 24VAC,

then the OVR input is recognized as a call for NLL Staged

Heating and the control enters NLL Staged Heating.

NOTE: For Dedicated Dehumidication Mode units, the

OVR input is used to monitor a Low Air Coil Pressure

switch, and the normal functions of the OVR input are

not available.

ESD: ESD is the input for Emergency Shutdown Mode.

When the ESD input is connected to Ground “C”, all inputs

are ignored and all outputs are turned off. There will be a

random start timer when coming back from ESD.

H: The H input function is determined by the setting of

DIP2.7, assuming the control is not controlling an internal

ow center or an accessory relay is not congured for

Dedicated Dehumidication Mode or humidier operation.

If DIP2.7 = on then the H input is dened as Automatic

Dehumidication Mode and is used as an “automatic”

counterpart to DIP1.5, meaning if H is connected to

24VAC then the selected fan outputs will operate using

dehumidication speeds and airow settings for cooling.

If H is not connected to 24VAC then the selected fan

outputs will operate using normal speeds and airow

settings for cooling.

If DIP2.7 = off then the H input is dened as High Speed

Fan input and is used as an input to call for High Speed

Fan. If the control is in normal operating modes such

as Standby, Cooling or Heating AND the H input is

connected to 24VAC, then the selected fan outputs will

operate using high speed, or high speed airows (this

operation is a high speed fan version of the G input).

Resulting

Demand #1

(From Table 4)

System Inputs

NSB Type

Resulting

Demand #2

(After ESD, NSB)

ESD NSB OVR

- X - - - ESD

Invalid - - - - Invalid

All

(Excluding Invalid) - - - - All

(Excluding Invalid)

All

(Excluding Invalid) - - M - All

(Excluding Invalid)

C1, C2 - - X - Invalid

OFF, F, H1,

H2, or H3 - - X - NLL Staged

Heating

EH - - X - EH

All

(Excluding Invalid) - X - Mechanical Standby/OFF

All

(Excluding Invalid) - X M Mechanical

All for 2 hours

and then revert

to Standby/OFF

(Excluding Invalid)

C1, C2 - X X Mechanical Invalid

OFF, F, H1,

H2, or H3 - X X Mechanical NLL Staged

Heating

EH - X X Mechanical EH

All

(Excluding Invalid) -X- Digital /

Comm

All

(Excluding Invalid)

All

(Excluding Invalid) - X M Digital /

Comm

All

(Excluding Invalid)

C1, C2 - X X Digital /

Comm Invalid

OFF, F, H1,

H2. or H3 - X X Digital /

Comm

NLL Staged

Heating

EH - X X Digital /

Comm EH

“M” is momentary input

“X” is continuous input

Resulting

Demand #2

(From Table 5)

HAuto Dehum /

F2 DIP 2.7

Resulting

Demand # 3

(After DIP 2.1-2.3, 2.7 Logic)

Standby/OFF X Auto Dehum

Mode Standby/OFF with Auto

Dehum enabled

Standby/OFF X High Fan Mode F2

F1 X Auto Dehum

Mode F1 with Auto Dehum enabled

F1 X High Fan Mode F2

C1 X Auto Dehum

Mode C1 with fan destage

C1 X High Fan Mode *Cooling with High Fan

C2 X Auto Dehum

Mode C2 with fan destage

C2 X High Fan Mode *Cooling with High Fan

H1 X Auto Dehum

Mode H1

H1 X High Fan Mode Heating with High Fan

H2 X - H2

H3 X - H3

EH X - EH

Invalid - - Invalid

* = signies that High Fan is locked on regardless of any Dehum demands

Table 5: System Inputs with the Resulting Demand

Table 5 describes demand changes with differing system input (ESD,

NSB, OVR) and DIP input settings. Resulting Demand #1 is derived

from Table 4.

Table 6: “H” Input with Resulting Demand Modes

Table 6 describes demand changes with “H” input and DIP 2.1-2.3,

and 2.7 settings. Resulting Demand #2 is derived from Table 5.

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

18

DXM2.5 Controls, Cont’d.

NOTE: Units with internal ow centers or accessory

relays congured for Dedicated Dehumidication Mode

or humidier operation operate differently from the

above descriptions. For the Dedicated Dehumidication

Mode conguration, the H input is either a humidistat

or dehumidistat (see table 2) input to activate the

Dedicated Dehumidication operating mode. For the

humidier conguration, the H input activates the

humidier output.

OTHER OUTPUTS

Electric Heat: Outputs EH1 and EH2 turn on whenever

the DXM2.5 Control is in the following modes: Heating

Stage 3, Emergency Heat, and Boilerless Operation.

Status LED: The Status LED is green. The Status LED

indicates the operating status of the DXM2.5 Control. See

Table 4: “LED and Alarm Relay Operation”.

Fault LED: The Fault LED is red. The Fault LED displays

the current operating status of the control, or ashes the

corresponding code for the last fault that has occurred

if the test mode is active. If there is no fault in memory,

then the Fault LED will ash Code 1. If the Fault type

is “Primary” (HP, LP, LT1, LT2, or CO) then the Fault

type will always be retained in memory (Primary faults

will overwrite Secondary faults). If the Fault type is

“Secondary” (Over/Under Voltage, UPS or Swapped LT1/

LT2) then the Fault type will only be retained if there are

no “Primary” faults in memory. The Secondary Fault types

will not “overwrite” the Primary fault memory. See Table

4: “LED and Alarm Relay Operation”.

Communications: The DXM2.5 has a single RS485

communications port that provides communication

capabilities for communicating thermostats or connecting

with other communicating controls.

Pressure Switches: All pressure switches are designed

to be normally closed during normal operating conditions,

and to open upon fault.

Condensate Sensor: The Condensate Sensor input will

fault upon sensing impedance less than 100,000 Ohms for

30 continuous seconds. The recommended design uses

a single wire terminated with a male 1/4” quick connect

located in the drain pan at desired trip level. Upon a high

condensate level the water will short between the air coil

and the quick connect producing a resistance less than

100,000 Ohms. Since condensate is free of impurities,

it has no conductivity. Only the impurities from the drain

pan and coil dust or dirt create the conductance. A second

ground wire with appropriate terminal to the drain pan can

be used with the control to replace the air coil ground path.

The Condensate Sensor can also essentially be any open

contact that closes upon a fault condition.

Thermistor Temperature Sensors: The thermistors

used with the DXM2.5 are NTC (negative temperature

coefcient) type. Table 7 shows the replacement part

numbers for the LT1 and LT2 thermistors. The sensors

have a 1% tolerance and follow the characteristics shown

in Table 8. Table 9 shows the nominal resistance at any

given temperature and can be used for eld service

reference. The sensor will use a minimum of 24 AWG wire.

Temp (°F)

Minimum

Resistance

(Ohm)

Maximum

Resistance

(Ohm)

Nominal

Resistance

(Ohm)

78.5 9523 9715 9619

77.5 9650 9843 9746

76.5 10035 10236 10135

75.5 10282 10489 10385

33.5 30975 31598 31285

32.5 31871 32512 32190

31.5 32653 33310 32980

30.5 33728 34406 34065

1.5 80624 82244 81430

0.5 83327 85002 84160

0.0 84564 86264 85410

Table 8: 1% Sensor Calibration Points

19

DXM2.5 Unit Control

Created: October 18, 2022

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Temp (ºC) Temp (ºF) Resistance

(kOhm) Temp (ºC) Temp (ºF) Resistance

(kOhm)

-17.8 0.0 85.34 55 131.0 2.99

-17.5 0.5 84.00 56 132.8 2.88

-16.9 1.5 81.38 57 134.6 2.77

-12 10.4 61.70 58 136.4 2.67

-11 12.2 58.40 59 138.2 2.58

-10 14.0 55.30 60 140.0 2.49

-9 15.8 52.38 61 141.8 2.40

-8 17.6 49.64 62 143.6 2.32

-7 19.4 47.05 63 145.4 2.23

-6 21.2 44.61 64 147.2 2.16

-5 23.0 42.32 65 149.0 2.08

-4 24.8 40.15 66 150.8 2.01

-3 26.6 38.11 67 152.6 1.94

-2 28.4 36.18 68 154.4 1.88

-1 30.2 34.37 69 156.2 1.81

032.0 32.65 70 158.0 1.75

133.8 31.03 71 159.8 1.69

235.6 29.50 72 161.6 1.64

337.4 28.05 73 163.4 1.58

439.2 26.69 74 165.2 1.53

541.0 25.39 75 167.0 1.48

642.8 24.17 76 168.8 1.43

744.6 23.02 77 170.6 1.39

846.4 21.92 78 172.4 1.34

948.2 20.88 79 174.2 1.30

10 50.0 19.90 80 176.0 1.26

11 51.8 18.97 81 177.8 1.22

12 53.6 18.09 82 179.6 1.18

13 55.4 17.26 83 181.4 1.14

14 57.2 16.46 84 183.2 1.10

15 59.0 15.71 85 185.0 1.07

16 60.8 15.00 86 186.8 1.04

17 62.6 14.32 87 188.6 1.01

18 64.4 13.68 88 190.4 0.97

19 66.2 13.07 89 192.2 0.94

20 68.0 12.49 90 194.0 0.92

21 69.8 11.94 91 195.8 0.89

22 71.6 11.42 92 197.6 0.86

23 73.4 10.92 93 199.4 0.84

24 75.2 10.45 94 201.2 0.81

25 77.0 10.00 95 203.0 0.79

26 78.8 9.57 96 204.8 0.76

27 80.6 9.16 97 206.6 0.74

28 82.4 8.78 98 208.4 0.72

29 84.2 8.41 99 210.2 0.70

30 86.0 8.06 100 212.0 0.68

31 87.8 7.72 101 213.8 0.66

32 89.6 7.40 102 215.6 0.64

33 91.4 7.10 103 217.4 0.62

34 93.2 6.81 104 219.2 0.60

35 95.0 6.53 105 221.0 0.59

36 96.8 6.27 106 222.8 0.57

37 98.6 6.01 107 224.6 0.55

38 100.4 5.77 108 226.4 0.54

39 102.2 5.54 109 228.2 0.52

40 104.0 5.33 110 230.0 0.51

41 105.8 5.12 111 231.8 0.50

42 107.6 4.92 112 233.6 0.48

43 109.4 4.72 113 235.4 0.47

44 111.2 4.54 114 237.2 0.46

45 113.0 4.37 115 239.0 0.44

46 114.8 4.20 116 240.8 0.43

47 116.6 4.04 117 242.6 0.42

48 118.4 3.89 118 244.4 0.41

49 120.2 3.74 119 246.2 0.40

50 122.0 3.60 120 248.0 0.39

51 123.8 3.47 121 249.8 0.38

52 125.6 3.34 122 251.6 0.37

53 127.4 3.22 123 253.4 0.36

54 129.2 3.10

Table 9: Nominal Resistance at Various Temperatures

DXM2.5 Controls, Cont’d.

WATER-SOURCE HEAT PUMPS

DXM2.5 Unit Control

Created: October 18, 2022

20

Basic Troubleshooting Information/ Service & Application Notes

General Troubleshooting: Basic DXM2.5 board

troubleshooting in general is best summarized as simply

verifying inputs and outputs. After this process has been

veried, condence in board operation is conrmed and

the trouble must be elsewhere. Below are some general

guidelines required for developing training materials and

procedures when applying the DXM2.5 Control.

DXM2.5 Field Inputs: All conventional inputs are 24VAC

from the thermostat and can be veried using a voltmeter

between C and Y1, Y2, W, O, and G.

Sensor Inputs: All sensor inputs are ‘paired wires’

connecting each component with the board. Therefore

continuity on pressure switches can be checked at the

board connector.

The thermistor resistance should be measured with the

connector removed so that only the impedance of the

thermistor is measured. If desired, this reading can be

compared to the chart shown in the thermistor section

of this manual based upon the actual temperature of

the thermistor clip. An ice bath can be used to check

calibration of a thermistor if needed.

DXM2.5 Outputs: The compressor relay is 24VAC and

can be veried using a voltmeter. The Alarm Relay can

either be 24VAC as shipped or dry contacts (measure

continuity during fault) for use with DDC by clipping

the J4 jumper. Electric heat outputs are 24VDC and

require a voltmeter set for DC to verify operation. When

troubleshooting, measure from 24VDC terminal to EH1 or

EH2 terminals.

Test Mode: Test mode can be entered for 20 minutes

by pressing the Test button. For Diagnostic ease at a

conventional thermostat, the Alarm Relay will also cycle

during test mode.The Alarm Relay will cycle on and off in

sync with the Fault LED to indicate a code representing

the last fault, at the thermostat. Test mode can also be

entered and exited by cycling the G input, 3 times within

60 seconds.

DXM2.5 Thermostat Details

Anticipation Leakage Current: Maximum leakage current

for “Y1” is 50mA and for “W” is 20mA. Triacs can be used

if leakage current is less than above. Thermostats with

anticipators can be used if anticipation current is less than

that specied above.

Thermostat Signals:

• “Y1”, “Y2”, “W”, “O”, and “G” have a 1 second

recognition time when being activated or being

removed.

• “R” and “C” are from the transformer.

• “AL1” and “AL2” originate from the Alarm Relay.

• “A” is paralleled with the compressor output for use

with well water solenoid valves.

Safety Listing: The DXM2.5 Control is listed under UL

873, and is CE listed under IEC 60730.

Table of contents