DKG-116 User Manual V-02 (

11.08.2010)

Tel: +90-216-466 84 60

http://www.datakom.com.tr

Fax: +90-216 364 65 65

DKG-116 MANUAL AND REMOTE START UNIT

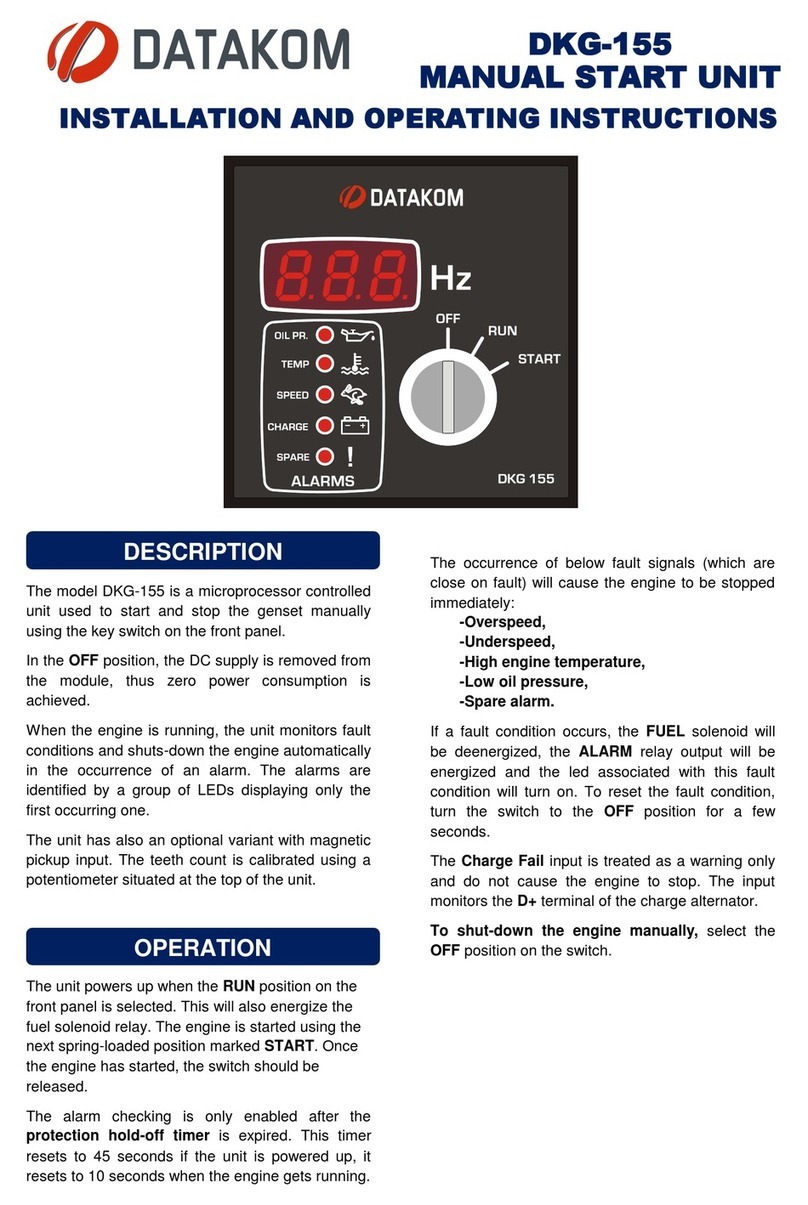

DESCRIPTION

The DKG-116 is a low cost

gasoline/diesel genset control unit

designed to start and stop a genset both

manually and remotely.

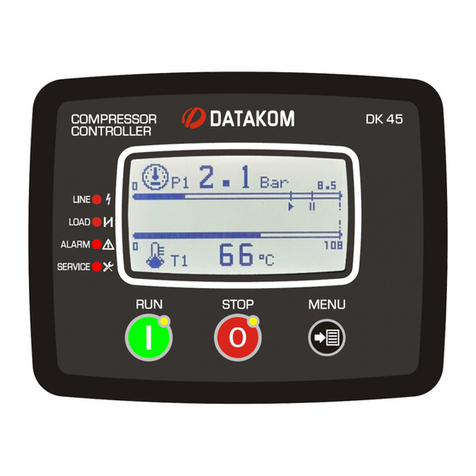

The manual control is made using RUN

and STOP pushbuttons on the front

panel. The remote control is made via

REMOTE START input signal.

When RUN button is pressed or a Remote

Start signal arrives, the engine will be

cranked up to 3 times. When it runs, the

crank relay will be immediately deactivated

and after Holdoff timer delay, fault

checking will be enabled. When the engine

is running, if a fault condition is detected

then the engine is shutdown immediately

and the unit indicates the source of the

failure through related alarm led.

If STOP button is pressed or the Remote

Start signal disappears, the genset will

continue to run during cooldown period. At

the end of the period the engine will stop.

The MENU button selects display

parameter scroll and allows program

mode entry and lamp test functions.

The total engine run hours is kept in a

tamper-proof non-erasable memory which

is not affected by power failures.

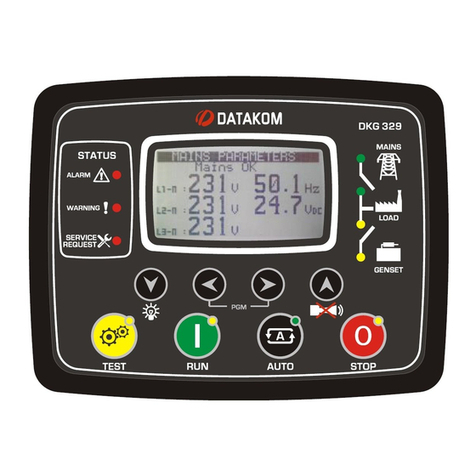

MEASUREMENTS

Generator Volts: L1-N, L2-N, L3-N

Generator Volts: L1-L2, L2-L3, L3-L1

Generator Frequency

Battery Voltage

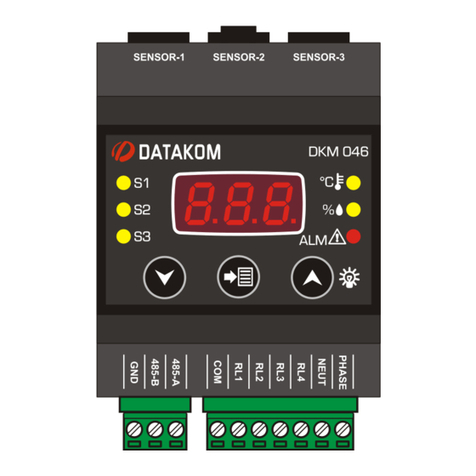

OPTIONS

Auxiliary output (negative pulling).

FEATURES

Both Manual and remote control

Generator protection

Built in alarms and warnings

Remote Start operation available

True RMS measurements

Tamper-proof engine hours display

Field adjustable parameters

High current Fuel and Crank outputs

Protected semiconductor auxiliary

output

Digital inputs: 4

Survives cranking dropouts

Sealed front panel

Standard panel dimensions: 96x48mm

Plug-in connection system