ClimateMaster Flow Controller 3 Guide

Residential Geothermal Loop,

Single and Two-Pump Modules

Installation, Operation &

Maintenance Instructions

97B0015N01

Revision: 2/9/16

Flow Controller 3

Table of Contents

Model Nomenclature 3

General Information 3

Flow Controller Mounting 4

Piping Installation 5

Electrical Wiring 9

Flushing the Earth Loop 10

Antifreeze Selection 13

Antifreeze Charging 15

Low Temperature Cutout Selection 16

Flow Controller Pump Curves 17

Pump Replacement 18

Geothermal Closed Loop Design 19

Loop Fusion Methods 19

Parallel Loop Design 19-22

Closed Loop Installation 23-24

Pressure Drop Tables 25-30

Building Entry 31

Site Survey Form 31

Warranty 32

Revision History 34

Flow Controller 3

Rev.:Feburary 9,2016

2Geothermal Heat Pump Systems

This page has intentionally been left blank.

3

Flow Controller 3

Rev.: Feburary 9, 2016

A F C G 2 C 1

1 2 3

4

567

Accessory Flow Controller

1 = 1 Pump

# of Pumps B = Brass 3-way valve with double O-ring fittings

Valves

Pump Model #

1 = UP26-99

2 = UP26-116 (AFC2B2 only)

3 = UPS32-160

4 = UPS60-150

Vendor/Series

G = Current Series

2 = 2 Pumps

C = Composite 3-way valve with double O-ring fittings

Rev.: 12/07/10

Model Nomenclature

GENERAL INFORMATION

Figure 1a: Flow Controller Dimensions (1 Piece Cabinet)

7.6” [192mm]

(includes pump)

10.2” [259mm]

13.5” [335mm]

5.0” [127mm]

4.7” [119mm]4.7” [119mm] 4.7” [119mm]4.7” [119mm]

Figure 1b: Flow Controller Dimensions (2 Piece Cabinet)

6.9” [174mm]

(includes pump)

10.2” [259mm]

14.9” [378mm]

5.0” [127mm]

4.5” [114mm]4.5” [114mm] 4.5” [114mm]4.5” [114mm]

FLOW CONTROLLER DESCRIPTION

The AFC series Flow Controller is a compact, easy to mount

polystyrene cabinet that contains 3-way valves and pump(s)

with connections for ushing, lling and pumping residential

geothermal closed loop systems. The proven design is foam-

insulated to prevent condensation. Full ow service valves

minimize pressure drop. One or two Grundfos pump models

UP26-99 or UP26-116 are available for a variety of unit ow

rates and loop layouts. Flow Controllers are designed for

systems that require water ow rate of up to 20 U.S. GPM

[1.26 l/s]. Unit and loop connections are designed for double

o-ring adaptor ttings for a variety of connection types

(fusion, threaded, barbed, cam). Pumps are 230VAC, 60Hz.

An attractive gray polystyrene cabinet with black pump(s)

provides an esthetically pleasing enclosure for pump(s) and

valves.

Safety

Warnings, cautions and notices appear throughout this

manual. Read these items carefully before attempting any

installation, service or troubleshooting of the equipment.

DANGER: Indicates an immediate hazardous situation, which

if not avoided will result in death or serious injury.

DANGER labels on unit access panels must be observed.

WARNING: Indicates a potentially hazardous situation, which

if not avoided could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice, which if not avoided could result in minor or

moderate injury or product or property damage.

NOTICE: Notication of installation, operation or

maintenance information, which is important, but which is

not hazard-related.

Flow Controller 3

Rev.:Feburary 9,2016

4Geothermal Heat Pump Systems

Flow Controller Mounting

CAUTION! Figure 2: Mounting Flow Controller on Stud Wall

Figure 3: Mounting Flow Controller on the Side of Unit

NOTICE! - Flow Controller pumps must be mounted so that

the pump shaft is always in a horizontal position. In other

words, Flow Controller must always be mounted in a vertical

position (not on it’s back or mounted to the ceiling). Pump

damage will occur with pump shaft in a vertical orientation.

General

The Flow Controller should be located as close to the unit

as possible to limit the length of rubber hose kit and thus

its associated pressure drop. In general the Flow Controller

can be mounted in any orientation with the exception of

when the pump shafts are in a vertical position as when it is

laid at on the oor or any similar position. The controller is

typically mounted in one of three locations (see below). Be

certain that there is adequate access to all required ush

ports and valves before mounting.

Stud Wall - Mounting on stud wall with or without drywall

can be accomplished by using the two supplied lag bolts

through the top and bottom center holes directly into the

studs as shown in Figure 2.

Side of Unit - Mounting on the side of the unit can be

accomplished by using the four self-drilling screws directly

into the sheet metal access panels or cabinet as shown in

Figure 3. Be careful not to puncture any internal refrigerant

piping or other components with the screws. It should be

remembered that heat pump access will be limited in this

mounting position.

Concrete wall - Mounting onto a concrete wall can be

accomplished by using 4-1/4” [10.8 cm] ‘Tapcon’ screws

(supplied by others) directly into the concrete wall.

CAUTION! The following instructions represent industry

accepted installation practices for closed loop earth

coupled heat pump systems. Instructions are provided

to assist the contractor in installing trouble free ground

loops. These instructions are recommendations only.

State/provincial and local codes MUST be followed and

installation MUST conform to ALL applicable codes. It is

the responsibility of the installing contractor to determine

and comply with ALL applicable codes and regulations.

5

Flow Controller 3

Rev.: Feburary 9, 2016

Piping Installation

Figure 4: Double O-Ring Adapters

To Fittings Part #

Polyethylene (PE) Fusion 1-1/4” PE Fusion x Double O-ring AFC6F

PE Fusion 1” PE Fusion x Double O-ring AFC5F

PE Barb 1-1/4” insert barb x Double O-ring1AFC6I

PE/Rubber Hose Barb 1” insert barb x Double O-ring1AFC4I

Cam Adapter Male Cam adapter x Double O-ring2AFC4C

Copper Sweat or PVC Glue 1” MPT x Double O-ring3AFC4T

NOTES:

1. Use two all-stainless hose clamps per connection. One set of 1” insert barb x

Double O-ring adapter ttings is included with AHK5EC hose kit.

2. One set of cam adapters required for connection to ush cart hoses. Cam

connectors should be left with the installed Flow Controller for future service.

Most ush carts will have female cam ttings that will mate to these ttings.

3. Adapters from 1” MPT to copper sweat or PVC glue provided by others.

Table 1: Flow Controller Connection Materials

Piping Material Insulation Description

1” Hose Kit 1-3/8” [34.9 mm] ID - 1/2” [12.7 mm] wall

1” IPS PE 1-1/4” [31.8 mm] ID - 1/2” [12.7 mm] wall

1-1/4” IPS PE 1-5/8” [41.3 mm] ID - 1/2” [12.7 mm] wall

2” IPS PE 2-3/8” [60.3 mm] ID - 1/2” [12.7 mm] wall

Table 2: Typical Piping Insulation Materials

AFC4C

AFC4I

AFC4T

Hose Kit

AHK5EC

AFC5F

AFC6F

Piping Installation

The Flow Controller features Double O-ring ttings for

exible and easy installation. Table 1 illustrates the

connection options available for Flow Controllers with

polystyrene cabinets. Avoid using 3/4” [19.1mm] piping

on ows greater than 6 gpm [0.38 l/s]. Pressure drop in

piping systems should be calculated to insure adequate

ow through unit. All piping should be properly insulated

with closed cell insulation of 1/2” [12.7 mm] wall thickness.

Table 2 shows the insulation requirements for typical piping

materials. Piping insulation should be glued and sealed

to prevent condensation using closed cell insulation glue.

The swivel connectors on the Flow Controller are designed

to be hand tightened only. Connections between the Flow

Controller and adapters are sealed with double o-rings

ttings shown in gure 4.

Loop side piping is typically polyethylene piping directly

into the Flow Controller. Connection to the Flow Controller

Flow Controller 3

Rev.:Feburary 9,2016

6Geothermal Heat Pump Systems

Piping Installation

Figure 5: AHK5EC Hose Kit Typical Detail

Figure 6: Two Units Utilizing One Flow

Controller (One Side Shown)

can be accomplished by a fusion or barbed tting as shown

in Table 1. In multiple Flow Controller systems such as

multifamily housing, PE can also be used on the heat pump

side. Polyethylene is the only acceptable material for pipe

buried in the ground.

Unit side piping is typically connected using the hose

kit (AHK5EC), which contains all ttings necessary for

connection between the Flow Controller and the unit as

shown in Figure 5.

In multiple unit systems, PE piping materials can be used

to ‘tee’ more than one unit into the Flow Controller. It is

recommended that a hose kit still be used at the end of the

PE piping run to facilitate ease of installation and service of

the units as shown in Figure 6. Insulate all exposed piping.

Plastic to metal threads should not be used due to their

leakage potential.

The APSM pump slaving module can be used to allow a

single Flow Controller to be controlled by two heat pumps as

shown in gure 7a.

7

Flow Controller 3

Rev.: Feburary 9, 2016

Two Units with One Flow Controller

NOTES:

1. Piping is shown schematically

. Actual pipe diameter and layout must be determined before installation.

2. Pressure drop calculation must be made to verify that Flow Controller can deliver design flow rate when both units are oper

ating.

3. Hose kits of longer than 10 ft. (3 meters) one way should not be used. PE pipe or SCH80 PVC should be used for lengths gre

ater than 10 ft. (3 meters).

4.

All units must include P/T ports for flow rate measure and balancing.

5. Use optional field-installed loop pump slaving relay (part #

APSM) to wire both units to the Flow Controller pump(s).

Heat Pump Heat Pump

Flow

Controller

Field-supplied

full-port ball valve

for balancing

Each heat pump

must include P/T

ports to verify flow rates

LWT

EWT

LWT

EWT

Heat Pump Heat Pump

Flow

Controller

Water Out

Water In

Water Out

Water In

Figure 7a: Parallel Unit Piping 1

Piping Installation

Flow Controller 3

Rev.:Feburary 9,2016

8Geothermal Heat Pump Systems

NOTES:

1. Piping is shown schematically. Actual pipe diameter and layout must be determined before installation.

2. Pressure drop calculation must be made to verify that parallel pumping arrangement provides enough head to deliver design flow rate to each unit

when all units are operating.

3. Flow Controller should be mounted close enough to unit to maintain short (approx. 10 ft., 3m) hose kit from Flow Controller to unit.

4. All units must include P/T ports for flow rate measure and balancing.

Multiple Units on Common Loop Field

Parallel Pumping Arrangement

Heat Pump Heat Pump Heat Pump

Field-supplied

full-port ball valve

for balancing

Field-supplied

check valve to

prevent short-cycling

Each heat pump

must include P/T

ports to verify flow rates

Water Out

Water In

Water Out

Water In

LWT

EWT

Flow

Controller

Flow

Controller

Flow

Controller

Heat Pump

Water Out

Water In

Figure 8b: Parallel Unit Piping 2

Piping Installation

9

Flow Controller 3

Rev.: Feburary 9, 2016

Flow Controller Electrical Wiring

Model Qty Volts Amps HP

UP26-99 1 230 1.07 1/6

UP26-99 2 230 2.14 1/3

UP26-116 2 230 3.50 1/3

Figure 8a: Heat Pump / Circulator Pump

Power Wiring

Figure 8b: Wiring for Two Units Sharing One Flow

Controller (APSM Module)

WARNING!

CAUTION!

Power wiring to the Flow Controller should conform to all

applicable codes. Figure 8a illustrates the wiring required

between the heat pump and Flow Controller. Note the Flow

Controller is available only in 230V single phase voltage.

Pumps are fused through a pair of circuit breakers in the

unit control box. See electrical table for Flow Controller

characteristics.

The pump slaving module is designed to allow two units

to share one Flow Controller. The module is mounted in a

NEMA enclosure, which is designed to be mounted on the

Flow Controller or on the outside of the unit. Wire the pumps

and unit as shown in gure 8b.

Electrical Table

WARNING! To avoid possible injury or death due to

electrical shock, open the power supply disconnect switch

and secure it in an open position during installation.

CAUTION! Use only copper conductors for eld installed

electrical wiring. Unit terminals are not designed to accept

other types of conductors.

Flow Controller 3

Rev.:Feburary 9,2016

10 Geothermal Heat Pump Systems

Flushing the Earth Loop

Figure 10a: Valve Position A - Loop Fill

Unit

Garden

Hose

Flow

Controller

Loop

Valve

Position

Flush Cart

Figure 9a: Typical Cleanable Flush

Cart Strainer (100 mesh [0.149mm])

Figure 9b: Cam Fittings for Flush Cart Hoses

Attach

to Flow

Controller

Flush Port

Connect

to Flush

Cart Hose

(1 of 2)

NOTICE: A hydrostatic pressure test is recommended on ALL

piping, especially underground piping before nal backll per

IGSHPA and the pipe manufacturers recommendations.

Front of F.C.

Valve Position

WARNING!

Once piping is completed between the unit, Flow Controller

and the ground loop, nal purging and charging of the loop

is needed.

A ush cart (at least a 1.5 hp [1.1kW] pump) is needed to

achieve adequate ow velocity in the loop to purge air and

dirt particles from the loop itself. Antifreeze solution is used

in most areas to prevent freezing. All air and debris must be

removed from the earth loop piping system before operation,

Flush the loop with a high volume of water at a high velocity

(2 fps [0.6 m/s] in all piping), both directions using a lter

in the loop return line, of the ush cart to eliminate debris

from the loop system. See charts 6a through 6e for ow rate

required to attain 2fps [0.6 m/s]. The steps below must be

followed for proper ushing.

Fill loop with water from a garden hose through ush cart

before using ush cart pump to ensure an even ll and

increase ushing speed. When water consistently returns

back to the ush reservoir, switch to valve position B.

WARNING! Disconnect electrical power source to prevent

injury or death from electrical shock.

11

Flow Controller 3

Rev.: Feburary 9, 2016

Figure 10b: Valve Position B - Unit Fill

Unit

Garden

Hose

Flow

Controller

Loop

Valve

Position

Flush Cart

Flushing the Earth Loop

Front of F.C.

Valve Position

Figure 10c: Valve Position C - Loop Flush

Unit

Garden

Hose

Flow

Controller

Loop

Valve

Position

Dead Head

Pump Test for

Air

Flush Cart

Front of F.C.

Valve Position

This position should be switched while lling to ll the

unit heat exchanger and hose kit. The position should be

maintained until water consistently is returned into the ush

reservoir.

Switch to valve position C. The supply water may be shut o

and the ush cart turned on to begin ushing. Once the ush

reservoir is full, do not allow the water level in the ush cart

tank to drop below the pump inlet line or air can be pumped

back out to the earth loop. Try to maintain a uid level in the

tank above the return tee so that air can not be continuously

mixed back into the uid. Surges of 50 psi [345 kPa] can

be used to help purge air pockets by simply shutting o the

return valve going into the ush cart reservoir. This process

‘dead heads’ the pump to 50 psi [345 kPa]. To dead head

the pump until maximum pumping pressure is reached,

open the valve back up and a pressure surge will be sent

through the loop to help purge air pockets from the piping

system. Notice the drop in uid level in the ush cart tank.

If all air is purged from the system, the level will drop only

1 - 2 inches [2.5 - 5 cm] in a 10” [25.4 cm] diameter PVC

ush tank (about a half gallon [1.9 liters]) since liquids are

incompressible. If the level drops more than this level,

ushing should continue since air is still being compressed

in the loop uid. Do this a number of times. When the uid

level is dropping less than 1-2” [2.5 - 5 cm] in a 10” [25.4 cm]

diameter tank, the ow can be reversed.

NOTICE: Actual ushing time require will vary for each

installation due to piping length, conguration, and ush cart

pump capacity. Most closed loop installations will require at

least 20 minutes or longer.

Flow Controller 3

Rev.:Feburary 9,2016

12 Geothermal Heat Pump Systems

Figure 10d: Valve Position D - Full Flush

Unit

Garden

Hose

Flow

Controller

Loop

Dead Head

Pump Test for

Air

Flush Cart

Add

Antifreeze

Now if

Needed

Figure 10e: Valve Position E - Pressurize and Operation

Unit

Garden

Hose

3

Close Flow

Controller

Valves for

Operation

Mode

Loop

1

Dead Head

Pump to

Pressurize

to 50 psi

Flush Cart

2

Close to

Isolate Flow

Controller

Valve

Positions

Flushing the Earth Loop

Front of F.C.

Valve Position

Front of F.C.

Valve Position

Move valves to position D. By switching both valves to this

position, water will ow through the loop and the unit heat

exchanger. Finally, the dead head test should be checked

again for an indication of air in the loop. Fluid level drop

is your only indication of air in the loop. Antifreeze may

be added during this part of the ushing procedure; see

antifreeze section for details.

As shown in Figure 10E, close the ush cart return valve

to pressurize the loop to at least 50 psi [345 kPa], not to

exceed 75 psi [517 kPa]. After pressurizing, close the ush

cart supply valve to isolate the ush cart. Move the Flow

Controller valves to position E. Loop static pressure will

uctuate with the seasons and pressures will be higher in

the winter months than during the cooling season. This

uctuation is normal and should be considered when

charging the system initially. Unhook the ush cart from the

Flow Controller. Install Flow Controller caps to ensure that

any condensation/leakage remains contained within the Flow

Controller package. If water pressure is too low to pressurize

the loop to between 50 and 75 psi [345 to 517 kPa], use a

hydraulic pump to pressure the loop through the P/T port,

being careful to bleed any air before introducing any uid

through the P/T port (Some weed sprayers works well as

hydraulic pumps).

NOTICE: It is always a good idea to plan for a service call/

check-up the rst summer of operation, as the loop pressure

may be low due to the stretching of the pipe/rubber hose

after the pipe has settled into the ground and the warmer

summer loop temperatures cause the piping to expand. This

is typical of all new installations. Pressures can easily be

“topped o” with the use of a garden hose and P/T adapter.

Install the garden hose and adapter in the “water in” P/T

tting; install a pressure gauge in the “water out” P/T tting.

If the loop pressure is between 50 and 75 psi [345 to 517

kPa] upon completion of the service call, pressures should

be sucient for all seasons.

NOTICE: Consult the ClimaDry AOM for ushing instructions

for units with ClimaDry Whole House Dehumidication.

13

Flow Controller 3

Rev.: Feburary 9, 2016

-50°F -40°F -30°F -20°F -10°F 0°F 10°F 20°F 30°F 40°F 50°F

0.960

0.965

0.970

0.975

0.980

0.985

0.990

0.995

1.000

Low Temperature Protection

Specific Gravity

-45.6°C

-40°C

-34.4°C

-28.9°C

-23.3°C

-17.8°C

-12.2°C

-6.7°C

-1.1°C

4.4°C

10°C

1.00

1.01

1.02

1.03

1.04

1.05

1.06

1.07

Low Temperature Protection

Specific Gravity

-40°F -30°F -20°F -10°F 0°F 10°F 20°F 30°F 40°F

-40°C -34.4°C -28.9°C -23.3°C -17.8°C -12.2°C -6.7°C -1.1°C 4.4°C

0.975

0.980

0.985

0.990

0.995

1.000

-5°F 0°F 5°F 10°F 15°F 20°F 25°F 30°F 35°F

1.7°C-1.1°C-3.9°C-6.7°C-9.4°C-12.2°C-15.0°C-17.8°C-20.6°C

Low Temperature Protection

Antifreeze Selection

Fluid Volume (gal [liters] per 100’ [30 meters) Pipe)

Pipe Size Volume (gal) [liters]

Copper

1” 4.1 [15.3]

1.25” 6.4 [23.8]

2.5” 9.2 [34.3]

Rubber Hose 1” 3.9 [14.6]

Polyethylene

3/4” IPS SDR11 2.8 [10.4]

1” iPS SDR11 4.5 [16.7]

1.25” IPS SDR11 8.0 [29.8]

1.5” IPS SDR11 10.9 [40.7]

2” IPS SDR11 18.0 [67.0]

1.25” IPS SCH40 8.3 [30.9]

1.5” IPS SCH40 10.9 [40.7]

2” IPS SCH40 17.0 [63.4]

Unit Heat Exchanger Typical 1.0 [3.8]

Flush Cart Tank 10” Dia x 3ft tall

[254mm x 91.4cm tall] 10 [37.9]

Table 3: Fluid Volume

Chart 1a: Methanol Specic Gravity

Chart 1b: Propylene Glycol Specic Gravity

Chart 1c: Ethanol Specic Gravity

WARNING!

WARNING! Always dilute alcohols with water (at least 50%

solution) before using. Alcohol fumes are ammable and

can cause serious injury or death if not handled properly.

General

In areas where minimum entering loop temperatures drop

below 40°F [4.4°C] or where piping will be routed through

areas subject to freezing, antifreeze is needed. Alcohols

and glycols are commonly used as antifreeze solutions.

Your local representative should be consulted for the

antifreeze best suited to your area. Freeze protection should

be maintained to 15°F [8.5°C] below the lowest expected

entering loop temperature. For example, if 30°F [-1°C] is the

minimum expected entering loop temperature, the leaving

loop temperature would be approximately 22 to 25°F [-5.5

to -3.9°C] and freeze protection should be at 15°F [-9.5°C].

Calculations are as follows:

30°F - 15°F = 15°F [-1°C - 8.5°C = -9.5°C]

All alcohols should be premixed and pumped from a

reservoir outside of the building when possible or introduced

under water level to prevent fuming. Initially calculate the

total volume of uid in the piping system using Table 3.

Then use the percentage by volume shown in Table 4 for the

amount of antifreeze. Antifreeze concentration should be

checked from a well mixed sample using a hydrometer to

measure specic gravity.

Antifreeze Characteristics

Selection of the antifreeze solution for closed loop earth

coupled systems requires the consideration of many

important factors which have long-term implications on the

performance and life of the equipment. Each area of concern

leads to a dierent “best choice” of antifreeze. The fact is

that there is no “ideal” antifreeze and any choice will require

compromises in one area or another. Some of the factors

to consider are safety, thermal performance, corrosiveness,

local codes, stability, convenience, and cost.

Flow Controller 3

Rev.:Feburary 9,2016

14 Geothermal Heat Pump Systems

Antifreeze Selection

Table 4: Antifreeze Percentages by Volume

NOTICE: DO NOT use automotive windshield washer

uid as antifreeze. Most washer uid contains

chemicals that will cause foaming.

WARNING!

WARNING! Always use properly marked vehicles (D.O.T.

placards), and clean/suitable/properly identied containers

for handling ammable antifreeze mixtures. Post and

advise those on the jobsite of chemical use and potential

dangers of handling and storage.

CAUTION!

CAUTION! Always obtain MSDS safety sheets for all

chemicals used in ground loop applications including

chemicals used as antifreeze.

Methanol - Methanol or wood alcohol is considered toxic in

any form, has good heat transfer, low to mid price, ammable

in concentrations greater than 25%, non-corrosive, and low

viscosity. Methanol has delivered outstanding performance in

earth loops for over 20 years. Its only drawbacks are toxicity

and ammability. Although methanol enjoys widespread

consumer use as a windshield washer uid in even higher

concentrations, some local codes may limit its use in earth

loops. To increase safety, a premixed form should be used on

the jobsite to increase the safety factor. Pure methanol can be

purchased from any chemical supplier.

Ethanol - Ethanol or grain alcohol exhibits good heat

transfer (slightly less than methanol), higher price, and is

ammable in concentrations greater than 10%. Ethanol

is generally non-corrosive and has medium viscosity.

Ethanol in its pure form is considered nontoxic and shows

promise as a geothermal heat transfer uid. However the

U.S. Bureau of Alcohol, Tobacco, and Firearms (ATF) limit

its distribution. All non-beverage ethanol is required to be

denatured and rendered unt to drink. Generally this is done

by adding a small percentage of toxic substances such

as methanol, benzene, or gasoline as a denaturant. Many

of these denaturants are dicult to identify by the casual

user and many are not compatible with polyethylene pipe.

Only denatured ethanol can be purchased for commercial

use. The use of ethanol is not recommended because of

the unknown denaturants included in the solution, and their

possible toxicity and damage resulting to polyethylene

piping systems. Denaturing agents that are petroleum based

can damage polyethylene pipe.

Ethylene glycol - Generally non-corrosive, expensive,

medium heat transfer, considered toxic. Its toxicity has

prevented its widespread use in the ground source industry

in spite of its widespread use in traditional water-source

heat pump applications. Ethylene glycol is not currently

recommended as ground-source antifreeze.

Propylene glycol - Nontoxic, non-corrosive, expensive, hard to

handle when cold, poorest heat transfer, has formed “slime-

type” coatings inside pipe. Poor heat transfer has required

its removal in some systems. Propylene glycol is acceptable

in systems anticipating loops temperatures no colder than

40°F [4.4°C]. These systems typically use antifreeze because

of low ambient conditions (outside plumbing or cooling

tower, etc.). When loop temperatures are below 40°F [4.4°C],

the uid becomes very dicult to pump and heat transfer

characteristics suer greatly. Only food grade propylene glycol

is recommended to prevent the corrosion inhibitors (often

present in other mixtures) from reacting with local water and

‘coming out’ of solution to form slime type coatings inside heat

exchangers and thus hinder heat transfer. If propylene glycol

must be used (e.g. code requirements), careful consideration

of loop Reynolds numbers, pump selection and pressure drop

must be considered.

Potassium acetate - Nontoxic, good heat transfer, high price,

non-corrosive with added inhibitors, low viscosity. Due to its

low surface tension, Potassium Acetate has been known to

leak through mechanical ttings and certain thread sealants.

A variant of the salt family, it can be extremely corrosive when

exposed to air. Potassium Acetate is not recommended in

ground-source applications due to the leaking and (ultimately)

corrosion problems associated with it.

Contact the Technical Services Department if you have any

questions as to antifreeze selection.

Type

Minimum Temperature

for Low Temperature Protection

10°F

[-12.2°C]

15°F

[-9.4°C]

20°F

[-6.7°C]

25°F

[-3.9°C]

Methanol

Propylene Glycol

Ethanol*

21%

29%

23%

17%

24%

20%

13%

18%

16%

8%

12%

11%

* Must not be denatured with any petroleum based product

15

Flow Controller 3

Rev.: Feburary 9, 2016

Antifreeze Charging

WARNING!

WARNING! Always dilute alcohols with water (at least

50% solution) before using. Alcohol fumes are ammable

and can cause serious injury or death if not handled

properly.

It his highly recommended to utilize premixed antifreeze uid

where possible to alleviate many installation problems and

extra labor.

The following procedure is based upon pure methanol and can

be implemented during the Full Flush procedure with three

way valves in the Figure 10D - Valve Position D. If a premixed

methanol of 15°F [-9.4°C] freeze protection is used, the system

can be lled and ushed with the premix directly to prevent

handling pure methanol during the installation.

1) Flush loop until all air has been purged from system and

pressurize to check for leaks before adding

any antifreeze.

2) Run discharge line to a drain and hook up antifreeze

drum to suction side of pump (if not adding below

water level through approved container). Drain ush cart

reservoir down to pump suction inlet so reservoir can

accept the volume of antifreeze to be added.

3)

Calculate the amount of antifreeze required by rst

calculating the total uid volume of the loop from Table 3.

Then calculate the amount of antifreeze needed using Table

4 for the appropriate freeze protection level. Many southern

applications require freeze protection because of exposed

piping and Flow Controller to ambient conditions.

4) Isolate unit and prepare to ush only through loop.

Start ush cart, and gradually introduce the required

amount of liquid to the ush cart tank (always introduce

alcohols under water or use suction of pump to draw

in directly to prevent fuming) until attaining the proper

antifreeze protection. The rise in ush reservoir level

indicates amount of antifreeze added (some carts are

marked with measurements in gallons or liters). A ten

inch [25.4 cm] diameter cylinder, 3 foot [91.4 cm] tall

holds approximately 8 gallons [30.3 liters] of uid plus the

hoses (approx. 2 gallons, [7.6 liters], which equals about

10 gallons [37.9 liters] total. If more than one tankful is

required, the tank should be drained immediately by

opening the waste valve of the ush cart noting the

color of the discharge uid. Adding food coloring to the

antifreeze can help indicate where the antifreeze is in the

circuit and prevents the dumping of antifreeze out the

waste port. Repeat if necessary.

5) Be careful when handling methanol (or any alcohol).

The fumes are ammable, and care should be taken

with all ammable liquids. Open ush valves to ush

through both the unit and the loop and ush until uid is

homogenous and mixed. It is recommended to run the

unit in the heating and cooling mode for 15-20 minutes

each to ‘temper’ the uid temperature and prepare it for

pressurization. Devoting this time to clean up can be

useful. This procedure helps prevent the periodic “at”

loop condition.

6) Close the ush cart return valve; and immediately

thereafter, close the ush cart supply valve, leaving a

positive pressure in the loop of approximately 50 psi [345

kPa]. This is a good time to pressure check the system

as well. Check the freeze protection of the uid with the

proper hydrometer to ensure that the correct amount of

antifreeze has been added to the system. The hydrometer

can be dropped into the ush reservoir and the reading

compared to Chart 1A for Methanol, 1B for Propylene

Glycol, and 1C for Ethanol to indicate the level of freeze

protection. Do not antifreeze more than a +10°F [-12.2°C]

freeze point. Specic gravity hydrometers are available

in the residential price list. Repeat after reopening and

ushing for a minute to ensure good second sample

of uid. Inadequate antifreeze protection can cause

nuisance low temperature lockouts during cold weather.

7)

Close the ush cart return valve; immediately thereafter,

close the ush cart supply valve, shut o the ush cart

leaving a positive pressure in the loop of approximately

50-75 psi [345-517 kPa]. Refer to Figure 10E for more

details.

Heat Pump Low Water Temperature Cutout Selection

The CXM control allows the eld selection of low water

(or water-antifreeze solution) temperature limit by clipping

jumper JW3 - FP1, which changes the sensing temperature

associated with thermistor FP1. Note that the FP1 thermistor

is located on the refrigerant line between the coaxial heat

exchanger and expansion device (TXV). Therefore, FP1 is

sensing refrigerant temperature, not water temperature,

which is a better indication of how water ow rate/

temperature is aecting the refrigeration circuit.

NOTICE: Always verify proper freeze protection level

BEFORE changing FP1 setting.

The factory setting for FP1 is for systems using water (30°F

[-1.1°C] refrigerant temperature). In low water temperature

(extended range) applications with antifreeze (most ground

loops), jumper JW3 - FP1 should be clipped as shown in

Figure 11 to change the setting to 10°F [-12.2°C] refrigerant

temperature, a more suitable temperature when using

an antifreeze solution. All residential units include water/

refrigerant circuit insulation to prevent internal condensation,

which is required when operating with entering water

temperatures below 59°F [15°C].

NOTICE: Failure to clip jumper JW3 - FP1 will result in a

service call in heating season when the unit locks out on low

water temperature fault.

Flow Controller 3

Rev.:Feburary 9,2016

16 Geothermal Heat Pump Systems

Antifreeze Charging

Figure 11: Low Temperature Cutout Selection

LT1

LT2

LT 1

LT 1

LT 2

LT 2

CXM PCB

JW3-FP1 jumper

should be clipped

for low temperature

operation

Pressure/Temperature Ports

The pressure/temperature ports (P/T ports) supplied with

the earth loop connector kit are provided as a means of

measuring ow and temperature. The water ow through

the unit can be checked by measuring the incoming water

pressure at the supply water P/T port and subtracting

the leaving water pressure at the return water P/T port.

Comparing the pressure dierential to the pressure drop

table/ow rate in the unit installation manual will determine

the ow rate through the unit. Ground loop required ow

rates are 2.25 to 3 U.S. gpm per nominal cooling ton [2.41 to

3.23 l/m per kW]. Note: Minimum ow for units is 2.25 gpm

per ton [2.41 l/m per kW].

Example: Model 036 has a 50°F entering water temperature

(EWT) and 50 psi entering water pressure (EWP). The leaving

water pressure (LWP) is 46 psi. Pressure Drop (PD) = EWP

- LWP = 50 - 46 = 4 psi. In the unit Installation manual, a 3.9

PSI pressure drop is equivalent to 9 GPM at 50°F EWT on

the chart. More ow will not hurt the performance. However,

insucient ow can signicantly reduce capacity and

possibly even cause damage to the heat pump in extreme

conditions. Digital thermometers and pressure gauges

are needed for the P/T ports, which are available in the

residential price list.

NOTICE: Pressure/temperature gauges should be pushed

gently into P/T ports to prevent internal damage to the

port. Use same gauge and thermometer to determine the

dierential in pressure and temperature

Earth Loop Pressure

The earth loop must have a slight positive pressure to

operate the pumps [>3 psi, >20.7 kPa]. The system pressure

will drop as the earth loop pipe relaxes, and will uctuate as

the uid temperature changes. Typical earth loop pressures

range from approximately 15-50 psi [103-345 kPa]. At the

start-up of a system, the earth loops should have a (static)

holding pressure of approximately 50-75 psi [345-517 kPa].

Maximum operating pressure should never exceed 100 psi

[689 kPa] under any circumstance.

NOTICE: It is recommended to run the unit in the cooling,

then heating mode for 15-20 minutes each to ‘temper’ the

uid temperature and prepare it for pressurization. This

procedure helps prevent the periodic “at” loop condition of

no pressure.

After pressurization, be sure the loop Flow Controller

provides adequate ow through the unit by checking

pressure drop across the heat exchanger and comparing it

to the pressure drop/ow rate tables in the unit Installation

manual. Flow Controller pump performance is shown in

Chart 2.

Start-Up of Flow Controller

1) Check to make sure that the loop and unit isolation

valves (if applicable) are completely open and the ush

ports are closed and sealed.

2) Check and record the earth loop pressure via the P/T

ports. Loop Pressure = In_______ Out_______.

3) Check and record the ow rate.

Flow Rate = _______gpm.

4) Check performance of unit. Refer to unit installation

manual. Replace all caps to prevent pressure loss.

When replacing a pump, isolate the pump from loop as in

Figure 12. Always disable power to the pumps and remove

pump power wiring if needed. The ve steps below outline

the detailed procedure.

17

Flow Controller 3

Rev.: Feburary 9, 2016

Flow Controller Pump Curves

0

20

[60]

40

[120]

60

[180]

80

[240]

100

[290]

120

[360]

0123456789101112131415161718192021222324252627282930

Flow Rate

Head, ft [kPa]

1-Grundfos 26-99

2-Grundfos 26-99

2-Grundfos 26-116

3-Grundfos 26-99

0.06 0.13 0.19 0.25 0.32 0.38 0.44 0.50 0.57 0.63 0.69 0.76 0.82 0.88 0.95 1.01 1.07 1.14 1.20 1.26 1.32 1.38 1.45 1.51 1.58 1.64 1.70 1.77 1.83 1.89

GPM

L/S

Chart 2: Flow Controller Performance

Flow Controller Pump Curves

Flow Controller 3

Rev.:Feburary 9,2016

18 Geothermal Heat Pump Systems

Pump Replacement Procedure

Figure 12: Pump Replacement Procedure

Front of F.C.

Valve Position

WARNING!

NOTICE: Remember this procedure will dilute the antifreeze

mixture by a couple of gallons [7-8 liters]. If performed more

than twice on any earth loop, the antifreeze concentration

should be checked with a hydrometer and antifreeze added

as needed.

NOTICE: Before attempting to replace an existing Flow

Controller pump motor, verify the model numbers with a

distributor, as there have been several pump/valve/Flow

Controller vendors used with this equipment. Grundfos and

Taco pumps and even dierent revisions of the same brand

of pump are not compatible with each other.

1. Close valves as shown in Figure 12.

2. Place rag under pump to collect loop uid.

3. Remove 4 Allen head mounting bolts and lift o pump

stator housing.

4. Replace with new pump insuring no foreign material has

been introduced, and evenly install the four Allen head

mounting bolts.

5.

Place garden hose supply and return on ush ports as

shown in Figure 12 and open valves to ush through

the unit portion of loop. When water ows clear, close

return side to pressurize. Then, close the supply side

valve. Finally, close 3-way valves to operation position as

shown in Figure 10E. In situations where this procedure

may not be feasible, the loop can also be re-ushed

using the complete ushing procedure outlined for

installation.

WARNING! Disconnect electrical power source to prevent

injury or death from electrical shock.

Closed Loop Basics

Closed Loop Earth Coupled Heat Pump systems are

commonly installed in one of three congurations: horizontal,

vertical and pond loop. Each conguration provides the

benet of using the moderate temperatures of the earth as

a heat source/heat sink. Piping congurations can be either

series or parallel.

Series piping congurations typically use 1-1/4 inch, 1-1/2

inch or 2 inch pipe. Parallel piping congurations typically

19

Flow Controller 3

Rev.: Feburary 9, 2016

Geothermal Closed Loop Design

Table 5: Fusion Times for Polyethylene 3408 ASTM Pipe

use 3/4 inch or 1 inch pipe for loops and 1-1/4 inch, 1-1/2

inch or 2 inch pipe for headers and service lines. Parallel

congurations require headers to be either “closed-coupled”

short headers or reverse return design.

Select the installation conguration which provides you and

your customer the most cost eective method of installation

after considering all application constraints.

Loop design takes into account two basic factors. The rst is

an accurately engineered system to function properly with low

pumping requirements (low Watts) and adequate heat transfer

to handle the load of the structure. The second is to design a

loop with the lowest installed cost while still maintaining a high

level of quality. These factors have been taken into account in

all of the loop designs presented in this manual.

In general terms, all loop lengths have been sized by the

GeoDesigner loop sizing software so that every loop has

approximately the same operating costs. In other words,

at the end of the year the homeowner would have paid

approximately the same amount of money for heating,

cooling, and hot water no matter which loop type was

installed. This leaves the installed cost of the loop as the main

factor for determining the system payback. Therefore, the

“best” loop is the most economical system possible given the

installation requirements.

Pipe Fusion Methods

Two basic types of pipe joining methods are available for earth

coupled applications. Polyethylene pipe can be socket fused

or butt fused. In both processes the pipe is actually melted

together to form a joint that is even stronger than the original

pipe. Although when either procedure is performed properly

the joint will be stronger than the pipe wall, socket fusion

in the joining of 2” pipe or less is preferred because of the

following:

• Allowable tolerance of mating the pipe is much greater in

socket fusion. According to general fusion guidelines, a

3/4” SDR11 butt fusion joint alignment can be o no more

than 10% of the wall thickness (0.01 in. [2.54mm]). One

hundredth of an inch (2-1/2 mm) accuracy while fusing in a

dicult position can be almost impossible to attain in the

eld.

• The actual socket fusion joint is 3 to 4 times the cross

sectional area of its butt fusion counterpart in sizes

under 2” and therefore tends to be more forgiving of

operator skill.

• Joints are frequently required in dicult trench

connections and the smaller socket fusion iron is more

mobile. Operators will have less of a tendency to cut

corners during the fusion procedure, which may happen

during the facing and alignment procedure of butt fusion.

In general socket fusion loses these advantages in fusion

joints larger than 2” and of course socket ttings become

very expensive and time consuming in these larger sizes.

Therefore, butt fusion is generally used in sizes larger than

2”. In either joining method proper technique is essential for

long lasting joints. All pipe and ttings in the residential price

list are IGSHPA (International Ground Source Heat Pump

Association) approved. All fusion joints must be performed

by certied fusion technicians. Table 5 illustrates the proper

fusion times for Geothermal PE 3408 ASTM Pipe.

Parallel vs Series Congurations

Initially, loops were all designed using series style ow due

to the lack of fusion ttings needed in parallel systems. This

resulted in large diameter pipe (>1-1/4”) being used to reduce

pumping requirements due to the increased pressure drop of

the pipe. Since fusion ttings have become available, parallel

ow using (3/4” IPS) for loops 2 ton [7 kW] and above has

become the standard for a number of reasons.

• Cost of Pipe - The larger diameter (>1-1/4”) pipe is twice

the cost of the smaller (3/4” IPS) pipe. However, the

heat transfer capability due to the reduced surface area

of the smaller pipe is only decreased by approximately

10-20%. In loop designs using the smaller pipe, the pipe

length is simply increased to compensate for the small

heat transfer reduction, although it still results in around

50% savings in pipe costs over the larger pipe in series.

In some areas 1-1/4” vertical bores can be more cost

eective, where drilling costs are high.

• Pumping power - Parallel systems generally can have

much lower pressure drop and thus smaller pumps due

to the multiple ow paths of smaller pipes in parallel.

• Installation ease - The smaller pipe is easier to handle

during installation than the larger diameter pipe. The

‘memory’ of the pipe can be especially cumbersome

when installing in cold conditions. Smaller pipe takes less

time to fuse and is easier to cut, bend, etc.

Pipe Size

Socket

Fusion

Time (Sec)

Butt Fusion

Holding

Time

Curing

Time

Time

(sec.)

Bead,

in [mm]

3/4” IPS 8 - 10 8 1/16 [1.6] 60 Sec 20 min

1” IPS 10 - 14 12 1/16 [1.6] 60 Sec 20 min

1-1/4” IPS 12 - 15 15 1/16 - 1/8

[1.6 - 3.2] 60 Sec 20 min

1-1/2” IPS 15 - 18 15 1/16 - 1/8

[1.6 - 3.2] 60 Sec 20 min

2” IPS 18 - 22 18 1/8 [3.2] 60 Sec 20 min

Always use a timing device

Flow Controller 3

Rev.:Feburary 9,2016

20 Geothermal Heat Pump Systems

Geothermal Closed Loop Design

In smaller loops of two tons [7 kW] or less, the reasons for

using parallel loops as listed above may be less obvious.

In these cases, series loops can have some additional

advantages:

• No header - ttings tend to be more expensive and

require extra labor and skill to install.

• Simple design - no confusing piping arrangement for

easier installation by less experienced installers.

Parallel Loop Design

Loop Conguration - Determining the style of loop primarily

depends on lot (yard) size and excavation costs. For instance,

a horizontal 1 pipe loop will have signicantly (400%) more

trench than a horizontal 6 pipe loop. However, the 6 pipe will

have about 75% more feet of pipe. Therefore, if trenching

costs are higher than the extra pipe costs, the 6 pipe loop

is the best choice. Remember that labor is also a factor in

loop costs. The 6 pipe loop could also be chosen because

of the small available space. Generally a contractor will know

after a few installations which conguration is the most cost

eective. This information can be applied to later installations

for a more overall cost eective installation for the particular

area. Depth of the loop in horizontal systems generally does

not exceed 5 feet [1.5 meters] because of trench safety issues

and the sheer amount of soil required to move. In vertical

systems economic depth due to escalating drilling costs in

rock can sometimes require what is referred to as a parallel-

series loop. That is, a circuit will loop down and up through

two consecutive bores (series) to total the required circuit

length. Moisture content and soil types also eect the earth

loop heat exchanger design. Damp or saturated soil types will

result in shorter loop circuits than dry soil or sand.

Loop Circuiting - Loops should be designed with a

compromise between pressure drop and turbulent ow

(Reynold’s Number) in the heat exchange pipe for heat

transfer. Therefore the following rules should be observed

when designing a loop:

• 3 gpm per ton [3.23 l/m per kW] ow rate (2.25 gpm per

ton [2.41 l/m per kW] minimum). In larger systems 2.5 to

2.7 gpm per ton [2.41 to 2.90 l/m per kW] is adequate in

most cases. Selecting pumps to attain exactly 3 gpm per

ton [3.23 l/m per kW] is generally not cost eective from

an operating cost standpoint.

• One circuit per nominal equipment ton [3.5 kW] with

3/4” IPS and 1” IPS circuit per ton [3.5 kW]. This rule can

be deviated by one circuit or so for dierent

loop congurations.

Header Design - Headers for parallel loops should be

designed with two factors in mind, the rst is pressure

drop, and the second is ability to purge all of the air from

the system (“ushability”). The header shown in Figure 13A

is a standard header design through 15 tons [52.8 kW] for

polyethylene pipe with 2” supply and return runouts. The

header shown in Figure 13B is a standard header design

through 5 tons [17.6 kW] for polyethylene pipe using 1-1/4”

supply and return runouts. Notice the reduction of pipe from

2” IPS supply/return circuits 15 to 8 to 1-1/4” IPS pipe for

circuits 7 to 4 to 3/4” IPS to supply circuits 3, 2, and 1. This

allows minimum pressure drop while still maintaining 2 fps

[0.6 m/s] velocity throughout the header under normal ow

conditions (3 gpm/ton [3.23 l/m per kW]), thus the header

as shown is self-ushing under normal ow conditions. This

leaves the circuits themselves (3/4” IPS) as the only section

of the loop not attaining 2 fps [0.6 m/s] ush velocity under

normal ow conditions (3 gpm per ton [3.23 l/m per kW],

normally 3 gpm [11.4 l/m] per circuit). Pipe diameter 3/4” IPS

requires 3.8 gpm [14.4 l/m] to attain 2 fps [0.6 m/s] velocity.

Therefore, to calculate ushing requirements for any PE loop

using the header styles shown, simply multiply the number

of circuits by the ushing ow rate of each circuit (3.8 gpm

for 2 fps velocity [14.4 l/m for 0.6 m/s]). For instance, on a 5

circuit loop, the ush ow rate is 5 circuits x 3.8 gpm/circuit

= 19 gpm [5 circuits x 14.4 l/m per circuit = 72 l/m or 1.2 l/s].

NOTICE: Whenever designing an earth loop heat exchanger,

always assume the worst case, soil and moisture conditions

at the job site in the nal design. In other words, if part of the

loop eld is saturated clay, and the remainder is damp clay,

assume damp clay for design criteria.

Headers that utilize large diameter pipe feeding the last

circuits should not be used. PE 1-1/4” IPS pipe requires 9.5

Table of contents

Other ClimateMaster Control Unit manuals

Popular Control Unit manuals by other brands

Leviton

Leviton LV200 user guide

SymCom

SymCom PumpSaver Plus 111P installation instructions

Measurement Computing

Measurement Computing CIO-DDA06/16 user guide

Energeeks

Energeeks EG-VALVKIT001 Quick installation guide

getAir

getAir SmartFan TOUCH Installation and operating instructions

Spirax Sarco

Spirax Sarco HM Series Installation and maintenance instructions

Heicko

Heicko HD15BT user manual

Buderus

Buderus EM100 Installation instructions for skilled labour

Motorline professional

Motorline professional MC102 User& installer's manual

Telit Wireless Solutions

Telit Wireless Solutions GC864 Series Hardware user's guide

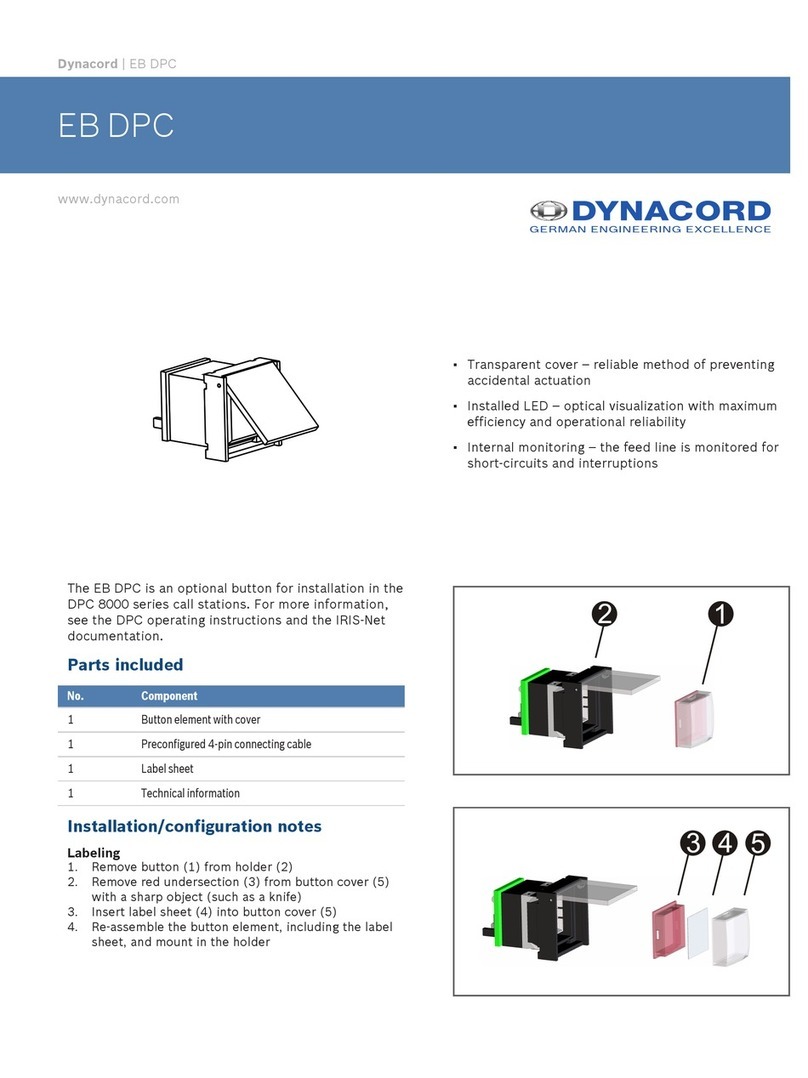

Dynacord

Dynacord EB DPC manual

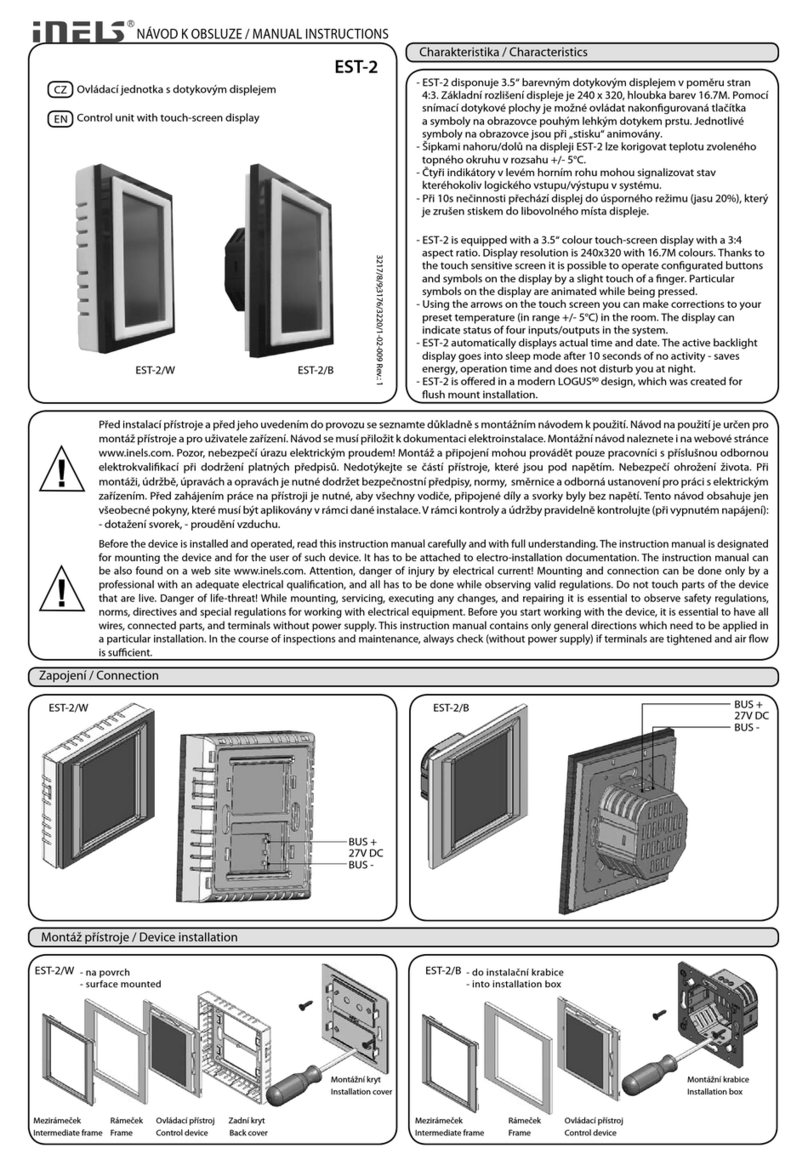

iNels

iNels EST-2 Series Manual instructions