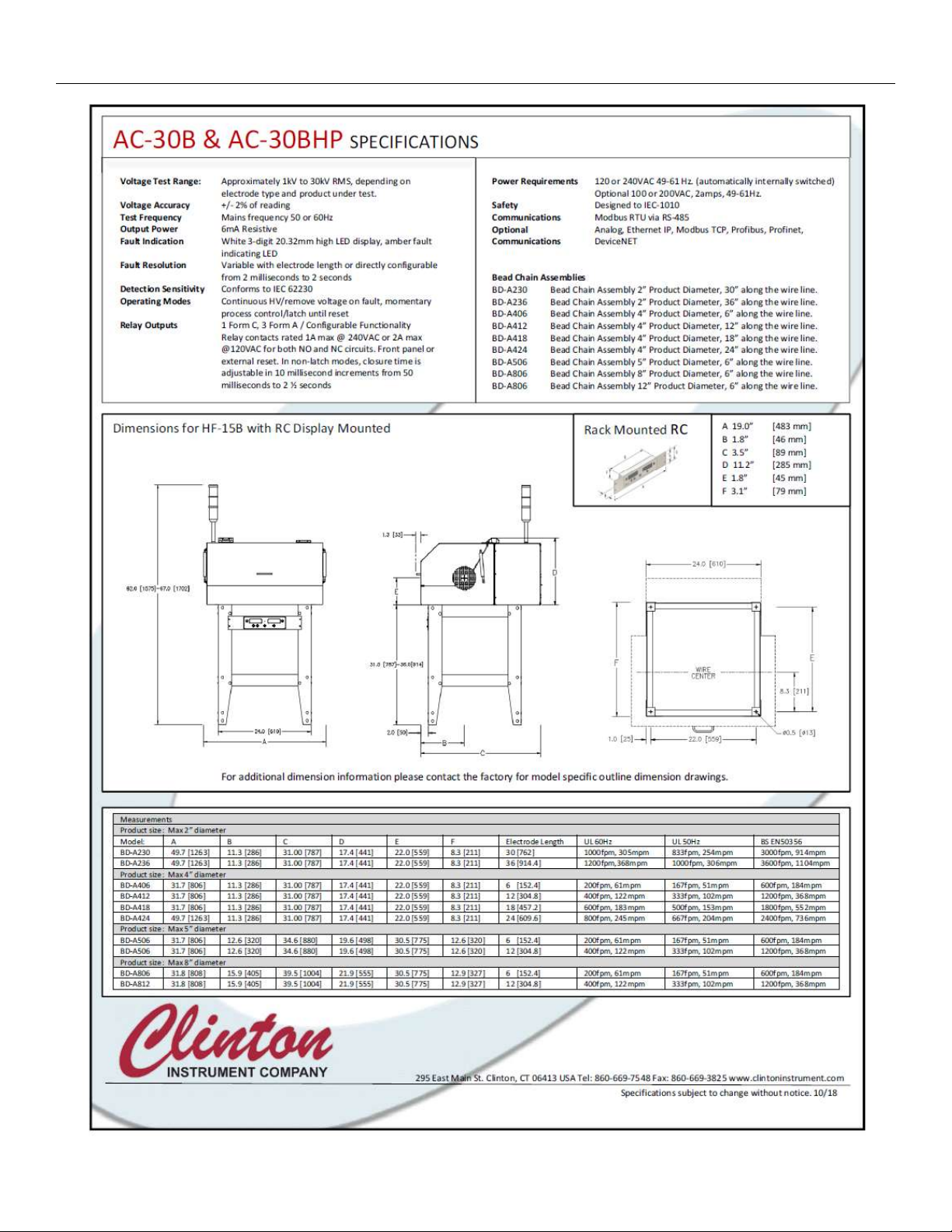

Models AC-30B and AC-30BHP Mains Frequency Spark Tester

AC-30B Instruction Manual –Page 2

Contents

DECLARATION OF CONFORMITY........................................................................................................................................................5

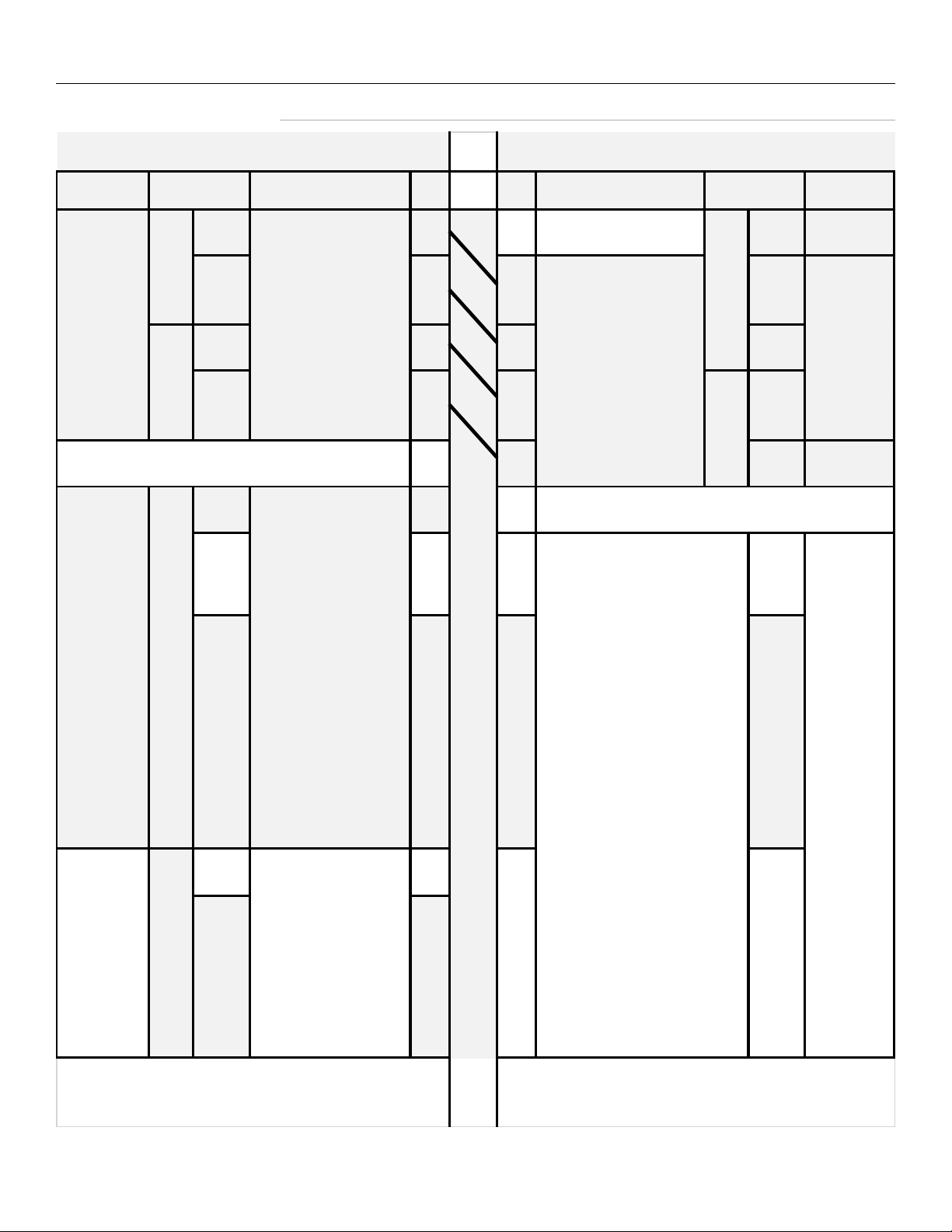

SPECIFICATIONS ................................................................................................................................................................................6

SAFETY ..............................................................................................................................................................................................8

SAFETY SYMBOL .........................................................................................................................................................................................8

ENVIRONMENTAL CONDITIONS......................................................................................................................................................................8

AVOID THE RISK OF FIRE! .............................................................................................................................................................................9

CAUTION:PACEMAKER WARNING .................................................................................................................................................................9

CAUTION:OZONE PRODUCTION ....................................................................................................................................................................9

ELECTRICAL SHOCK HAZARD FROM PRODUCTION LINE SPARK TESTERS................................................................................................................ 10

INSTALLATION .................................................................................................................................................................................11

CAUTION:.............................................................................................................................................................................................11

UNPACKING.............................................................................................................................................................................................11

SITE PREPARATION....................................................................................................................................................................................12

Select a suitable location for the spark tester: ................................................................................................................................12

Select a suitable location for the spark tester: ................................................................................................................................12

RC Control Unit:............................................................................................................................................................................... 13

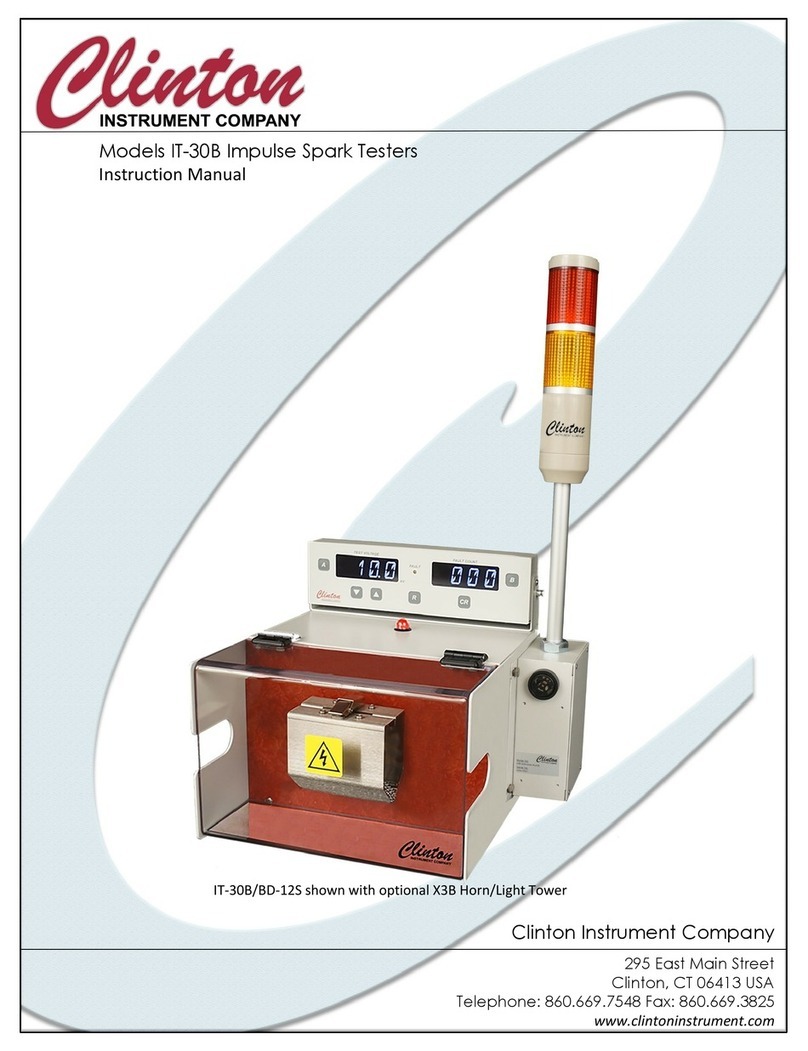

X3B Horn/Light Tower: ....................................................................................................................................................................13

Provide for ventilation of the Test Module......................................................................................................................................13

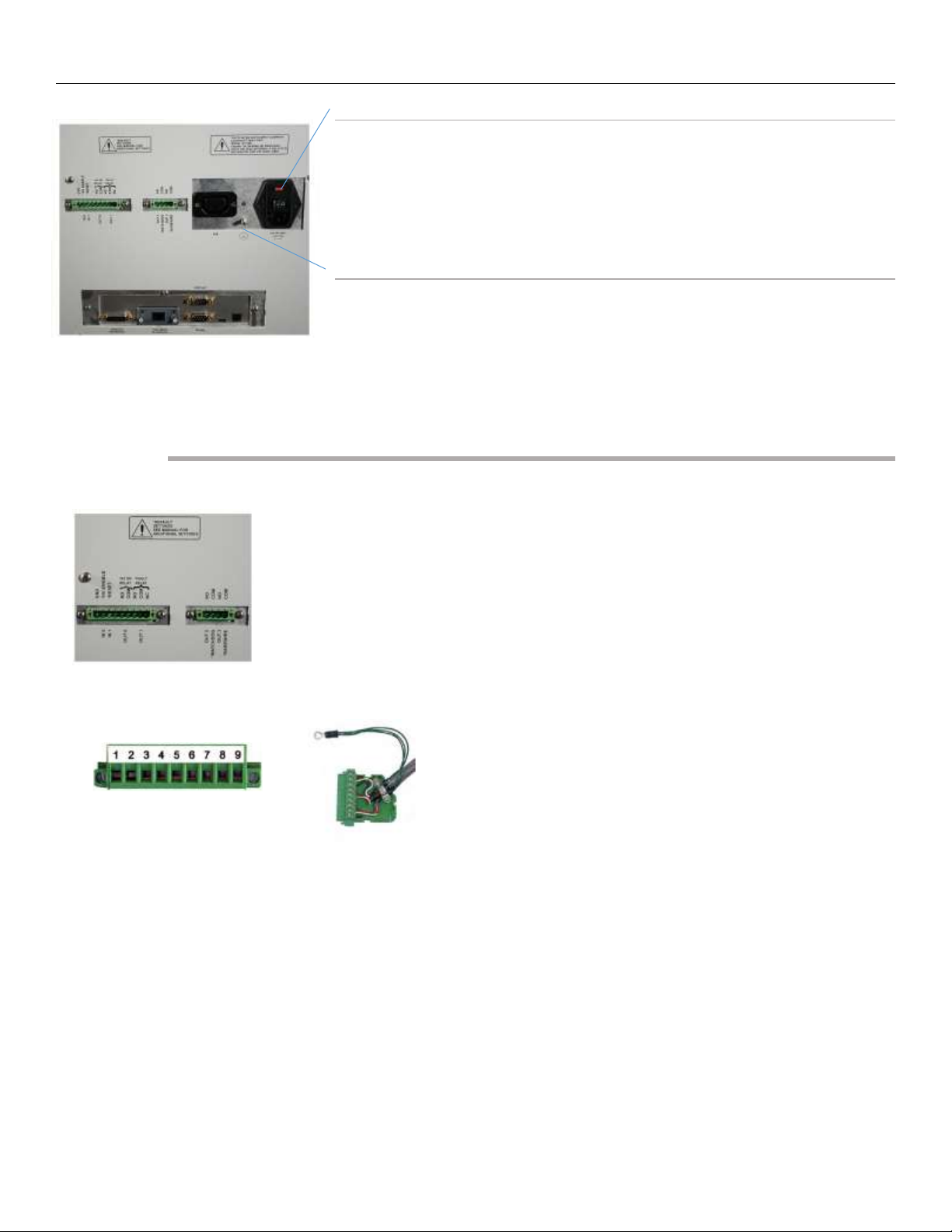

POWER WIRING .......................................................................................................................................................................................13

Install an external disconnecting device..........................................................................................................................................13

Mains Power....................................................................................................................................................................................14

Ground the Spark Tester.................................................................................................................................................................. 14

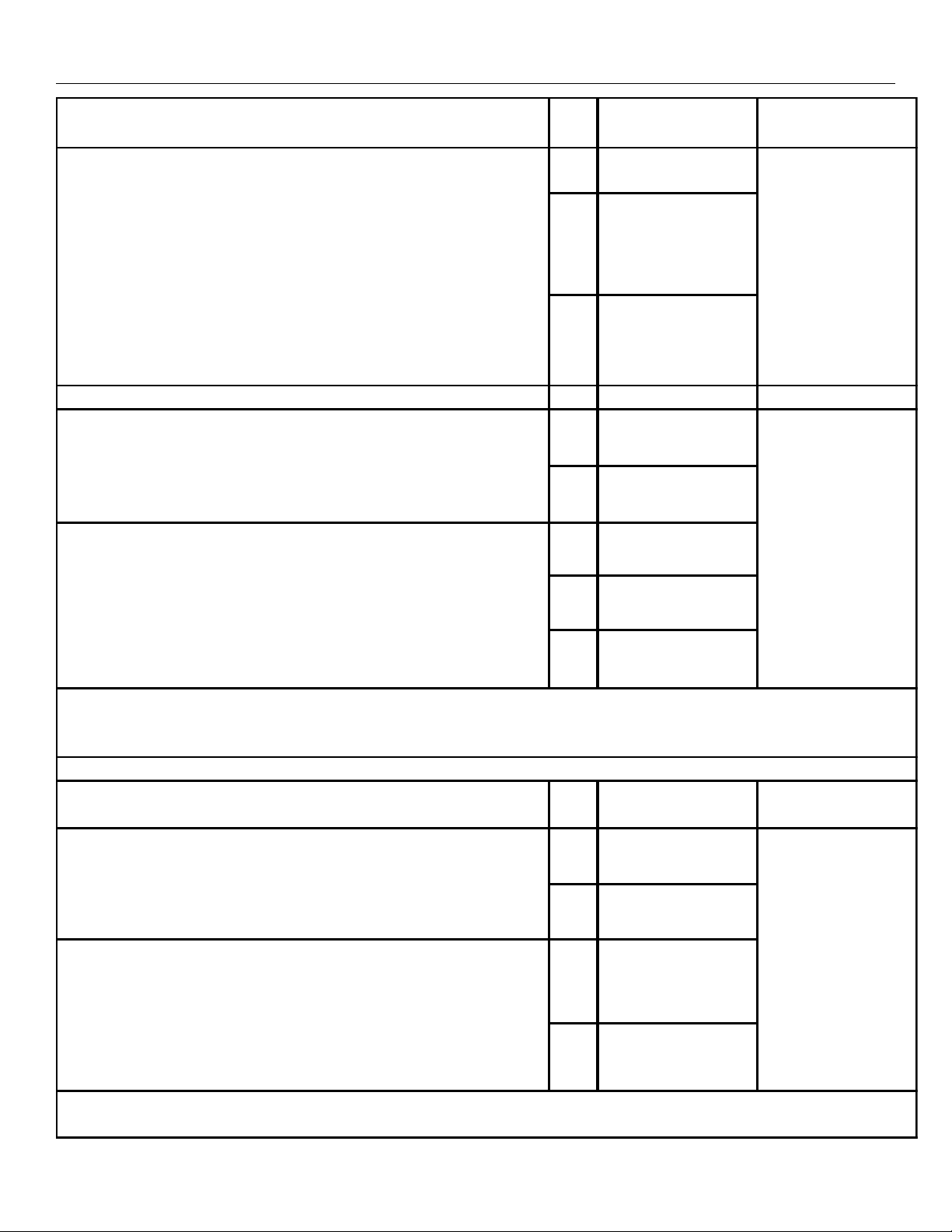

TERMINAL BLOCK WIRING..........................................................................................................................................................................14

CONNECTING THE SERIAL RS-485 ...............................................................................................................................................................16

CONNECTING TO THE ANALOG INTERFACE .....................................................................................................................................................16

INSTALLING THE COMPACTCOM™MODULE ..................................................................................................................................................16

CONNECTING THE X3B ..............................................................................................................................................................................17

Unpacking the X3B ..........................................................................................................................................................................17

Connecting the X3B .........................................................................................................................................................................17

X3B to Spark Tester Connections.....................................................................................................................................................18

SPARK TESTER CONTROLS ...............................................................................................................................................................19

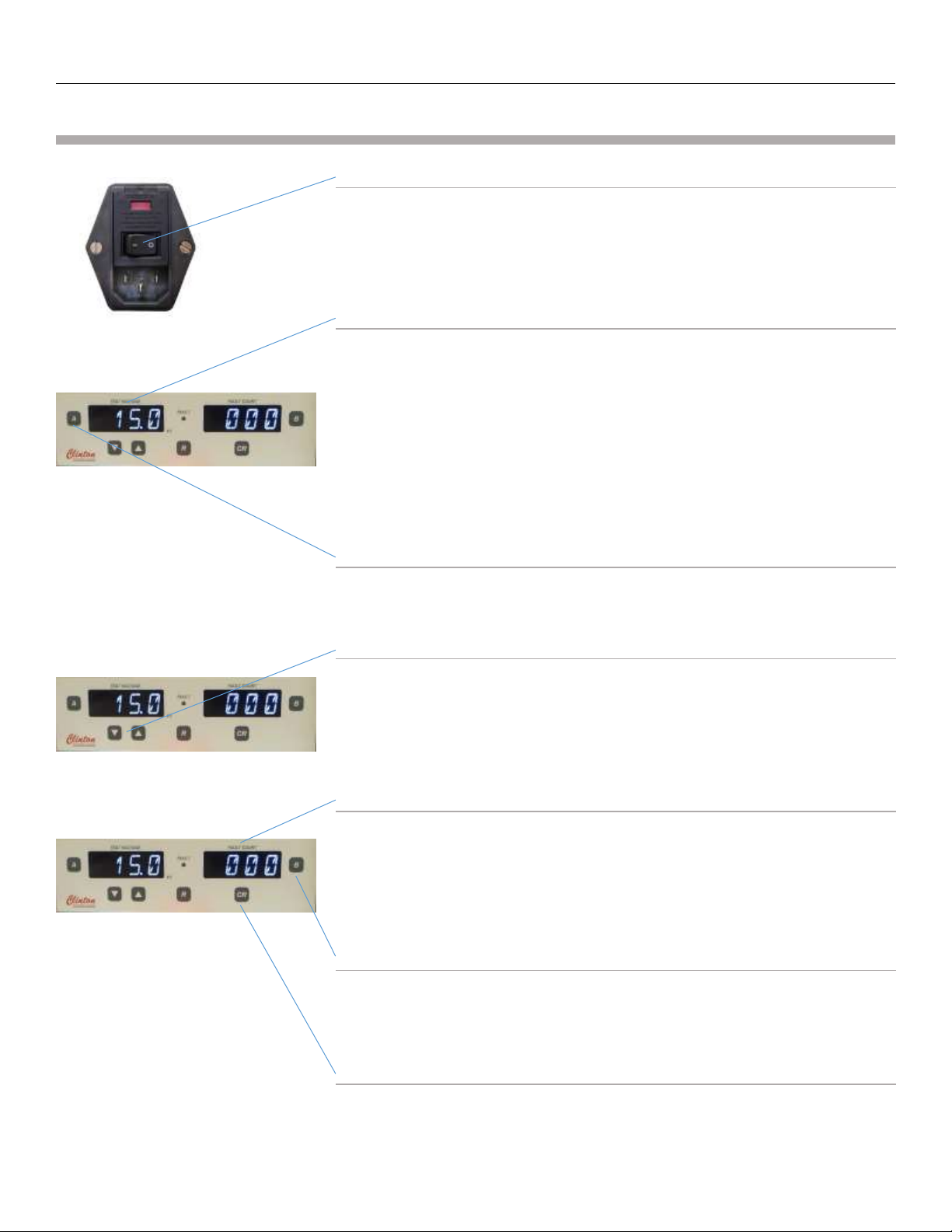

ON/OFF Power Switch .....................................................................................................................................................................19

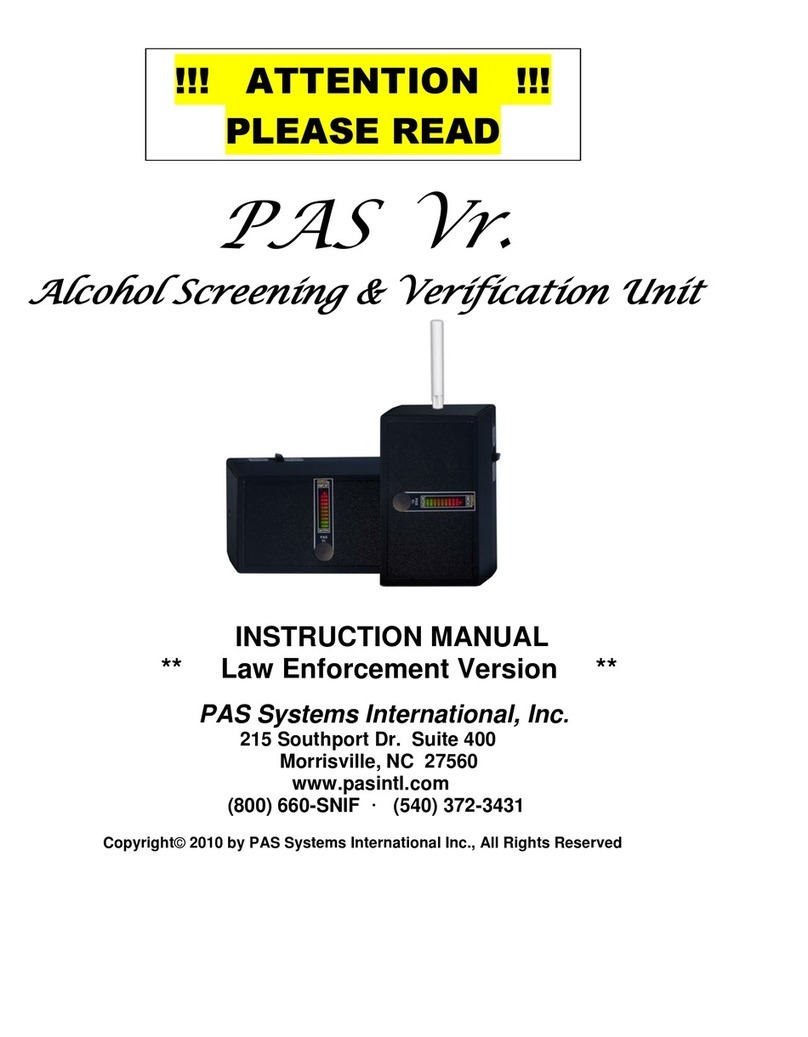

Voltmeter ........................................................................................................................................................................................ 19

“A” Button .......................................................................................................................................................................................19

UP/DOWN ARROW (VOLTAGE ADJUST) buttons.............................................................................................................................19

Fault Counter...................................................................................................................................................................................19

“B” Button .......................................................................................................................................................................................19

“CR” COUNT RESET button ..............................................................................................................................................................19

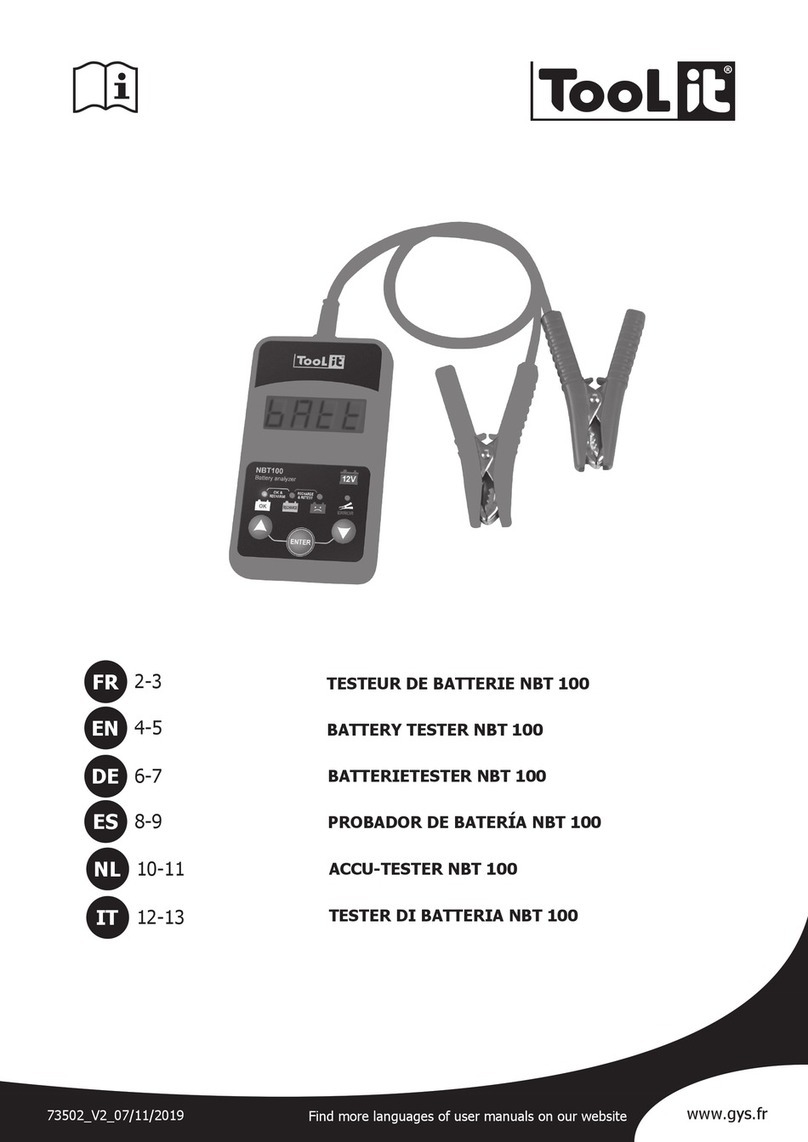

FAULT light ...................................................................................................................................................................................... 20

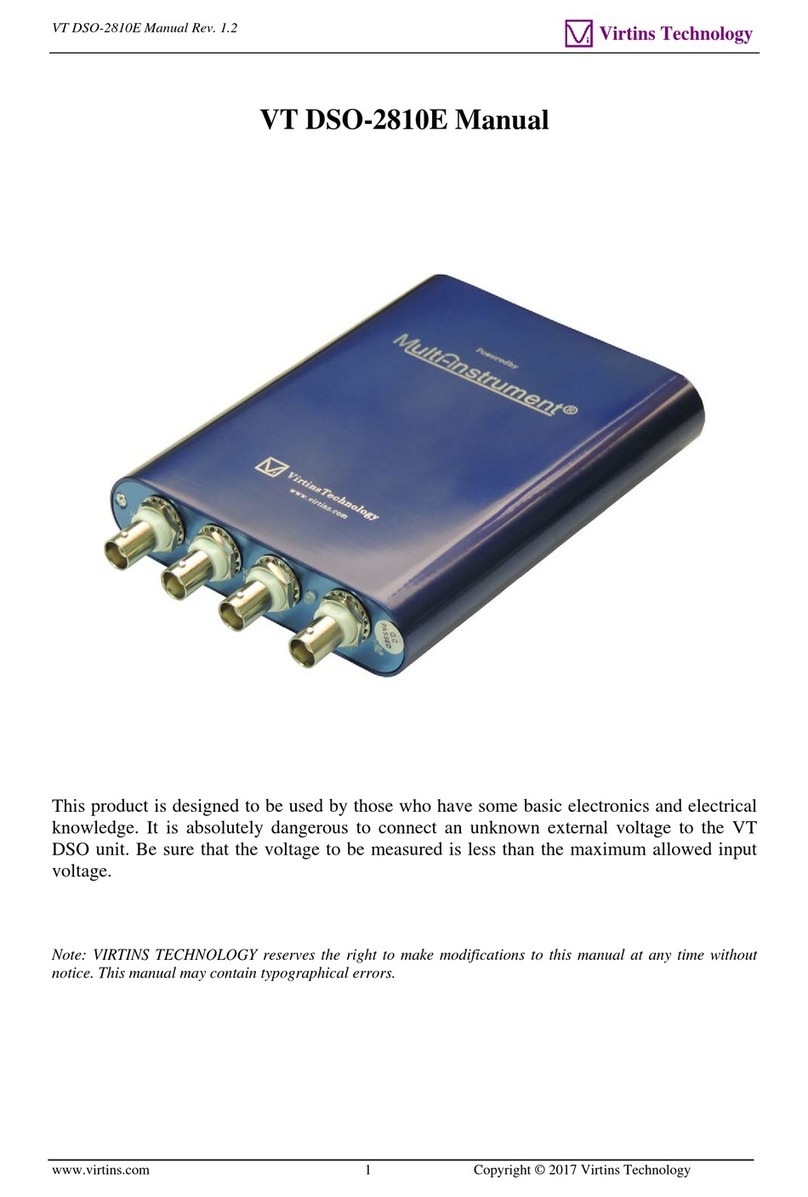

“R” RESET button............................................................................................................................................................................. 20

High Voltage On Lamp ....................................................................................................................................................................20

Safety Interlock switch ....................................................................................................................................................................20

Protective Cover ..............................................................................................................................................................................20

Bead Chain Electrode ......................................................................................................................................................................20

DEFINITION OF TERMS ....................................................................................................................................................................21