Clinton FL-20A User manual

Clinton Instrument Company

295 East Main Street

Clinton, CT 06413 USA

Telephone: 860.669.7548 Fax: 860.669.3825

www.clintoninstrument.com

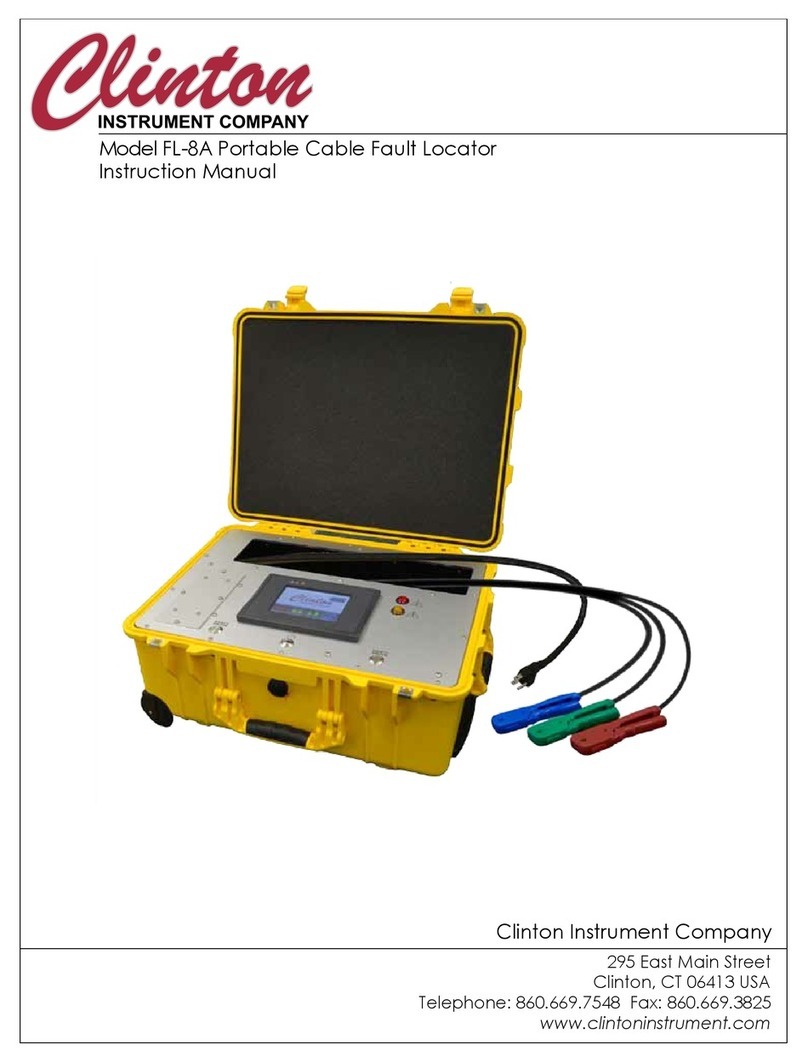

Model FL-20ACable Fault Locator

Instruction Manual

Rev J 11/19

MODEL FL-20A

Cable Fault Locator

Reels of rejected multi-conductor and shielded cable sit-

ting on the production oor are an expensive problem.

Until now, nding opens and shorts with an analog cable

fault locator took expertise and patience, since the procedure

required tedious meter and sensitivity adjustments as well as

mathematical calculation once the test was completed.

The digital FL-20A automates cable fault detection,

greatly reducing the time and training required to nd these

problems. Opens, metallic shorts, or high voltage shorts

between conductors or between conductor and shield are

pinpointed quickly and with ease. The operator simply con-

nects the FL-20A test probes to each end of the cable under

test, enters the cable length on the digital touch screen, and

selects “Shorts” or “Opens” to begin the test. The unit

quickly calculates the distance of the fault site from each test

probe, displays the location in feet or meters, and provides

a suggested trim area. The failure can then be cut out or

repaired and the remaining good product salvaged, resulting

in great savings to the producer.

>> Quickly locates opens, shorts and high

voltage shorts in cable lengths

>> Fully automated testing

>> Simple to operate

>> Color touch screen

>> Compact, lightweight unit

>> CE approved

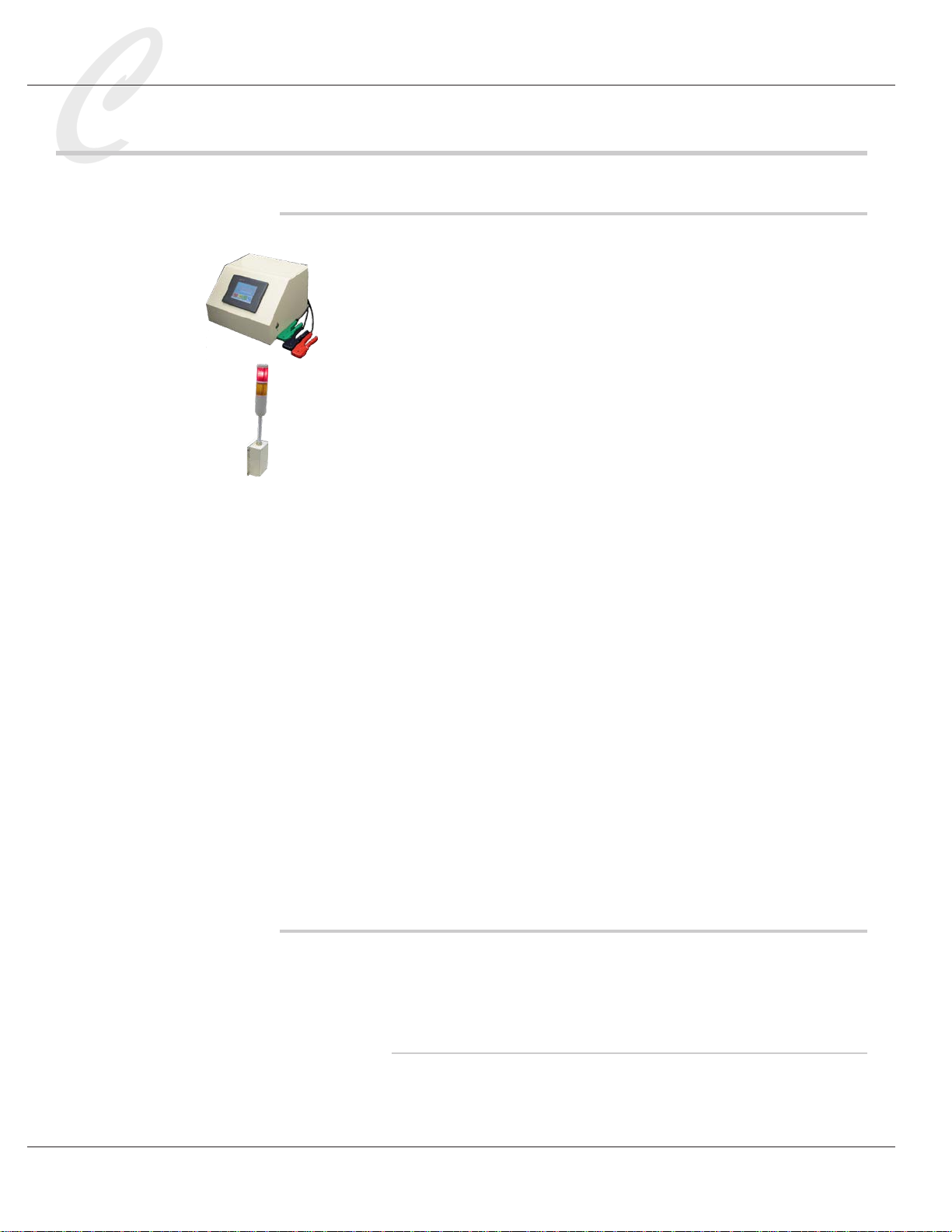

The FL-20A Cable Fault Locator, a compact 15”W x 14”D

x 10”H weighing only 38 lbs., is signicantly smaller and lighter

than its predecessors. It promises a great return on investment

by salvaging expensive cable assemblies and lowering the costs

associated with salvage.

Sample display screens

295 East Main St. • Clinton, CT 06413 USA • Tel: 860.669.7548 • Fax: 860.669.3825 • www.clintoninstrument.com

Fault Definitions:

Open.. ................................ A condition where a single conductor has no

continuity from one end to the other.

Metallic Short ...................... Two conductors without insulation or a conductor and

a shield which physically come into contact with one

another.

High Voltage Short .............. Two conductors or a conductor and a shield which

have no insulation between them but do not contact

one another.

Voltage Test Range ..............0-20KV D.C.

Display ............................... 6-inch backlit color TFT touch screen.

Output Current .....................6 ma. maximum.

FL-20A

SPECIFICATIONS

Equipment Accuracy .............Better than 1% of total cable length (dependent on

accuracy of actual cable footage and product uniformity).

Cable Loop Resistance

Metallic Short .............50 milliohms minimum.

High Voltage Short ......300 milliohms minimum.

Dimensions:

FL-20A ....................... 15”W x 14”D x 10”H.

FL-20A with X3F .........15”W x 14”D x 25.5”H.

Test Leads...................10’ standard, 20 & 30 ft. available.

Weight ...............................38 lbs. (17.3kg.).

Power Requirements ............100 - 240 volts AC, 50/60 Hz 2 amps.

*dependent on accuracy of actual cable footage and product uniformity.

Specifications subject to change without notice. 11/11 EN

z

Shorts

z

Typical Lead Connections

Opens

Green

Blue

(Ground Strap)

Green

Blue

Red

Red

Coaxial Cable

Top of Reel Bottom of reel

Multi Conductor Cable

Green

(Ground Strap)

Green

Coaxial Cable

Top of Reel Bottom of reel

Multi Conductor Cable

Blue Red

Blue Red

1

1

2

2

3

3

4

4

A A

B B

C C

D D

DWG NO:

ALL DIMENS ION IN INCHE S:

TOLERANCES:

FRACTIONAL: ±1/64

DECIMAL:

2 PLACES: ±.015

3 PLACES: ±.010

ANGULAR: ±1~

UNLESS OTHERWISE NOTED

USED IN:

APPROVED:

12/10/2009

DRAWN:

tlane

FL-20

C

DATE:

295 EAST MAIN STREET, CLINTON, CT 06413

PHONE: ( 860) 669-7548 F AX: (860) 669-3825

THIS DRAWING IS THE PROPERTY

OF THE CLINTO N INST RUMENT

COMPANY, INC. THE INFORMATION

CONT AINED HEREON MAY NOT

BE REPRODUCED OR DISTRIBUTED

WITHOUT T HE EXPRESS PER-

MISSION OF THE CLINTON

INSTRUMENT CO.

the clinton instrument company

C

TITLE:

SIZE SHEET 1 OF 1

CHECKED QA: REV

Table of Contents

Safety ........................................................................................................................................ 1

Installation ............................................................................................................................... 4

Denitions ............................................................................................................................... 7

FL-20A Controls .................................................................................................................... 9

Settings Menu........................................................................................................................11

Testing Large Cables with the FL-20A ............................................................................17

Performing a Shorts Test.....................................................................................................18

Performing an Open Tests.................................................................................................. 20

Performing a Hi-Pot Test.................................................................................................... 22

Calibration ............................................................................................................................24

Maintenance ..........................................................................................................................26

Cable Capacitance Chart......................................................................................................27

Cable Loop Resistance Chart..............................................................................................28

Locating Shorts in Medium and High Voltage Cables.................................................... 29

How to Use the 91785 FL Test Box.................................................................................. 32

Troubleshooting....................................................................................................................34

Replacement Parts ................................................................................................................35

Optional Accessories ........................................................................................................... 36

“Electric Shock Considerations for Electric Vehicle Charging Systems”.................... 37

Warranty.................................................................................................................................44

Declaration of Conformity

Manufacturer: ..............The Clinton Instrument Company

Address: ........................295 East Main Street

Clinton, CT USA 06413

Herewith declares that

The Cable Fault Locator

Type FL-20A

is in conformity with the provisions of the following EEC directives:

89/236/EEC

73/23/EED

Conforms with the emissions requirements of EN 61326-1:2006; Clause 7.2:

CISPR 11 Edition 4:2003 .....Conducted Emissions, Class A

CISPR 11 Edition 4:2003 .....Radiated Emissions, Class A

IEC 61000-3-2:2000..............Harmonics

IEC 61000-3-3:2002..............Flicker

Conforms with the immunity requirements of EN 61326:2006; Table 1:

IEC 61000-4-2:2001..............Electrostatic Discharge

IEC 61000-4-3:2002..............Radiated Immunity

IEC 61000-4-4:2004..............EFT/Burst, Power and I/O Leads

IEC 61000-4-5:2001..............Surge Immunity

IEC 61000-4-6:2003..............Conducted Immunity, Power and I/O Cables

IEC 61000-4-11:2004............Voltage Dips and Interrupts

Conforms to the safety requirements of EN61010.

Clinton, CT USA February 2010

Marianne Szreders

President Ted P. Lane

Chief Engineer

FL-20A Instruction Manual - Page 1

Model FL-20A Cable Fault Locator

Safety

Danger! High Voltage Safety Hazards

Caution--Read before using this equipment.

DISCHARGE ALL CONDUCTORS OF THE TEST CABLE

PRIOR TO CONNECTING TO THE FL-20A. YOU MUST

REMOVE ANY STORED CHARGE FROM THE PREVI-

OUS OPERATION, SUCH AS A HI-POT TEST. A STORED

CHARGE IN THE CABLE CAN KILL!!!

The FL-20A employs high voltage to locate cable faults. It is imperative

that only personnel trained in the dangers of high voltage operate this

equipment. A stored charge in the TEST PRODUCT can be lethal,

even when the cable is no longer attached to the FL-20A. Please read

and understand the manual prior to operating this equipment.

A Warning to Supervisors!

The FL-20A is equipped with such safety features as external and inter-

nal safety interlocks, a red high voltage warning light, grounding sensors,

and password protection. Do not attempt to defeat or bypass any safety

feature. Failure to observe proper safety precautions can result in severe

injury or death!

Supervisory personnel are strongly advised to use the built-in password

protection feature to prevent unauthorized persons from defeating

safety features or changing test parameters. Read the section in Installa-

tion entitled, “Password Protection,” for further information.

A Warning Note to Operators!

When cables are being tested with this or any high voltage equipment,

the possibility of leaving a dangerous charge in the cable is always pres-

ent. Always bunch together and ground all conductors not under test,

including to the cable shield and to the earth ground, using the provided

ground probe. Make sure the test is complete, that the high voltage

indicator lamp is off, and that all leads are shorted to ground before

touching any part of the cables.

Although the high voltage output of the FL-20A is not in itself capable

of delivering a truly dangerous shock, a stored charge in the cable can, if

proper safety precautions are not taken. For this reason, operators and

supervisors should establish rigid safety procedures for the use of this

and all high voltage equipment.

Page 2 - FL-20A Instruction Manual

Model FL-20A Cable Fault Locator

High Voltage Facts

The commonly accepted maximum values of 60 Hz. current passing

through the human adult body which permit a subject to let go of elec-

trodes are nine milliamperes for males and six milliamperes for females.

At 3000 Hz. this value increases to about 22 milliamperes for men or 15

milliamperes for women. DC currents do not present the same let–go

problems, but a subject can readily let go at a level of 60 milliamperes.

A continuous 60 Hz. current above 18 milliamperes stops breathing for

the duration of the shock only. Ventricular brillation may occur above

a level of 67 milliamperes. The reaction current level of 60 Hz. is about

.5 milliamperes. Above this level a muscular reaction can occur which

can cause a secondary accident. The DC and 3 kHz. levels are probably

considerably higher.

Capacitor discharge energy of 50 Joules (watt–seconds) is regarded as

hazardous.

For references, see: Dalziel, Ogden, Abbot, “Effect of Frequency on

Let–Go Currents,” Transactions of A.I.E.E., Volume 62, December

1943, and Dalziel, “Electric Shock Hazard,” I.E.E.E., Spectrum, Febru-

ary 1972.

Safety Symbols

The symbols depicted below are safety symbols placed on the spark test

equipment. It is important to understand the meaning of each.

The Caution symbol found in the instruction manual calls attention to

a procedure, practice, or the like, which if not correctly performed or

adhered to, could result in personal injury or damage to or destruction

of part or all of the product. Do not proceed beyond a Caution symbol

until the indicated conditions are fully understood and met.

Risk of electric shock symbol.

Earth (ground) symbol.

Environmental Conditions

The Model FL-20A Cable Fault Locator is designed to be safe under the

following conditions:

• Indoor use.

• Altitude to 2000 m.

• Temperatures from 5ºC to 40ºC.

• Humidity to 80% R.H. at 31ºC, decreasing linearly to 50% R.H. at

FL-20A Instruction Manual - Page 3

Model FL-20A Cable Fault Locator

40ºC.

The Clinton Instrument Company certies that this equipment met its

published specications at the time of shipment. Clinton further certi-

es that its calibration measurements are traceable to the United States

National Institute of Standards and Technology to the extent allowed

by the Institute’s calibration facility. For customer service or technical

assistance with this equipment, please contact:

The Clinton Instrument Company

295 East Main Street, Clinton, CT 06413 USA

Telephone: 860-669-7548 Fax: 860-669-3825

Website: www.clintoninstrument.com.

email: support@clintoninstrument.com.

Page 4 - FL-20A Instruction Manual

Model FL-20A Cable Fault Locator

Installation

Unpacking

The following items are included in the shipment:

• FL-20A Cable Fault Locator, with a set of 3 test probes (red, blue and

green) connected to the back of the unit

• A green 2-position connector, to be used as a safety interlock if prod-

ucts will be tested in a cage. This will also be used during calibra-

tion.

• X3F Light Tower

• A 4-conductor cable with a 4-pin connector on one end, and a 10-pin

connector on the other, to connect the FL-20A to the X3F

• 4 bolts to mount the X3F to the FL-20A

• A Y- power cord

• 91785 FL Test Box

• (3) 92100 Probe Clip Assemblies (other sizes available)

• An instruction manual

If a printer was ordered, the following items are included:

• Printer

• Printer cable

• Power adapter

• Roll of paper, part no. 91901

Remove the FL-20A and accessories from the carton. Retain the packing

material in the event that the unit is returned for calibration or service at

some future time.

Site Preparation

Caution: The installation procedures listed below are to be performed

by qualied service personnel only. Failure to follow these procedures

may result in danger to personnel and damage to equipment.

Caged Operation

Cables under high voltage test can build up a deadly charge. It is common

practice to enclose cables under test in a caged area to protect workers,

with the FL-20A located outside the cage. When the FL-20A Caged

FL-20A Instruction Manual - Page 5

Model FL-20A Cable Fault Locator

Operation mode is selected, the equipment operator can perform a cable test

by momentarily pressing the safety buttons on the side of the fault locator,

rather than having to press the buttons for the duration of the test. Caged

Operation requires that the high voltage safety interlock on the back of the

unit be connected to the cage door interlock. See “Wiring Requirements” for

external safety interlock wiring instructions.

Wiring Requirements

Mount the X3F Light Tower

Be sure the FL-20A is OFF. Mount the X3F to the right side of the FL-20A,

using the 4 bolts provided.

Locate the 10-pin green terminal block on the back of the X3F, the 4-pin

terminal block on the back of the fault locator, and the 4-conductor cable

supplied with the unit. Plug the 10-pin connector into the X3F 10-pin ter-

minal block and the 4-pin connector into the 4-pin block on the rear panel

of the FL-20A.

When the wiring is complete, plug the Y-power cord into the X3F and the

fault locator.

Ground the chassis

Connect a ground wire to the ground terminal on the rear of the FL-20A

chassis. Connect the other end to earth ground. Use 22 gauge wire or larger.

This is an important safety task that must not be neglected.

Wire the external safety interlock (Caged Operation)

Wire the green 2-position connector to 22 ga. or larger wire and connect to

the 2-pin FL-20A external safety interlock terminal block, found on the rear

of the FL-20A. Connect the other end of the wire to the cage door. If you

will not be using Caged Operation, skip this step.

Printer Installation

1. Plug the power adapter into the connector located on the back right

of the Thermal Receipt Printer.

2. Connect the male end of the printer cable into the back of the

printer and the female end of the printer cable into the FL-20A con-

nector labelled “Printer,” located on the rear of the unit.

3. Make sure paper (Part # 90901) is inserted and fed through the

printer.

4. Press the switch on the back left of the printer to turn ON. The

Page 6 - FL-20A Instruction Manual

Model FL-20A Cable Fault Locator

printer is ready when a green power light shows on front of

printer.

5. Printing occurs when the nal test page (results page) appears

on the FL-20A display screen, as shown in the picture to the left.

Password Protection

The FL-20A offers password protection that can prevent unauthorized

individuals from defeating safety features and changing voltage settings

and test parameters. Using password protection will make your work-

place safer.

After making necessary changes in the Settings menu, go to the Set

Admin Password setting. The default password is 1111. To change it,

press the displayed password to access a keypad. Enter a new 4-digit

password and press OK.

After entering a new password, go to the Lock Settings Menu function

and turn it ON. This will restrict unauthorized personnel from access-

ing the Settings menu. If the new password should be lost, contact the

factory.

FL-20A Instruction Manual - Page 7

Model FL-20A Cable Fault Locator

Denitions

Shorts

Metallic short

A condition where there is direct metal-to-metal contact between two

conductors.

High voltage short

Two conductors without insulation, or a conductor and a shield with no

insulation between them, where there is no direct contact. The condi-

tion is detected only at high voltage when arcing occurs between conduc-

tors.

Intermittent arc

An intermittent arc is a high voltage short present that breaks down mar-

ginally at the selected hi-pot voltage.

Opens

An open is a condition where a single conductor has no continuity from

one end to the other.

Hi-Pot Test

Also called a dielectric withstand test. The purpose of this test is to

charge one conductor to determine if high voltage at a predetermined

level will discharge to ground through the insulation. If too much cur-

rent ows, the conductor is not well insulated and it fails the test.

Loop Resistance

Conductor resistance to the ow of electrical current, measured in

ohms/1,000 feet. Resistance is inversely proportional to the cross-sec-

tional area of the conductor, so when the diameter of the conductor is

doubled, the resistance declines 50 percent. FL-20A tests for metallic

shorts are accurate on conductors with loop resistances of 50 milliohms

or greater. Tests for high voltage shorts are effective on conductors with

resistances of 200-250 milliohms or greater.

Accuracy

The accuracy of the test performed. Ratings are inuenced by cable

characteristics such as low loop resistance. Accuracy is reported as fol-

lows:

Page 8 - FL-20A Instruction Manual

Model FL-20A Cable Fault Locator

Low

There may be multiple faults in the cable, the cable may have low loop

resistance, or the fault is judged to be close to either end.

Standard

The test is considered good, with good results.

Exceptional

The fault location was easily located, and test results are accurate within

1% of the cable length.

FL-20A Instruction Manual - Page 9

Model FL-20A Cable Fault Locator

FL-20A Controls

ON/OFF power switch

This switch is located on the rear panel of the unit.

Ground connection

A 10-32 grounding stud located on the rear panel of the FL-20A chassis.

Wire to earth ground as directed in the Installation section.

External safety interlock (for Caged Operation)

If cables are to be tested in a caged area with the FL-20A located out-

side, the FL-20A external safety interlock must be wired to the cage door

so that cables may be tested only when the cage door is closed. When

the external interlock is engaged and the Caged Operation setting, found

in the Settings menu, is ON, the operator will be required to momentarily

press the FL-20A safety buttons during a test, rather than press them for

the full test. Refer to the section of Caged Operation for wiring details.

The safety interlock is also required for calibration. A two-position con-

nector is supplied for this purpose. Refer to the Calibration section for

instructions.

Front panel touch screen

The touch screen is used to set test parameters, run tests, and view test

results. Never press the touch screen with a tool or sharp object.

Safety buttons

Located on each side of the FL-20A, the safety buttons must be held in

during a shorts or hi-pot test. This is a safety feature that prevents the

operator from touching the charged test cable during a test.

Red and blue test probes

The red probe will connect to one end of a test conductor, and the blue

probe to the opposite end. Review the instructions in the Installation

section on how to properly strip back the conductors and insert them

into the probes. This is an important safety procedure.

Green ground probe

The green ground probe is used to make connections to the reference

Page 10 - FL-20A Instruction Manual

Model FL-20A Cable Fault Locator

conductor and to ground the test cable. Review the instructions in the

test sections on how to properly strip back the conductors and insert

them into the probe. This is an important safety procedure.

X3F Light Tower

When the X3F is properly installed, the red High Voltage light will go

ON when high voltage is present on the FL-20A test probes.

The yellow Test In Progress light will ash during a test.

Warning: when the red High Voltage light on the X3F is illu-

minated, do not touch the red and blue probes or the test cable,

because a charge is present. If the cable capacitance is large, the

light may be illuminated for several seconds after the test is com-

plete.

FL-20A Instruction Manual - Page 11

Model FL-20A Cable Fault Locator

Settings Menu

Test parameters are found on the touch screen Settings menu. They are

saved in memory even when the FL-20A is off. To view or change test

parameters, turn on the FL-20A power switch, which is located on the

back of the unit. The FL-20A will take a few moments to boot up. Do

not touch the screen until the Clinton logo appears. The main menu

will appear.

Press the Settings button.

The Password Entry screen will appear. Click inside the Password box

and enter the password on the keypad and press OK. The default pass-

word is 1111. Press NEXT. (If you wish to change the password, go to

Set Admin Password, on a later page of the Settings menu.)

The rst page of the Settings menu will appear.

Press Pg Down to the next few pages of the Settings menu to access the

following global settings: Calibration, Language, Caged Operation and

Unit of Measure. These settings apply to all Opens, Shorts and Hi-Pot

Testing.

Global Settings

Global settings such as Calibration, Language, Caged Operation, and

Unit of Measure apply to Opens, Shorts and Hi-Pot tests. They are found

in the several pages of the Settings Menu. To view or modify a setting,

press the appropriate button to access the subscreen. Addtional screens

such as System Information, System Errors, Set System Defaults, and

Set Admin Password are also included in the Settings menu.

Calibration

This setting allows the user to calibrate the FL-20A output voltage and

voltage reporting. Refer to the section entitled,”Calibration,” for spe-

cic instructions.

Language

Flag icons representing the languages that are available on the FL-20A are

displayed here. The languages are English, Japanese, Spanish, German,

French, Italian, Swedish, and Chinese. Press the ag icon of your choice.

The default setting is English.

Caged Operation

Cables under high voltage test can build up a deadly charge that remains

Page 12 - FL-20A Instruction Manual

Model FL-20A Cable Fault Locator

until the conductors are intentionally discharged. For this reason, an

operator using the FL-20A in an open area is required to hold in the

safety buttons on each side of the fault locator. This is a safety precaution

to prevent him or her from touching the test cable while it is charged. In

this situation, Caged Operation is OFF. This is the default setting.

Do not attempt to defeat the safety buttons. Failure to observe

proper safety precautions can result in severe injury or death!

Because it is common practice to use a fault locator in a caged area to

protect workers, the Caged Operation setting can be changed to ON, and

the FL-20A operator can perform a test without pressing in the safety

buttons on each side of the fault locator. To turn ON the Caged Opera-

tion setting, the external interlock on the back of the FL-20A unit must

be connected to the cage door. Press NEXT to access the next screen.

Then press the ON/OFF area of the screen to change Caged Operation

to ON. Press ACCEPT.

Unit of Measure

Test cable lengths may be displayed in feet or meters. The unit of mea-

sure cannot be changed during a test. Press the displayed choice to

toggle between Feet or Meters.

System Information

FL-20A rmware and software version numbers are stored here. During

troubleshooting, you may be asked for this information by a Clinton

technician.

System Errors

System error information is stored here. A Clinton technician may

request that you access this information during troubleshooting if the

yellow or red lights on the back of the FL-20A are ashing.

Set System Defaults

The Set System Defaults RESTORES system defaults. Restoring System

Defaults does not affect calibration.

Set Admin Password

When Lock Settings is ON, a password is required to access the Settings

menu. Reserving global setting access to supervisory personnel prevents

unauthorized individuals from changing test parameters or defeating

safety features. The default password is 1111. To change it, press the

displayed password to access a keypad. Enter a new 4-digit password

and press the check mark/accept button.

After changing the password, turn Locked Settings Menu ON to prevent

unauthorized access to the Settings menu.

Table of contents

Other Clinton Test Equipment manuals

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started