Clinton DC-1 User manual

DC-1, -10, -20B Instruction Manual –Page 0

Models DC-1, -10 and -20B DC Spark Testers

Instruction Manual

295 East Main Street

Clinton, CT 06413 USA

Telephone: 860.669.7548 Fax: 860.669.3825

www.clintoninstrument.com

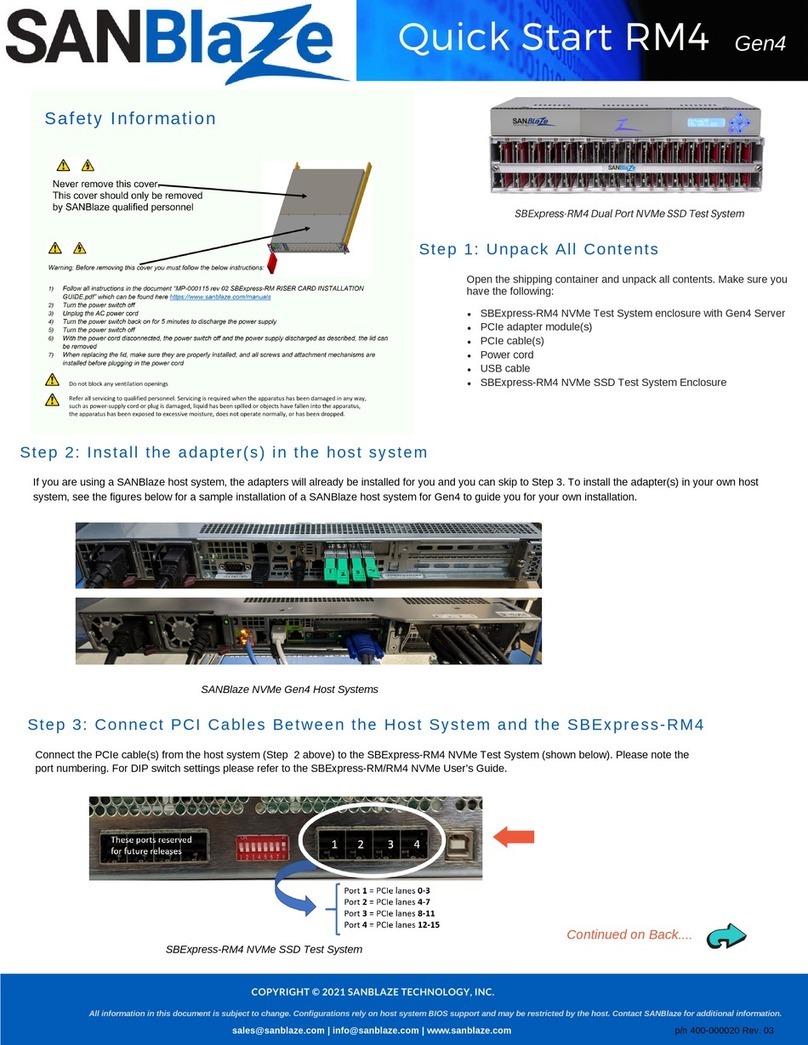

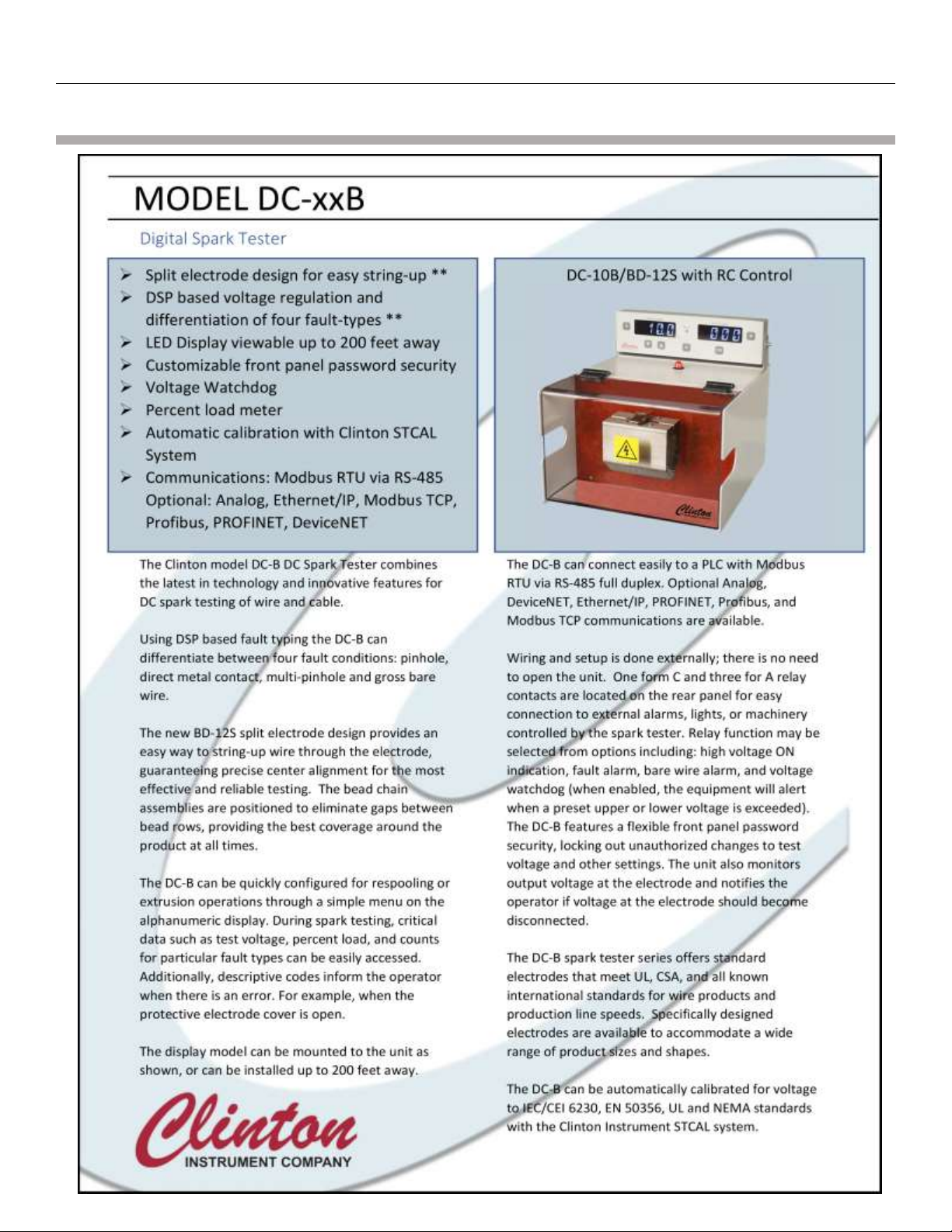

DCDC-20B/BD-12S shown with optional X3B Horn/Light Tower

Clinton Instrument Company

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 1

Rev Null b0002 10/11/17

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 2

Contents

DECLARATION OF CONFORMITY........................................................................................................................................................5

SPECIFICATIONS ................................................................................................................................................................................6

SAFETY ..............................................................................................................................................................................................8

SAFETY SYMBOL .........................................................................................................................................................................................8

ENVIRONMENTAL CONDITIONS...................................................................................................................................................................... 8

AVOID THE RISK OF FIRE! .............................................................................................................................................................................9

CAUTION:PACEMAKER WARNING .................................................................................................................................................................9

ELECTRICAL SHOCK HAZARD FROM PRODUCTION LINE SPARK TESTERS..................................................................................................................9

INSTALLATION .................................................................................................................................................................................11

CAUTION:.............................................................................................................................................................................................11

UNPACKING.............................................................................................................................................................................................11

SITE PREPARATION....................................................................................................................................................................................12

Select a suitable location for the spark tester: ................................................................................................................................ 12

To mount the unit on a horizontal surface: ..................................................................................................................................... 12

To install the unit on a Clinton floor stand: .....................................................................................................................................12

To install RC Display onto the DC-B .................................................................................................................................................13

Provide for ventilation of the Test Module......................................................................................................................................13

POWER WIRING .......................................................................................................................................................................................13

Install an external disconnecting device..........................................................................................................................................13

Mains Power....................................................................................................................................................................................13

Ground the Spark Tester..................................................................................................................................................................13

TERMINAL BLOCK WIRING..........................................................................................................................................................................14

CONNECTING THE SERIAL RS-485 ...............................................................................................................................................................16

CONNECTING TO THE ANALOG INTERFACE (OPTIONAL) ....................................................................................................................................16

INSTALLING THE COMPACTCOM™MODULE (OPTIONAL) ................................................................................................................................. 16

CONNECTING THE X3B (OPTIONAL) .............................................................................................................................................................16

Unpacking the X3B ..........................................................................................................................................................................17

Connecting the X3B ......................................................................................................................................................................... 17

X3B to Spark Tester Connections.....................................................................................................................................................18

SPARK TESTER CONTROLS ...............................................................................................................................................................19

ON/OFF Power Switch ..................................................................................................................................................................... 19

Voltmeter ........................................................................................................................................................................................ 19

“A” Button .......................................................................................................................................................................................19

UP/DOWN ARROW (VOLTAGE ADJUST) buttons............................................................................................................................. 19

Fault Counter...................................................................................................................................................................................19

“B” Button .......................................................................................................................................................................................19

“CR” COUNT RESET button .............................................................................................................................................................. 19

FAULT light ......................................................................................................................................................................................20

“R” RESET button.............................................................................................................................................................................20

High Voltage On Lamp ....................................................................................................................................................................20

Bead Chain Electrode ......................................................................................................................................................................20

Clear Protective Cover ..................................................................................................................................................................... 20

Safety Interlock switch ....................................................................................................................................................................20

Safety end guards............................................................................................................................................................................20

DEFINITION OF TERMS ....................................................................................................................................................................21

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 3

NEW FEATURES ...............................................................................................................................................................................22

DISPLAY: ................................................................................................................................................................................................ 22

FRONT PANEL SECURITY ............................................................................................................................................................................22

BD-12S DESIGN (PATENT PENDING)..........................................................................................................................................................22

COMMUNICATION MODULES .....................................................................................................................................................................23

VOLTAGE WATCHDOG ..............................................................................................................................................................................23

FAULT TYPING .........................................................................................................................................................................................23

BACKWARDS COMPATIBLE.........................................................................................................................................................................23

SPARK TESTER CONFIGURATION (FRONT PANEL) ............................................................................................................................24

NAVIGATING THE CONFIGURATION MENU..................................................................................................................................................... 24

RC DISPLAY SECURITY (PIN)....................................................................................................................................................................... 24

CONFIGURATION MENU OPTIONS................................................................................................................................................................25

SPARK TESTER INPUTS.....................................................................................................................................................................29

High Voltage Enable (HVE).............................................................................................................................................................. 29

Fault Reset (FR) ............................................................................................................................................................................... 29

SPARK TESTER OUTPUTS .................................................................................................................................................................29

GENERAL OUTPUTS...................................................................................................................................................................................30

Output Disabled (OFF) .....................................................................................................................................................................30

Cover Open (CVO):...........................................................................................................................................................................30

System OK (SOK)..............................................................................................................................................................................30

Discharge Bar (DIS)..........................................................................................................................................................................30

High Voltage Enable (HVE).............................................................................................................................................................. 30

VOLTAGE MONITOR OUTPUT OPTIONS.........................................................................................................................................................30

High Voltage On Lamp (HVL)...........................................................................................................................................................30

High Voltage Watchdog (WDL) .......................................................................................................................................................31

Electrode Voltage Percent Based Watchdog (EVP) .........................................................................................................................31

Actual Voltage Percent Based Watchdog (AVP)..............................................................................................................................31

Percent Load Limit (PLL) .................................................................................................................................................................. 32

FAULT OUTPUT OPTIONS ...........................................................................................................................................................................32

Fault Pulse (FPL) ..............................................................................................................................................................................32

Any Fault Alarm (AFA) .....................................................................................................................................................................32

Pinhole Alarm (PHA) ........................................................................................................................................................................33

Metal Contact Alarm (MCA)............................................................................................................................................................ 33

Multi Pinhole Alarm (MPA) .............................................................................................................................................................33

Gross Barewire Alarm (GBA) ...........................................................................................................................................................34

Any Fault Limit (AFL) .......................................................................................................................................................................34

Pinhole Limit (PHL) ..........................................................................................................................................................................35

Metal Contact Limit (MCL) .............................................................................................................................................................. 35

Multi Pinhole Limit (MPL) ................................................................................................................................................................35

Gross Barewire Limit (GBL).............................................................................................................................................................. 35

Fault Combination Limit (FCL) –Must be configured via USB computer interface .........................................................................35

Any Barewire Alarm (ABW) .............................................................................................................................................................36

Any Pinhole Alarm (APH) .................................................................................................................................................................36

FAULT TYPING .................................................................................................................................................................................37

PINHOLE ..........................................................................................................................................................................................37

DIRECT METAL CONTACT ................................................................................................................................................................ 37

MULTI PINHOLE...............................................................................................................................................................................37

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 4

GROSS BAREWIRE............................................................................................................................................................................ 37

SPARK TESTER CONFIGURATION (USB)............................................................................................................................................38

TESTING YOUR PRODUCT ................................................................................................................................................................39

PREPARING YOUR PRODUCT FOR TESTING .....................................................................................................................................................39

RS-485 INTERFACE ...........................................................................................................................................................................40

RS-485 CONNECTOR ................................................................................................................................................................................ 40

RS-485 PARAMETERS ...............................................................................................................................................................................40

ANALOG INTERFACE ........................................................................................................................................................................41

ANALOG INTERFACE PIN FUNCTIONS ............................................................................................................................................................41

FIELDBUS COMMUNICATIONS INTERFACE.......................................................................................................................................42

FIELDBUS COMMUNICATIONS PARAMETERS...................................................................................................................................................42

FIELDBUS SPARK TESTER PARAMETER ADDRESSES ...........................................................................................................................................43

CIC XM UTILITY.......................................................................................................................................................................................44

CALIBRATION ..................................................................................................................................................................................46

ST-CAL CALIBRATION ...............................................................................................................................................................................46

EVM CALIBRATION PROCEDURE..................................................................................................................................................................46

Connecting the EVM........................................................................................................................................................................46

Taking Calibration Readings............................................................................................................................................................47

Adjusting the Calibration................................................................................................................................................................. 47

MAINTENANCE ................................................................................................................................................................................48

FUSES.....................................................................................................................................................................................................48

PERIODIC INSPECTION................................................................................................................................................................................49

TROUBLESHOOTING ........................................................................................................................................................................50

SETTING FACTORY DEFAULTS ......................................................................................................................................................................51

REPLACEMENT PARTS......................................................................................................................................................................52

OPTIONAL ACCESSORIES..................................................................................................................................................................53

FS-4 FLOOR STAND ASSEMBLY.........................................................................................................................................................55

GROUNDING OF CONDUCTORS DURING THE SPARK TEST ...............................................................................................................56

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 5

EU Declaration of Conformity

Declaration of Conformity

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 6

Specifications

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 7

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 8

Safety

Safety Symbol

The symbols depicted below are safety symbols placed on spark test equipment.

It is important to understand the meaning of each.

Caution symbol. Caution- refer to the manual to protect against damage to the

equipment or to avoid personal injury.

Indicates Hot Surface. Do not touch.

Risk of electric shock symbol.

Earth ground symbol.

Environmental Conditions

The spark tester is designed to be safe under the following conditions:

• Indoor use.

• Altitude to 2000m.

• Temperatures from 5ºC to 40ºC.

• Humidity to 80% R.H. at 31ºC, decreasing linearly to 50% R.H. at 40ºC

The Clinton Instrument Company certifies that this equipment met its published

specifications at the time of shipment. The calibrations of the equipment are

checked against Measurement Standards (Reference) maintained by the Clinton

Instrument Company. The accuracy of these standards is traceable to the national

standards at the National Institute of Standards and Technology (NIST) or derived

by ratio type measurements. For customer service or technical assistance with

this equipment, please contact:

The Clinton Instrument Company

295 East Main Street, Clinton, CT 06413 USA

Telephone: 860-669-7548 Fax: 860-669-3825

Website: www.clintoninstrument.com

Email: support@clintoninstrument.com

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 9

Avoid the Risk of Fire!

Every time your wire line stops, be sure that the HV in the electrode goes off. If

the HV remains ON while your wire line is stationary, the wire insulation within

the electrode will heat and there is a danger of combustion. Refer to the table in

“Installation” labelled “Terminal Block connections,” under HV Enable on how to

safely install your spark tester.

Caution: Pacemaker Warning

Clinton Instrument Company strongly advises any individual using a pacemaker

or other such medical device to avoid operating or being in the vicinity of spark

testers. Current studies indicate that such medical devices can malfunction in the

presence of electrical and magnetic fields. When a fault occurs in the electrode

of a Clinton spark tester, both high and low frequency electromagnetic fields are

generated. The strengths of these emissions are unknown, since they depend on

test voltage and other variables. The danger is greater when a customer does not

ground the inner conductors of a test product. While Clinton cautions its cus-

tomers to ground the test product for safety reasons, many times this warning is

ignored. In this situation, both the spark tester and the entire length of the wire

line will radiate these emissions. There is also a serious risk of electrical shock if

an individual comes into contact with an ungrounded test product.

Email: support@clintoninstrument.com.

Electrical Shock Hazard from Production Line Spark Testers

By Henry H. Clinton

The commonly accepted maximum values of 60Hz. current passing through the

human adult body which permit a subject to let go of electrodes are nine

milliamperes for males and six milliamperes for females. At 3000 Hz. this value

increases to about 22 milliamperes for men and 15 milliamperes for women, DC

currents do not present the same let-go problems, but a subject can readily let go

at a level of 60 milliamperes. A continuous 60 Hz. current above 18 milliamperes

stops breathing for the duration of the shock only. Ventricular fibrillation may

occur above a level of 67 milliamperes. The reaction current level of 60 Hz. is

about .5 milliamperes. Above this level a muscular reaction can occur which can

cause a secondary accident. The DC and 3 kHz. Levels are probably considerably

higher. Capacitor discharge energy of 50 Joules (watt-seconds) is regarded as

hazardous.

Clinton DC spark testers are current limited to 5 milliamperes or less. Three

kilohertz spark testers are limited to 4 milliamperes or less, and 60 Hz. types to 7

milliamperes. Impulse spark testers can deliver a maximum charge of about .2

Joules 248 times per second. All these spark testers have current outputs above

the reaction level, but none above the let-go threshold level. Because of the

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 10

possibility of secondary accidents caused by muscular reactions, operators should

be protected against accidental shock. Electrodes are supplied with interlock

switches, and these should not be disabled. The conductor under test should be

grounded. If an operator must inspect the product by touching its surface while

it is being spark tested, he should be electrically insulated from his environment,

and any possible cause of a secondary accident caused by reaction should be

eliminated.

For references, see: Dalziel, Ogden, Abbot, “Effect of Frequency on Let-Go

Currents,” Transactions of A.I.E.E., Volume 62, December 1943, and Dalziel,

“Electric Shock Hazard,” I.E.E.E., Spectrum, February 1972.

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 11

Installation

CAUTION:

The installation procedures listed below are to be performed by qualified service

personnel only. Failure to follow these procedures may result in danger to

personnel and equipment damage.

Unpacking

Remove the spark tester from the carton. Retain the packing material in the event

that the unit is returned for calibration or service at some future time.

The following items are packed with the spark tester:

1. DC-B Spark tester

2. RC Display With mounting bracket (when ordered)

3. A power cord

4. A 9-Pin green terminal block connector for process control connec-

tions. After it is wired, it will plug into the terminal block on the back

of the spark tester

5. A 4-Pin green terminal block connector for process control connec-

tions. After it is wired, it will plug into the terminal block on the back

of the spark tester

6. RS-485 connecting cable 1 Foot Long

7. Quick Start Guide

8. Short Manual

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 12

Site Preparation

Select a suitable location for the spark tester:

The DC-B Spark Tester is designed for use in a fixed location, permanently

connected to its power source. The unit may be mounted on a table or on a

Clinton floor stand and should be placed at wire line height and within easy reach

of the operator. For detailed dimensions of the spark tester, please see the

specification sheet.

The spark tester should be adjusted so that the product runs centered in the

electrode in both the vertical and horizontal axes and parallel to the mounting

plate. Vertical and horizontal dimensions for wire centers for standard electrodes

can be found on drawings supplied with this manual. For non-standard

electrodes, or for copies of the required drawings, contact the Engineering

Department of The Clinton Instrument Company.

When the spark tester is to be placed on a primary or jacketing (sheathing)

extrusion line, it is desirable to locate the equipment as close to the extruder

cross-head as practical, this generally means locating it just after the water

cooling trough. In this case it is important to wipe the water off of the product

thoroughly before it enters the spark tester electrode containment. Failure to

adequately dry the surface of the wire or cable can cause false-counting, and can

cause premature failure of the equipment.

To mount the unit on a horizontal surface:

With a screwdriver, remove the (4) plastic feet from the tapped inserts in the

bottom of the spark tester chassis. Insert (4) M-6 screws through the mounting

surface into the (4) tapped inserts. Be sure the screws do not extend into the

chassis more than 1/2 inch (12mm).

To install the unit on a Clinton floor stand:

Assemble the floor stand as shown in the drawings at the back of this manual.

Secure the tripod base of the floor stand to the shop floor using 1/2” (12mm)

bolts and washers. Remove the (4) plastic feet from the tapped inserts on the

bottom of the spark tester chassis, as shown above. Mount the spark tester to

the stand by feeding (4) M-6 screws supplied with the floor stand through the

bottom of the floor stand plate and into the (4) tapped inserts in the bottom of

the spark tester.

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 13

To install RC Display onto the DC-B

With a screwdriver, remove the 2 Screws on the top of the DC-B. Align the 2

mounting holes on the RC display mounting bracket with the holes on the top

of the DC-B. Secure the bracket with the 2 screws that were removed.

Once the display is secure to the top of the unit Connect the 9-pin Serial port

on the rear of the RC display to the 9-pin “DISPLAY” port on the rear of the

DC-B spark tester using the supplied 1 foot long serial cable.

The RC display can be mounted remotely up to 200 feet away using an

optional serial cable. See Optional Accessories for part numbers.

Provide for ventilation of the Test Module

As with any apparatus producing a spark or electrical corona, the DC-B Spark

Tester produces ozone in the electrode region. While ozone reverts harmlessly to

oxygen within a few minutes, an external air extraction system is recommended

and should operate whenever the spark tester is in use. The exhaust of the

external air extraction system should be discharged either outdoors or into some

area well away from workers.

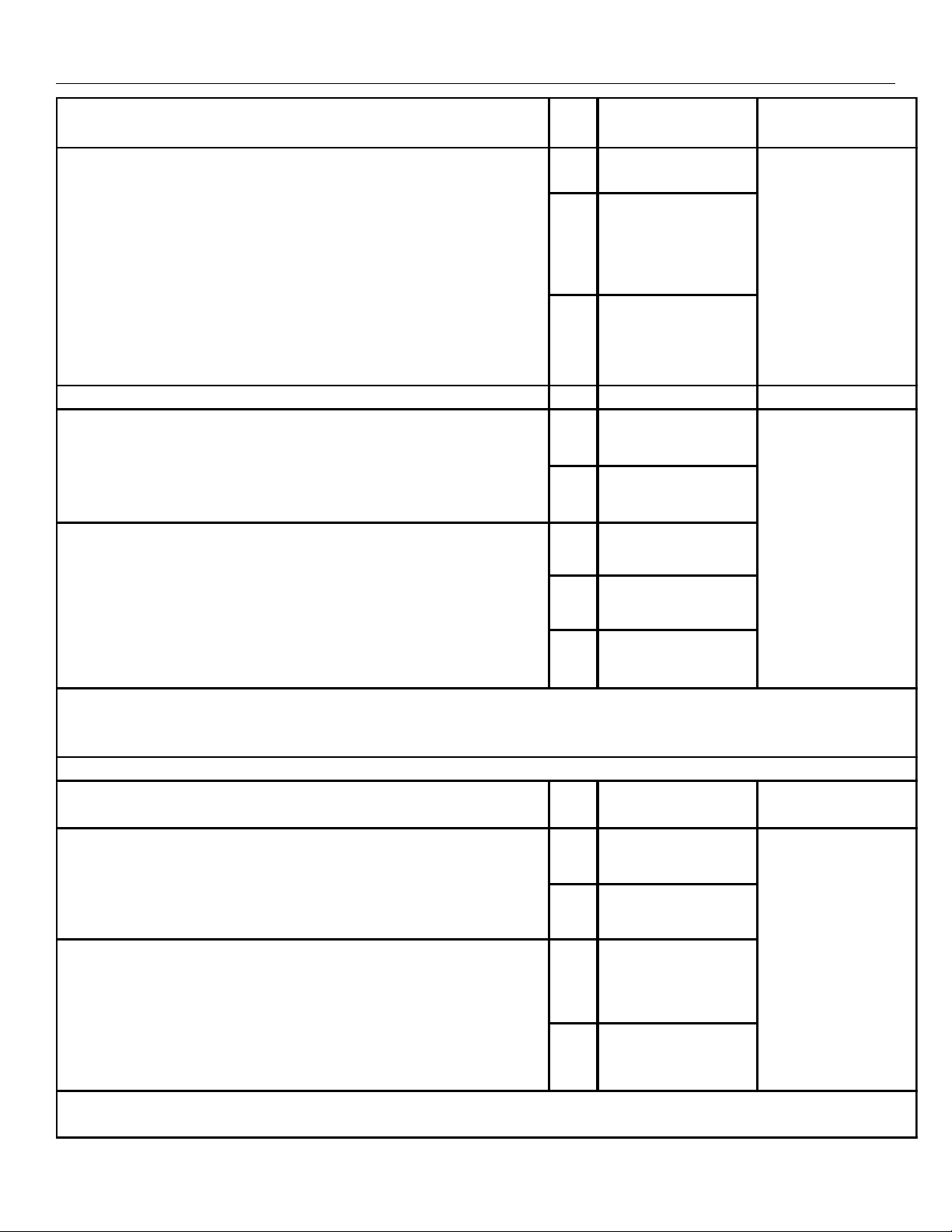

Power Wiring

Install an external disconnecting device

Install an external switch or circuit breaker in close proximity to the spark tester

and within easy reach of the operator. The switch or circuit breaker must meet

the relevant requirements of IEC 947-1 and IEC 947-3 and should be marked as

the disconnecting device for the equipment. The rating of the circuit breaker or

fuse should be no greater than 5 amperes.

Caution: Be sure the external disconnecting device is OFF and locked out before

continuing.

Mains Power

Note that the spark tester has a self-adjusting power supply with an operating

voltage range of 100V to 240V at 49-61 Hz.

Ground the Spark Tester

Locate the ground stud on the back panel of the spark tester. Remove the outer

nut and crimp terminal. Crimp a 16 awg. (1, 29 mm2 , 1, 31 cross section) stranded

insulated wire (preferably green with a yellow stripe) to the crimp terminal.

Fasten this to the ground stud and secure with the keps nut. Connect the other

end to a safety ground system in accordance with EN 60204-1:1993, Section 5.2,

Table 1.

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 14

Terminal Block Wiring

Refer to the following table for information on pin functions. Locate the green

terminal blocks on the back of the spark tester and its companion green terminal

block connectors that came with the unit.

Conductors connecting auxiliary equipment, relays and switches should be

shielded 22 gauge or larger and should be stripped back ¼” (6mm) and fed into

the green terminal block connector at the proper pin number. Shields from con-

ductors connecting auxiliary equipment should be grounded to the safety ground

terminal.

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 15

Pin

No.

Designation Conductor

1GND

2

HV ENABLE

3

RESET

4 not used

5

NO

6

COM

7NO

8

COM

9

NC

Pin

No.

Designation Conductor

1

NO

2

COM

3

NO

4

COM

9 - Pin Terminal Block Connections

HV Enable (IN0):

CAUTION: For HV on the el ectrode, i ns tal l a norma l ly clos ed s wi tch or

rel a y conta ct** between pi ns 1&2. Thi s switch or rel a y should open

automatical l y when the wi reline s top s wi tch is a cti vated or be opened

manua lly by the s ystem operator when the li ne stops . FAILURE TO DO SO

COULD RESULT IN A FIRE HAZARD If the HV remains ON i n the el ectrode

when your li ne is s ta ti ona ry, the wire ins ulation in the electrode wil l

hea t and there is a danger of combus ti on.

External Reset (IN1):

To res et the spa rk tes ter fault rel a y wi th a n external swi tch, wire a

momenta ry s wi tch** between pi ns 1&3. When thes e conta cts clos e, the

fa ult rel a y wi l l return to a norma l sta te. The interval that the conta cts

are clos ed mus t exceed 50 ms.

(3) 22 ga. stranded

conductors rated

250V, less than 10

meters in length,

contained in a

common insulating

sheath

*When connecting auxiliary equipment to dry relay contact pins 1, 2, 3,or 4, observe maximum ratings of

120VAC at 2 amps, 240VAC at 1 amp.

4 - Pin Terminal Block Connections

Watch Dog (OUT2):

Dry rel a y contact pi ns 1&2 wil l clos e when the tes t voltage i s between

the VWDL (Voltage Wa tchdog Low Thres hol d) a nd the VWDH (Volta ge

Wa tchdog Hi gh Thres hol d) val ues .

Bare Wire (OUT3):

To activate externa l li ghts, a l a rms or rela ys* when a Bare Wire type

fa ult occurs, wire them between dry rel a y conta ct pi ns 3 & 4. If the

output function i s set LCH or RVF, the dry rel a y conta cts wi l l remai n

closed until the RESET button i s pressed or when pi ns 1&3 are cl os ed by

remote s wi tch or rel a y output function is set to NLC, the dry rel a y

conta cts will return to normal s ta te after the interval known as the

ABMS (Any Ba re Wi re Alarm Ti me) ha s ela ps ed.

(3) 22 ga. stranded

conductors rated

250V, less than 10

meters in length,

contained in a

common insulating

sheath

HV ON Indication (OUT0):

Dry rel a y contact pi ns 5&6 wil l clos e when the tes t voltage exceeds

500v. For an i ndi cation tha t HV is ON i n the e lectrode, wi re a la mp or

auxil i a ry device* here.

(3) 22 ga. stranded

conductors rated

250V, less than 10

meters in length,

contained in a

common insulating

sheath

Process Control (OUT1):

To activate externa l li ghts, ala rms or relays* when a fault occurs, wi re

them between dry rel ay contact pins 9,8 & 7. If the output functi on is se t

to LCH or RVF the dry rel a y contacts will remain cl os ed unti l the RESET

button is pressed or when pi ns 1&3 are cl os ed by remote s witch or

rel a y. If the output function is set to NLC, the dry rela y contacts wi ll

return to norma l sta te a fter the i nterva l known as the AMFS (Any Fault

Alarm Ti me) has elaps ed.

* When connecting auxiliary equipment to dry relay contact pins 5, 6, 7, 8 or 9, observe maximum ratings of

120VAC at 2 amps, 240VAC at 1 amp.

**Switches and relays connected to pins 1,2, & 3 should be suitable for 24V low current applications.

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 16

Connecting the Serial RS-485

The model DC-B is equipped with an RS-485 serial interface allowing the spark

tester to receive commands and exchange information with a PLC or computer.

Programming and control of voltage settings, which can be done manually on the

DC-B display, can also be done through this interface. Control display buttons can

be disabled when the serial interface is in use. See the section entitled “RS-485

Interface” for connection and communication information.

The “RS-485” interface connector is located on the rear of the DC-B directly under

the “Display” connector.

Connecting to the Analog Interface (Optional)

The model DC-B can be purchased with an optional analog interface. (Model DC-

BA) The analog interface allows the DC-B to be controlled by a PLC with standard

analog and Digital I/O. The connecting cable for this interface is not supplied by

Clinton Instrument Company. The cable composition is normally dictated by the

PLC, but ordinarily 22 gauge conductors (individually shielded or shielded pairs)

are required. The maximum length of the cable is also determined by the

equipment the DC-B is being connected to. However, it is recommended that the

cable length not exceed 10 meters.

See the section entitled “Analog Interface” for the details regarding this

interface.

Installing the CompactCom™Module (Optional)

The model DC-B can be purchased with an optional Fieldbus Communications

Interface. (Model DC-BX) This interface will allow the installation of several

fieldbus options. (DeviceNet, Ethernet IP, Modbus TCP, Profibus, Profinet)

To enable the Fieldbus Interface the proper CompactCom™ module will need to

be installed into the DC-BX spark tester.

•First remove the Anybus Slot Cover from the rear of the spark tester.

•Remove the CompactCom™module from the packaging.

•Slide the CompactCom™module into the open slot on the rear of the

spark tester.

•Secure the CompactCom™module by tightening the 2 screws.

See the section entitled “Fieldbus Interface” for the details regarding this

interface.

Connecting the X3B (Optional)

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 17

Unpacking the X3B

Remove the following items from the carton:

1. X3B Horn/Light Tower with mounting plate. Note: If the X3B was ordered

for the BD-22 electrode, the carton should contain the BD-22 mounting

plate (part #91243).

2. Power Cord (part #03780)

3. A 4 conductor cable, with a 9-pin terminal block connector on one end and

a 10-pin connector on the other. (part #91247)

Connecting the X3B

1. Decide which side of the spark tester you wish to mount the X3B. Note that

you may have to remove the small plate from the X3B chassis and secure it

to the opposite side so that the green X3B terminal block is accessible from

the spark tester back panel. Mount the X3B using the mounting plate and

the (4) bolts that attach the end guard to the spark tester, as shown in the

picture to the left.

2. Make sure the spark tester is off before wiring to the X3B.

3. Locate the 10-pin green terminal block on the back of the X3B and the 9-

pin terminal block on the back of the spark tester. The X3B is supplied with

a 4 conductor cable. The 10-pin connector will plug into the X3B terminal

block and the 9-pin connector will connect to the spark tester terminal

block. Prior to inserting them, pins 1-5 of the 10-pin connector should be

wired to accessory equipment with 22 gauge or larger, stripped back 1/4”

(6mm) and fed into the green terminal block connector at the proper pin

numbers, as described on the following page. Pins 1-3 of the 9-pin

connector should be wired as described on the following page.

4. When wiring the two units, notice that pins 5-8 on the spark tester are now

being used to communicate with the X3B. The functions of pins 5-8 on the

spark tester have now been transferred to pins 1-5 on the X3B terminal

block. When the wiring is complete, plug in the power cords to both X3B

and the spark tester.

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 18

X3B to Spark Tester Connections

Conductor

Terminal Block

Connections

Pin

No.

Pin

No.

Terminal Block

Connections

Conductor

COM 10 9 Not Us ed NC

COM

8 7 NO

6 5 NO

NC 5 4

COM

2

Des i gna tion

4-Conductor

Cable

Supplied

with X3B (22

ga uge or

hi gher)

NO

NO

Fault Relay

HV ON Relay

To Spark Tester:

Wi re pi ns 10-7 to

spa rk

tes ter pins 8-5 on the

spa rk

tes ter terminal block

connector

GND

(3) 22 ga.

stranded

conductors

rated 250V,

les s tha n

10 meters

in length,

conta i ned

in a

common

ins ul a ti ng

shea th

Spark Tester Terminal Block Connections

X3B Horn/Light Tower Terminal Block Connections

Not Us ed

(3) 22 ga.

stranded

conductors

rated 250V,

les s tha n

10 meters

in l ength,

conta i ned in

a common

ins ul a ti ng

shea th

Fault Relay

RESET

HV

ENABLE

8

6

Not Us ed

To X3A:

Wi re pi ns 8-5 to X3A

pi ns 10-7 on X3A termi -

na l block connector

HV ON Relay

(OUT0)

Fault Relay (OUT1)

Des i gna tion

COM

COM

4-conductor

cable

supplied

with X3A

(22 gauge or

hi gher)

9

7

**Switches and relays connected to pins 1,2, & 3

should be suitable for 24V low current

applications.

NO

22 ga .

stranded

conductors

rated 250V,

les s tha n

10 meters

in l ength,

conta i ned in

a common

ins ul a ti ng

shea th

HV ON Indicati on:

Dry rel a y conta ct pins

1&2 wi ll cl os e when

the tes t volta ge

exceeds 500v. For a n

indi ca tion that HV is

ON in the electrode,

wire a l a mp or

auxil i a ry device* here.

HV ON Relay

*When connecti ng auxi liary equi pment to dry rel a y

conta cts pins 1, 2, 3, 4, or 5, observe ma ximum ratings of

120VAC at 2 a mps or 240VAC at 1 a mp.

External Reset:

To reset the spa rk tes ter fa ul t

rel a y with a n externa l s witch,

wire a momenta ry s witch**

between pi ns 1&3. Whe n

thes e contacts cl os e, the faul t

rel a y will return to a norma l

state. The interval that the

conta cts a re clos ed must

exceed 50 ms .

HV Ena ble:

CAUTION For HV on the

electrode, ins ta l l a normal l y

closed s witch or rel a y

conta ct** between pins 1&2.

Thi s swi tch or rel ay shoul d

open automatical l y when the

wireline s top s wi tch is

acti vated or be opened

manua lly by the s ystem

operator when the l i ne stops .

FAILURE TO DO SO COULD

RESULT IN A FIRE HAZARD If

the HV remai ns ON in the

electrode when your l ine i s

stati ona ry, the wire

ins ul a ti on i n the electrode

wil l hea t a nd there is a

da nger of combustion.

COM

NO

4

3

1

3

2

1

Process Control:

To activate external

lights,alarms or relays*

when a fault occurs, wire

them between dry relay

contact pins 5,4 & 3.

If the Lch function is ON

(set on the front panel),

the dry relay contacts will

remain closed until the

RESET button is pressed or

when pins 1&3 are closed

by remote switch

or relay. If the Lch

function is OFF, the dry

relay contacts will return

to normal state after the

interval known as the

PCd (Process Control

Duration, set on the front

panel) has elapsed.

Models DC-1, -10, -20B DC Spark Testers

DC-1, -10, -20B Instruction Manual –Page 19

Spark Tester Controls

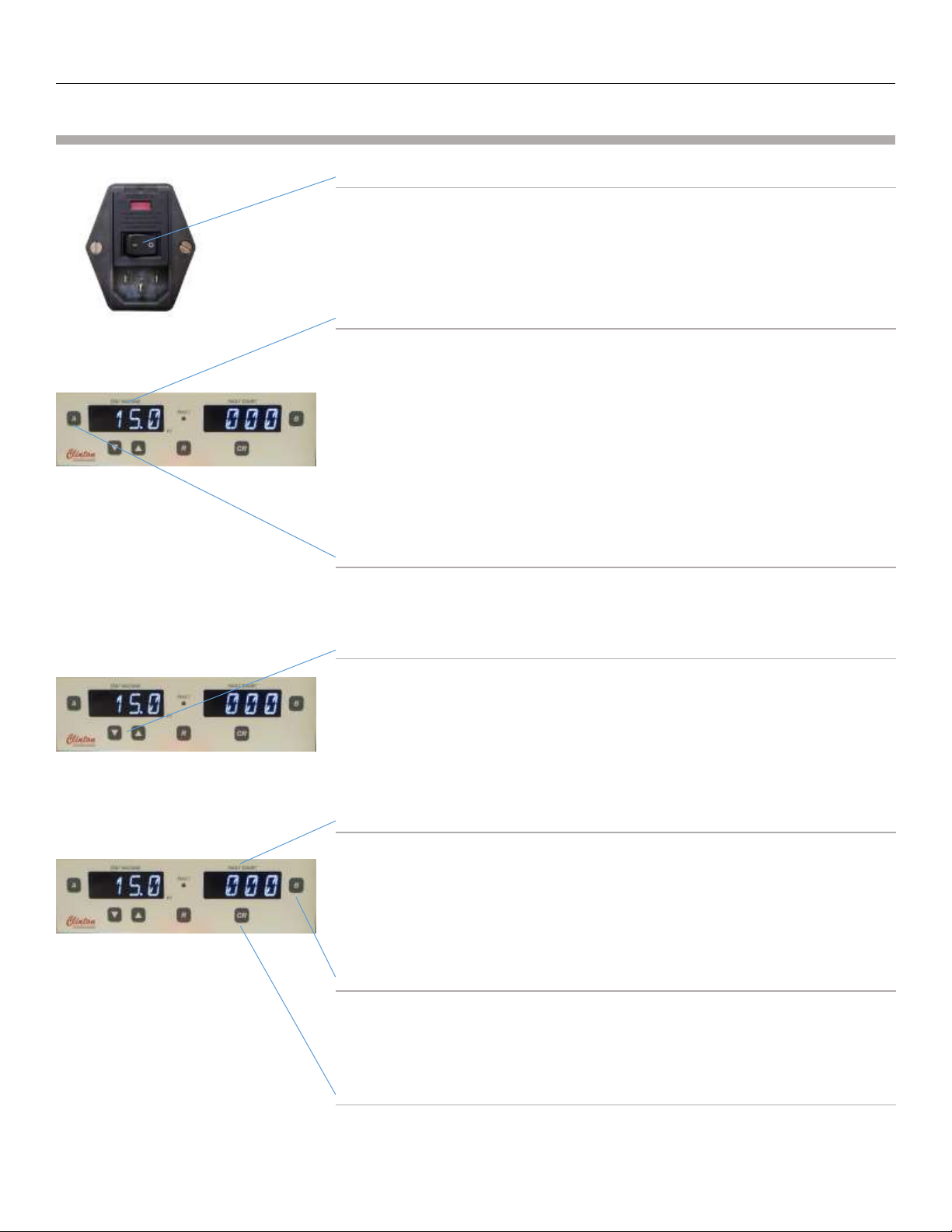

ON/OFF Power Switch

This switch is located on the rear panel of the spark tester.

Voltmeter

The voltmeter will indicate the high voltage present at the electrode. The

voltage is displayed in kV. When the output is set to 1,000V the display

will read 1.0. A reading of 10.2 indicates that the test voltage at the

electrode is 10.2kV DC.

This display can also display a “Percent Load” value and the “Set Point”

value by pressing the “A” Button. These values will be displayed

momentarily on the Voltmeter display and then will return to displaying

the spark tester voltage at the electrode.

“A” Button

Pressing the “A” button will momentarily cycle the Voltage display

through the “Percent Load” and the “Set Point” Values.

UP/DOWN ARROW (VOLTAGE ADJUST) buttons

The spark test voltage may be adjusted from 0 to the maximum voltage

(1,000 for the DC-1B, 10,000 for the DC-10B and 20,000 for the DC-20B)

in 100 volt increments by pressing the up and down arrow buttons under

the voltmeter. Press and hold a button to increase the speed at which

you change the voltage setting.

Fault Counter

The 3-digit fault counter registers a count each time any fault type is

detected in the electrode. This display can also momentarily show 4

additional fault counts by pressing the “B” button. These fault counts are

Pinhole, Metal Contact, Multiple pinhole, Gross Bare wire. Press the CR

button to reset the number of faults on the counter to 0.

“B” Button

Pressing the “B” button will momentarily cycle through the 4 additional

fault count values. (Pinhole, Metal Contact, Multiple Pinhole, Gross Bare

Wire)

“CR” COUNT RESET button

Pressing the “CR” button will reset all fault count values.

This manual suits for next models

2

Table of contents

Other Clinton Test Equipment manuals