Page 4

127(

BEFOREEXERCISINGONTHEVERSACLIMBER, READ THIS

OPERATION MANUAL THOROUGHLY. INSTRUCT OTHERS

HOW TO USE THE MACHINE IN ACCORDANCE

WITH THE PROCEDURES OUTLINED IN THIS MANUAL.

ADDITIONAL MANUALS ARE AVAILABLE UPON

REQUEST FROM HEART RATE, INC.

BEFORE BEGINNING THIS OR ANY OTHER EXERCISE

PROGRAM, CONSULT YOUR PHYSICIAN. THIS IS

ESPECIALLY IMPORTANT FOR THOSE INDIVIDUALS

OVER THE AGE OF 30 AND THOSE WHO HAVE

KNOWN HEALTH PROBLEMS. HRI ASSUMES NO

RESPONSIBILITY FOR PERSONAL INJURY OR PROPERTY

DAMAGE SUSTAINED BY OR THROUGH THEUSE OFTHE

VERSACLIMBER.

*(1(5$/,1752'8&7,21

7KH9HUVD&OLPEHU LQWURGXFHG LQ ZDV WKH

ILUVW FOLPELQJ H[HUFLVH PDFKLQH RQ WKH PDUNHW

DQGWRWKLVGD\UHPDLQVWKHOHDGHUDVDWUXHWRWDO

ERG\ FRQGLWLRQLQJ XQLW 7KLV IXOO ERG\ FOLPELQJ

H[HUFLVH PDFKLQH SURYLGHV DQ DOWHUQDWLQJ DUP

DQGOHJDFWLRQDJDLQVWJUDYLW\ZLWKYDULDEOHIRUFH

VWURNHOHQJWKDQGVSHHG$OOWKHPDMRUPXVFOHV

RIWKHDUPVFKHVWVKRXOGHUVEDFNKLSVEXWW

DQG

OHJV DUH XVHG ZKLOH FOLPELQJ7KH9HUVD&OLPEHU

KDV EHHQ SURYHQ ZRUOGZLGH DQG LV D ZLGHO\

DFFHSWHG WRWDO ERG\ H[HUFLVHU WKDW LV XVHG E\

KHDOWK FOXEV VSRUWV PHGLFLQH IDFLOLWLHV PLOLWDU\

ILUH GHSDUWPHQWV FRUSRUDWH J\PV DQG ZKHUHYHU

JURXSVRISHRSOHJDWKHUWRH[HUFLVH

7R FOLPEWKH SHUVRQVWDQGV LQD YHUWLFDOO\ HUHFW

SRVLWLRQ ZLWK ERWK IHHW OHYHO RQ SHGDOV ZKLOH

JUDVSLQJ WZR KDQGJULSV VHW DW DERXW VKRXOGHU

KHLJKW7RLQLWLDWHFOLPELQJPRWLRQVWHSGRZQRQ

RQHIRRWSHGDOZKLOHSXVKLQJXSRQWKHKDQGJULS

:KHQWKHIRRWDQGKDQGPRYHYHUWLFDOO\GRZQZDUG

WKH RWKHU IRRW DQG KDQG PRYH YHUWLFDOO\ XSZDUG

DQGWKHQDOWHUQDWHV\QFKURQRXVO\$F\FOLFDFWLRQ

RIWKHDUPVDQGOHJVLVSHUIRUPHGWKDWVLPXODWHV

PRWLRQ RI FOLPELQJ DQ HQGOHVV ODGGHU IRU DQ\

VHOHFWHG VWHS KHLJKW WLPH UDWH DQG GLVWDQFH $

PL F U R FRPSXWHU P RQ L W R UV DQ G G L VS OD\VFOLPELQJ

SHUIRUPDQFH KHDUWUDWHFDORULHVGLVWDQFHWLPH

DQGJLYHVDXGLEOHLQVWUXFWLRQVDQGPRWLYDWLRQDO

PHVVDJHV GXULQJWKHH[HUFLVH7KHPDFKLQHLV

RULHQWHGDWDGHJUHHFOLPEDQJOH

127(

'RQ¶W&OLPE7RR)DVW%HJLQQHUV

6KRXOG7DNHDLQFK6WHS$WD*HQWOH3DFH

)LUVWWLPHXVHUVRIWKH9HUVD&OLPEHUKDYHDWHQGHQF\

WRFOLPEWRRIDVWDQGWRWDNHWRRORQJDVWHS8QWLO

XVHUV EHFRPH WKRURXJKO\ IDPLOLDU ZLWK WKH

9HUVD&OLPEHULW LV LPSRUWDQWWR WDNHVKRUW VORZ

VWHSV 7R PDLQWDLQ D VKRFN DQG WUDXPD IUHH

PRWLRQ LW LV PDQGDWRU\ QRW WR ³ERWWRP RXW´ RU

LPSDFWWKHSHGDOVDWWKHHQGRIHDFKVWURNH

6(/(&7,1*(;(5&,6(7,0(

,I\RXDUHQRWDOUHDG\ZDUPHGXSDZDUPXSSHULRG

RIDWOHDVWWRPLQXWHVVKRXOGEHLQFOXGHGLQ

HDFK9HUVD&OLPEHUZRUNRXW7DNLQJDVKRUWVWHS

DW D VORZ FOLPELQJ VSHHG GXULQJ WKH ZDUP XS

SHULRGLVWKHNH\WRDJUHDWZRUNRXW7KHILUVWWLPH

XVHU FDQ HDVLO\ FOLPE IRU WR PLQXWHV E\

LQFOXGLQJDVORZPLQXWHZDUPXSDQGDWR

PLQXWHFRROGRZQSHULRG:LWKUHSHWLWLYHXVHLWLV

SRVVLEOH WR EXLOG XS WR ORQJHU FOLPEV DW KLJKHU

VSHHGV

0DQ\ LQGLYLGXDOV HQMR\ PLQXWHV RU PRUH RI

XQLQWHUUXSWHGFOLPELQJ$IWHUHDFKZRUNRXWQRWH

H[HUFLVHWLPHFOLPELQJVSHHGDQGKHLJKWFOLPEHG

IRU HVWDEOLVKLQJ D JRDO IRU IXWXUH VHVVLRQV 8VH

KHDUWUDWHDQGSHUFHLYHGH[HUWLRQWRGHWHUPLQHLI

\RX DUH DW D FRPIRUWDEOH H[HUFLVH OHYHO

5HPHPEHU WKDW ZRUN LQWHQVLW\ DQG FDORULH EXUQ

UDWHLVEDVHGRQFOLPELQJVSHHG,IWKHH[HUFLVHLV

WRRKDUGVORZGRZQ

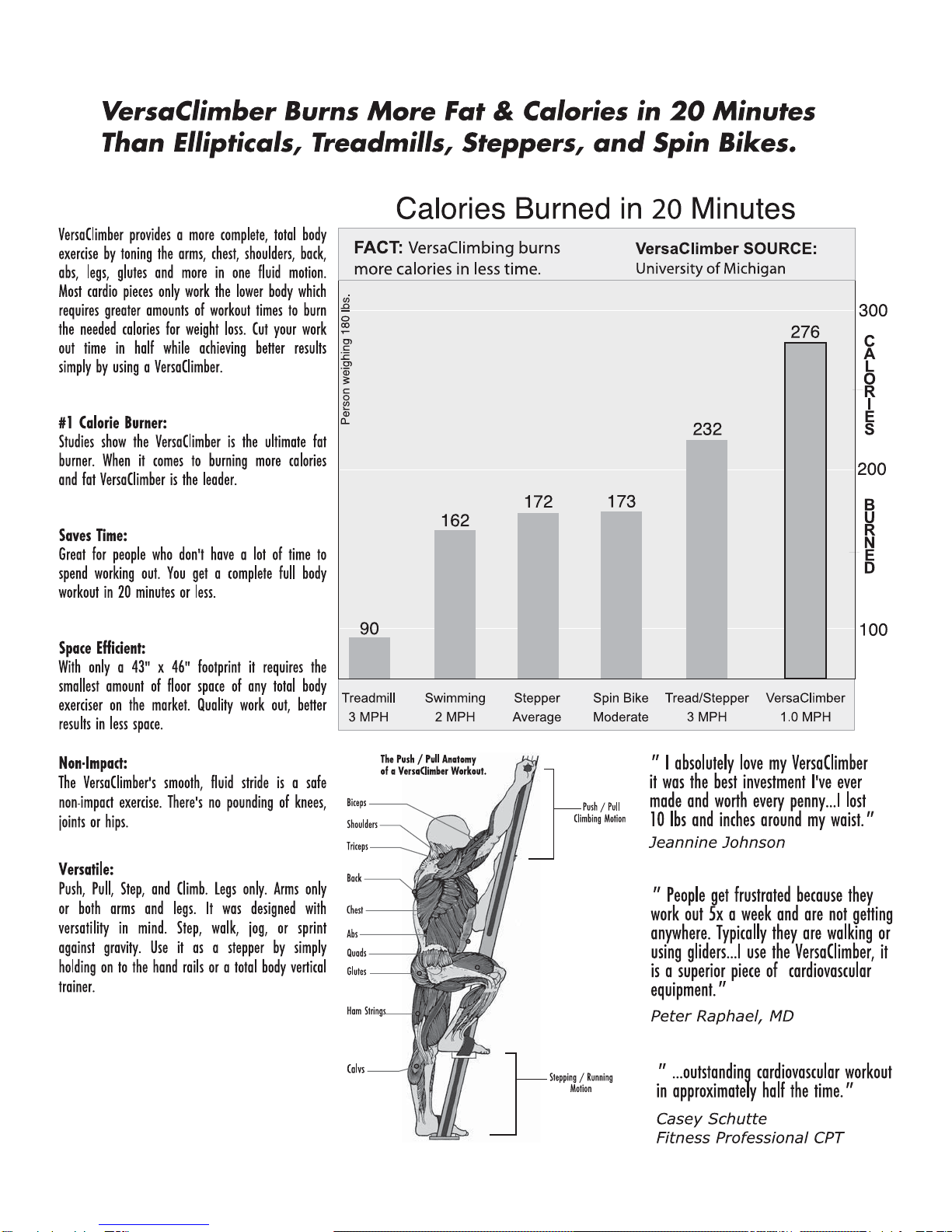

&$/25,(%8515$7(

)XOO ERG\ FOLPELQJ UDQNV KLJKHVW LQ FDORULHV

EXUQHG HYHQ WKRXJK FOLPELQJ VSHHG LV VORZHU

WKDQRWKHUDFWLYLWLHV)LUVWWLPHXVHUVRIWHQWU\WR

PDLQWDLQ WKH VSHHG WKH\ XVH LQ RWKHU DFWLYLWLHV

DQGWHQGWRRYHUH[HUWWKHPVHOYHV,WLVLPSRUWDQW

WR UHPHPEHU WKDW EHFDXVH 9HUVD&OLPELQJ LV D

WRWDO ERG\ FOLPE DJDLQVW JUDYLW\ LW LV QRW

QHFHVVDU\ WRFOLPE DW D KLJK UDWH RI VSHHG

GHPRQVWUDWHGDVIROORZV