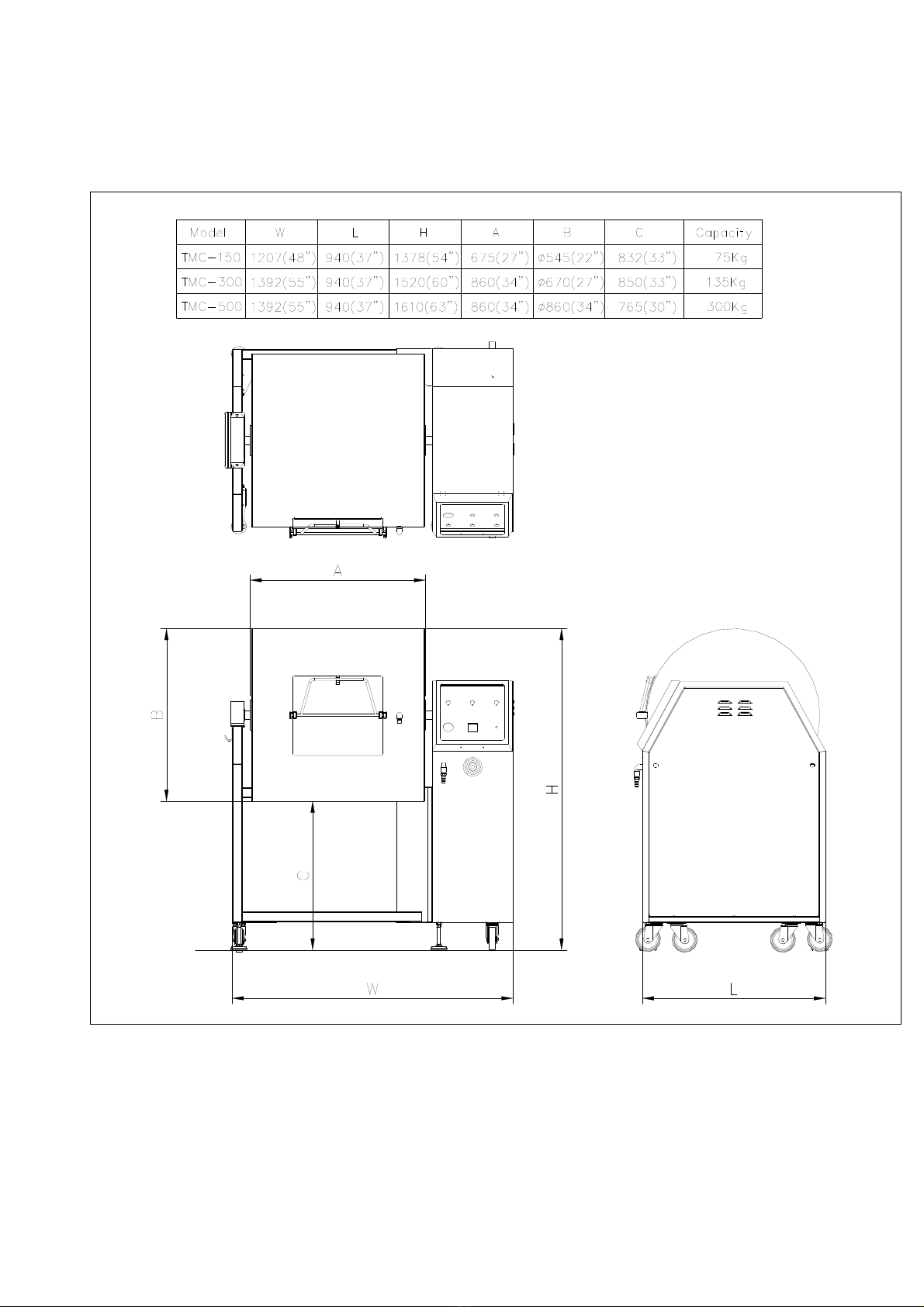

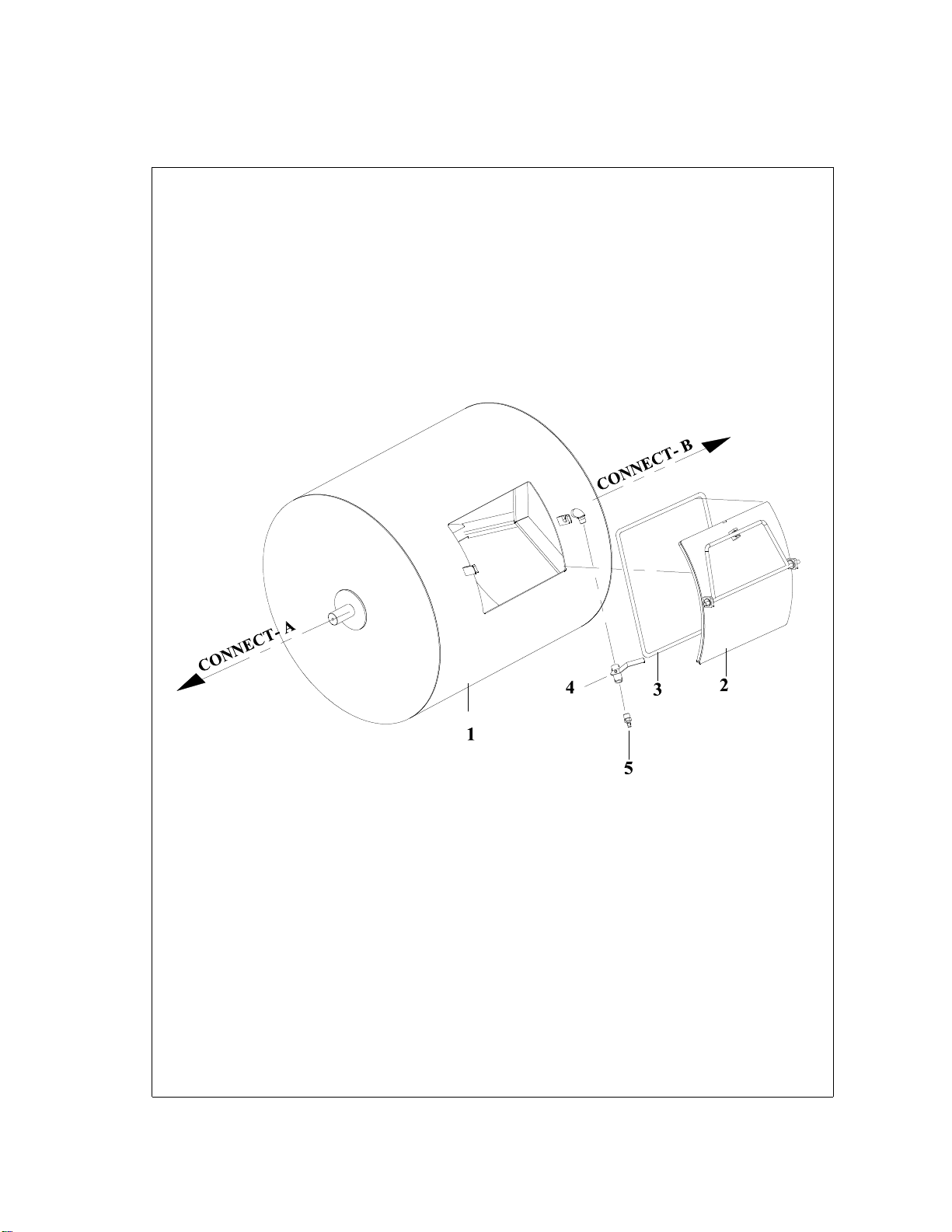

7.2-TMC5020P00

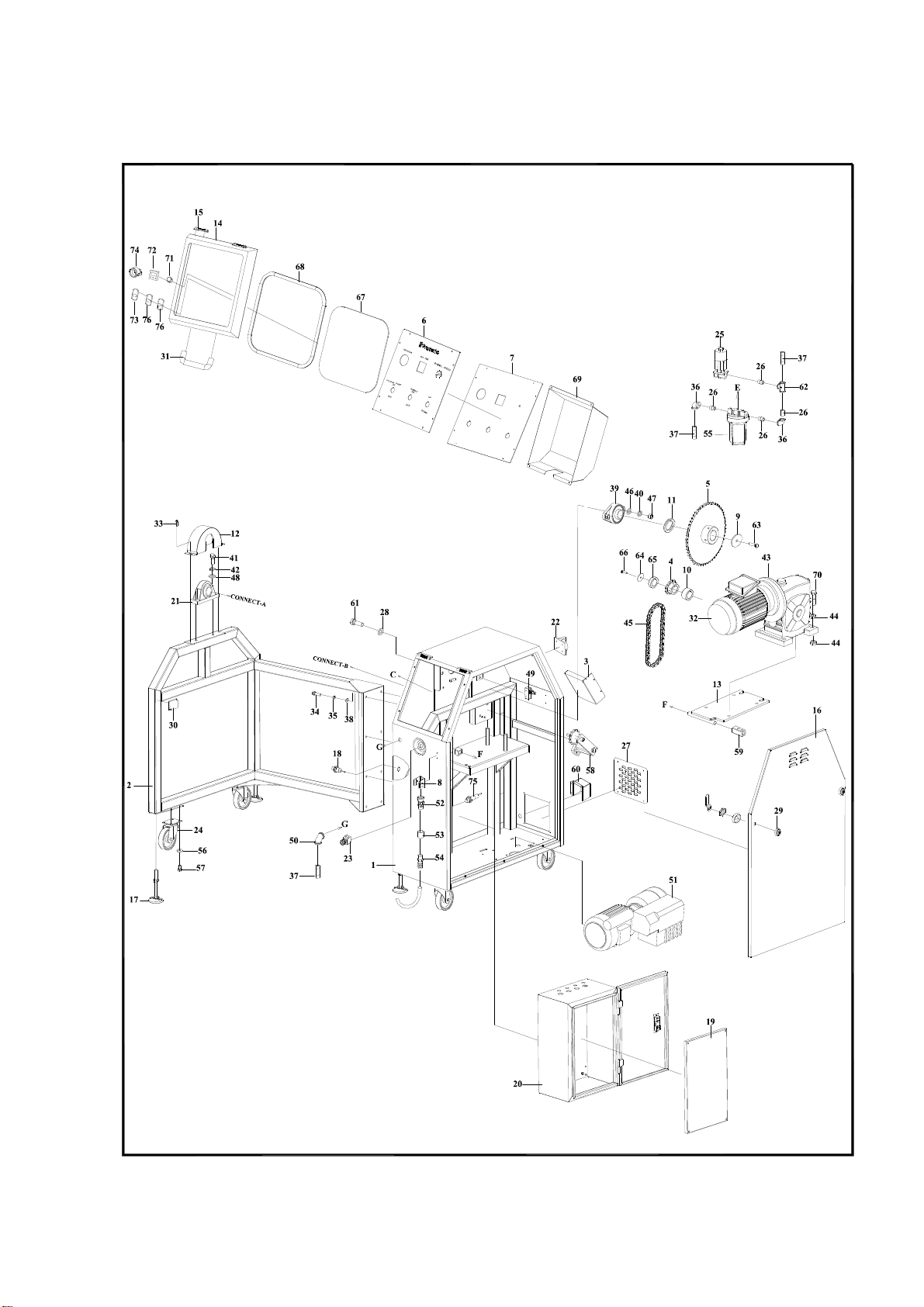

NO. PART NO. DESCRIPTION QTY NOTES

MC15101000 Frame(TMC150)

MC50101002 Frame(TMC300,TMC500) 1

MC15102000 Side frame(TMC150) 1

MC50102000 Side frame(TMC300.TMC500) 1

3 TM5H116000 Electrical protect plate 1

4 MC50106001 Chain wheel 1

5 MC50107000 Chain wheel 1

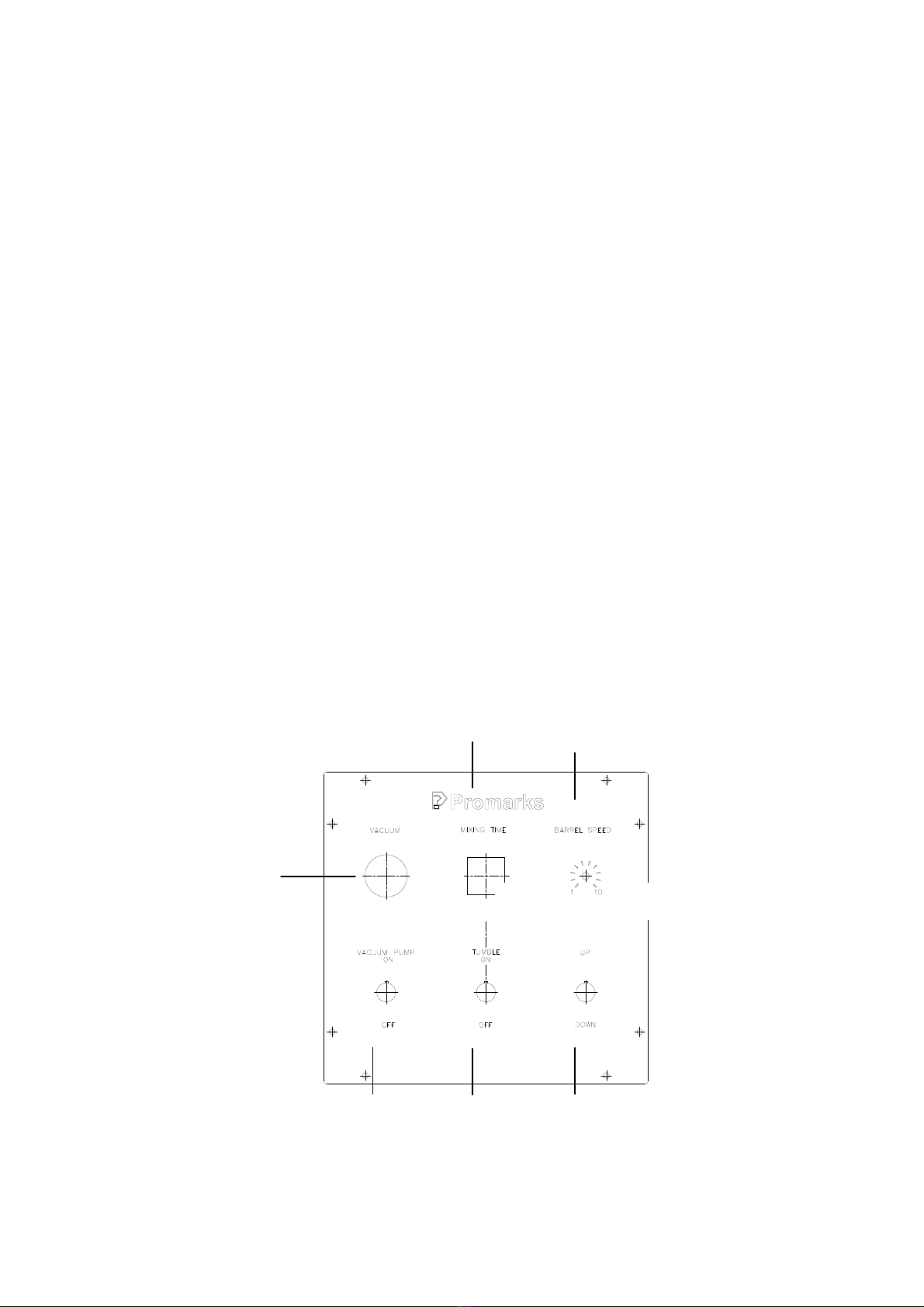

6 MC50109001 Control panel plate 1

7 MC50110001 Control panel bottom plate 1

8 MC50111001 Fixed plate 1

9 MC50118000 Pad 1

10 MC50113000 Reduction sleeve 1

11 MC50116000 Reduction sleeve 1

12 TM3H139000 Cover plate 1

13 MC50122001 Motor fixed plate 1

OPTION2

OPTION1

14 TM3H130011 Control panel cover plate 1

15 D2320020 Hinge 2

16 TM3H190000 Side door 1

17 2712222 Base leg 4

18 2850608 Sensor 1

19 TM3H803000 Panel 1

20 TM3H801000 Electrical box 1

21 2728537 Bearing pillow blockUCP209 1

22 28017051 Switch 1

23 2870074 Switch M22EL-TSF20E30 1

24 27121411 Casters 4" 4

25 29118085 Valve VXZ2242-04-BGR1(AC24V) 1

26 290932570 Nipple 1/2"x30 3

27 TM3H145000 Cover plate 2

28 2705329 Flat washer M16 2

29 2883349 Door lock C408K 2

30 28501030 Reflector 1

31 2883343 Hinge 1

8