TABLE OF CONTENTS

1. SAFETY ................................................................................................................... 1

1.1 SAFETY RECOMMENDATIONS ............................................................................... 1

1.2 PERSONALSAFETY .................................................................................................... 2

1.3 FOOD SAFETY ............................................................................................................ 3

2. INSTALLATION..................................................................................................... 4

2.1 UNPACKING .................................................................................................................. 4

2.2 MOVINGTHE MACHINE ........................................................................................... 4

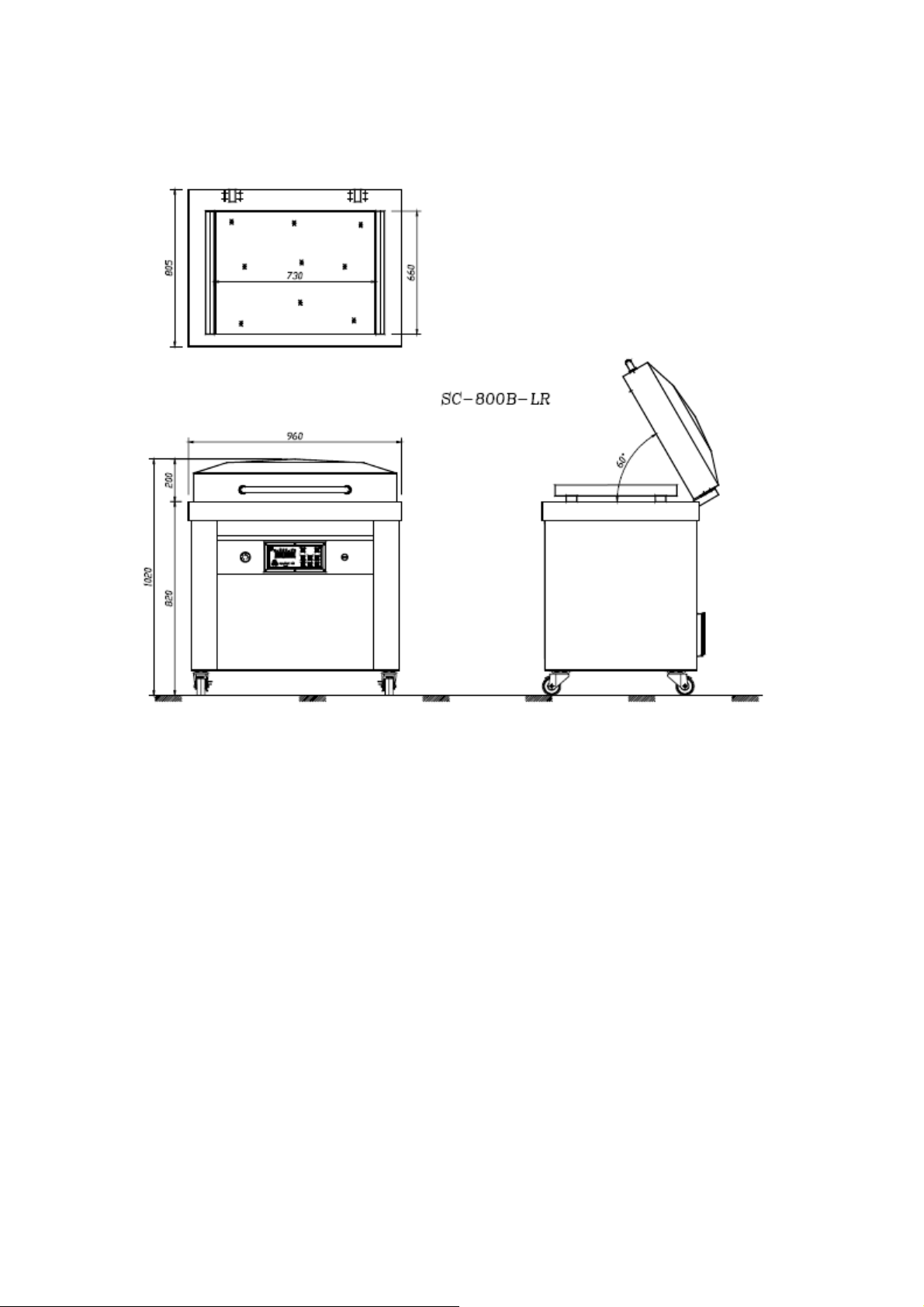

2.3 MACHINE

SPECIFICATI

ONS ..................................................................................... 5

2.4 ENVIRONMENT REQUIREMENTS .......................................................................... 5

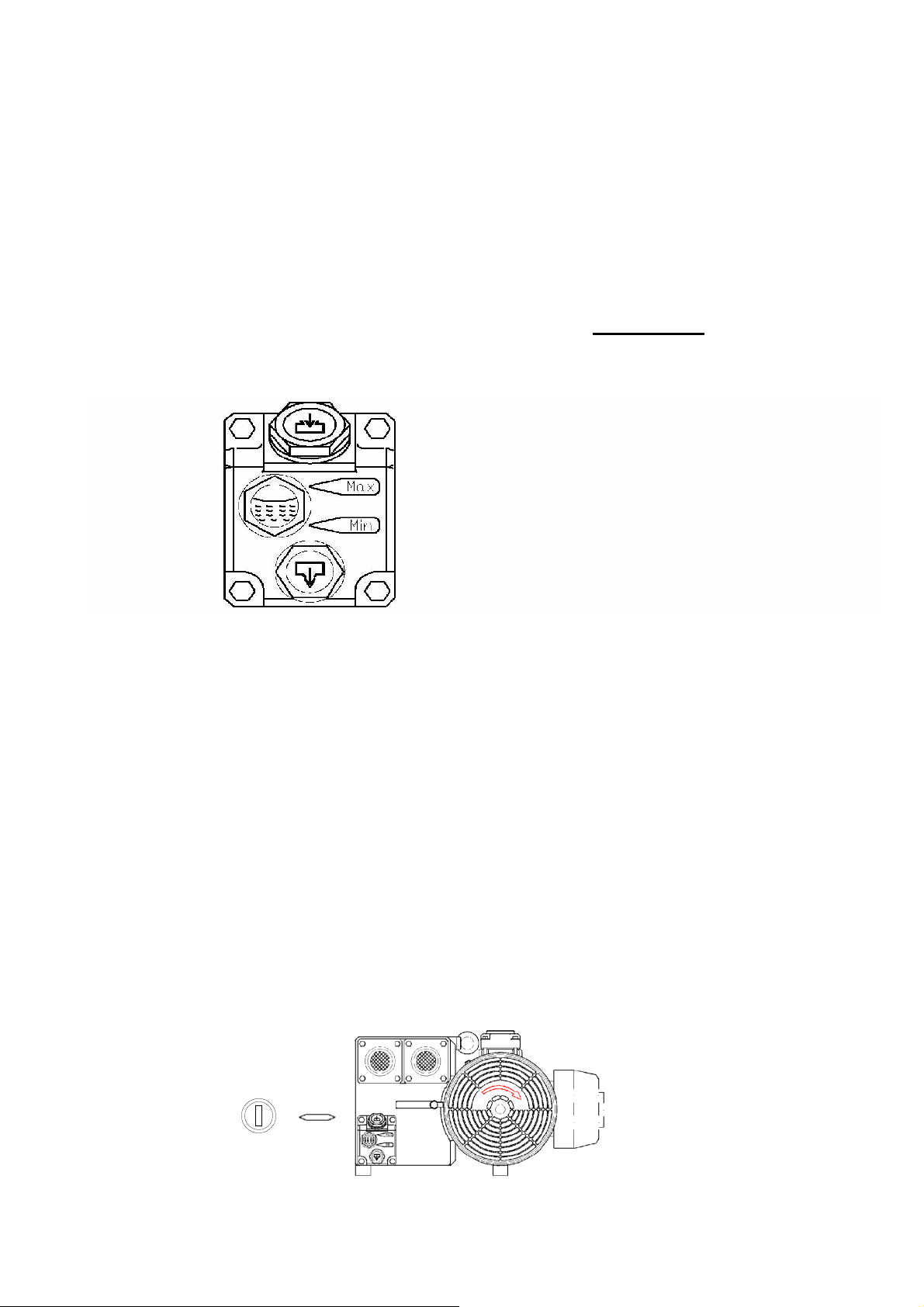

2.5 CHECK OIL LEVEL ..................................................................................................... 6

2.6 POWER CONNECTION ............................................................................................... 6

2.7 VACUUM PUMPROTATION ...................................................................................... 6

3. OPERATION........................................................................................................... 7

3.1 VACUUM SETTING GUIDELINES ............................................................................ 7

3.2 BASIC OPERATING INSTRUCTIONS ...................................................................... 7

3.3 OPTIONALDEVICE ..................................................................................................... 7

3.3.1 GAS FLUSHING UNIT ....................................................................................... 7

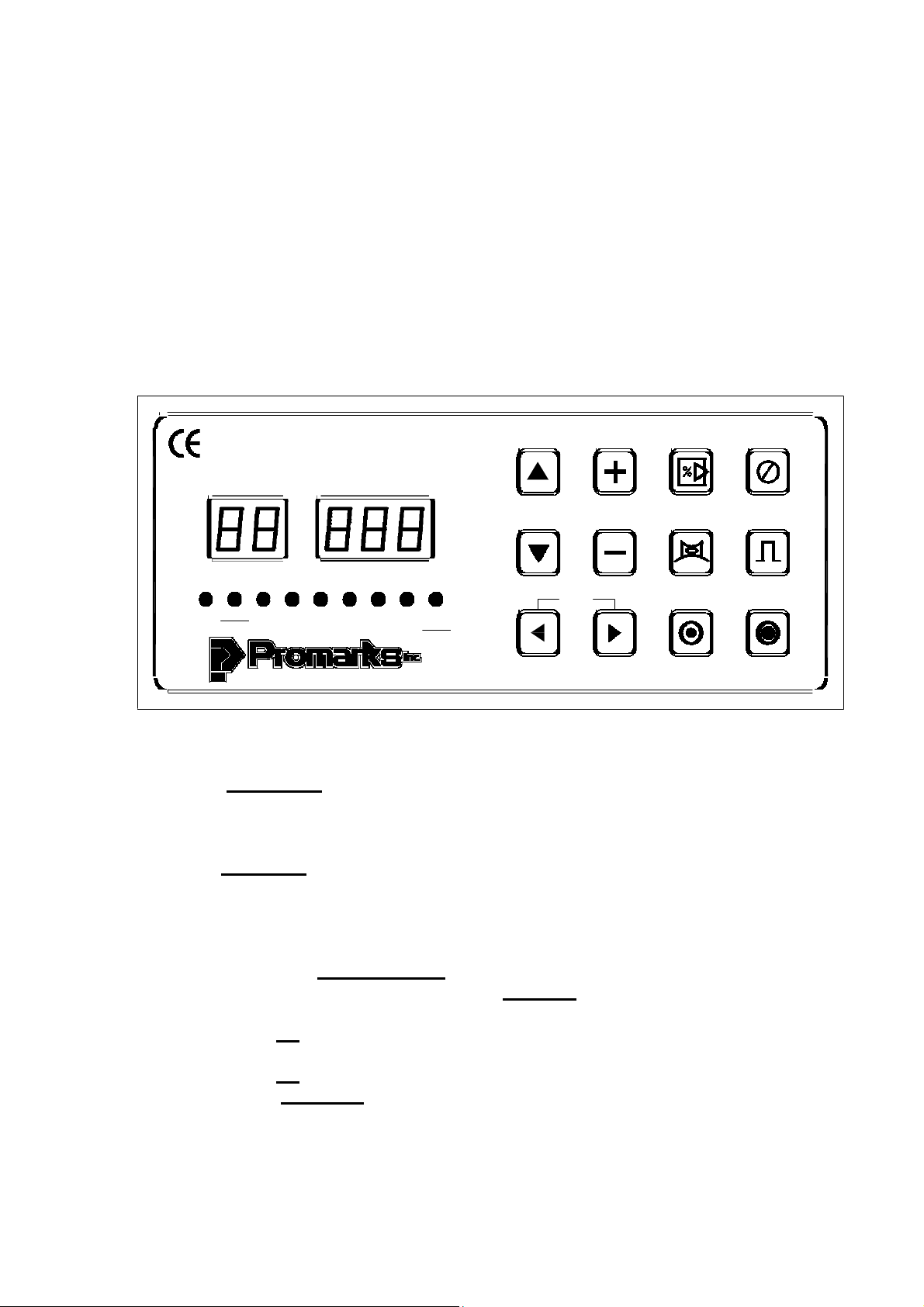

3.4 OPERATION OF THE PNC-01 DIGITALCONTROLPANEL ............................... 8

3.4.1 STANDARD MACHINE – BASIC INSTRUCTIONS ..................................... 8-9

3.4.2 SETTINGTHE PARAMETERS FOR THE OPTIONAL SETTINGS............ 10-12

4. MAINTENANCE .................................................................................................... 13

4.1 BASIC MAINTENANCE ............................................................................................. 13

4.1.1 DAILYVISUAL INSPECTION ......................................................................... 13

4.1.2 DAILY CLEANING ............................................................................................. 14

4.2 VACUUM PUMPMAINTENANCE ............................................................................. 14

4.3 SEALBAR MAINTENANCE ....................................................................................... 14

4.4 VACUUM VALVE MAINTENANCE ......................................................................... 17

5. TROUBLESHOOTING ........................................................................................ 18

5.1 OPTIONAL DEVICE ..................................................................................................... 18

5.2 25 PIN D TYPE TERMINALWIRING CONNECTION INSTRUCTIONS ............ 19

5.3 PNEUMATIC DIAGRAM ............................................................................................. 20

5.4 ELECTRICALDIAGRAM ........................................................................................... 21

6. FABRICATION ..................................................................................................... 22

6.1 BODY DIAGRAM ........................................................................................................ 23-24

6.2 WORKING BED ............................................................................................................. 25

6.2.1 WORKING BED(LR) .......................................................................................... 25-28

6.2.2 WORKING BED(FB) .......................................................................................... 29-32

6.3 LID DIAGRAM ............................................................................................................... 33

6.3.1 LID DIAGRAM(LR) ........................................................................................... 33-34

6.3.2 LID DIAGRAM(FB) ............................................................................................ 35-36

6.4 SEALING BAR-STANDARD DIAGRAM ................................................................... 37-40

6.5 ELECTRICAL BOX ....................................................................................................... 41