C.M.C. n.v. - Airmaster S1 installation guide – V1.2 – MANY0402A.00

Table of contents

1. Introduction.................................................................................................................................4

2. Models.........................................................................................................................................5

2.1 Basic versions ....................................................................................................................5

2.2 Analog conditioning modules...........................................................................................6

3. Technical specifications..............................................................................................................7

3.1 General technical data......................................................................................................7

3.2 Temperature range............................................................................................................7

3.3 Resistance to vibration and shock ..................................................................................8

3.4 Protection degree ..............................................................................................................8

4. Safety ..........................................................................................................................................8

5. Electromagnetic compatibility....................................................................................................9

6. Installation.................................................................................................................................10

6.1 Cable connector types ....................................................................................................10

6.2 Power supply and fusing ................................................................................................10

General..................................................................................................................................11

For the American market (UL).............................................................................................11

For the European market (CE)..............................................................................................12

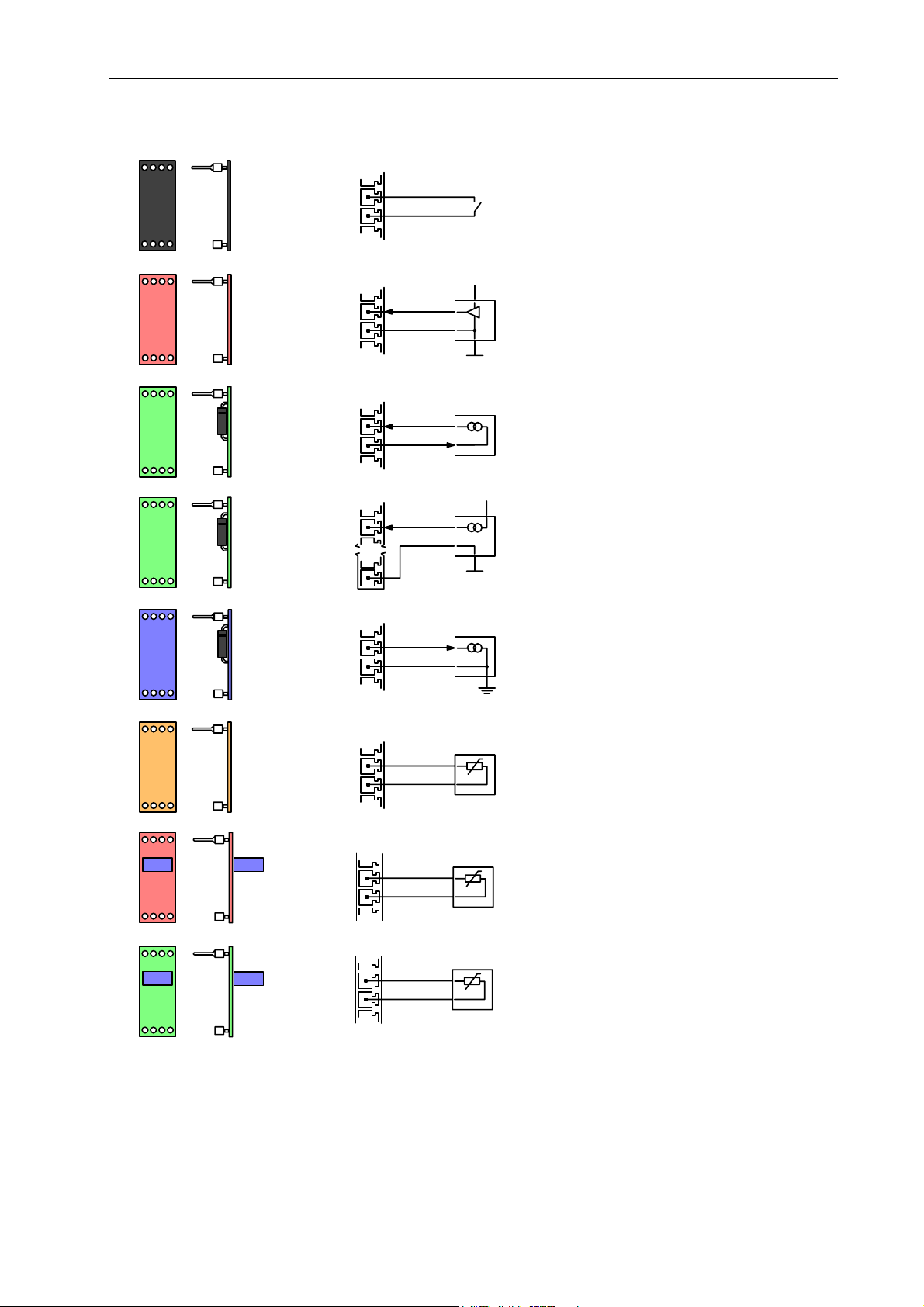

6.3 Analog inputs....................................................................................................................13

6.3.1 ACM type 1: digital input on analog connector...........................................................13

6.3.2 ACM type 2: 0-10Vdc voltage input ...........................................................................13

6.3.3 ACM type 3: 4-20mA input (standard)........................................................................14

6.3.4 ACM type 4: 4-20mA earth referenced (special type).................................................14

6.3.5 ACM type 5: KTY temperature sensor (-10…+132 deg C).......................................15

6.3.6 ACM type 5: RTD temperature sensor (-40…+150 deg C) .......................................15

6.3.7 ACM type 6: PT100 temperature sensor (-50…+250 deg C)......................................15

6.3.8 ACM type 7: PT1000 temperature sensor (-50…+250 deg C)....................................16

6.4 Digital inputs.....................................................................................................................17

6.4.1 The emergency stop contact input ...............................................................................18

6.4.2 The contact inputs........................................................................................................18

6.4.3 The PTC input..............................................................................................................18

6.5 Relay outputs ...................................................................................................................19

6.6 analog output (optional)..................................................................................................21

6.7 Communication ................................................................................................................21

6.7.1 RS485 port1 (standard)................................................................................................21

6.7.2 RS485 port2 (option) ...................................................................................................21

7. Mounting of the Airmaster S1 ..................................................................................................22

8. Putting into operation................................................................................................................23

9. Configuration............................................................................................................................23

10. Adjusting.................................................................................................................................24

11. Trouble shouting.....................................................................................................................24

Appendix 1: Dimensions and mounting of the S1 controller .......................................................25

Appendix 2: connectors for machine wiring.................................................................................29

Connector X01: Supply .........................................................................................................30

Connector X02: relays (optional) .........................................................................................30

Connector X03: relays...........................................................................................................30

Connector X04: digital inputs ...............................................................................................31

Connector X05: analog inputs..............................................................................................31

Page 2 of 35