CO/Tech 2502W User manual

Important!

Read the entire instruction manual carefully

and make sure that you fully understand

it before you use the equipment. Keep the

manual for future reference.

Viktig information:

Läs hela bruksanvisningen noggrant och

försäkra dig om att du har förstått den innan

du använder utrustningen och spara den för

framtida bruk.

Viktig informasjon:

Les disse anvisningene nøye og forsikre deg

om at du forstår dem før du bruker enheten

og oppbevar dem for senere bruk.

Tärkeätä tietoa:

Lue nämä ohjeet huolellisesti ja varmista

että olet ymmärtänyt ne, ennen kuin alat

käyttää laitetta. Säilytä ohjeet myöhempää

tarvetta varten.

Art.no Model

40-7993 92502W

ENGLISH

SVENSKA

NORSKSUOMI

Combination Saw

Kombinationssåg

Kombinasjonssag

Yhdistelmäsaha

Ver. 201107

Original instructions

Bruksanvisning i original

Original bruksanvisning

Alkuperäinen käyttöohje

2

ENGLISH

Combination Saw

Art.no: 40-7993 Model: 92502W

Please read the entire instruction manual before using the product and save it for future reference.

We apologise for any text or photographic errors and any changes of technical data. If you have any

questions concerning technical problems please contact our Customer Service Department (see address

on reverse.)

!

Important safety instructions:

Read the entire instruction manual before using this product.

1. Safety

Warning: When using this machine all basic safety precautions must be followed to avoid the risk of re,

electrocution and personal injury. Read these instructions carefully before using the product and keep them

for future reference.

1. Keep the working area tidy. Cluttered areas and benches invite accidents.

2. Take stock of your working environment. Do not expose the machine to rain. Do not use the machine in moist

or wet areas. Keep the working area well lit. Never operate the machine near ammable liquid or gas.

3. Avoid electric shocks. Avoid body contact with earthed objects, such as pipes, radiators, ovens or refrigerators.

4. Keep other people at a safe distance. Do not allow anyone not involved in the work process to touch the

machine or its electric cable, especially children. Keep all bystanders at a distance.

5. Store the machine in a safe place. When your machines are not in use, keep them in a locked, dry area, away

from children.

6. Do not overload the machine. The correct feed rate makes the work better and safer.

7. Use the correct machine. Do not try to use small machines to perform jobs requiring more powerful machines.

Do not use a machine for a purpose for which it was not designed, e.g. using a circular saw for lopping

branches off trees or cutting timber.

8. Wear suitable clothing. Do not wear loose-tting clothing or jewellery, they could get caught in moving parts.

Non-slip shoes are recommended for outdoor work. Wear a hairnet or similar if you have long hair.

9. Always use safety glasses. Wear safety glasses. Use a face mask or dust lter when working in dusty

environments.

10. Use dust extractors. If the machine is equipped with or connected to a dust extractor/collector, make sure that

it is turned on and used correctly.

11. Do not abuse the lead. Do not jerk the lead, grip the plug itself when disconnecting the power. Make sure that

the mains lead does not come into contact with heat, oil, or sharp edges.

12. Secure the workpiece rmly. If possible use vices or clamps to hold the workpiece in place. This is much safer

than holding the workpiece in one hand.

13. Do not overreach. Make sure that you stand steady and balanced all times.

14. Look after the machine. Keeping the machine clean and the blades sharp will ensure the best results. Follow

the manuals advice regarding lubrication and the replacement of accessories. Regularly inspect the power

lead. If it damaged it should be replaced by a qualied service technician. Regularly inspect all extension leads

for any damage. Keep the handles of the machine and all controls and switches dry and free from oil and

grease.

3

ENGLISH

15. Turn the power off. Pull out the plug and push in the emergency stop button before servicing or changing

any blades, drill bits, cutters or sanding discs.

16. Remove all spanners and repair tools. Make a habit of checking to make sure that the machine is free of

all spanners and tools before turning the power on.

17. Avoid accidental starting. Do not walk around with the machine with your nger on the power button if it

is plugged in. Make sure that the on/off switch is set to OFF before plugging in any power tool.

18. Use the correct extension leads. If you use extension leads outdoors, only use those designed for

outdoor use. Only use extension leads with thick enough diameter core wires and roll out the whole lead.

19. Use common sense and be careful. Think before carrying out any task, so that it is carried out safely.

Never operate machines when you are tired, under the inuence of medicine etc.

20. Check the following before turning the machine on:

• That all guards and other parts are whole and in working order.

• That moving parts are free and correctly aligned.

• That no moving parts can get caught.

• That no defects are apparent.

• Other factors that can inuence work execution.

• A safety guard or any other part that is damaged should be repaired by a tradesman or replaced.

Damaged power leads and switches must always be replaced by a tradesman or qualied service

centre. Never operate the machine if you cannot stop or start the tool safely.

21. Use only recommended accessories. The use of non-recommended accessories can cause accidents

and personal injury.

22. Should only be repaired by a qualied technician. This machine conforms to current safety requirements.

Repairs to the machine should only be carried out by a tradesman using original spares; otherwise the

machine could cause accidents and personal injury.

1.2. Safety Instructions Specific to Combination Saws

Warning: Always unplug the machine before carrying out any maintenance or changing the blade.

Helpful Suggestions:

• Working with wood can be dangerous if the correct procedures are not observed.

• Using the saw with common sense and caution will greatly reduce the risk of personal injury.

• Safety devices such as guards, push-sticks, clamps, safety goggles, dust masks and ear defenders

can never make up for bad judgement, carelessness or inattentiveness.

• Remember: you are responsible for your own safety. The saw has been designed to perform certain

tasks. We strongly recommend that the saw is not altered in any way and that it is not used for

performing any task for which it was not designed.

• DO NOT USE THE SAW if you are unsure if the saw can perform the task you intend to perform.

Make sure that all the parts are working properly and that the safety devices are in place before starting

the saw.

1. Warning: Use only cross-cut saw blades. Make sure that TCT blades have negative rake. Do not use

blades with deep spacing between the teeth because the teeth might bend and come into contact with

the blade guard. A damaged blade should be replaced immediately.

2. Do not use the saw unless it has been completely assembled using the instructions in this manual.

Check that the motor and the blade are rotating the right way (see direction arrow on blade guard). Make

sure that the blade does not come into contact with the table in any of the settings. Unplug the machine

and manually tilt the blade to 45° and 90°. Adjust the saw head if necessary.

3. If you do not understand how the saw should be used, ask a knowledgeable person for advice.

4

ENGLISH

4. Do not saw freehand. Make sure that the workpiece is rmly secured against the fence before you start

sawing. If the workpiece that you are sawing requires you to have one hand as close as 10 cm from the

blade, x the workpiece to the table using a clamp, etc. before sawing.

5. Warning: Keep hands away from the saw blade. Never saw small objects. Use a push-stick.

6. Check that the blade is well-centred, sharp and that it rotates freely and without vibration.

7. Let the motor come up to speed before starting to cut.

8. Always keep the motor’s ventilation openings free of dust and debris.

9. Make sure that all clamps are tight before starting to saw, even if the table is locked at a xed angle.

10. Make sure that the blade and anges are clean and that the spindle nut is tight. Use only the blade

anges belonging to your saw.

12. Use only saw blades having a diameter and speed rating complying with those in the technical

specications.

13. When sawing long objects, make sure that the ends are adequately supported.

14. Always check the blade for cracks and fractures before using it. Replace a damaged blade immediately.

15. Do not use the saw if any of the parts is missing, damaged or not working properly. Unplug the saw if

it starts to make strange noises or vibrate. Get a professional to replace the missing or damaged part

before you use the saw again.

16. Never use the saw if the blade guard is not in place and working properly.

17. Never stretch round or over the blade when it is rotating. Maintain a steady stance and remain balanced

at all times.

18. Make sure that the blade can rotate freely (especially after transportation/blade changes) before plugging

in and starting the saw.

19. Never lock the switch in the ON position.

21. Important: When the workpiece has been completely sawn through: Turn the machine off and wait until

the blade has stopped rotating before lifting the saw head.

22. Turn the machine off and wait until the blade has stopped before moving the workpiece or adjusting any

setting.

23. Do not remove any offcuts or jammed material from around the blade area until the blade has stopped.

24. Never saw into ferrous metals, brick or mortar.

25. Never use the saw near ammable uids or gas.

26. Never clean the plastic parts of the saw using solvents. Solvents can dissolve or otherwise damage

plastic; use a soft, moist cloth only.

27. Unplug and clean the saw before leaving it. Always tidy the work area when you have nished working.

28. Keep this instruction manual safe. Read through it regularly and use it to help instruct other users.

Make sure that everyone using the saw has read these instructions.

29. Do not expose the saw to rain and do not use it in humid environments.

30. Ensure that the work area is well-lit.

31. Wear suitable clothing, loose clothing or jewellery can get caught in moving parts.

32. The saw must only be operated by persons over the age of 18; persons over the age of 16 may operate

the tool under supervision. Keep children away from the saw when it is connected to the power supply.

33. Keep the work area tidy, do not leave offcuts or waste material around the saw unnecessarily. Make sure

that all offcuts can be removed from the saw blade; otherwise they might be ejected by the blade.

34. Do not distract the operator of the saw.

35. Do not try to stop the blade by pushing something against the side of the blade when the power has

been turned off.

5

ENGLISH

36. Never use saw blades that do not comply with the specications in this manual.

37. Always make sure that the blade guard is in place and working properly.

38. Never lock the blade guard in the open position or alter any of the machines safety devices in any way.

Never use a faulty safety device, replace it immediately.

39. Always position your hands in such a way that they will not slip into the saw blade should you lose your

balance. Never saw workpieces that are too small to hold safely.

40. Use a table, roller stand, etc for support when working on long workpieces, to prevent the table from

tipping over.

41. Secure round workpieces to the table using suitable clamps to stop them from rotating.

42. Never cut a workpiece with nails or screws in it. Inspect the workpiece before sawing.

43. Always stand to the side of the blade when using the saw so that you are not in its path in case it breaks.

44. Always ensure that the workpiece is securely pressed against the rip fence and surface of the table so

that it cannot twist whilst being sawed.

45. Never saw more than one workpiece at a time.

46. Never attempt to remove sawdust or offcuts trapped around the blade whilst the saw blade is rotating.

Always switch off the machine and unplug it before adjusting the machine or removing waste material.

47. Always switch off the machine and unplug it before cleaning the machine or measuring the workpiece.

48. Always switch off the machine and unplug it before leaving the work area.

49. Electrical installations, repairs or maintenance must be carried out by a qualied person.

50. All safety devices must be reattached to the machine immediately after any repairs or maintenance.

51. It is very important to observe the directions for the safety, operation and maintenance of the machine as

well adhering to the characteristics specied in Technical Data.

52. It is essential to follow all Health and Safety Executive regulations as well as general safety regulations.

53. Use only a machine with a dust extractor in a closed room if the room has an air inlet, to prevent the

build-up of a vacuum.

54. The saw must only be used with a 230 V plug protected by at least a 10 A slow-blow fuse.

55. Faulty safety devices and damaged parts must be repaired or replaced by a qualied tradesman at an

authorised service centre.

56. This machine conforms to all relevant safety standards. The machine must only be repaired by a

qualied tradesman at an authorised service facility using original spare parts. Failure to adhere to this

rule can lead to an accident and endanger the user.

57. Do not use saw blades that are thicker or thinner than the riving knife (applies to circular saws).

58. Always use a riving knife when rip cutting.

59. Make sure that the riving knife is adjusted so that: The distance between the saw blade and the riving

knife should be 5-6 mm.

60. The riving knife should have a radius compatible with the diameter of the saw blade.

61. Do not use high speed steel blades (HSS) if the machine is delivered with tungsten carbide (TCT) blades.

6

ENGLISH

Failure to respond to the safety warnings could result in injury

or damage the tool.

Keep the saw head lowered until the saw blade has completely

stopped after a cut has been made to avoid being injured by

ying splinters and wood chips.

Unplug the machine before turning the table and using another

method of working.

Note: The blade nut has a left-hand thread.

Clear any saw dust, waste material, etc from the table before

using the combination saw.

Think about where you place your hands when carrying

the saw.

2. Product safety symbols and their meaning

Always use ear protection.

Always wear protective glasses or a visor and breathing protection.

7

ENGLISH

3. Description

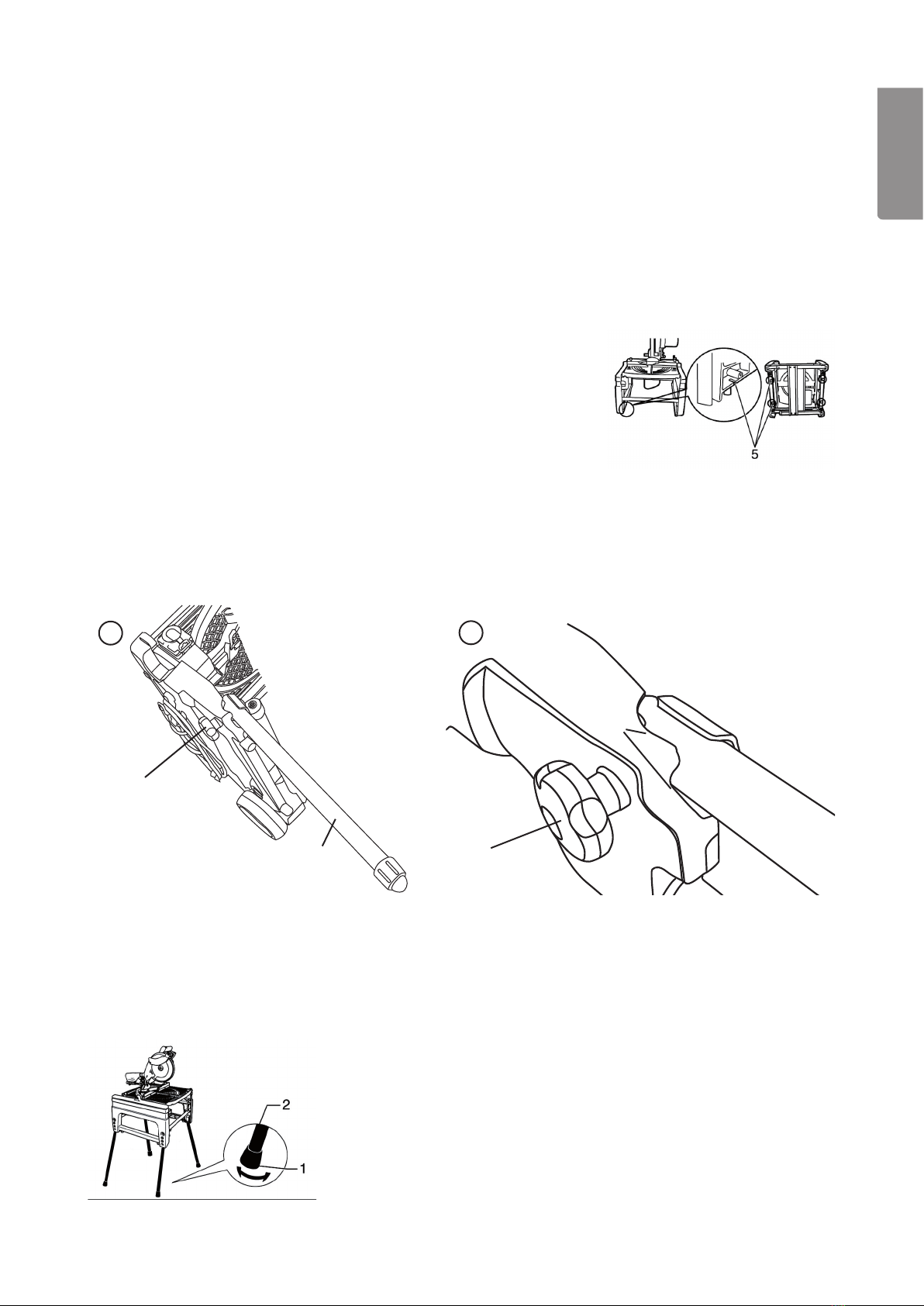

1. Adjustable foot

2. Leg 5. U-shaped slot

6. Adjustable blade guard

7. Fixed blade guard

8. Lower blade guard

(only for mitre saws)

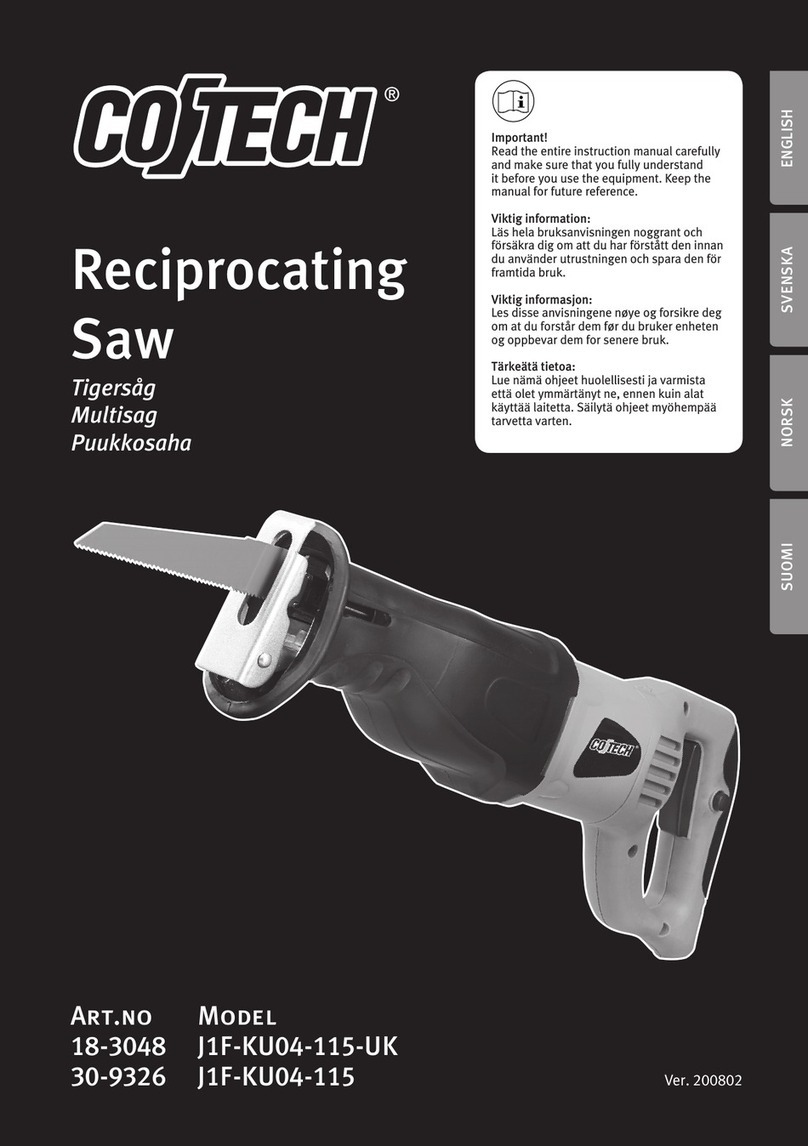

9. Upper blade guard lock

10. Riving knife

11. Upper blade guard

(only for circular saw)

12. Surface of the table

13. Edge of the blade

14. Fence

4. Bolt

15. Depth stop

16. Lock nut

14. Fence

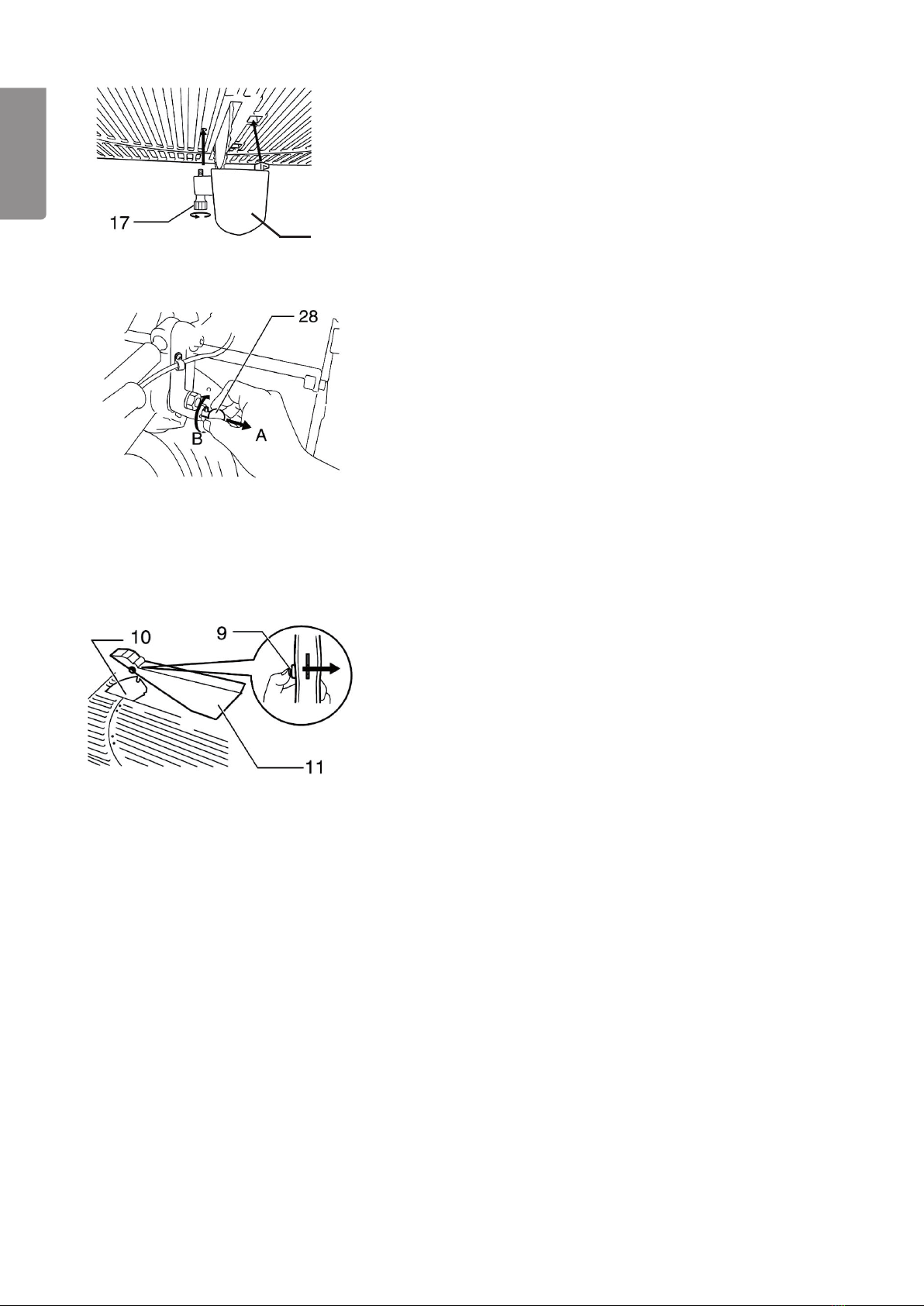

17. Locking knob

18. Handle

19. Turntable

20. Locking knob 18. Handle

20. Locking knob

21. Cutting depth adjusting screw

1 2 3

4 5 6

7 8 9

10 11 12

8

ENGLISH

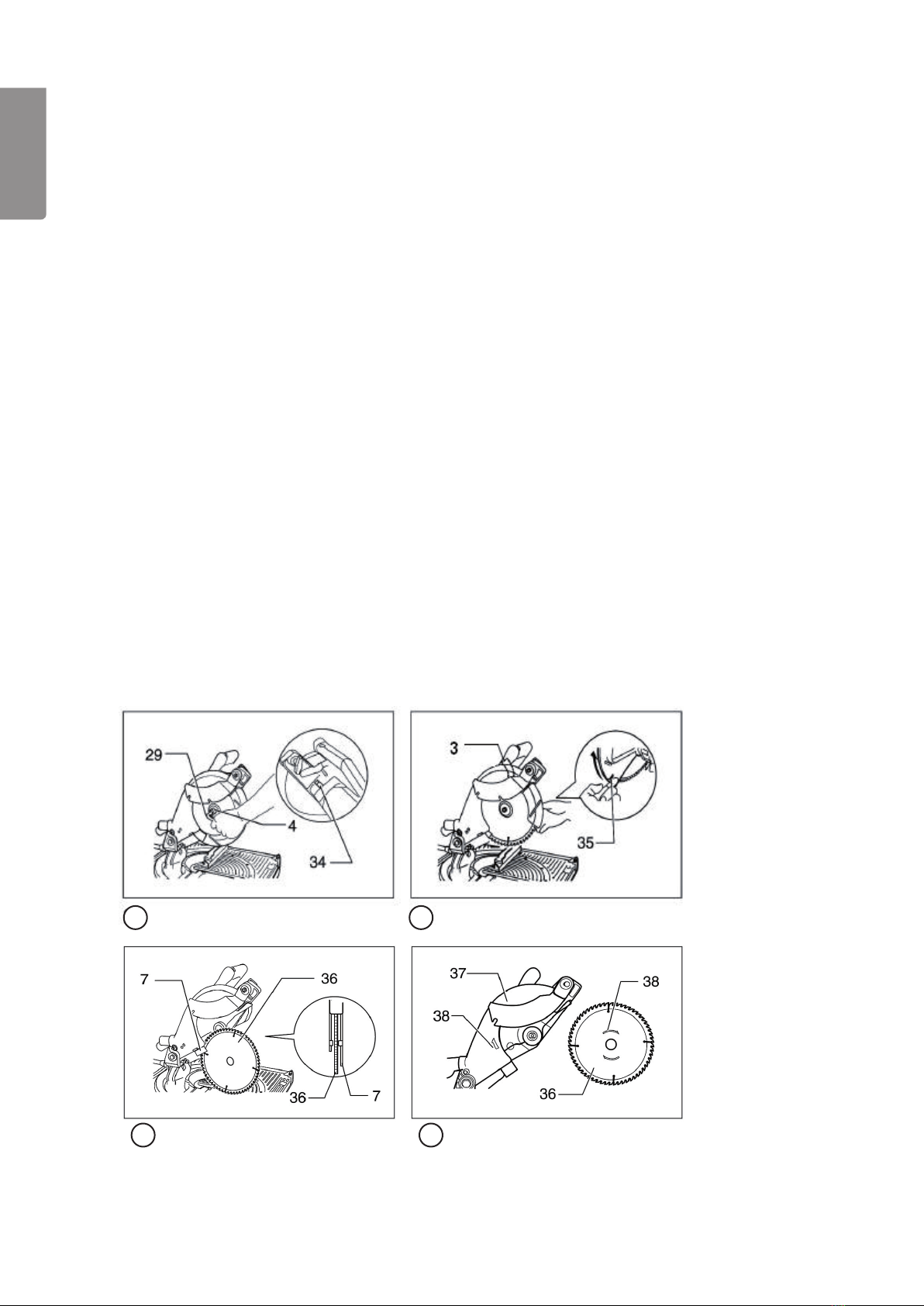

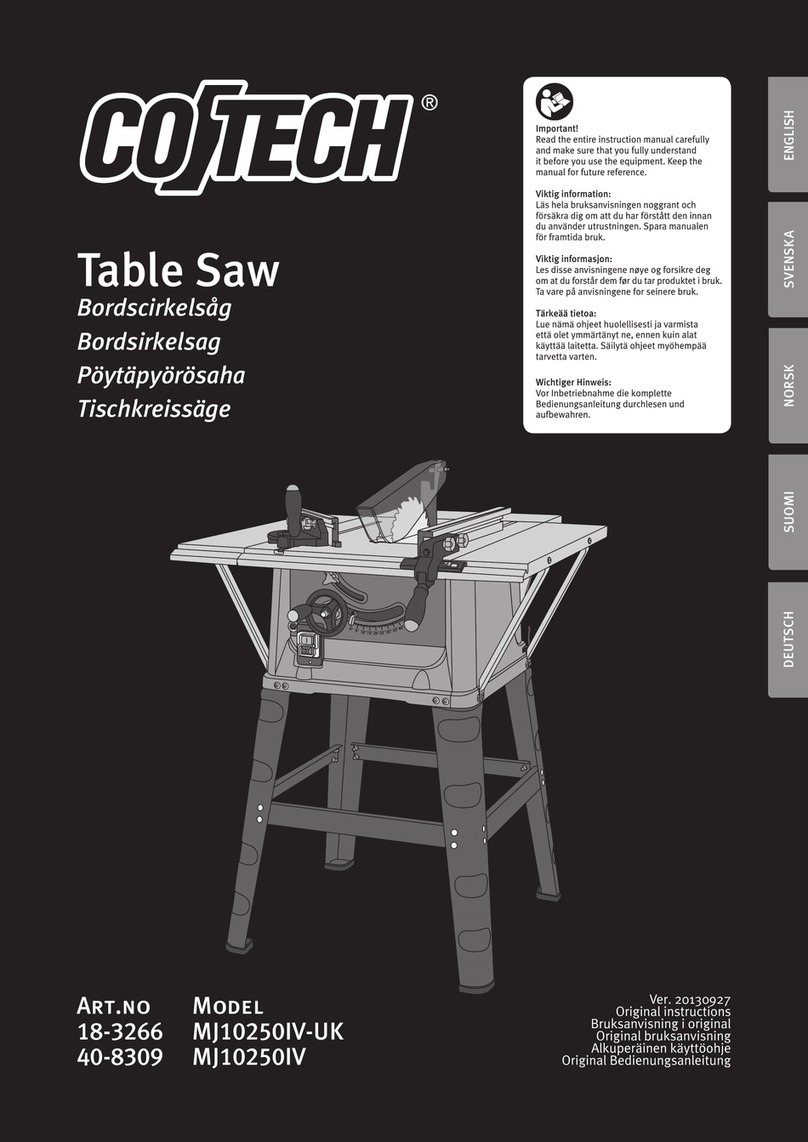

21. Cutting depth adjusting screw 28. Saw head lock

29. 13 mm Allen key for saw blade

30. Allen key holder

4. Bolt

29. 3 mm Allen key for saw blade

34. Spindle Lock Button 35. Lifting grip

7. Fixed blade guard

36. Saw blade

36. Saw blade

37. Saw blade cover

38. Rotation arrow

4. Bolt

36. Saw blade

39.Outer blade ange

40. Inner blade ange

41. Spindle

42. Washer

4. Bolt

10. Riving knife

43. Riving knife locking knob

31. Leg locking knob

32. Leg

31. Leg locking knob

33. Leg seat

18. Handle

3. Lock

22. Power switch (for compound mitre saw mode)

23. Power switch /Emergency stop (for circular

saw mode)

24. Safety Catch

25. Power switch in handle (for compound mitre

saw mode)

26. ON switch (green) (for circular saw mode)

27. OFF switch (red) (emergency stop with lid)

13 14 15

16

19 20 21

22 23 24

31

32

17

33

31

18

9

ENGLISH

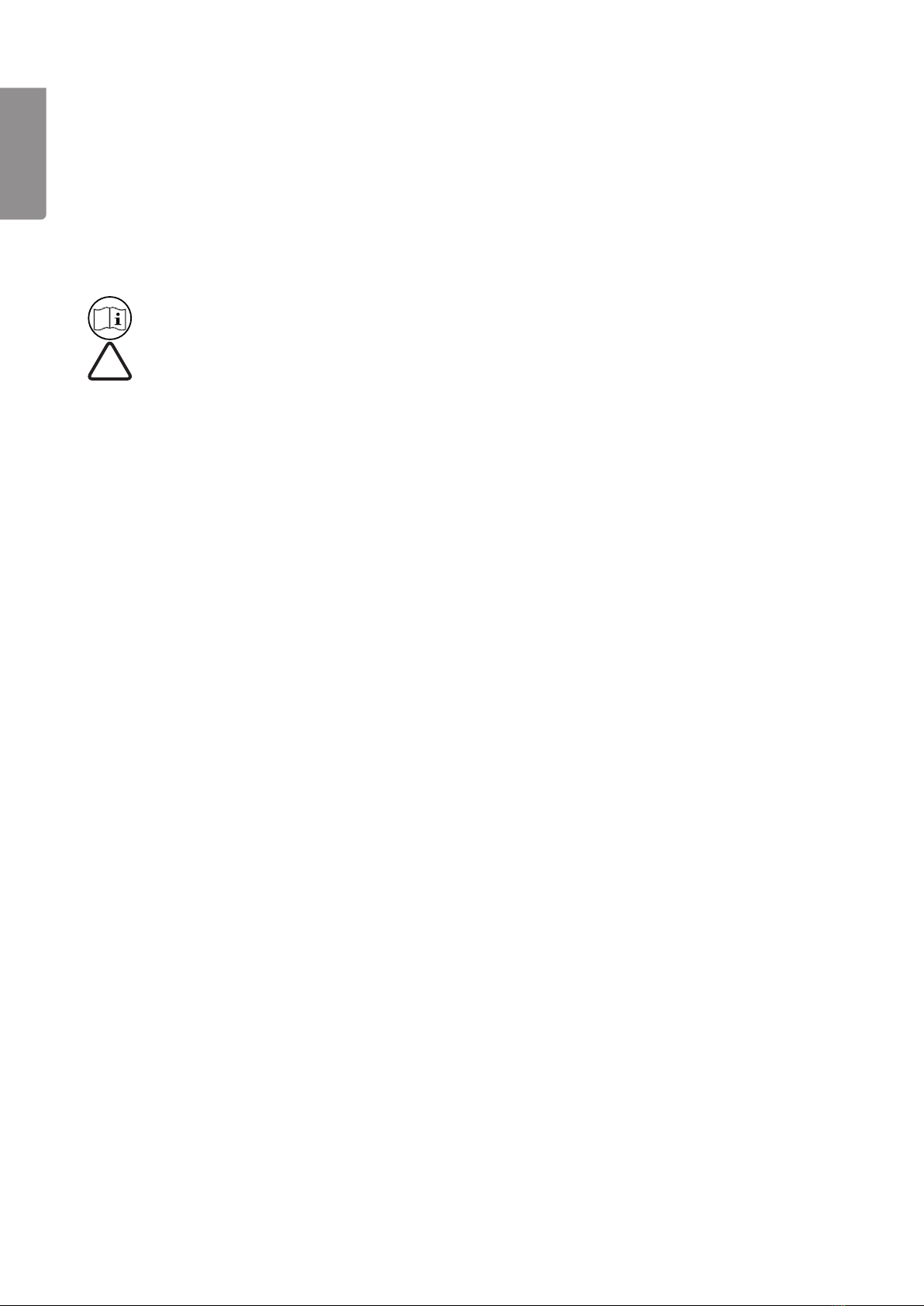

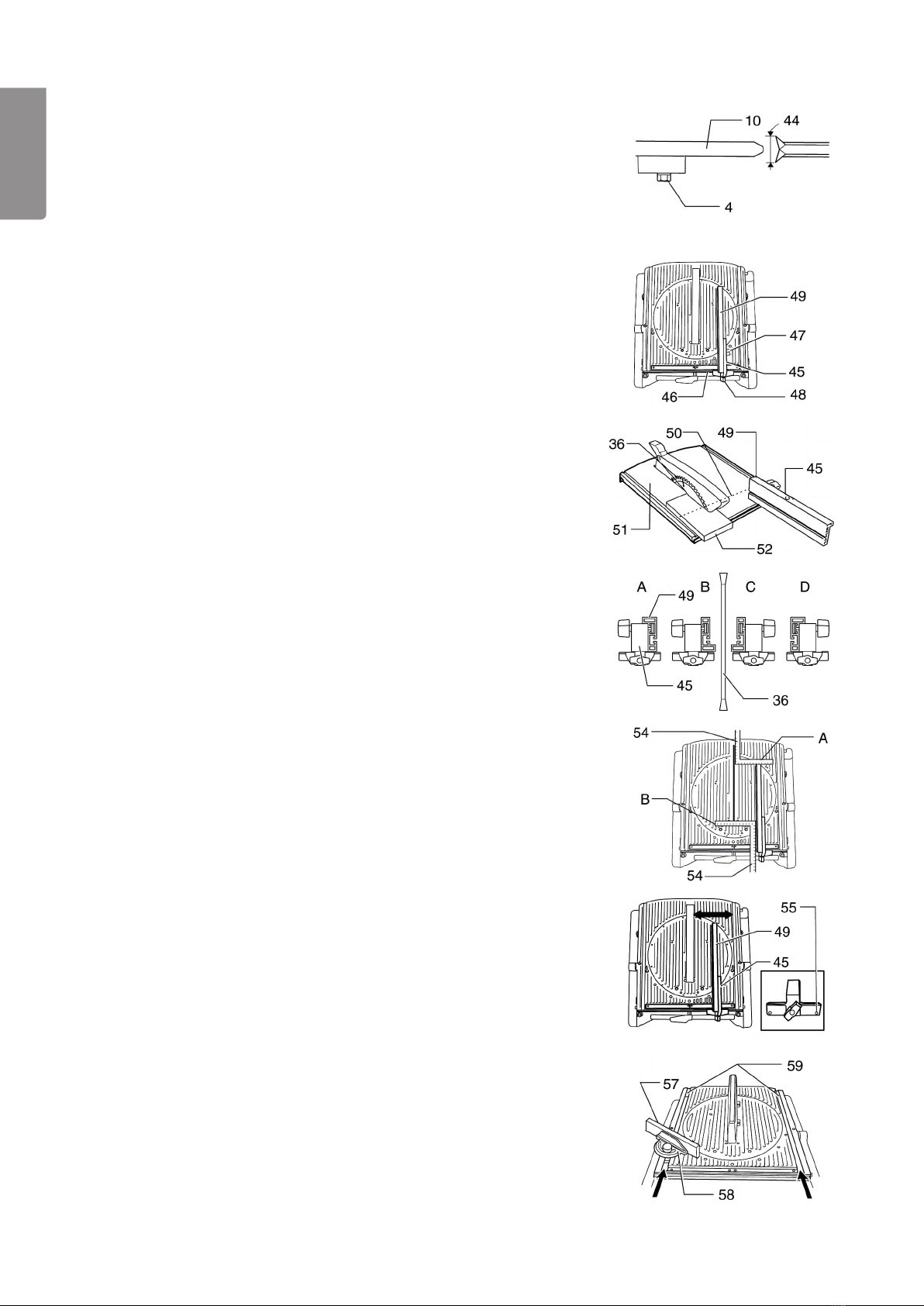

10. Riving knife

36. Saw blade

4. Bolt

10. Riving knife

44. Kerf

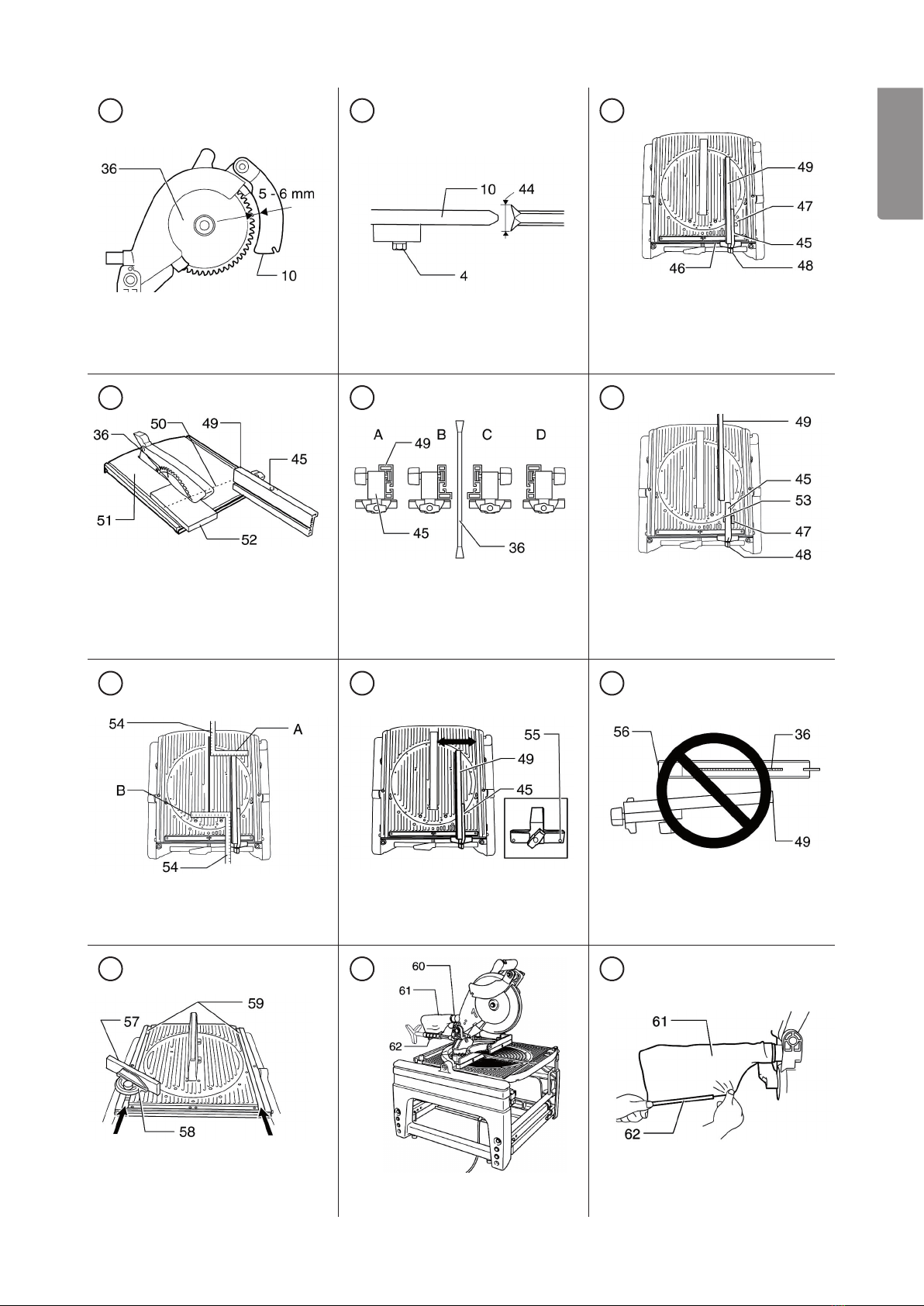

45. Rip fence guide clamp

46. Rip fence slot

47. Rip fence locking knob

48. Rip fence guide locking knob

49. Rip fence

36. Saw blade

45. Rip fence guide clamp

49. Rip fence

50. Index line

51. Circular saw

52. Workpiece

36. Saw blade

45. Rip fence guide clamp

49. Rip fence

45. Rip fence guide clamp

47. Rip fence locking knob

48. Rip fence guide locking knob

49. Rip fence

53. Nut

54. Try square (not included)

45. Rip fence guide clamp

49. Rip fence

55. Adjusting screw

36. Saw blade

49. Rip fence

56. Upper blade guard

57. Mitre guide track

58. Mitre guide

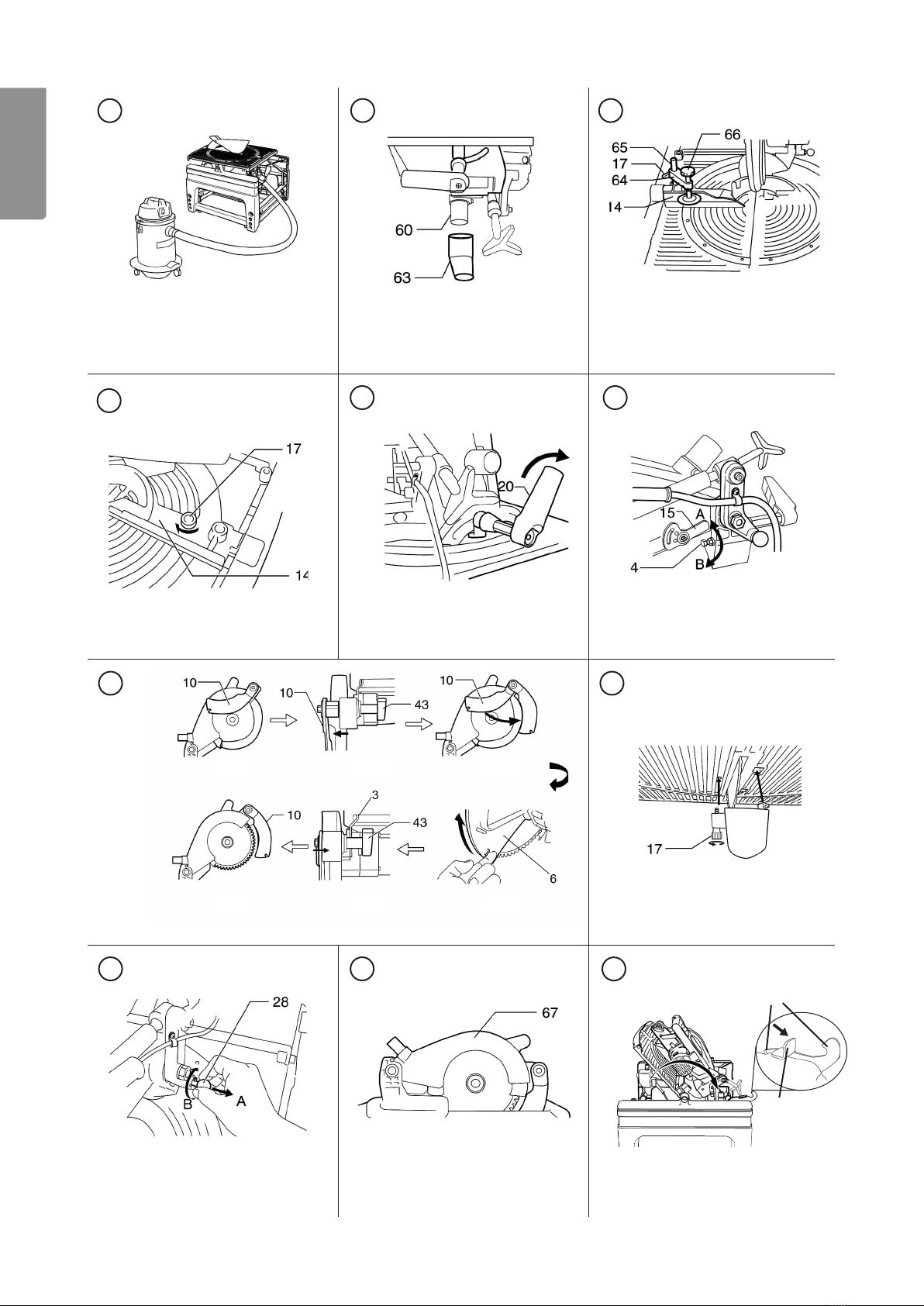

60. Dust bag/extractor coupling sleeve

61. Dust bag

62. Zip

61. Dust bag

62. Zip

25 26 27

28 29 30

31 32 33

34 35 36

10

ENGLISH

60. Dust bag/extractor coupling sleeve

63. Angled coupling sleeve for dust bag/

extractor

14. Fence

17. Locking knob

64. Clamp arm

65. Clamp rod

66. Clamp knob

14. Fence

17. Locking knob 20. Locking knob

4. Bolt

15. Depth stop

17. Locking knob

28. Saw head lock 67. Saw blade guard

68. Table lock for changing from

compound mitre saw to circular saw

69. Catches

10. Riving knife

43. Riving knife locking knob

43 A 43 B 43 C

43 D43 E43 F

37 38 39

40 41 42

43 44

45 46 47

68

69

11

ENGLISH

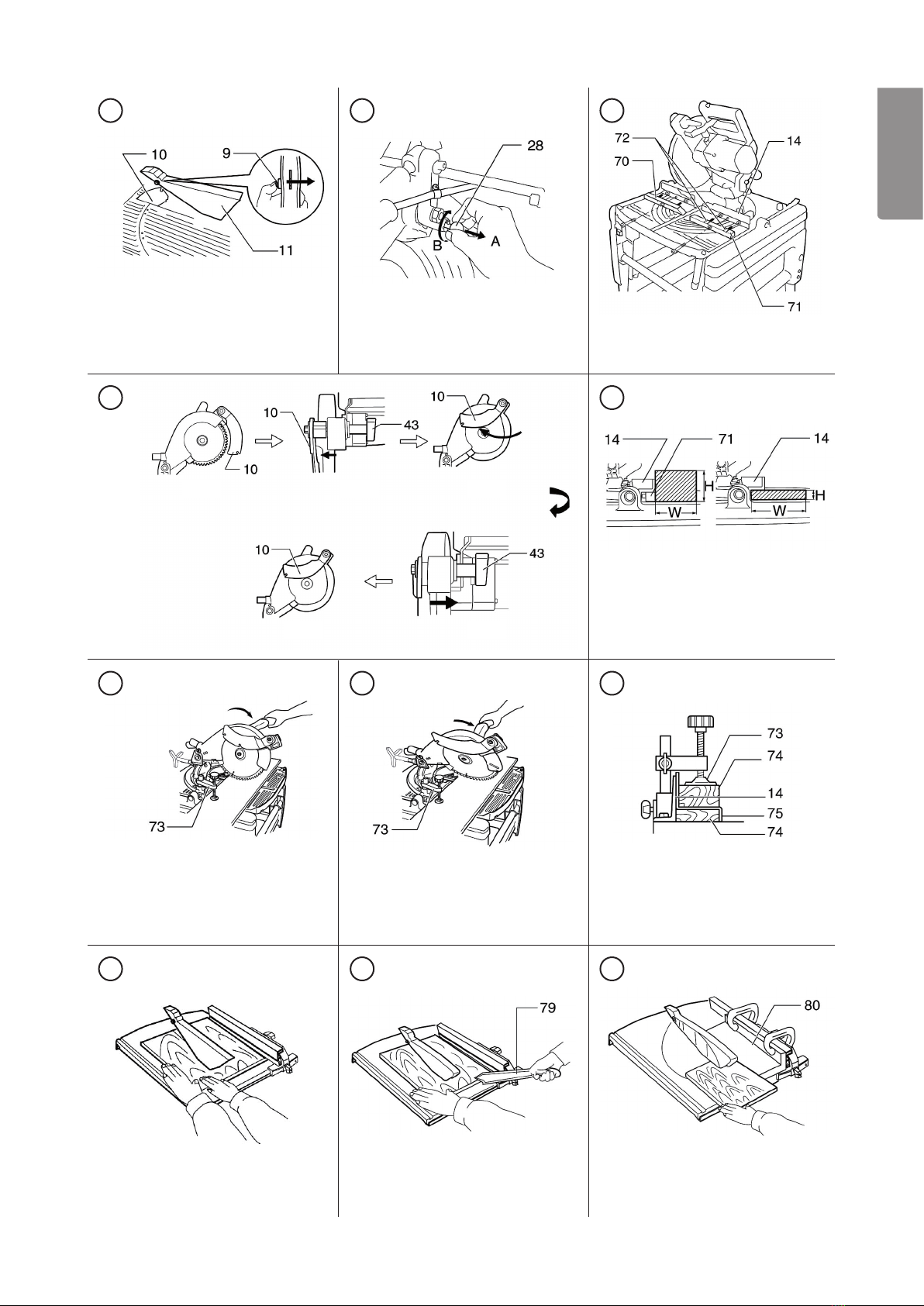

9. Upper blade guard lock

10. Riving knife

11. Upper blade guard (only for circular saw) 28. Saw head lock

10. Riving knife

43. Riving knife locking knob 14. Fence

71. Lower right fence

73. Clamp 73. Clamp

14. Fence

73. Clamp

74. Scrap wood

75. Aluminium section (workpiece)

79. Push stick 80. Sawing block (not included)

14. Fence

70. Lower left fence

71. Lower right fence

72. Guide pins

50 A 50 B 50 C

50 D50 E

48 49 51

50 52

53 54 55

56 57 58

12

ENGLISH

28. Saw head lock

87. Suitable holding point for

transportation.

14. Fence

36. Saw blade

88. Try square (not included)

89. Adjustment screw (0°)

90. Adjustment screw (45°)

12. Surface of the table

36. Saw blade

88. Try square (not included)

19. Turntable

91. Locking knob

92. Tilt angle scale

93. Index mark

82. Right angle cut

83. Mitre cut

84. Bevel cut

85. Compound cut (both bevel and mitre)

58. Mitre guide

59. Mitre guide track

86. Locking knob

20. Locking knob

59 60

61 62 63

64 66

67 68

65

13

ENGLISH

Circular Saw/Table saw: (motor under table)

Compound Mitre Saw (motor over table)

4. Preparing the saw for use

Note:

• Always make sure that the oor surrounding the saw is clear of waste material, sawdust or anything that

one might trip over.

• The combination saw can be used standing on the oor with its legs extended or mounted on a bench

with its legs folded.

• If the saw is to be mounted on a bench, table, etc it must be securely anchored by passing bolts through

the bench/table and the U-shaped slots (5) on the base of the saw.

4.1 Unfolding the legs

1. Lay the combination saw on its side.

2. Undo the big locking knobs (31) which hold the legs in place.

3. Unfold the legs and tighten the knobs again to lock the legs in the extended position.

4. Do the same with the other side.

Adjusting the legs

The legs must be steady on the oor, adjust them if necessary using the adjustable feet (1) on the ends of

the legs if the oor is uneven. Turn the foot anticlockwise to screw it in and clockwise to screw it out.

31

32

17

31

33

18

14

ENGLISH

5. Description

5.1. Starting/stopping

The combination saw is started and stopped in different ways depending on how the saw is being used.

In circular saw (table saw) mode: (motor under table)

The machine is started and stopped using the power switch (23) (underneath the yellow lid)

• Push the green button (26) to start the motor.

• Push the red button (27) to turn the machine off.

In compound mitre saw mode: (motor over table)

The machine is started and stopped using the power switch (22)

• Hold in the safety catch (24) and the power switch (25) to start the motor.

• Release the power switch (25) to stop the motor.

Warning: Always unplug the machine before carrying out any adjustments or maintenance.

The combination saw is equipped with two types of blade guard which are to be attached depending

on whether the saw is being used as a circular saw or compound mitre saw.

Warning:

• Before using the saw, check that all safety devices are intact and that the handle (18) cannot be lowered

without the safety catch (3) having rst been slid to the left.

• Make sure that the adjustable blade guard (6) does not open without the safety catch (3) rst having

been slid to the left.

• Make sure that the lower blade guard (8) is mounted before using the saw in compound mitre saw mode.

• Make sure that the lower blade guard (11) is mounted before using the saw in compound mitre saw

mode.

• The table must be locked in one of the working modes for the catches to spring out and lock the table.

• The compound mitre saw can be very dangerous if it is used without proper safety guards, the operator

could be seriously injured.

24 25

3

18

6

69

68

69

15

ENGLISH

5.2. Attaching/removing blade guards

The lower blade guard (8) and upper blade guard (11) are never to be used at the same time. One of the

guards should be attached and the other removed depending upon the mode the saw is set in:

• The lower blade guard (8) (used in compound mitre saw mode) is mounted underneath the table, hook

onto the catches under the table and tighten the screws (17) on the other side. First, remove the guard

(11) if it is tted.

Undo the riving knife (10) and attach it to the side:

1. Undo the knob (43) and pull the riving knife to the side (Fig. 50-B).

2. Move the riving knife in the direction indicated by the arrow to move it out of the way (Fig. 50-C).

3. Push in the riving knife and lock the knob (43) (Fig.50-D).

4. Test by hand that the blade moves freely and does not catch on anything.

• The upper blade guard (11) (used

only in circular saw mode) attaches

to the riving knife (10).

5. Turn the table over so that the

motor is on top. First, remove

the guard (8) if it is tted.

6. The riving knife (10) is moved to

the side when the saw is used in

compound mitre saw mode (Fig

43-A).

7. Undo the knob (43) and pull the

riving knife to the side (Fig. 43-B).

8. Move the riving knife in the

direction indicated by the arrow

until it just clears the teeth of the

saw blade (Fig. 43-C).

9. Push in the safety catch (3) and

raise the blade guard (6) as far

as it will go and lock the knob

(43) (Fig.43-E).

10. Test by hand that the blade

moves freely and does not catch

on anything.

11. Push the control/selector lever

(68) down and turn the table over.

12. Take the upper blade guard (11),

press in the lock (9) and keep

it pressed in, place the guard

over the notch in the riving knife

and release the lock. Check that

the guard is secure and able to

move up and down freely.

850 A 50 B 50 C

50 D50 E

43 A 43 B 43 C

43 F 43 E 43 D

16

ENGLISH

5.3 Cleaning the blade guards

Warning!

Always unplug the machine before cleaning or carrying out any adjustments or maintenance.

The transparent blade guard will need cleaning occasionally if sawdust sticks to it and obscures vision.

• Wipe the guard using a lightly moistened cloth.

• Clean the adjustable blade guard (6) as follows: Raise the handle fully, remove the saw blade (see

chapter Changing Saw Blade). Slide the safety catch (3) to the side and move the guard to a position

in which it can be cleaned. Replace the saw blade.

• Always check that all the safety devices work properly after cleaning or servicing.

5.4 Changing the blade

1. Turn the table to compound mitre saw mode (motor above table)

2. Lift the handle and saw head to maximum elevation.

3. Push in the spindle lock (34), use the spanner (29) to undo the bolt (4) by turning it clockwise.

4. Release the lock (3) and lift and hold the adjustable blade guard using the lifting handle (35).

5. Unscrew the bolt (4), remove the blade ange (39) and remove the blade (36).

6. Carefully t the new blade making sure that it is the right way round, look at the arrow indicating

the direction of rotation (38) on the saw blade (36) and the blade guard (37).

7. Replace the outer ange (39) and screw the bolt (4) back on.

8. Make sure that the blade rotates freely and it correctly mounted.

19 20

21 22

17

ENGLISH

6. Emergency Stop

When the saw is used as a circular saw the motor is connected to an

emergency stop button. When the saw is used as a compound mitre saw

the emergency stop button is not connected to the motor, instead the motor is

started/stopped using the power switch on the handle (22).

The cover over the switch (23) acts as an “emergency stop button”.

Note: Always use the “emergency stop” and pull out the plug when the saw

is not in use or when left unattended, to prevent children or unauthorised per-

sons from using the saw.

Triggering the emergency stop

Push in the cover over the power switch (23) to stop the motor and the cover stays pushed in.

Resetting the emergency stop

Reset the emergency stop as follows: Press the red button upwards (towards the table) to release the catch

and the cover over the switch can be opened. Start the motor in the normal way.

Note: Always reset the cover over the switch when the motor has started in case you need to stop the motor

in an emergency. (be careful not to trigger the emergency stop whilst resetting the cover)

6.1 Riving knife

The riving knife (10) is an important safety feature which prevents the blade from binding and getting stuck in

the workpiece, thereby reducing the risk of the workpiece being ejected violently towards the operator of the

saw. When the saw is used as a table saw the riving knife must always be mounted behind the blade.

Adjust the riving knife if necessary

There must be a distance of 5-6 mm between the saw blade (36) and the riving knife (10). Adjust the

riving knife by undoing the bolt (4) and adjusting the gap between the knife (10) and the saw blade (36)

to 5 - 6 mm. Retighten the bolt (4).

The riving knife must be in line with the saw blade.

Warning!

If the saw blade and riving knife are not in line with each other the workpiece could bind and be ejected

towards the operator. The saw blade and riving knife must line up.

26

23

27

18

ENGLISH

6.2 Attaching and adjusting the rip fence

1. Attach the rip fence guide holder (45) in the slot (46) in the table.

2. Set it to the desired width according to the scale and lock the

knob (48).

3. Undo the locking knob (47).

4. Slide the fence (49) into the holder (45) so that it stops just where

the saw blade (36) emerges from the table (see the index line

50). Note: This is important to prevent the workpiece from being

ejected back towards the operator if it gets squashed between the

rip fence and saw blade. Note: The setting should be changed

depending on the thickness and angle setting.

5. Lock the knob (47) so that the fence is fastened in place.

Note:

The rip fence guide can be mounted in the holder (45) in four different

ways.

The rip fence must be parallel to the saw blade, check it as follows:

1. Set the saw blade to its maximum height above the table.

2. Mark one of the teeth.

3. Rotate the blade by hand until the marked tooth is level with the

table, measure the distance from the tooth to the rip fence. Use

a try square, set square, etc.

4. Rotate the blade backwards by hand until the marked tooth is

level with the table, measure the distance from the tooth to the rip

fence at that place. If the two distances (A) and (B) are the same,

the rip fence is parallel to the saw blade.

5. Adjust the rip fence guide if necessary: the holder (45) has an

adjustment screw on the outside, undo the locking knob (48)

slightly, turn the adjustment screw until the rip fence is parallel

to the saw blade. Tighten the locking knob (48).

6. Make sure that the saw blade can rotate freely and that all safety

guards work properly.

Note: Do not lift the rip fence, the holder can break.

6.3 Mitre guide

1. Attach the fence (57) to the mitre guide (58).

2. Fit the mitre guide (58) to the table by sliding the long aluminium

section of the mitre guide into the track (59) at the front of the

table.

19

ENGLISH

7. Using the combination saw as a circular saw (table saw)

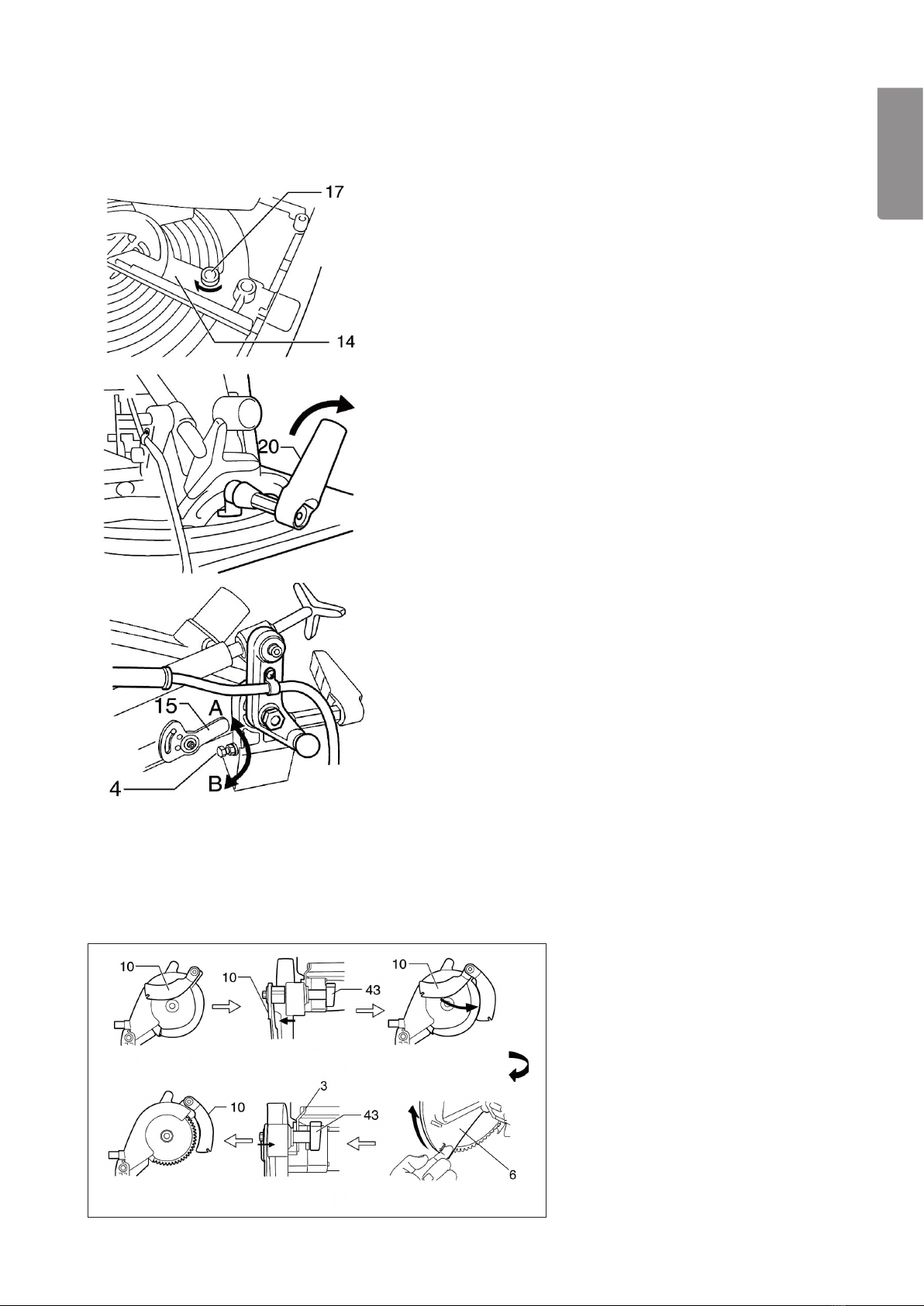

7.1 Setting up the machine as a circular saw

1. Set the table to an angle of 0° and

lock it using the knob (17).

2. Tighten the locking knob (20)

to lock the saw head in place.

3. Lift the depth stop (15) up

towards A so that it is clear of

the bolt (4).

4. Move the riving knife into place.

The upper blade guard (11) (used only in circular saw

mode) attaches to the riving knife (10).

a) The riving knife (10) is moved to the side when

the saw is used as a circular saw (Fig. 43-A).

b) Undo the knob (43) and pull the riving knife to the

side (Fig. 43-B).

c) Move the riving knife in the direction indicated by

the arrow until it just clears the teeth of the saw

blade (Fig. 43-C).

d) Push in the safety catch (3) and raise the blade

guard (6) as far as it will go (Fig.43-D) and lock

the knob (43) (Fig.43-E).

43 A 43 B 43 C

43 F 43 E 43 D

20

ENGLISH

5. Remove the lower blade guard (8).

6. Lock the saw head in place. Pull out the saw head lock (28)

and turn it 90° clockwise as shown by arrow B, push the

handle down until the saw head locks.

Warning: The saw head lock (28) must be on before the

table is turned over. If t is not possible to lock the saw

head down using the lock (28), the cutting depth adjustment

screw (21) must be turned clockwise until the saw head can

be locked.

7. Turning the table over

Warning: Things to consider before turning the table over:

• Switch the machine off using the emergency stop

button. Unplug the machine. Make sure the blade is

not rotating.

• Think about the position of your hands when turning

the table. Hold the middle of the table edge and push

down the control/selector (68). Turn the table carefully.

• Push down far enough to lock the table lock (68) again

8. Attaching the upper blade guard

• Take the upper blade guard (11), press in the lock (9)

and keep it pressed in, place the guard over the notch

in the riving knife and release the lock.

• Check that the guard is secure and able to move up

and down freely.

7.2 Using the combination saw as a table saw

Note:

• Always use a push stick or some other form of “arm extension” instead of taking risks and having your

hands and ngers close to the saw blade.

• Always keep the workpiece pressed against the rip fence and the table top, do not try to bend or lean the

workpiece as it is likely to be ejected from the saw blade towards the operator.

• NEVER pull the workpiece backwards when the saw blade is rotating, turn off the saw, let the blade stop

and then move the workpiece backwards, otherwise it could be thrown backwards towards the operator.

• NEVER try to clear sawdust or offcuts from around the blade when it is rotating.

• NEVER hold hands or ngers close to the blade or on the workpiece in the path of the blade when the

blade is rotating.

• The rip fence must always be securely fastened, otherwise the workpiece could be thrown backwards

toward the operator.

8

Table of contents

Languages:

Other CO/Tech Saw manuals

CO/Tech

CO/Tech TC180C-UK User manual

CO/Tech

CO/Tech MJ10250IV-UK User manual

CO/Tech

CO/Tech J1F-KU04-115-UK User manual

CO/Tech

CO/Tech HF-ZJ-0101 User manual

CO/Tech

CO/Tech M1W-TD2-210E-UK User manual

CO/Tech

CO/Tech RS 18 DMF008C-180 User manual

CO/Tech

CO/Tech JFB10-UK User manual

CO/Tech

CO/Tech 92107L-UK User manual

CO/Tech

CO/Tech ST12 User manual

CO/Tech

CO/Tech J1x-JF2-210 User manual