Maintenance manual coatmaster Flex V2.0

Maintenance manual coatmaster Flex V2 EN Page 2of 10 Thomas Baumgartner / 1.2023

Index

1 Introduction................................................................................................................................3

2 Material......................................................................................................................................4

2.1 Spare parts (supplied by CM AG) ...................................................................................4

2.2 Tools (not supplied by CM AG)......................................................................................4

3 Maintenance works.....................................................................................................................5

3.1 Cleaning and Care................................................................................................................5

3.2 Safety instructions...............................................................................................................6

3.3 Replacement of the front glass ............................................................................................6

3.4 Replacement of the outlet filter and clean the device inside ...............................................7

3.5 Install a new glass................................................................................................................9

3.6 Replacement of the inlet filter .............................................................................................9

3.7 Send the Service Report to coatmaster..............................................................................10

Table of figures

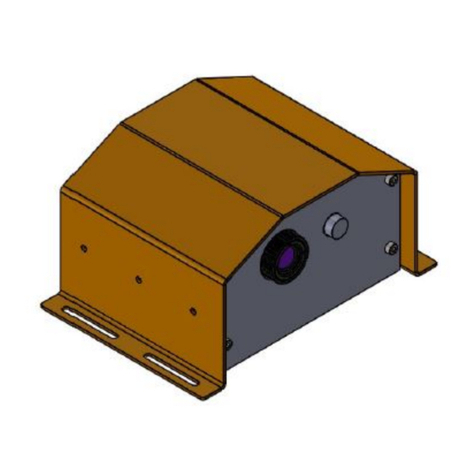

Fig. 1 spare parts.................................................................................................................................4

Fig. 2 disconnect the battery...............................................................................................................6

Fig. 3 front screws position ................................................................................................................6

Fig. 4 remove the front glass...............................................................................................................6

Fig. 5 cover screws position ................................................................................................................7

Fig. 6 housing opening ........................................................................................................................7

Fig. 7 outlet filter ................................................................................................................................7

Fig. 8 clean inside................................................................................................................................8

Fig. 9 close the housing.......................................................................................................................8

Fig. 10 o-ring position .........................................................................................................................9

Fig. 11 the order of o-ring and the glasses...........................................................................................9

Fig. 12 inlet filter cover opening..........................................................................................................9