Coatmaster Flex User manual

coatmaster Flex

User Manual

flex.coatmaster.com

Version: 05-2021

coatmaster Flex

1

© 2019-2021 coatmaster AG

Distribution and duplication of this document, and utilization and communication of its contents

other than for legitimate purposes, are not permitted without the express permission of

coatmaster AG. Violations will result in legal action. All rights are reserved in the event of patent

grant or utility model registration (ISO 16016).

Subject to technical changes and printing errors, the values given are approximate and are not to be

understood as legally warranted characteristics. These values may vary according to component

tolerance.

Last update: 05/2021

coatmaster Flex

2

1Table of contents

1Technical Data ................................................................................................................................. 3

2Customer Requirements and Device Specification ......................................................................... 4

3Applications..................................................................................................................................... 5

4Functionality and Measuring Principle............................................................................................ 6

5Safety and Responsibility ................................................................................................................ 7

5.1 Warning Symbols..................................................................................................................... 7

5.2 Signs and Icons ........................................................................................................................ 8

5.2 Intended Use ........................................................................................................................... 8

5.3 Improper Use........................................................................................................................... 9

5.4 Product Safety ....................................................................................................................... 10

6Delivery Scope ............................................................................................................................... 11

7Set-Up............................................................................................................................................ 12

7.1 Battery................................................................................................................................... 13

7.2 Navigation Panel.................................................................................................................... 14

7.3 Turning the Power On/Off..................................................................................................... 14

7.4 Language Selection................................................................................................................ 14

7.5 Wi-Fi Settings......................................................................................................................... 15

7.6 Activation .............................................................................................................................. 16

7.7 Operation with coatmaster®Local server…………………………………………………………………………..17

8Operating Instructions................................................................................................................... 18

8.1 System Settings ..................................................................................................................... 18

8.2 Main Menu ............................................................................................................................ 21

8.3 Block Menu............................................................................................................................ 22

8.4 Application Menu .................................................................................................................. 23

8.5 Measurement........................................................................................................................ 32

8.6 Data Transfer/Cloud .............................................................................................................. 33

9Troubleshooting and Best Practice................................................................................................ 36

9.1 Error Messages...................................................................................................................... 36

9.2 Error Codes............................................................................................................................ 36

9.3 Frequently Asked Questions (FAQs)...................................................................................... 38

9.4 Hotline ................................................................................................................................... 38

10 Storage and Transportation .......................................................................................................... 38

11 Maintenance and Repair ............................................................................................................... 39

11.1 Replacement of the Inlet Filter.............................................................................................. 39

11.2 Replacement of the Front Glass ............................................................................................ 40

11.3 Cleaning and Care.................................................................................................................. 40

11.4 Warranty ............................................................................................................................... 40

12 API-Interface Description ............................................................................................................. 41

coatmaster Flex

3

Foreword

Dear Customer,

With the purchase of a coatmaster® Flex, you have acquired a high-quality, precise product. To help

you to work successfully and productively with this device for many years, in this manual we provide

you with some instructions for use. coatmaster AG has made every effort to manufacture a safe and

high-quality device that complies with all applicable regulations. Our strict quality control procedures

ensure high quality standards even for high volume production. Please add your own and treat the

device with care. Should you have any questions regarding the use of the equipment, please do not

hesitate to contact us.

We wish you success and ‘a perfect coating’.

The Founders Prof. Dr. N. A. Reinke and Andor Bariska

coatmaster AG

1Technical Data

Characteristics

Tolerance/ Description

Measuring distance range

20-150 mm

Measurement angle /

tolerance

±70°

Measuring point size

2 mm2 at 75 mm distance

Measuring range thickness

10–500 µm (depending on coating type)

Standard deviation

Typical < 2% of the thickness1

Measuring time

Typical 300ms (depending on setting for coating thickness)

Storage conditions

-10–50°C max. 80% humidity (non-condensing)

Power supply

Bosch Professional Lithium-Ion battery GBA 18V 3.0 Ah

Number of measurements

Up to 800 measurements per battery charge (3Ah)

Operating conditions

Temperature: 0–35°C, rel. humidity: 10%-75%

Weight (without battery)

1.3 kg

Dimensions

374 x 91 x 203 mm

IP protection type

IP50

Table 1: Technical data

coatmaster Flex

4

2Customer Requirements and Device Specification

Measuring the coating thickness early in the process is the key to documenting and controlling coating

processes, saving coating material, improving coating quality, and reducing running-in time and scrap.

Coating processes are highly sensitive to changes in environmental conditions; therefore, it is crucial

to have access to a thickness gauge that is easy to handle and works in an industrial environment.

The patented measurement process used by the coatmaster® Flex is non-contact (as opposed to

systems based on magnetic induction or ultrasound) and non-destructive. It can be applied on wet,

powder, and cured coatings, independently of the coating material, thickness, or color (including

white). In contrast to magnetic induction-based systems, the Flex device permits measurement of

coating thickness early in the process, i.e. directly after the application of the coating material, before

drying or curing. This allows to:

•Savings of 10%-30% coating material

•Reducing time for color changes

•Accelerating training of new personnel

•Avoiding cost-intense rejects & reworks

•Documenting coating processes

•Reducing environmental impacts

•Establishing industry 4.0 standards

•Online-connection to ERP-System

coatmaster® Flex is the most advanced measurement gauge for non-contact thickness measurements.

It outperforms any other photothermal, LED/laser-based, and ultrasound systems on the market in all

industrial relevant aspects. It requires minimal calibration and is insensitive to the angle and distance

of measurement. Its superior reliability, user-friendliness, safe usage, cost-effectiveness, precision,

and accuracy is highly appreciated by the major coating-line manufacturers, biggest paint

manufacturers, renowned experts and most importantly by coaters around the globe.

coatmaster Flex

5

3Applications

The coatmaster® Flex is a flexible and robust handheld device for non-contact

measurement of coatings.

The coatmaster® Flex is unique and versatile and can be used in a wide variety of industries and

industrial sectors:

•Automotive

•Rail

•Aerospace

•Construction

•Furniture

•Profiles

•Wind Power

•Pipelines

•Medical/Technical

The coatmaster® Flex is particularly suitable for the following applications:

Powder paints

Due to control of coating thickness with Flex measurement, up to 30% of the

powder quantity can be saved. Measurement early in the process saves time

and reduces rework rates.

Wet paints

Precise measurements are possible even before drying. The measuring

equipment capability is guaranteed. This saves material and time, and ensures

quality.

Functional coatings

Thickness measurement of functional coatings (i.e. e-coats, adhesives, anti-

corrosive coatings) in wet and dried state. Highly accurate measurement even on

rough surfaces and for soft coatings.

coatmaster Flex

6

4Functionality and Measuring Principle

The coatmaster® works according to the principle of advanced thermal optics (ATO). The surface of

the coating is heated with a light pulse. After brief heating by a few degrees, the surface is cooled

by heat conduction to deeper areas of the coating and the substrate. The cooling process on the

surface depends on the thermal properties of the coating and the substrate. The thinner the coating,

the faster the surface temperature decreases, providing it has a lower thermal conductivity than

the substrate. The thickness and thermal properties of the coating are derived from the dynamics

of the surface temperature.

Illustration of the measuring principle

① Flash lamp

② Pulsed heat input

③ Coatings

④ Substrate

⑤ IR radiation

⑥ IR sensor

Generally, coatings have a very irregular surface. Powder coatings before curing have an even rougher

surface, but can nevertheless be measured with the coatmaster® Flex. The properties of this roughness

are influenced by various factors, such as pre-treatment, the type and roughness of the substrate, the

type of coating (e.g. particle size, distribution, and chemical composition), and the exact conditions

(temperature distribution, baking time) during baking. The figure below shows a microscopic sketch of

this roughness. The TLT automatically compensates for the roughness described above, using an

optical averaging process. This allows a reliable determination of the coating thickness, even with

changing parameters.

2

1

Sketch of surface roughness of a powder coating after curing

① Substrate

② Coating

coatmaster Flex

7

5Safety and Responsibility

This section provides an overview of all relevant safety features for optimum personal protection

and safe and trouble-free operation. Keep the operating instructions with the safety instructions

so that you can refer to them later.

5.1 Warning Symbols

For your safety, it is important to read and fully understand the following table showing the different

warning signs and their definitions!

Symbol Definition

DANGER

Warning of an immediate danger that, if not avoided, will result in death

or very serious injury.

◇

Measures to avoid the danger.

WARNING

Warning of an immediate danger that, if not avoided, will result in

serious injury.

◇

Measures to avoid the danger.

CAUTION

Indication of a hazardous situation that, if not avoided, may result in minor

or moderate injury.

◇

Measures to avoid the situation.

Warning of optical radiation.

Warning of electrical voltage.

Warning of hazards associated with charging batteries.

CAUTION

Indication of a hazardous situation that, if not avoided, may result in

property damage; however, no action is required with regard to personal

injury.

◇

Measures to avoid the damage.

Table 2: Warning symbols

coatmaster Flex

8

5.2 Signs and Icons

Symbol Definition

This symbol means that your device meets the safety requirements of all

applicable EU directives.

This symbol means that you may only dispose the device at an approved local

disposal site.

Information: a highlight containing particularly important information for better

understanding.

Table 3: Signs and icons

5.2 Intended Use

The coatmaster® Flex is intended exclusively for the measurement of coating thicknesses.

The device should only be used as a handheld device.

The device should not be mounted on a robot or fixture, or operated for an

extended period of time.

The instrument may only be operated and cleaned by trained personnel. The intended use also

includes compliance with these instructions and the maintenance intervals must be observed.

Have your device repaired only by qualified personnel and only with original spare parts. This

ensures that the safety of the device is maintained.

The device is not approved for operation in environments with potentially explosive

atmospheres.

Keep the device away from rain or moisture. Penetration of water into an electrical appliance

increases the risk of electric shock. Do not place the measurement device in a place where

components could come into contact with corrosive gases or salty air.

Do not block ventilation openings. The ventilation openings prevent the interior of the unit from

overheating.

Remove the battery before cleaning. Do not use solvents for cleaning, to avoid damaging the

housing surface. Use a clean, dry cloth.

In accordance with Directive 2012/19/EU, please take old parts to the appropriate recycling facilities

for proper disposal, reprocessing, and reuse. Never throw electrical equipment into the household

waste! By properly disposing of the electrical appliances, you help to protect valuable resources and

prevent possible negative effects on health and the environment, which could otherwise occur due

to improper waste disposal. Accessories and packaging should also be recycled in an environmentally

friendly manner.

coatmaster Flex

9

5.3 Improper Use

Use not mentioned above or use that does not comply with the technical specifications, is considered

to be improper use. The operator is solely responsible for any damage caused by improper use.

The following applications are prohibited:

•

Use of the equipment in environments where liquids may get into the device.

•

Introduction of any objects into the coatmaster® Flex or similar devices.

•

Opening of the device, except for cleaning or changing filters and changing the plexiglass

pane. This only applies when the battery is not in place. Opening the device, other than for

standard maintenance operations (see section 11), voids the warranty and the

manufacturer assumes no liability.

The following safety instructions point out dangers of a general nature that may occur when handling

the device. The user must observe all the instructions listed to minimize possible hazards.

Additional warning messages can be found in this manual whenever the actions described could

result in hazards.

Symbol Description

Integrated light source.

The coatmaster® Flex with SpectralBlue contains a Xenon flash lamp. The Evaluation

of the photobiological safety of a Xenon flash light according to IEC-62471:2006

shows that the coatmaster Flex flash lamp falls under the exempt group and thus

does not pose any photobiological hazard.

CAUTION

Device damage may occur if the battery is changed during operation.

Never change the battery during operation, as this can lead to the device being

damaged.

◇

Always switch off the device before changing the battery.

Table 4: Warning – improper use

coatmaster Flex

10

5.4 Product Safety

The measuring device has been designed and built with the latest state-of-the-art

technology; however, risks to users, property, and the environment may arise if

the measurement device is used carelessly or improperly, for which coatmaster AG bears no

responsibility.

coatmaster AG has identified the following residual risks from the device:

•

The device is operated by inadequately trained personnel.

•

The device is not being operated in compliance with the instructions.

Warnings in this manual are intended to alert the user to these remaining hazards.

The equipment has been tested in accordance with the safety requirements for electrical

equipment for measurement, control, and laboratory use (IEC 61010-1:2010) and the Low

Voltage Directive 2014/35/EU.

To ensure photobiological safety for the user coatmaster Flex (SpectralBlue model) was

thoroughly tested. The operation by the end-user is classified safe according to IEC

62471:2006.

1.1 Compatibility with flame detectors

The coatmaster Flex has been tested and is compatible in operation with the flame detectors listed in below

table.

Manufacturer Flame Detector Type

STS

FL 7-64, 8-64 and 9-64. Note: must be set to UV+IR mode!

Minimax

FMX 5000 UV.

Conditionally compatible: YMX 5000 FMX EX 90° IR (for distances > 1m)

Total Walther

UV-03

Table 1: Flame detectors compatible with Flex.

Before operating Flex in any environment, check if the measurement area is under surveillance of flame

detectors. If the flame detector is not listed in the above table, use the Flex in that area after receiving written

confirmation either from coatmaster AG or from the supplier of the flame detector only.

coatmaster Flex

11

6Delivery Scope

The coatmaster® Flex is delivered with the following components in a robust transport case

(scope of delivery can vary):

Delivery inclusions

Ⓐcoatmaster® Flex

ⒷLocal Server LS (opt.)

ⒸLocal server power

supply LSPS (opt.)

ⒹLSPS 230v mains cable

(opt.)

ⒺLS antennae 2x (opt.),

replacement filters

ⒻBattery charger

ⒼRechargeable battery 18V

Bosch (2x)

ⒽTransport case

Ⓗ

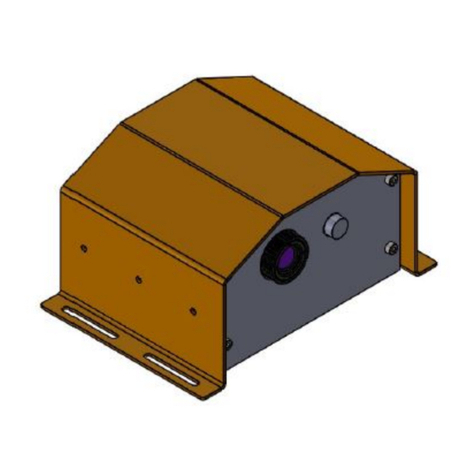

Overview of dimensions and components

① Trigger button

② Input panel

③ Display

④ Filter cover

⑤ Removable battery

⑥ Air intake

⑦ Air outlet

coatmaster Flex

12

7Set-Up

To use your coatmaster® Flex, you must set it up to connect to a Flex server by Wi-Fi connection. The Flex server

can either be a coatmaster® Cloud server (through internet connection) or a coatmaster® Local server (no Internet

required). To connect to the coatmaster Cloud server, a connection to the Internet is necessary.

Prior to the first usage of the Flex, the device must be activated using a 6-character license code and a 6-character

activation key. License and key are provided by your Flex purchasing point. For the local Server, an additional

license and key are available.

Depending on the type of server, different steps are required to activate your coatmaster® Flex:

A. coatmaster® Cloud server

To connect your Flex to the coatmaster Cloud server, you need to have a Wi-Fi network which

provides internet access. This can be your company Wi-Fi network or any mobile Wi-Fi network

provided by routers, laptops or mobile phones (hotspots). The following steps must be carried

out:

1. Select Wi-Fi network and enter network credentials (see Chapter 7.6)

2. Select appropriate cloud server (see Chapter 7.6)

3. Enter licence code and activation key received from your Flex purchasing point (see Chapter

7.7)

B. coatmaster® Local server

To connect your Flex to the coatmaster Local server, you need to have a local Server device

located within reach of your Flex. The following steps should be carried out:

1. Select Wi-Fi network “flex-local” (see Chapter 7.6)

2. Select local server (see Chapter 7.7)

3. Enter local server licence and key (see Chapter 7.7)

If you are using a local Wi-Fi network, the following steps should be carried out:

2See sections 7.5 7.5 7.7

Symbol Description

The Flex supports both WPA2 and WPA2-Enterprise secured Wi-Fi

connection.

coatmaster Flex

13

7.1 Battery

7.1.1 Battery Charging

First charge the 18V battery pack by sliding the battery pack into the battery charger (see

Figure 5: Battery charging). Use only the approved power charger.

Battery inserted in charger

Standalone battery

After battery charging, double-check the status of the battery by pressing the ‘On’ button of the

battery pack. If the battery is fully charged, all 3 LEDs should be green

(see Figure 5: Battery charging).

If the battery becomes defective, liquid can escape. Avoid contact. If contact

accidentally occurs, flush with water. If liquid comes into contact with the eyes, also

seek medical help. Liquid ejected from the battery may cause irritation or burns.

If the battery becomes defective, escaping liquid may come into contact with adjacent

components. Check any concerned parts. Clean such parts or replace them, if required.

7.1.2 Battery Installation

Push the fully charged battery into

the designated holder at the bottom of the

device until it snaps into place.

Ensure that the red tab is

completely engaged.

Battery installation

coatmaster Flex

14

7.2 Navigation Panel

Figure 10: Input panel - keys and elements shows an overview of the most important

elements for navigating the menus.

Input panel – keys and elements

ⒶOn/Off button

ⒷBack button (to go

back to the previous

screen or, in the menu,

one level up)

ⒸOK button

ⒹArrow keys

7.3 Turning the Power On/Off

After you have connected to the Flex server, and the charged battery is inserted, turn on

the unit by pressing the On/Off button Ⓐin the input panel (see Figure 10: Input panel -

keys and elements).

It takes about 40 seconds for the coatmaster® Flex to boot up. To see the time until our coatmaster®

Flex is fully operational, view the boot window on the coatmaster® Flex screen; the boot indicator

scale is shown in the display.

Turning off

To switch off the device, press the On/Off button

Ⓐ

, then confirm the action by moving the left/right arrow

keys Ⓓonto the ‘Yes’ field and pressing the OK

button Ⓒ.

CAUTION Do not remove the battery to turn off the device!

The device can be forced to shut down when the On/Off button is pressed for more than

seven seconds. With this shortcut procedure, a ‘Yes’ confirmation is not necessary.

7.4 Language Selection

After switching on the coatmaster® Flex, you will be directed to the language selection menu

(see Figure 12: Language selection).

Language selection

The default language is English.

Available languages: Czech, Deutsch, Spanish,

French, Italian, Chinese, Korean, Polish,

Portuguese, Russian, Thai, Turkish, Japanese.

Move the cursor to your

preferred language, using the up and down

arrow keys Ⓓand the OK

button Ⓒto confirm.

You will then be taken to a 'Settings' menu.

coatmaster Flex

15

7.5 Wi-Fi Settings

To use your coatmaster® Flex, you must set it up to connect to a Flex server by Wi-Fi connection. The Flex

server can either be a coatmaster® Cloud server (through internet connection) or a coatmaster® Local server

(no Internet required). To connect to the coatmaster Cloud server, a connection to the Internet is necessary.

If no Internet access is possible, a coatmaster® Local server needs to be used.

The Wi-Fi connection setup must be conducted only once for the activation of the coatmaster Flex (see

Figure 13). The login credentials are stored on the device, the Flex will afterwards automatically try to

connect to previously stored Wi-Fi networks.

If no connection is stored, the Flex will automatically start the Wi-Fi network connection process. To connect

to a new Wi-Fi network, select the “Systems Settings” icon in the main screen (see Figure 13), then select

“Network”.

Wi-Fi Settings

When starting the coatmaster® Flex for the first

time, it will automatically connect to the

coatmaster® router, if available. If

not, after language selection, the

device opens the Wi-Fi network submenu so that

you can select the network you wish to connect

to.

Choose your local Wi-Fi network in the list using

the up/down arrow

keys

Ⓓ

and the OK button

Ⓒ

to

validate.

The coatmaster® Flex supports two Wi-Fi

security standards: WPA2 (only password

required) and WPA2-Enterprise (username and

password required). Select the desired Wi-Fi

network, using the arrow keys

Ⓓ

to navigate

the keyboard and press the OK button

Ⓒ

to

confirm the characters (see Figure 10: Input

panel - keys and elements). Activate the option

“wpa2-enterprise” if the network requires this

security level. Activate the option “auto-

connect” if you want to store the network

credentials on the coatmaster® Flex for

automatically connecting to this network if it is

available upon boot time.

During the connection period, the following

message in the status field appears:

When the Wi-Fi connection is successfully

established, you must confirm using the OK

button

Ⓒ

.

coatmaster Flex

16

The Wi-Fi symbol in the status line indicates

the strength of the Wi-Fi signal:

high medium low none

If you have conducted a factory reset and need to re-activate

your coatmaster® Flex, the Wi-Fi network you were connected to before resetting will be

saved and the coatmaster® Flex will automatically connect to it.

Connection to the internet may be provided by mobile phone hotspots. Internet availability

of course depends on mobile connection stability. Use an Android phone to connect to the

coatmaster® Flex to the Internet. Usage of iOS devices may lead to connection errors.

7.6 Activation

When starting the device for the first time, or

after a factory reset, with the device connected

to the Internet (either with the provided router

or via the selection of a Wi- Fi network), the

license number and the activation code must be

entered to unlock your device. These details will

have been sent separately to your purchasing

point. If you are not prompted to enter the

activation code and the coatmaster® Flex is

working, we have already activated the device

for you and no further action is required.

Before entering the license and activation key,

make sure to select the correct server from the

drop-down menu as follows:

Location

Server to select

Europe

Europe

Americas

US

China

China

Asia (without

China)

Europe

Local server

Local server

License: hkeqex

Key: oxjzbe

Custom

servers

Custom, then enter the

IP address.

Figure 14: Activating menu

coatmaster Flex

17

If you are prompted to enter the activation

code, the cursor moves to the license code field.

When the OK button

Ⓒ

is

pressed, a submenu with a keyboard opens

. Here

the code can be entered, using the arrow keys

Ⓓ

to navigate the keyboard in conjunction with

the OK button

Ⓒ

(see Figure 10: Input panel -

keys and elements) to validate a character and

move to the next one.

To save the license code, use the arrow keys

Ⓓ

to move the cursor down to the ‘Enter’

field, then press the OK button

Ⓒ

. You can

interrupt the operation at any time by

moving the cursor to the ‘Cancel’ key and

confirming with the OK button

Ⓒ

.

After saving the license code, the submenu for

the activation key will be opened.

Proceed in a similar way to enter and save

the activation key.

After the activation key is saved, you will be automatically redirected to the main menu (see

Figure 24: Main display).

Your coatmaster® Flex is now registered with the Flex server. Before you can start measuring, you

need to select the appropriate user level, the units in which you want to measure (metric or

imperial), and the local time zone (see section 8.1).

7.7 Operation with coatmaster® Local server

The coatmaster® Local server may be used in cases where not Internet access is possible. It provides a

solution for operating the Flex in a local environment, using small computer (the local server) which provides

its own Wi-Fi network.

Scope of delivery:

•Local server computer (no keyboard, no mouse, no display)

•External power supply

•2x Wi-Fi antennae

•230V power cord

The local server computer is pre-configured and runs the coatmaster® server software, no additional

software may be installed on this computer. Simply press the power button to start the local server.

It opens a Wi-Fi network called “flex-local”, which requires no password to connect. Select this Wi-Fi from

your network setting on the coatmaster Flex. The license code is hkeqex, the activation key is oxjzbe.

coatmaster Flex

18

8Operating Instructions

The following steps guide you step-by-step through the individual process and menus. For the

navigation in the following sections, the arrow keys and buttons of the input panel are used according

to section 7.3 (Figure 10: Input panel - keys and elements).

8.1 System Settings

In the main menu, select the system settings icon by

using the right arrow key twice and the OK button

Ⓒto open the system settings menu.

Figure 16: System settings

menu

System settings

contain the following categories:

•Network: to select and connect to a local Wi-Fi network

(see 7.5).

•Troubleshooter: to perform

a network diagnosis and obtain

information on the Wi-Fi status (see 8.1.1).

•Language: to change the language (see 7.6).

•User Level: to differentiate between the operational

functionalities in the normal or

advanced modes (see 8.1.2).

•Timezone: to select the local time zone, and control the

time setting of the device (see 8.1.3).

•Measurement Unit: to configure and display measurement

results in micrometres or in mils.

•Factory Reset: to return the system to the factory

settings (see 8.1.5).

•

Choose the desired menu in the list, using

the up/down arrow

keys and the OK button

Ⓒ

to validate.

8.1.1 Network Troubleshooter

Figure 17: Troubleshooting

Troubleshooter

When activated, the system performs a network

diagnosis.

After a few seconds, the result of the network diagnosis will

be shown in a report (see

Figure 17: Troubleshooting).

Colour coding:

•Green – functionality correct

•Red – functionality not correct

coatmaster Flex

19

8.1.2 User Level

Figure 18: User level password

Figure 19: User level selection

The coatmaster Flex can be operated in two

different User Level modes, the attributes of

which are given in Table 5: User Levels.

You can toggle between the different modes by

selecting the User Level menu. When this

setting option is selected for the first time, you

will be directed to a keyboard window to enter

your user level password. The Administrator

password is admino041.

Enter the password, using the arrow keys

Ⓓ

to navigate the keyboard, in conjunction

with the OK button

Ⓒ

(see Figure 10: Input

panel - keys and elements) to validate a

character and move to the next one.

To validate the password, move the cursor

down with the arrow keys and

Ⓓ

into the

‘Enter’ field, then press the OK button

Ⓒ

.

You can interrupt the operation at any time

by moving the cursor to the ‘Cancel’ key and

confirming with the OK button

Ⓒ

.

After validating the user level password, you

must choose the user

level (Standard/Admin). The default User

Level is Admin. Once you have selected a user

level, the level will be saved, even if you

switch off your device.

Whenever you are switching from the Normal

user level to the Admin user level, you must re-

enter the password as

described above.

After the user level selection, you will be directed back to the system settings.

User Level Password

protected Measurement Block

Management

Application

Management

Factory

Reset

Standard

No

Measure

Add

Select

Rename

Select

No

Admin

Yes

Password:

admino041

Measure

Add

Select

Rename

Delete

Add

Select

Rename

Delete

Yes

Table 5: User level privileges

Other manuals for Flex

2

Table of contents

Other Coatmaster Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ICS

ICS HYDROTECHNIK MultiHandy 2025 quick guide

Toshiba

Toshiba RemotEye 4 Procedure for Installing

CS Instruments

CS Instruments LD 500 instruction manual

PCB Piezotronics

PCB Piezotronics 353B77 Installation and operating manual

Westfalia

Westfalia 51 21 52 instruction manual

SIXTOL

SIXTOL SX3002 Instructions for use

Water I.D.

Water I.D. Primelab 2.0 quick start

Gossen MetraWatt

Gossen MetraWatt MID U1281 operating instructions

Vega

Vega VEGAFLEX 81 operating instructions

CRYOMAGNETICS

CRYOMAGNETICS LM-500 quick guide

GOK

GOK BC-1 Series Assembly and operating manual

ADA INSTRUMENTS

ADA INSTRUMENTS LASERMARKER 70 operating manual