Coax Quadax Series User manual

Operating Instructions

Quadax Series Butterfly Valves

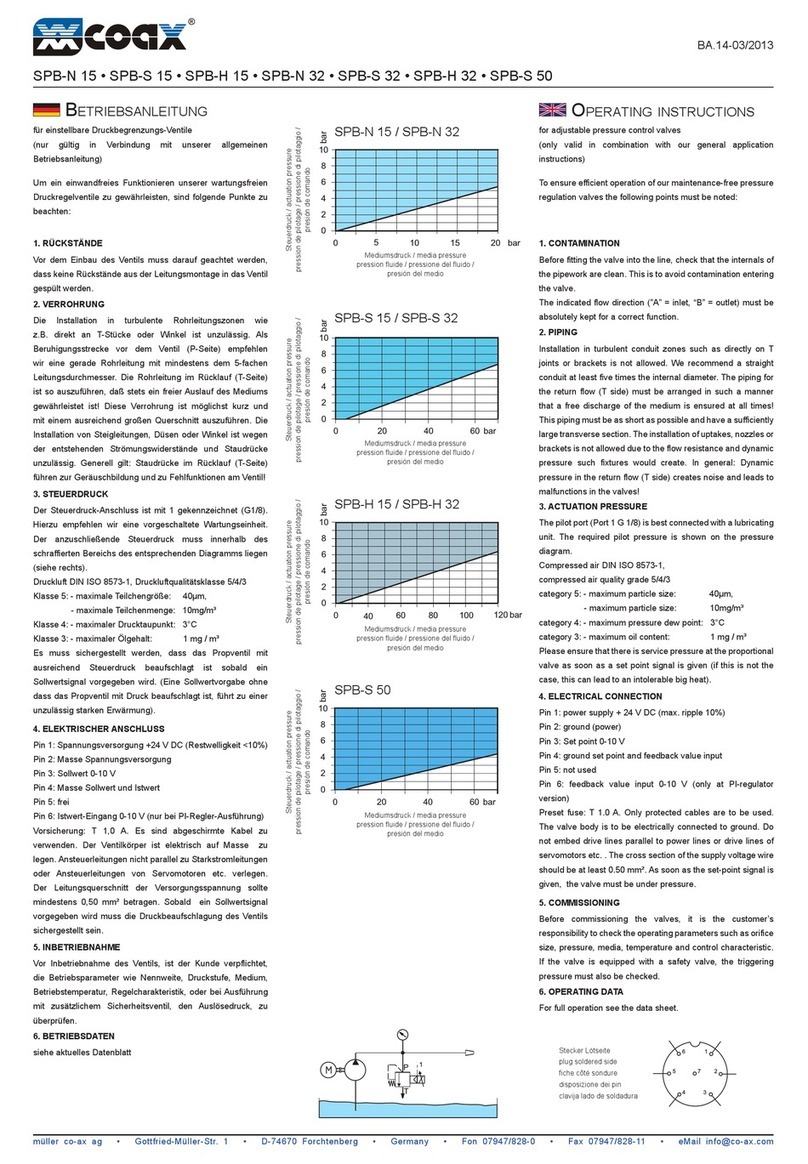

(with actuator)

Version January 2011

müller co-ax ag

Gottfried-Müller-Str. 1

74670 Forchtenberg

Germany

Tel. +49 7947 828-0

Fax +49 7947 828-11

E-Mail [email protected]

Internet www.co-ax.com

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 2/11

Table of contents

0 Introduction 3

1 Intended use 3

2 Safety instructions 3

2.1 General safety instructions 3

2.2 Safety instructions for the operator 3

2.3 Particular hazards 4

2.4 Labeling of the butterfly valve 5

3 Transport and storage 5

4 Installation in the pipeline 6

4.1 General 6

4.2 Working steps 6

5 Pressure test and commissioning 8

6 Normal operation and maintenance 9

7 Troubleshooting 9

8 Warnings 10

9 Further information 11

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 3/11

0 Introduction

These operating instructions are designed to offer the user of butterfly valves from the

QUADAX series support in terms of installation, operation and maintenance and warn of any

hazards in particular.

Attention

Non-adherence to the following caution and warning notices may lead to

hazards, which in turn may cause the warranty to become invalid.

Please contact the manufacturer for any questions. For addresses please refer to

section 9.

1 Intended use

Butterfly valves from the QUADAX series are only to be used - following the installation of a

pipeline system (between flanges or by welding) and following the connection of the actuator

to the controls - to close off or pass on media or to regulate flow within the permitted

pressure and temperature limits. These butterfly valves are not recommended for media with

more than just a low amount of solid particulates, they are especially not recommended for

wear-causing solid media.

The maximum pressure (Ps), that may not be exceeded, is specified on the type plate, as is

the temperature range (Ts) that may not be exceeded. The precise relation between

pressure and temperature can be requested from the manufacturer.

When using the valve please ensure that section 2.2 < Safety instructions for the operator> is

observed.

Attention

If there is a pressure difference larger than 0.4 bar (liquid agents at ca. 20°C) for

valves used for uninterrupted operation for controlling, please discuss the respective

application limits with the manufacture. Cavitations must be avoided.

2 Safety instructions

2.1 General safety instructions

The same safety instructions apply to valves as to the remaining piping system in which it is

installed, as well as the control system to which the actuator is connected. These instructions

only offer safety instructions that should be observed additionally for valves.

For actuator assemblies please refer to the additional safety instructions in the instructions of

the assembly manufacturer.

2.2 Safety instructions for the operator

It is not the responsibility of the manufacturer CO-AX and, it should therefore be ensured

prior to use of the valve that:

the valve is only used as intended, as described in section 1.

Danger -

Life

threatening

No valve may be operated, whose permissible pressure/temperature range (=

"rating") is insufficient for operating conditions: The permissible range can be

requested from the manufacturer. For materials, pressures or temperatures that have

not been approved by the manufacturer during the offer phase, permissible pressures

above room temperature must be released by the manufacture.

Non-observance of these instructions can endanger life and limb and may

cause damage to the pipe system.

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 4/11

Caution

It must be ensured that the selected materials for the parts of the valve that come into

contact with media must be suitable for the media used. The manufacturer assumes

no liability for damages that have been caused by corrosion or aggressive media.

Non-observance of these instructions can endanger life and limb and may

cause damage to the pipe system.

An actuating unit which was subsequently mounted on the valve, which was adjusted

to the valve and in both end positions correctly adjusted. In the closed position, the

end stop must be in the seat of the valve. A stroke limitation in the actuating unit for

the closed position should either be reset or made ineffective.

The pipe system and the control system were professionally mounted. The wall

thickness of the valve body is dimensioned so that in such professionally routed

pipelines an axial pipe force Fzas per Barlow's formula (Fz= π/4٠DN²٠PS) is

considered. With butterfly valves for clamping even higher values for Fzcan be

permitted. Any shear forces applies to the valve may not exceed 10% of the

aforementioned forces.

(PS = maximum permissible rated pressure at room temperature),

The valve is professionally connected to these systems, especially such valves which

are connected to the pipeline by welding,

The operating time of a pneumatic/hydraulic actuator is adjusted to the system

parameters,

In this pipe system the usual flow rates (e.g. 4 m/s for liquids) in continuous operation

are not exceeded and abnormal operating conditions such as vibrations, water

hammers, temperature shocks, cavitations, wet steam with a high water content and

more than insignificant portions of solids in the medium - particularly abrasive ones -

are cleared with the manufacturer,

Valves which are operated at operating temperatures of >50°C or <-20°C are

protected against contact together with the pipe connections,

The valves are only operated and maintained by specialized and trained personnel.

2.3 Particular hazards

Danger -

Life

threatening

The valve shaft is sealed by a stuffing box. Before the nuts on the stuffing box gland

are loosened or unscrewed, the pressure in the pipeline has to be completely

reduced and the pipe system empty, so that no medium escapes from the stuffing

box.

Danger -

Life

threatening

Before loosening the plug (or the cover) on the body or before removing the valve

from the pipeline the pressure in the pipeline has to be completely reduced so

that no medium can escape from the line uncontrollably. It must be ensured that the

valve is opened 5°-10, so that any pressure can escape from both sides of the

valve. The actuator may – if required – be disassembled only once the valve has

been opened for for this purpose and that it remains in this opened position.

Caution

For valves used as terminal valves:

With normal operation, especially with gaseous, hot and/or hazardous media a

dummy flange or a sealing cover has to be mounted on the free connecting

socket or (only for short-term use!) the valve has to be securely locked in “CLOSED”

position.

Caution when closing such as valve: Danger of crushing!

Caution

If a valve has to be opened in a pressurized line as a terminal valve, this must be

accomplished with utmost caution so that spurting medium does not cause any

damage.

Caution when closing such as valve: Danger of crushing!

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 5/11

Caution

If a valve has to be removed from a pipeline:

Medium may escape from the line or the valve. In the case of media which are

harmful to health or hazardous the pipeline has to be completely empty before the

valve is removed. Please be careful with residues which continue to flow from

dead spaces of the valve or line or which remain in the valve (under pressure).

Depending on the length of the valve, the disc of the opened valve extends into the

bordering pipeline. As a security measure, the QUADAX valve with actuator should be

removed from the pipeline in the closed position. A disc which is not held by the

actuator may unintentionally open and thus lead to damages or injuries.

2.4 Labeling of the butterfly valve

Each butterfly valve is labeled with the following data (type plate):

Marking Comment

Manufacturer www.co-ax.com Address see section 9 <Information>

Type code e.g.:EQK102004XXXXXXXXX

XXX XXC XXXXX Code no.: valve identification

Serial number e.g.: 251896.1-AA Corresponds to: Order no. and production no.

KNA-Nr. e.g.: 800005 Kundenneutrale Artikelnummer

Type / PN QUADAX DNXXX (X“) Numerical value in mm, e.g. DN200 or in inches, e.g. 8"

PN / class Numerical value for PN /

class

PN / class = Dimension standard for flanged butterfly

valve

CWP / PS Numerical value in bar or

PSI

= Pressure, upper limit of usage at 20°C

max. T / TS Numerical value in °C or °F = Temperature, upper limit of usage

Year of

manufacture

e.g.: 43/09 = Delivery week/year of manufacture

0036 number of the specified body in accordance with RL

97/23/EG

II 2 GD c T6 Ex-marking „none electrical part“

directional

arrow

Marking of the preferred flow direction

The materials used in the valve, as well as parts that come into contact with the media, as

well as pressure parts are uniquely coded in the type code. The manufacturing date can be

uniquely traced via the serial number. In order to be able to identify the valve, the type plate

may not be removed nor damaged.

3 Transport and storage

Valves have to be handled, transported and stored with care:

The valve is to be kept in its original packaging and/or with the protection caps on the

flange connections/weld ends. The valve should be stored and transported (also to

the installation site) on a pallet (or supported in a similar way).

If stored prior to installation, valve and actuator are to be stored in a closed room and

to be protected against harmful influences such as dirt or moisture.

Especially the actuator and the flange connection faces/weld ends must not be

damaged by mechanical or any other influences.

Valves must be stored in the same way they were delivered. The actuator may not be

activated.

Caution

Values delivered without an actuator:

The valve must be transported carefully: The unsecured valve disc may open from

closing position due to external effects (e.g shaking).

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 6/11

Attention

Valves with actuator type “safety position OPEN”

The valve disc of short valves protrudes from the housing on both sides. The

transport of such valves is only permitted with disassembled actuator and

closed valve disc!

4 Installation in the pipeline

4.1 General

The same instructions apply to the installation of valves in a pipeline as for the connection of

pipes and similar piping elements. The following instructions additionally apply to valves.

For the transport to the installation site please also observe section 3 (above).

Attention

Butterfly valves – especially those with short face-to-face dimensions – must be

transported and installed with a closed valve disc. Otherwise the discs might be

damaged. Leak tightness may no longer be ensured.

Attention

Danger of crushing for non-installed butterfly valves:

The actuator may only be closed and activated once the butterfly valve has been

installed in the pipeline.

If the valve is intended to be used as an end flap, either the closing lid has to be

mounted at the outlet or the actuator must be securely shielded against

unauthorized operation, in order to prevent any risk of crushing.

Note

The butterfly valve must be adjusted by the manufacturer for a sealed closed position:

In the closed position, the end stop of the valve/actuator unit must be in the base of

the butterfly valve. A stroke limitation in the actuator should either be reset or made

ineffective.

The "CLOSED" position of the end stop may not be changed.

Danger -

Life

threatening

If – in an exceptional case – a valve has to be mounted without actuator:

It must be ensured that such a valve is not pressurized.

If an actuating unit is retrofitted, torque, direction of rotation, actuating angle and the

setting of the end stops “OPEN” and “CLOSED” of the valve have to be adjusted to

the operating conditions. It must be ensured that the valve is sealed in a clockwise

direction!

Non-observance of these instructions can endanger life and limb and may

cause damage to the pipe system.

Attention

Valves with electric actuator:

It must be ensured that the valve is shut off in the "Closed" position by the signal

of the torque switch. In the "Open" position, the valve must be shut off with the

signal of the limit switch .

For further information, please refer to the operating instructions for the electric actuator.

4.2 Working steps

Transport valve in the protective packaging to the installation site and unpack it only

there.

Inspect valve and actuator for any damages that may have occurred during transport.

Damaged valves or actuators may not be installed.

Ensure that only valves are installed with the pressure class, the connection type and

connection dimensions which meet the application requirements. Observe the type

plate on the valve. The connection data for the actuator has to correspond to the data

of the controls. Observe type plate on actuator.

Danger -

Life

threatening

No valve may be installed, whose permissible pressure/temperature range (= "rating")

is insufficient for operating conditions: This permitted range is described in the CO-AX

brochure <QUADAX butterfly valves> - see section 9 <Information>. For materials,

pressures or temperatures that have not been specified in the above brochure,

permissible pressures above room temperature must be released by the manufacture.

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 7/11

Non-observance of these instructions can endanger life and limb and may

cause damage to the pipe system.

If in doubt, please contact the manufacturer.

Butterfly valve with short face-to-face dimension:

Counter flanges and/or pipe ends have to have a clear span allowing for sufficient

space for the opened valve disc, so that the latter is not damaged when being

swiveled out.

Prior to installation the valve and the downstream pipeline have to be thoroughly

cleaned of any contamination, especially of hard foreign substances.

Danger -Life

threatening

Butterfly valves with a short face-to-face dimension and actuator safety position OPEN":

For installation

- the opened valve disc has to be closed with control medium,

- then the valve has to be kept in the "CLOSED" position while fully pressurized,

until it is inserted in the line and securely screwed on,

- finally slowly reduce the control pressure.

Non-observance of these instructions can endanger life and limb and may

cause damage to the pipe system.

Butterfly valves of the series QUADAX can generally be installed irrespective of the flow

direction. To benefit from the optimum function of the butterfly valves:

it is recommended to install the valve so that an arrow direction marked on the type

plate corresponds to the direction that the pressure exerts on the closed disc. This

direction may well be opposite to the flow direction with opened butterfly valve!

The preferred installation position is the one with horizontal valve shaft. If this is not

possible, the shaft should be installed as much as possible from vertical position. If

possible, the actuator should not be mounted directly below the valve. Stuffing box

leakage could damage the actuator. If possible, the actuator should not be mounted

directly above the valve: Air heated by the pipeline may damage the actuator.

Caution

A subsequently mounted actuator must be supported if, as a result of its weight

and/or the mounting position on the mounting kit, a non-scheduled bending load

occurs between the valve and the actuator.

When inserting the valve (and the flange seals) in an already mounted pipeline the

distance between the pipeline ends has to be dimensioned in such a way that all

connecting surfaces (and seals) remain undamaged.

The gap, however, must not be larger than necessary so that no additional stress is

generated in the pipeline during installation.

Only butterfly valve with flanges:

The counter flanges of the pipeline have to be flush, level and parallel.

Attention

Butterfly valves with flange ends:

The sealing surfaces on bodies with flange ends of the butterfly valve are designed in

such a way that flange seals according to EN1514-1 or ANSI B16.21 are to be

implemented. Counterflanges must have smooth sealing strips, e.g. shape C, D or E

in line with EN 1092 or stock finish as per Ansi B16.5. Other flange shapes are to be

agreed with the manufacturer CO-AX.

Attention

Butterfly valves with a short face-to-face dimension must be inserted in the gap

between the pipeline ends with a closed valve disc; otherwise the valve disc may be

damaged and the valve no longer seals.

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 8/11

Flanged butterfly valves are to be centered on the counterflange during installation by

means of the flange screws before the screws are tightened.

Attention

Butterfly valves with a short face-to-face dimension partly require screws of a varying

length for the connection to the counterflanges. For the measurements for the flange

screws please refer to CO-AX planning documentation

Only butterfly valve with weld ends:

The weld ends of the valve have to be flush, level and parallel and of the same

material as the pipes - see type plate of the valve. Opposite weld ends have to fit to

one another in terms of diameter and shape.

Welding cables must not be connected to the valve but to the pipeline.

By professional welding it has to be ensured that neither considerable tensions are

generated in the pipe section or transferred to the valve nor that the butterfly valve is

damaged by heat effect; only temperatures of <300°C measured on the body wall

next to the bearing socket, are permissible.

Attention

When welding the valve into the pipeline, the welding process has to be controlled so

that the supplied thermal energy is limited and a distortion of the valve body is

avoided. For example, the weld end should be "crossed" in order to prevent tension

to the valve housing.

Non-compliance with these constructions may lead to a distortion of the valve

housing. A lasting distortion of 1/10 mm in the seat area (around the bearing

sockets) can render the valve useless.

All butterfly valves:

To the connection of the actuator to the control the manual of the actuator

manufacturer applies.

At the end of the installation an operational check with the signals of the control is to

be performed: the valve has to close and open properly in line with the control

commands. The signals of the position feedback (if in place) must correctly show the

position of the valve.

Discernible malfunctions must be remedied prior to commissioning. See also section

7, <Troubleshooting>.

Caution

Incorrectly executed control commands may lead to a risk to life and limbs of

operating staff and cause damage to the pipe system.

5 Pressure test and commissioning

The pressure test of the valves has already been performed by the manufacturer. For the

pressure test of the pipe section with installed valves, the following should be taken into

consideration:

First thoroughly flush newly installed line systems in order to flood out all foreign substances.

Valve opened: The testing pressure may not exceed the value 1.5 x PS (according to type

plate). (PS = maximum permissible rated pressure at 20°C).

Valve closed: The testing pressure may not exceed the value 1.1 x PS (according to type

plate).

If any leakage occurs from a valve, please refer to section 7 <Troubleshooting>.

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 9/11

6 Normal operation and maintenance

The valves are to be operated with the signals of the control. Valves which were delivered ex

works with the actuator are adjusted for correct operation and should not be re-adjusted as

long as the valve is in perfect working order.

For the manual emergency actuation on the actuator (if available) normal manual forces are

sufficient; the use of extensions to increase the actuation torque is not permitted.

Regular maintenance work on the valves is not required; however, when the line section is

inspected no leakage may escape to the outside on any valve. In such cases, please refer to

section 7 < Troubleshooting>.

It is recommended to actuate valves remaining in one position once or twice a year.

The prospective switching cycles of the valve are being calculated with the following formula:

( 4,000,000 / DN(mm) ). If the actual amount of switching cycles exceeds the calculated

number, please review with the manufacturer.

Caution

A butterfly valve is normally not self-locking:

The actuator may not be removed as long as the butterfly valve is pressurized.

Note

A piston actuator is not self-locking:

Piston actuators without spring reset require a permanent supply of control

pressure for all positions which are triggered under control pressure.

7 Troubleshooting

When remedying faults, it is imperative that section 2 <Security notes> is observed.

Type of

malfunction Measure Note

If an actuator with

spring reset

has to be removed

Risk of injury

Before the actuator is removed from the valve,

depressurize the pipeline and uncouple the actuator

from the control pressure supply. Note 1:

Spare parts must be

ordered based on all

data contained on the

type plate. Only

original CO-AX spare

parts can be installed.

Note 2:

If after the removal it

is discovered that the

body and/ or the inner

parts are not

sufficiently resistant to

the medium, parts

made of a suitable

material are to be

selected.

Leakage on the

flange connection or

plug or

housing cover

Retighten flange screws.

If the leakage cannot be remedied in this manner:

repair required: replace seal. Observe section 2.3.

<Particular hazards> and request spare parts and

necessary manual from CO-AX.

Leakage in the seat

seal

Check whether the valve is 100% sealed.

If the valve is sealed:

Check whether the actuator closes with full torque.

If this is the case:

Open/ close valve repeatedly under pressure.

If the valve still leaks:

Increase torque in the "CLOSED" position to max.

1.1. x nominal torque.

If the valve continues to leak:

repair required: Replace seat seal. Observe section

2.3. <Particular hazards> and request spare parts

and necessary manual from CO-AX.

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 10/11

Leakage on the

stuffing box

Retighten both nuts on the stuffing box gland

alternately and in small steps of quarter turns each

clockwise.

If the leakage cannot be remedied in this manner:

repair required: Request spare parts and necessary

instructions from CO-AX.

If the nuts on the stuffing box gland have to be loosened or

unscrewed (counterclockwise):

Danger! Life threatening!

In order to protect the operating personnel against

any danger, please ensure that the line has been

depressurized on both sides of the valve.

Please observe section 2.3 <Particular hazards>.

Malfunction

Check actuating unit and control commands.

If actuator and control are ok:

Remove and inspect valve (in observance of the

notes from section 2.3, <Particular hazards>).

If the valve is damaged:

Repair required: Request spare parts and necessary

instructions from CO-AX.

In the event of malfunctions to the actuator, please refer to the manufacturer's operating

manual.

8 Warnings

Source of danger Measure

Generation of a flammable atmosphere Operating instructions: Please watch out for leakages, as a flammable

atmosphere may otherwise develop

Sparks during commissioning /

assembly Operating instructions: Assembly / disassembly / service only allowed for

a non-flammable atmosphere

Loading single components Please make sure that the QUADAX valve is earthed. Any existing

attachment parts should be dealt with in line with manufacturer

instructions.

Application Any heat buildup of valve parts as a result of hot media must be below

ignition temperature

Sound energy can be caused by attachment parts or flow noise

Closing times below the rule of thumb are not allowed (Closing time in s =

nominal width in mm / 100) not allowed

The specific manufacturer operating instructions must be referred to for

any existing attachment parts

Generation of ignition sources

When installing additional parts which have not been installed by the

manufacturer or have been explicitly approved for installation, such as

aluminum plates or other fittings, e.g. electric position feedback, a NEW

hazard analysis has to be performed.

Corrosion Corrosion exceeding 1.5mm may lead to a weakening of pressure parts

and impair the functionality of the valve or may even lead to breakdown.

Operating Instructions Quadax Series Butterfly Valves with Actuator

Version January 2011

Page 11/11

9 Further information

These operating instructions, the so-called CO-AX brochures and further information – also

in other languages – can be obtained here:

müller co-ax ag

Gottfried-Müller-Str. 1

74670 Forchtenberg

Germany

Tel. +49 7947 828-0

Fax +49 7947 828-11

www.co-ax.com

Table of contents

Other Coax Control Unit manuals

Popular Control Unit manuals by other brands

GCE druva

GCE druva MPLH0XS0 Instructions for use

WOMIX

WOMIX MIX M 3-20 Mounting and operating instruction

Genebre

Genebre 2108 Installation, operation and maintenance manual

Texas Instruments

Texas Instruments BOOSTXL-TPS652170 user guide

Nexans

Nexans XPLORER 144 - 3X48 Notice Instructions

VAT

VAT 650 Series Installation, operating, & maintenance instructions