2

DESCRIPTION

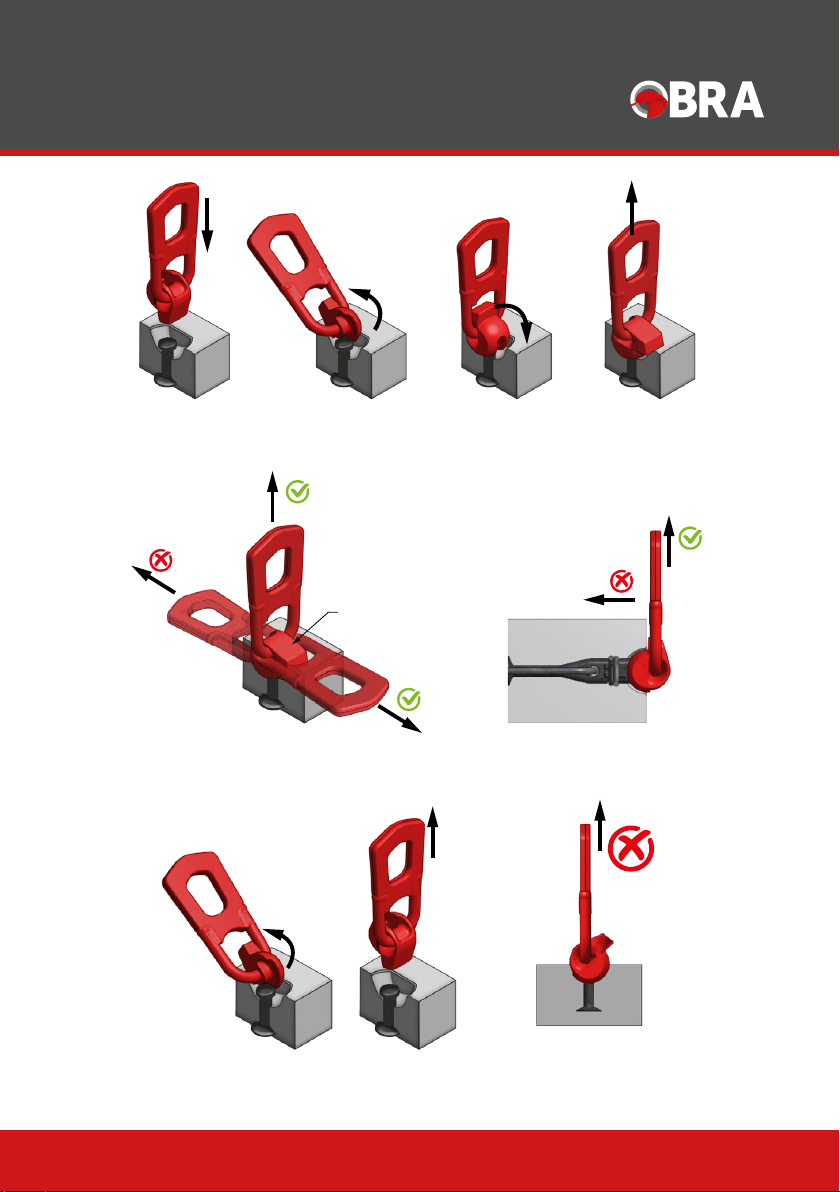

Cobra grade 80 concrete lifting clutch is designed

to engage to the head of a lifting anchor system

precast into concrete elements. It consists of two

components;

• Spherical head anchor.

• Lifting link.

The design allows a precast panel to be lifted, turned,

tilted and rotated under load. The design ensures that

only matching components fit together.

The head anchor and lifting link all come from the

same load group. Take note of the load group marked

on the link.

PERIODIC INSPECTION

Before each use of the device and regularly, the

operator shall carry out a thorough inspection in a

clean, well-lit place to check the clutches condition

and proper operation. Carefully check all elements,

paying particular attention to any damage, excessive

wear, corrosion, abrasion, cuts and malfunction.

Keep a record of all periodic inspections, which must

be carried out by a skilled person. The maximum

interval between inspections is one year, but

frequency may vary according to legislation in force

in the country in which the clutches are used. In

the case of continuous or particularly heavy use,

the frequence of inspections must be increased

accordingly.

Any defects found should be corrected before use. It

is important to determine the amount of wear. If wear

is more than 5% take the clutch out of service. The

lettering and identification must be visible. If the link

is deformed or damaged, the device must be taken

out of use and cannot be repaired.

Damage, distortions, cracks and extensive corrosion

can reduce the load-carrying capacity and lead to

failure. This causes a hazard of injury or potentially

death. Any affected parts must be taken out of

service immediately.

In case of any doubts as to the condition and usage of

this device. Do not put into service and consult GT.

SAFETY STANDARD

These warnings indicate a potential hazardous

situation, that if not avoided could result in death or

serious injury. It may also be used to alert against

unsafe practices.

Use only trained personnel. Using the clutch and

lifting device by untrained personnel poses the risk

of incorrect use or falling, which may cause injury

or death. The lifting systems must be used only for

lifting and moving precast concrete elements.

• All lifting anchors and devices must be

operated manually.

• Do not use this device contrary to it’s

intended use.

• This device shall not be used to lift or lower

personnel.

• Do not lift or lower loads over an area

occupied by people.

• Check the stability of the load attached on

which it is hoisted to prevent accidental

detatchment of any element. Hook in all lifting

systems separately, without using force.

• Never use a hammer or tools alike to attempt

to force close the lifting clutch.

Operator should be a competent person.

DO NOT ALLOW PERSONS TO OPERATE OR

ASSEMBLE THIS UNIT UNTIL THEY HAVE

DEVELOPED A THOROUGH UNDERSTANDING OF

SAFETY PRECAUTIONS AND HOW IT WORKS.

DO NOT CHANGE, REPAIR OR REPLACE ANY

ELEMENTS OF THIS DEVICE.

GT holds no responsibility for the change of

mechanical properties which are caused directly

or indirectly from maintenance by a third party,

without written permission from GT.

Safety Information

WARNING

WARNING