ENGLISH

7

Instructions for use

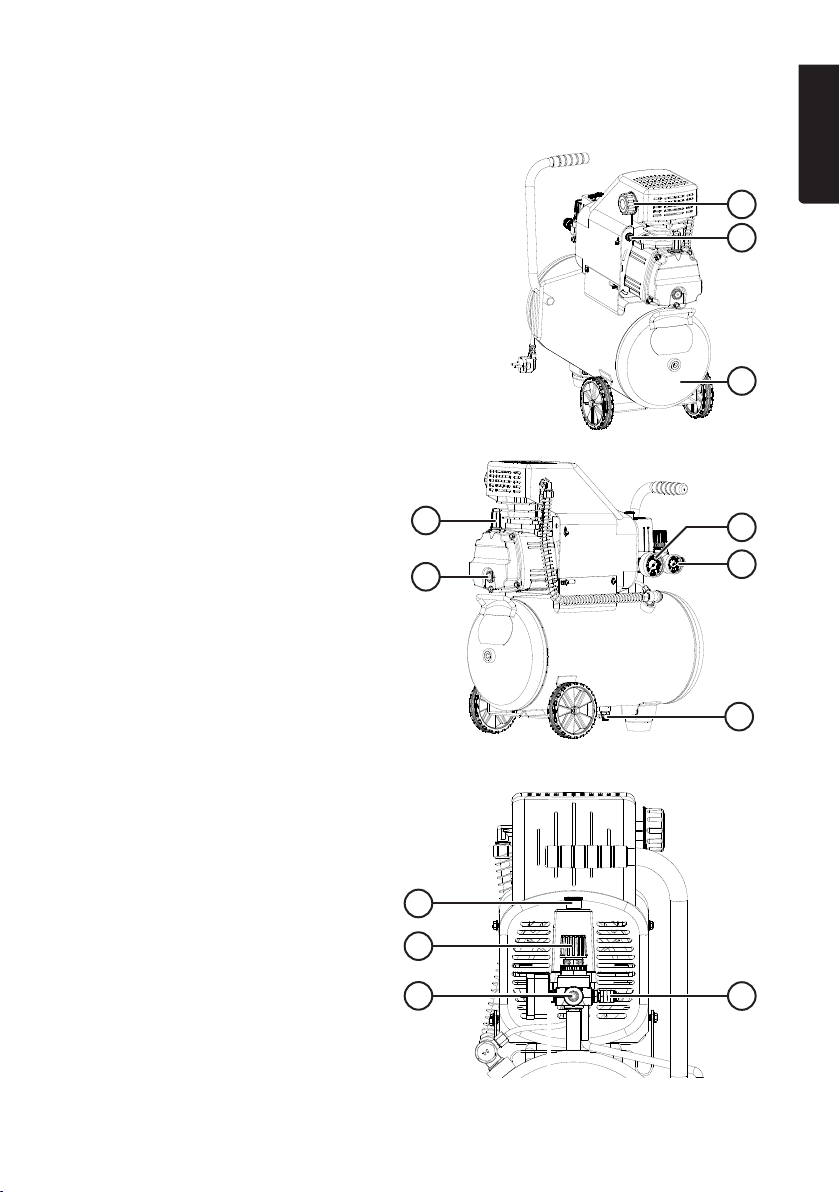

1. Check the oil level in the window (5).

2. Attach the appropriate air tool for the work you wish to undertake: blow gun, spray gun, tyre

inflator, etc.

3. Read the instruction manual of the connected air tool and if necessary, set the recommended

working pressure using the pressure regulator (10).

4. When you have finished work and the compressor has been turned off, the pressure inside

the air tank must be released by pulling out the safety valve (12).

Use an oil suitable for air compressors such as SAE 30, ISO 68 or equivalent.

Care and maintenance

• Repairs must only be carried out by qualified service technicians and only using original spare

parts.

• An initial replacement of the oil in the air compressor should be carried out after 10 hours of

operation.

• Change the oil and clean the air filter after every 120 hours of use. Check the safety valve and

pressure gauges at the same time.

• Test the safety valve by unscrewing the uppermost nut until it is loose and then pulling it out

until the spring-loaded valve opens. If the safety valve is working properly (and the air tank

is under pressure) air should seep out through the safety valve. Once the valve has been

tested, screw the uppermost nut back in again.

• Perform a visual inspection at least once a year to check that the inside and outside of the air

tank is free of corrosion. Under no circumstances must the wall thickness of the air tank be

less than 2 mm.

• Under no circumstances must the safety valve be tampered with or blocked.

• Regularly check that the ventilation hole in the oil filler cap (4) is open.

• Regularly check that all bolts holding the compressor and air tank together are tight.

• Make it a habit to open the drain tap (8) and release any condensation inside the air tank.

• Do not clean the compressor or air tank with solvents or flammable liquids.

• If the compressor is not to be used for a long time: Unplug the mains lead, empty the air tank

and open the drain tap (8).

Motor overload cut-out

• If thesafety cut-out has tripped, themotor has been overloaded in

some way.

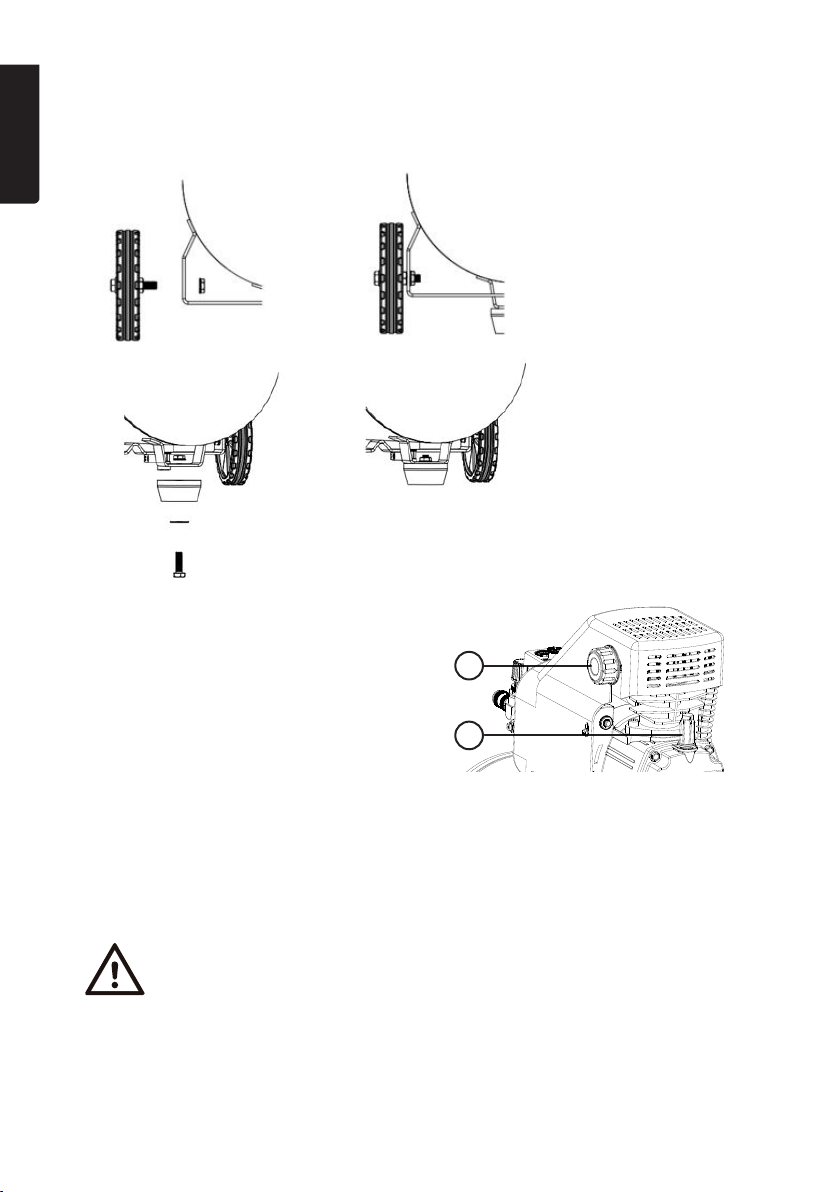

• Thebutton on themotor overload cut-out (2) will pop out acouple of

millimetres when it has been tripped and is reset by pushing it back in.

• There are anumber of possible reasons why theoverload cut-out

might trip such as avoltage drop caused by theuse of long exten-

sion leads, low ambient temperature (under10°C), or that thepres-

sure switch is not used to turn thecompressor on/off in theevent of

apower cut for example.