General!

Read the instructions carefully before you start working with this equipment.

The equipment should be installed and serviced by trained staff

Dispenser description for Slim line

Slim Line is a dispenser for cooling water and mixing juice concentrate

to a ready to drink product. The dispenser is for

two non-carbonated

drinks and chilled water.

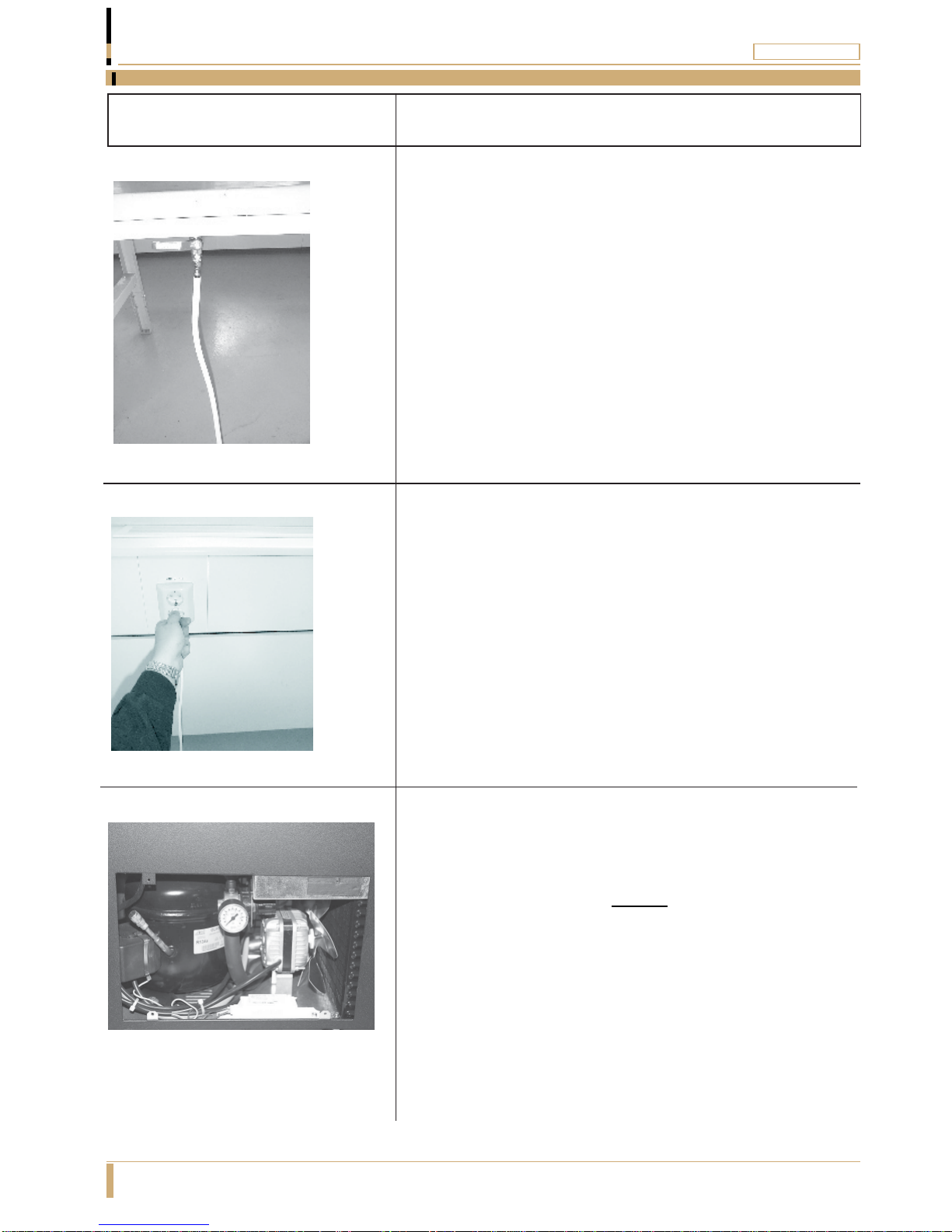

The dispenser is connected to the water mains by a pressurized tube and to

an electric wall socket by a power plug.

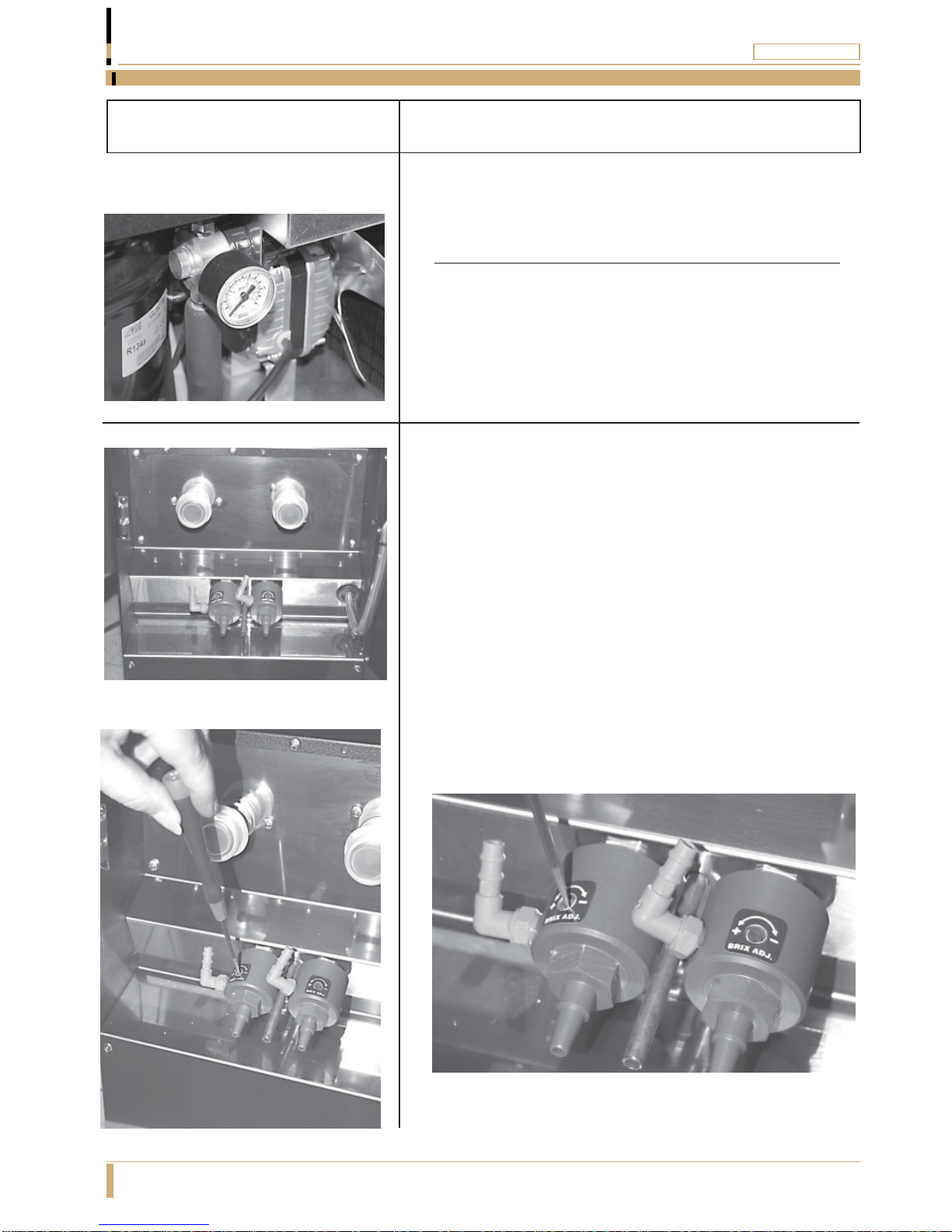

The water-pressure is adjusted with the water-regulator and the pressure is

displayed on the manometer.

The water is chilled by the cooling-block, which in its turn is chilled by the air-

cooled compressor.

The water-temperature is adjustable with a thermostat.

The mixing ratio product/water is adjusted with the ejectors.

Pushing one of the four buttons on the front panel dispenses the mixed

product or water.

3

General Page 3

General Operating Outline

Where fitted the decanter function is operated via the 3 buttons located on

top of the front door.