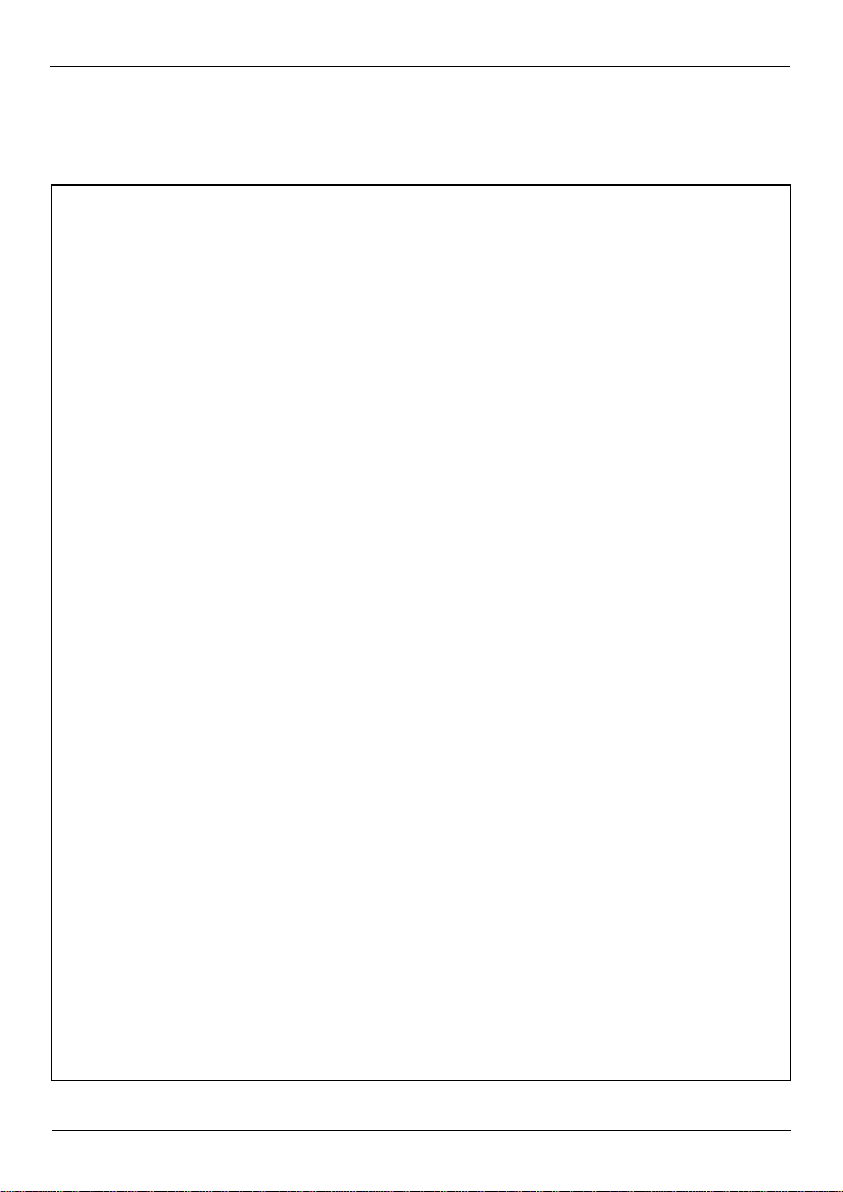

(4) Remove the impellor disk Bby pulling it in the

direction shown.

(5) Remove the whipper seal C and ensure that the

running surface D is smooth and free of

ingredient residues.

(6) Inspect whipper seal for damage and replace as

necessary.

(7) Wash all the removed mixing system

components in destaining fluid and then rinse

thoroughly with clean water.

(8) Reassemble the mixing systems by following

the reverse procedure. Ensure that whipper

seal C is tight against the running surface

before refitting the impellor.

(9) Ensure that both locking pegs Eon the mixing system are correctly located by

pressing firmly on the lower part of the mixing system.

(10) When all mixing system components have been refitted, switch on the machine

and perform a flush operation. Check the mixing systems for leaks and listen

for abnormal sounds that may indicate incorrect assembly.