COFFEtek LTD

BEAN TO CUP Issue 1 01/12/2005 2

BEAN TO CUP BEVERAGE MACHINE

TECHNICAL MANUAL

FOREWORD......................................................................................................................................4

SECTION 1 TECHNICAL INFORMATION ........................................................................................6

INTRODUCTION ................................................................................................................................................6

SPECIFICATIONS..............................................................................................................................................7

SERVICES REQUIRED......................................................................................................................................8

Electrical Supply.............................................................................................................................................8

Water Supply..................................................................................................................................................8

GENERAL DESCRIPTION ................................................................................................................................9

Cabinet Front..................................................................................................................................................9

Cabinet Interior...............................................................................................................................................9

WATER SYSTEM.............................................................................................................................................10

Heater Control and Boosting ........................................................................................................................10

Tank Filling & Overflow Protection ...............................................................................................................11

ELECTRICAL AND ELECTRONIC SYSTEM..................................................................................................12

Functional Description..................................................................................................................................12

Circuit Description ........................................................................................................................................13

SECTION 2 PROGRAMMING........................................................................................................14

INTRODUCTION ..............................................................................................................................................14

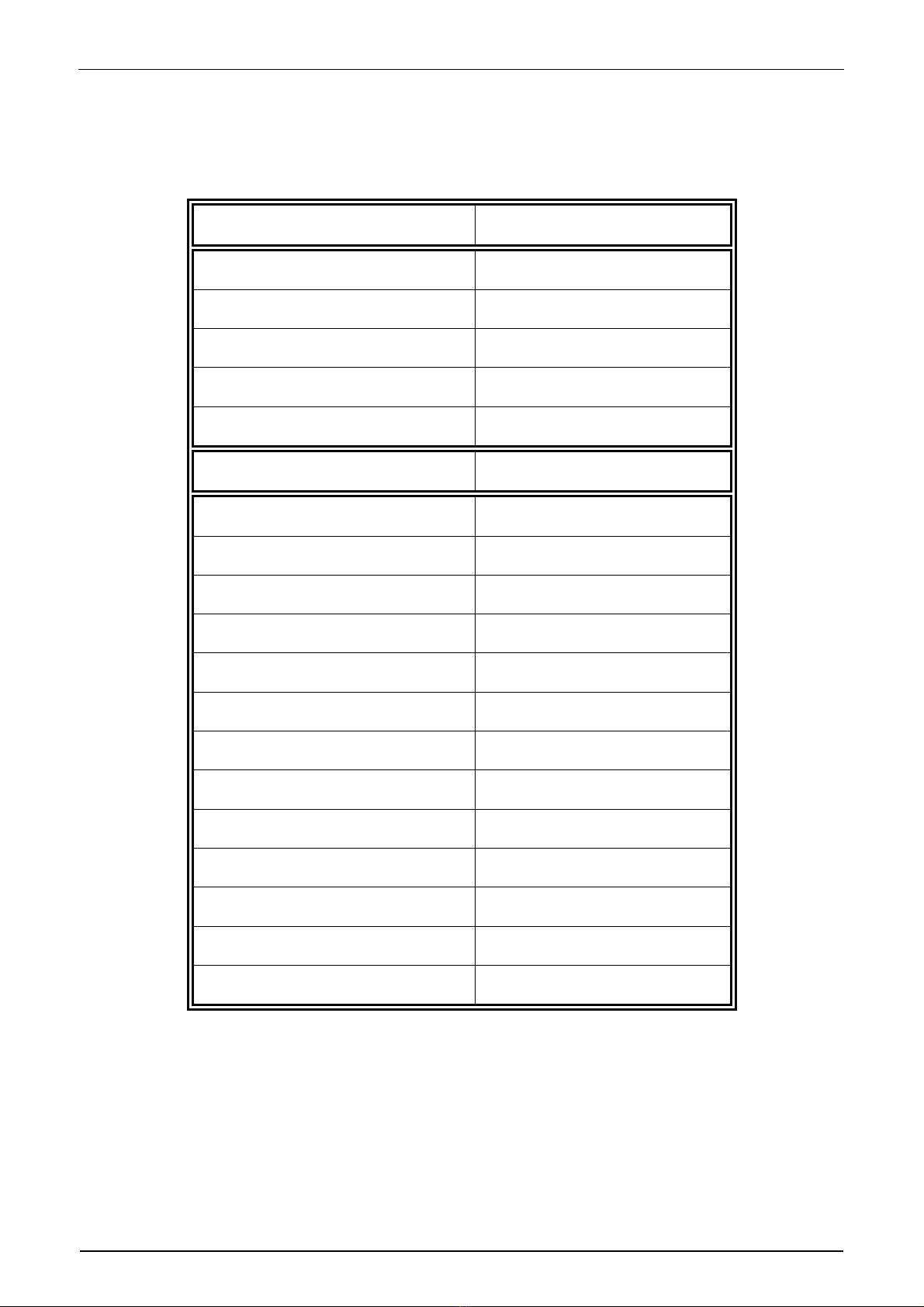

INTERNAL KEYPAD LAYOUT........................................................................................................................15

KEYPAD FUNCTIONS.....................................................................................................................................15

OPERATOR PROGRAM..................................................................................................................................16

ENGINEER PROGRAM ...................................................................................................................................17

Accessing the Engineers Mode....................................................................................................................17

Program Options ..........................................................................................................................................18

SECTION 3 INSTALLATION AND MAINTENANCE ......................................................................26

INTRODUCTION ..............................................................................................................................................26

SAFETY WARNINGS.......................................................................................................................................27

FROST WARNING ...........................................................................................................................................27

INSTALLATION ...............................................................................................................................................28

Location ........................................................................................................................................................28

Levelling .......................................................................................................................................................28

Securing .......................................................................................................................................................28

CONNECTING THE WATER SERVICES........................................................................................................29

CONNECTING THE ELECTRICAL SERVICES ..............................................................................................30

DESCALING THE TANK .................................................................................................................................32

COMMISSIONING............................................................................................................................................33