10 6X-1050

6110 CAMERA INSTALLATION AND OPERATION

Preliminary 3a 4-14-05

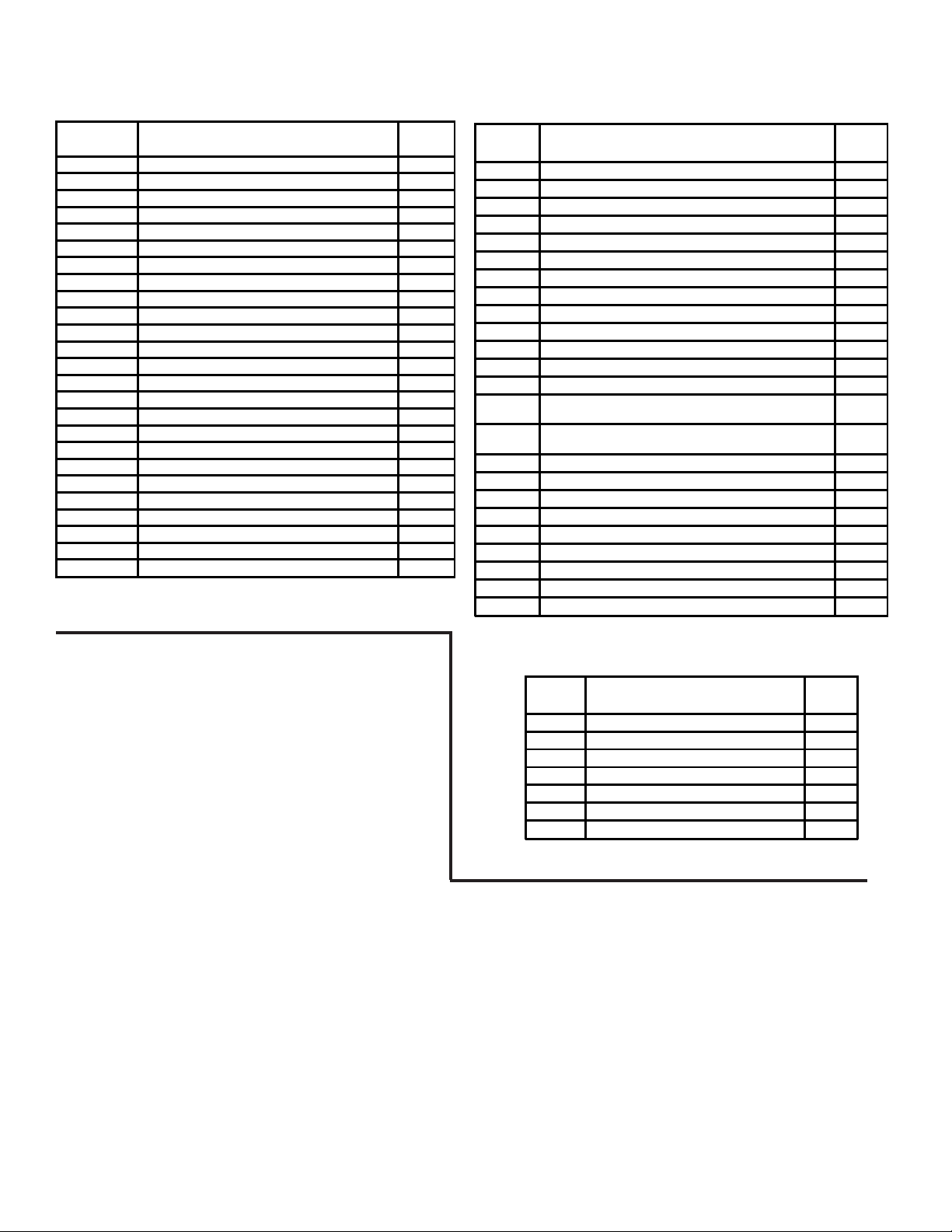

Table 3. Items Supplied

ITEMS TYPICALLY REQUIRED BUT NOT SUPPLIED

ITEM Description Characteristics

1Lens, CS-mount or C-mount

(manual iris only) For 1/2-inch sensor

2Cable, IEEE-1394

(must supplypower) 6-wire version to supply powe

3 Cable, Auxiliary (optional)

Auxiliary cable for using the

triggering and strobe functions

if desired. Mates with RJ-45

connector on rear panel

4Power source for strobe

functions (Vcc). Noiminal 5 V

dc at apporoximately 25 mA.

Via pin 7 of RJ-45 connector.

Return line(s) are the strobe

outputs. (Open collector)

5VideomonitorCompatible with PC video

output

6 PC, laptop or other 6-wire (powered) IEEE-1394a

7Alternate Camera Control

Software

National Instruments Lab View

or custom software written /

modified for the 6100

Table 4. Item Typically Required

But Not Supplied

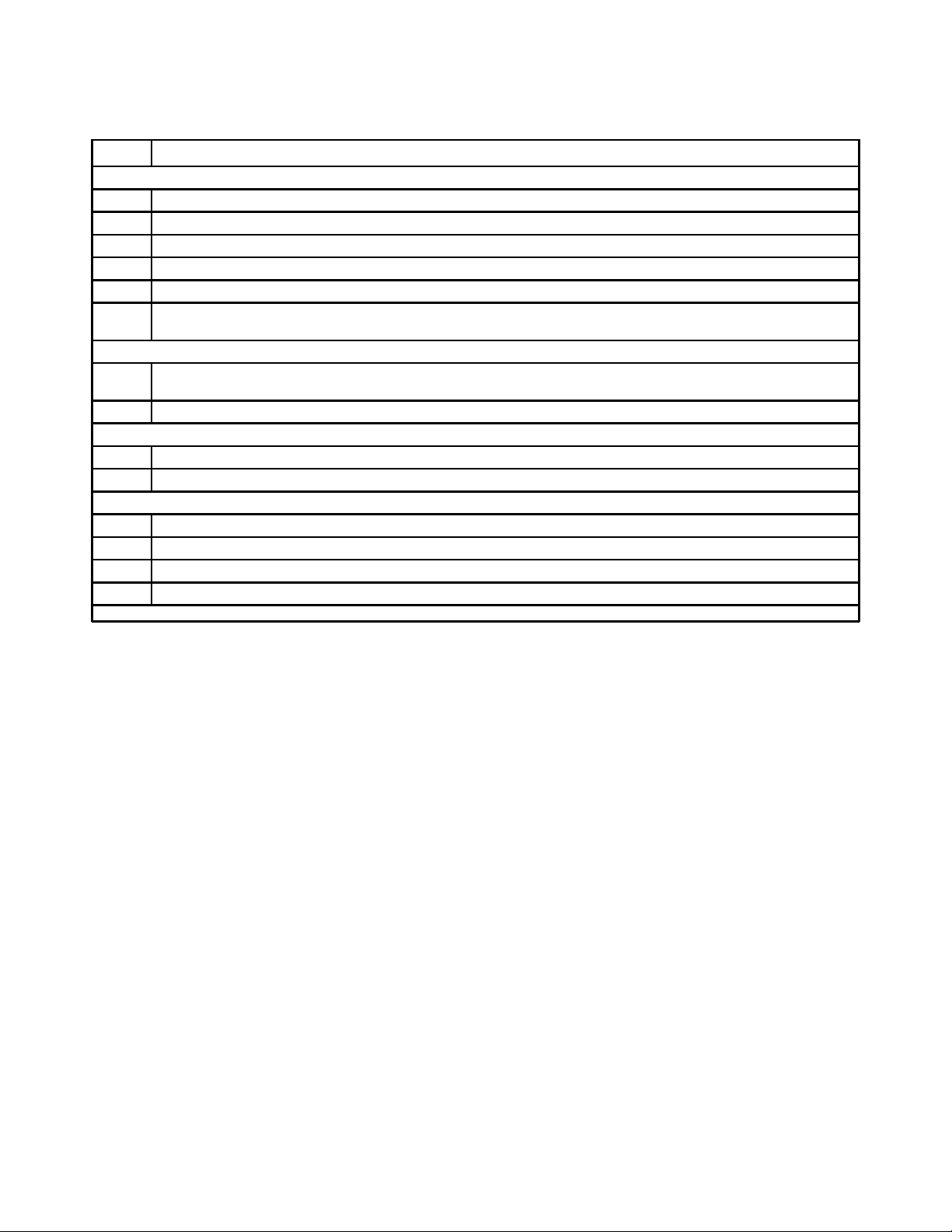

Table 5 lists the two cables that interconnect

with the Camera rear panel. The RJ-45 cable is

required only if external triggering or strobe

outputs are to be used.

The following is a general description of the

typical installation procedure for a camera.

1. Prepare the auxiliary interface and cable for the

RJ-45 connector if this is required. Use of the

strobe functions requires that power be supplied to

the opto-isolator stages in the camera dedicated to

the strobe circuits. (The trigger input directly drives

the cathode and anode of a photodiode in the

Camera and does not use the Vcc input of the

strobe circuits.)

2. Prepare the PC by verifying that it has an IEEE-

1394a port with power output and also the appro-

priate software to communicate with the camera

3. Install a CS- or C-mount lens on the camera

suitable for use with a 1/2-inch sensor. It may have

to be mechanically back focused once the camera

is operational. Back focus will have been factory

set using the lens that the Camera was ordered

with, but if the Camera was not ordered with a

lens then a typical lens would have been used. A

field supplied lens may have a slightly different

characteristic and thus require back-focusing of

the lens mount adapter. This procedure is de-

scribed in section 2.8.3.

4. Mount the camera

5. Connect the 1394a and if required the auxiliary

cable

6. Obtain a picture from the camera. This requires

use of the Viewer GUI software operating on a PC.

See section 3.0 for Operating instructions.

7. Adjust mechanical back focus by rotating the

lens and C-mount if required. See section 2.8.3.

8. Make any other adjustments to focusing and

mechanical alignment if required.

9. Perform an operational test of the camera

functions. Sections 2.8.1 through 2.8.4 provide

additional installation instructions about the rear

panel connectors, the back focus adjustment for

the lens, and other features.

ITEMS SUPPLIED

Item Description Cohu Part

Number

Kit 8366-7 Supplied Items

1 CS-mount 8359208-001

2Set Screw, stainless steel, hex

head, nylon tipped, 4-40-5/32 2010258-005

3Hex/Allen Wrench, L-style,

0.050-inch across flats 9710010-009

45-mm Extender

(CS to C-mount adapter) 2010695-001

Also Included with Camera (not part of kit 8366-7)

5Mounting Block

(mounts to bottom of Camera) 8369405-003

6 Screws (2), Flat Head, 6-32 x 3/8 0310010-027

7 Camera Control Software on CD Cohu 6100

Viewer

Note: Items 3 & 4 typically supplied loose. Items 5 & 6 ypically part of camera body

when shipped. Item 7, the CD, is supplied loose.