1

Table of Contents

Introduction........................................................................................................................................................... 2

General Information .............................................................................................................................................. 2

General Safety Information ......................................................................................................................... 2

Safety Recommendations............................................................................................................................ 3

Unpacking Your Immersion Probe Cooler ..................................................................................................... 3

Regulatory Compliance & Testing ................................................................................................................ 4

Contents .................................................................................................................................................... 4

Controls & Components......................................................................................................................................... 5

Quick-Start ............................................................................................................................................................ 6

Installation & Startup ............................................................................................................................................ 7

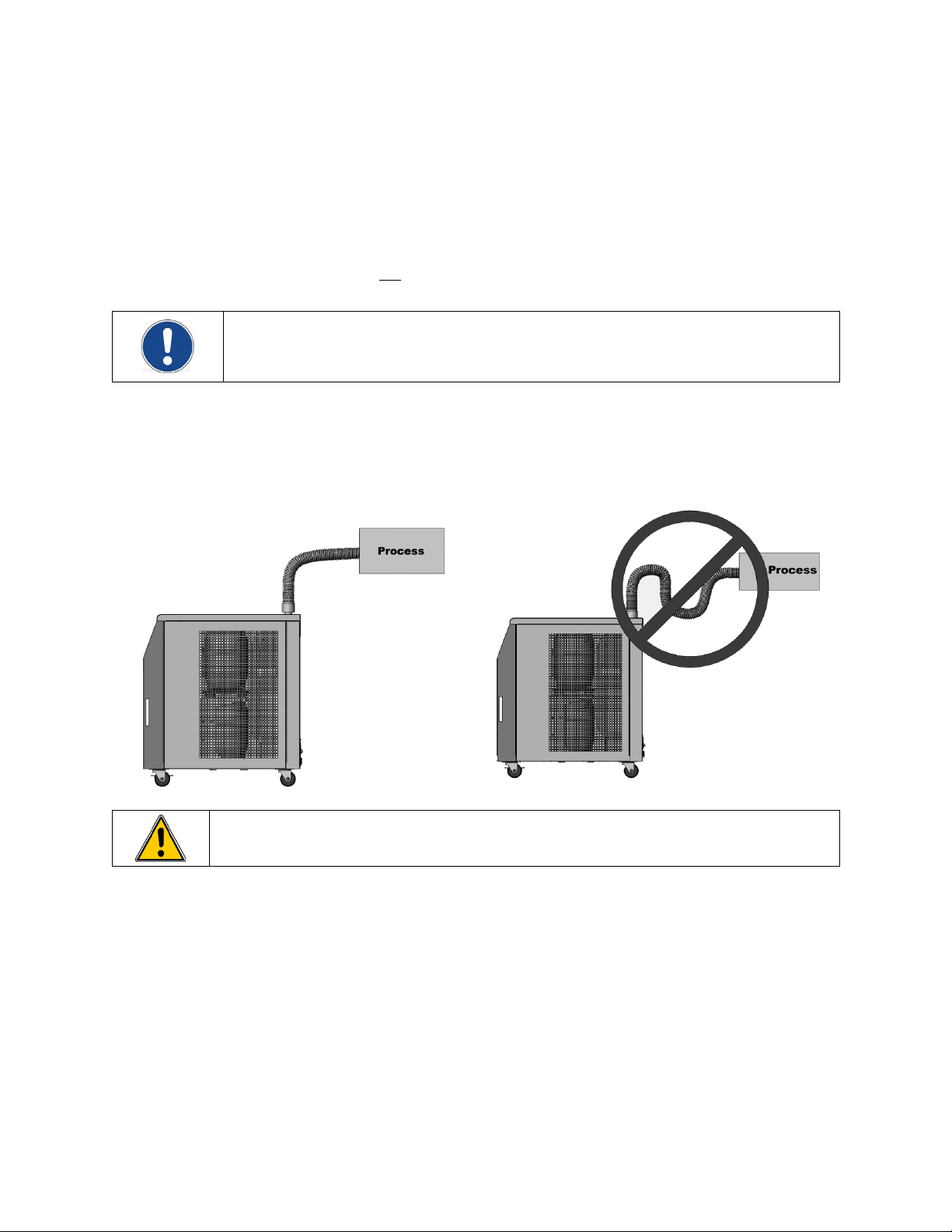

General Site Requirements.......................................................................................................................... 7

Positioning the Immersion Probe Assembly .................................................................................................. 7

Electrical Power.......................................................................................................................................... 8

Normal Operation.................................................................................................................................................. 8

Turning Your Immersion Probe Cooler ON .................................................................................................... 8

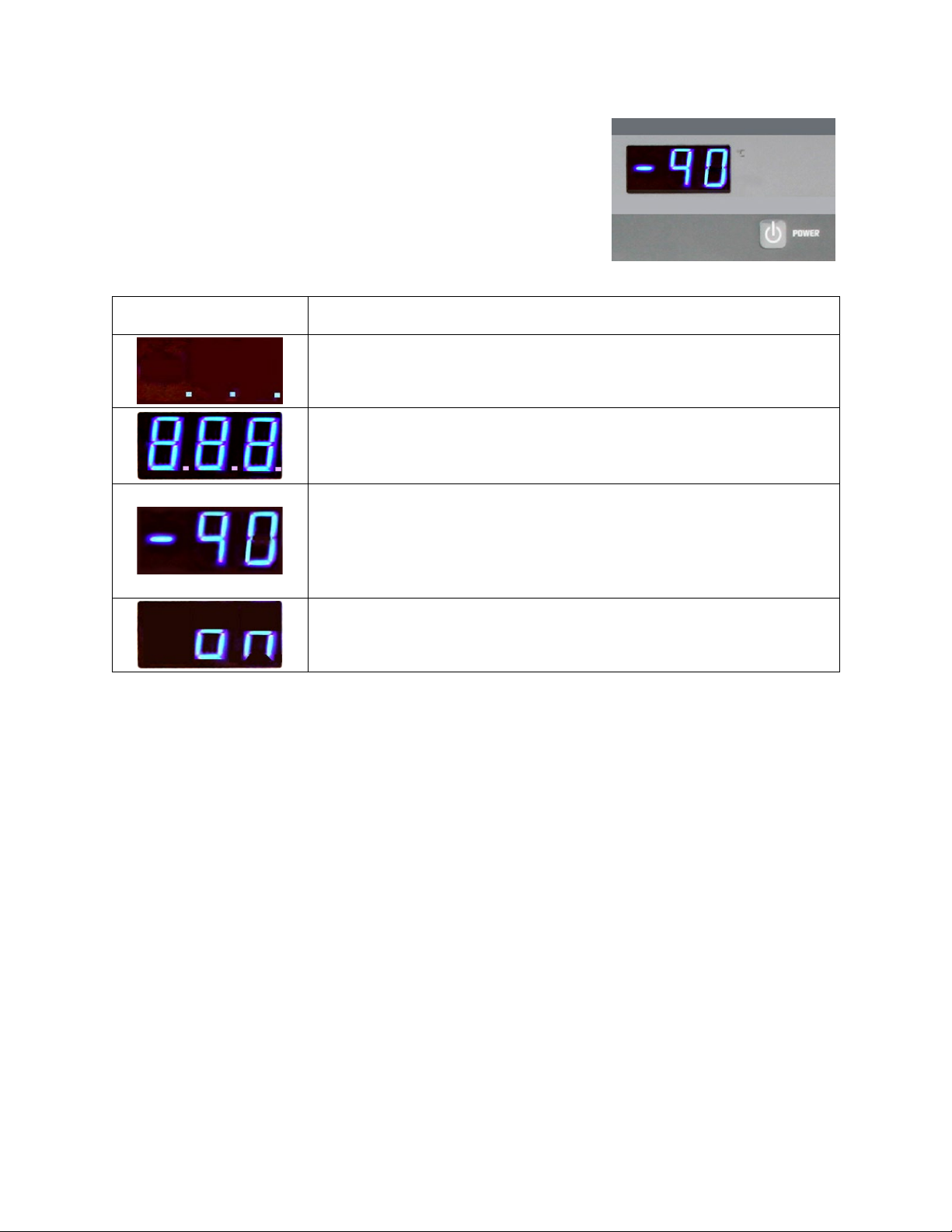

Main Operational Display............................................................................................................................ 9

Display Messages ....................................................................................................................................... 9

Loss of Power Restart ................................................................................................................................. 9

Routine Maintenance & Troubleshooting ............................................................................................................ 10

Cleaning Exterior Surfaces ......................................................................................................................... 10

Cleaning the Air Filter ............................................................................................................................... 10

Draining Residual Oil from the Immersion Probe Assembly .......................................................................... 10

Troubleshooting ....................................................................................................................................... 11

Technical Information.......................................................................................................................................... 12

Performance Specifications ....................................................................................................................... 12

Equipment Disposal (WEEE Directive).................................................................................................................. 13

Service & Technical Support ................................................................................................................................ 13

Warranty ............................................................................................................................................................. 14