Page 5

1. Application and Features

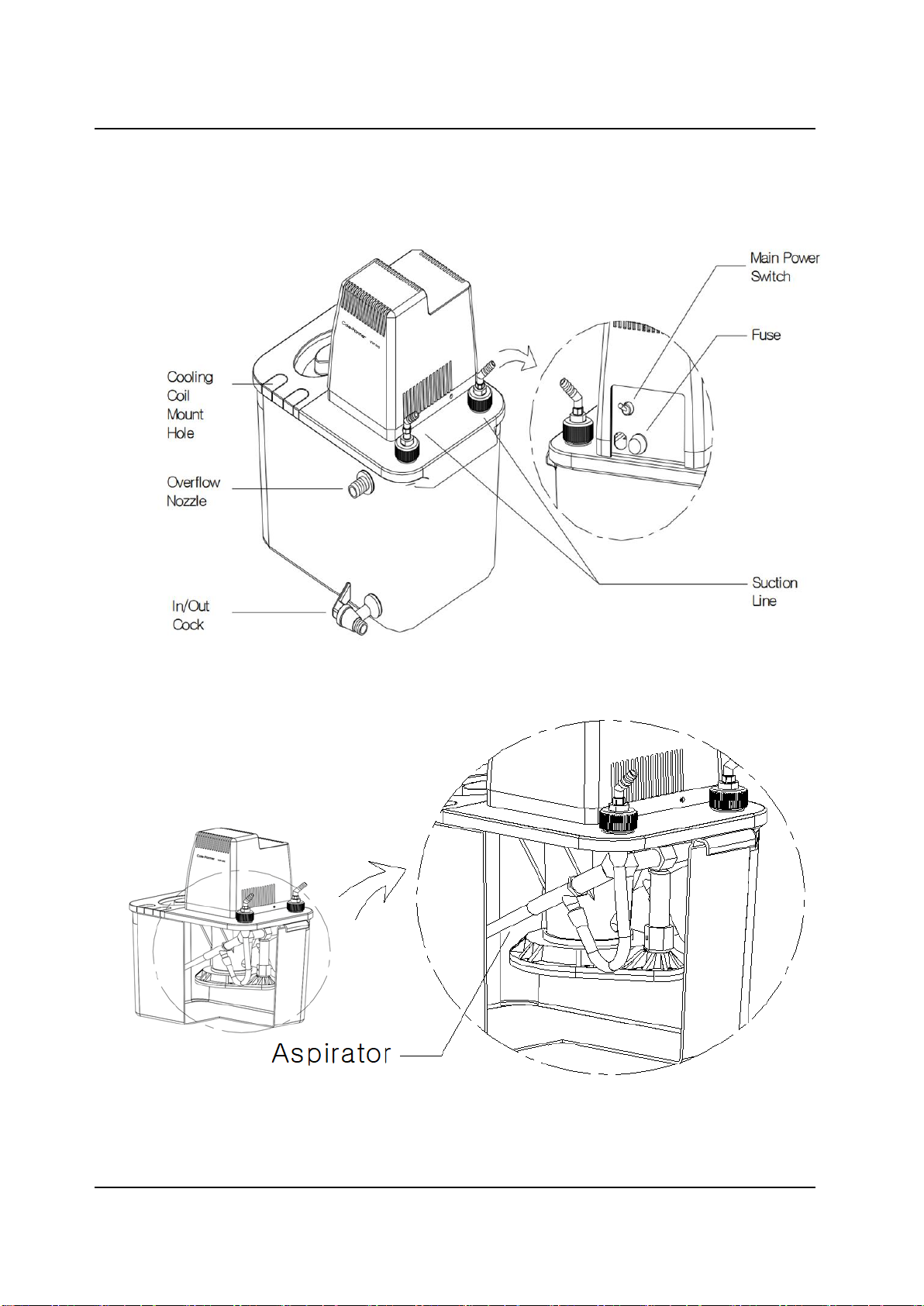

- The Electric aspirator 35031-00 produces a low vacuum condition using

Bernoulli's principle by pumping water through aspirator head. When using

35031-00 with rotary vacuum evaporator or for Gel dryer or low vacuum oven,

inflow of a little water or solvent into the equipment do not make trouble to the

instrument. And you can use this equipment continuously if you change the

water in the bath.

- The 35031-00 is manufactured as polypropylene that has chemical resistance

against most solvents. For effective usage, a small quantify of water

(100ml/min) has to be continuously supplied by a user through the drain cock at

the bottom part of the bath and drained through the over-flow nozzle. It reveals

liquid circulation of the inner bath and means dilution that helps the instrument

to be used longer.

- Check-valve is designed for preventing water from flowing backward during the

power failure. But this valve can’t protect the equipment permanently. It is for

short protection that saves the time to fix its original troubles that may be

happened.

To prevent flowing backward of water upon a power failure of the moment, the unit

has a flowing backward double breaker. It only makes users have some times to deal

with the situation however, it does not mean the complete stop valve.