About this manual

This manual contains the most relevant instructions required for operation of the Colifast ALARM.

In addition, there are available quick guides for daily operation.

1SCOPE AND APPLICATION..................................................................................................................... 3

2SUMMARY OF METHOD.......................................................................................................................... 3

3APPARATUS AND EQUIPMENT ............................................................................................................. 4

3.1 COLIFAST ALARM .......................................................................................................................................................................... 4

3.2 SOFTWARE........................................................................................................................................................................................ 4

4COLIFAST ALARM INSTALLATION STEPS........................................................................................ 5

4.1 SITE .................................................................................................................................................................................................. 5

4.2 UNPACKING AND INSPECTION........................................................................................................................................................... 5

4.3 PLACEMENT OF THE INSTRUMENT .................................................................................................................................................... 5

4.4 INSTALLATION OF THE SAMPLE COLLECTOR FLASK......................................................................................................................... 5

4.5 CONNECTING CABLES AND TUBES (SEE FIGURE 4.1)........................................................................................................................ 5

5PREPARATION OF REAGENTS.............................................................................................................. 7

5.1 REQUIRED EQUIPMENT..................................................................................................................................................................... 7

5.2 REPLACING THE COLIFAST MEDIUM FLASK ..................................................................................................................................... 7

5.3 REPLACEMENT /REFILLING OF EXTERNAL REAGENTS AND WASTE................................................................................................. 8

5.4 PREPARATION OF THE 0.1M HCL SOLUTION .................................................................................................................................... 8

5.5 PREPARATION OF 10% SODIUM THIOSULPHATE SOLUTION.............................................................................................................. 8

6COLIFAST ALARM OPERATING PROCEDURE................................................................................. 8

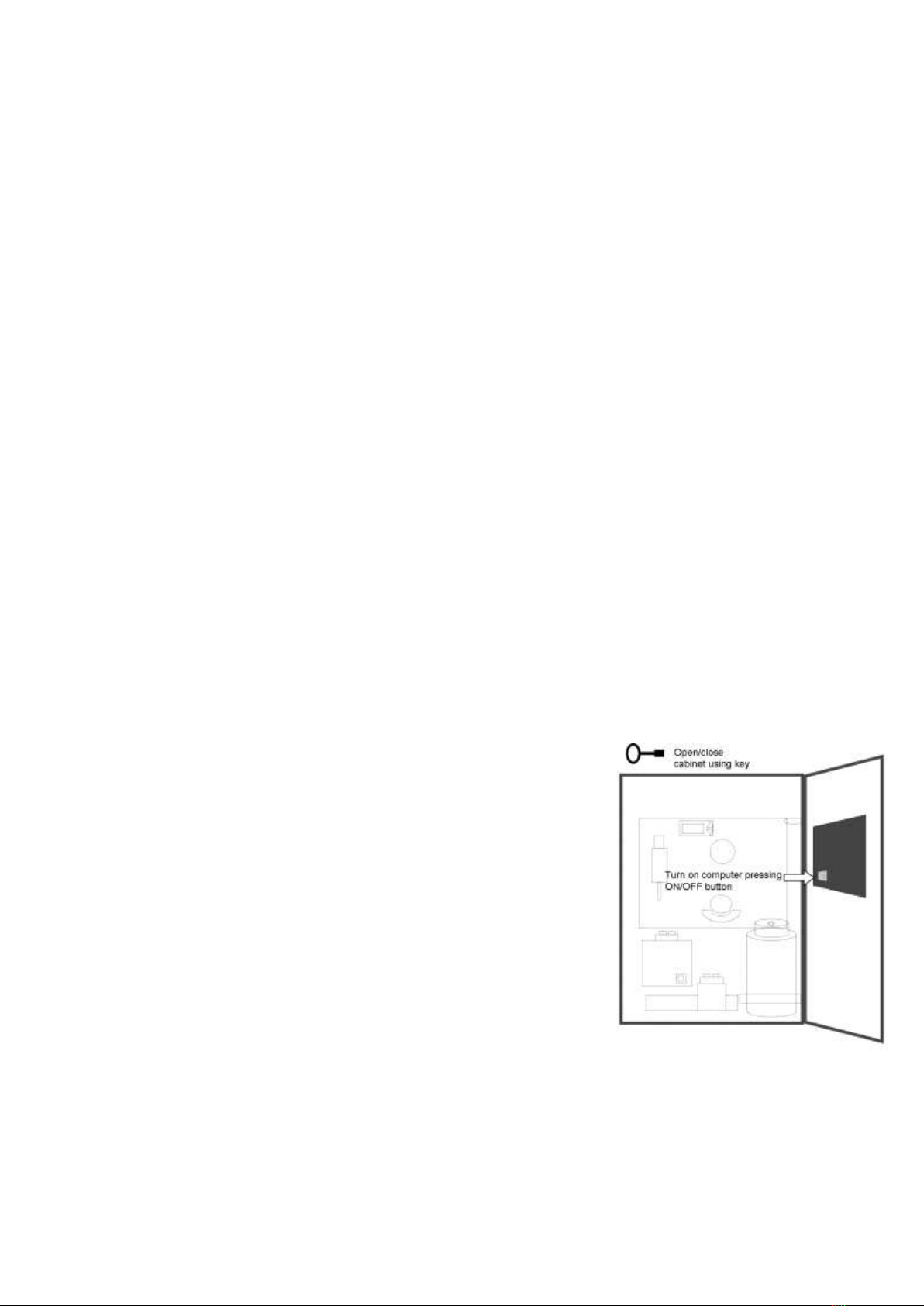

6.1 START-UP ......................................................................................................................................................................................... 8

6.2 INSTRUMENT CONTROL.................................................................................................................................................................... 9

SOFTWARE BASICS ...................................................................................................................................................................................... 10

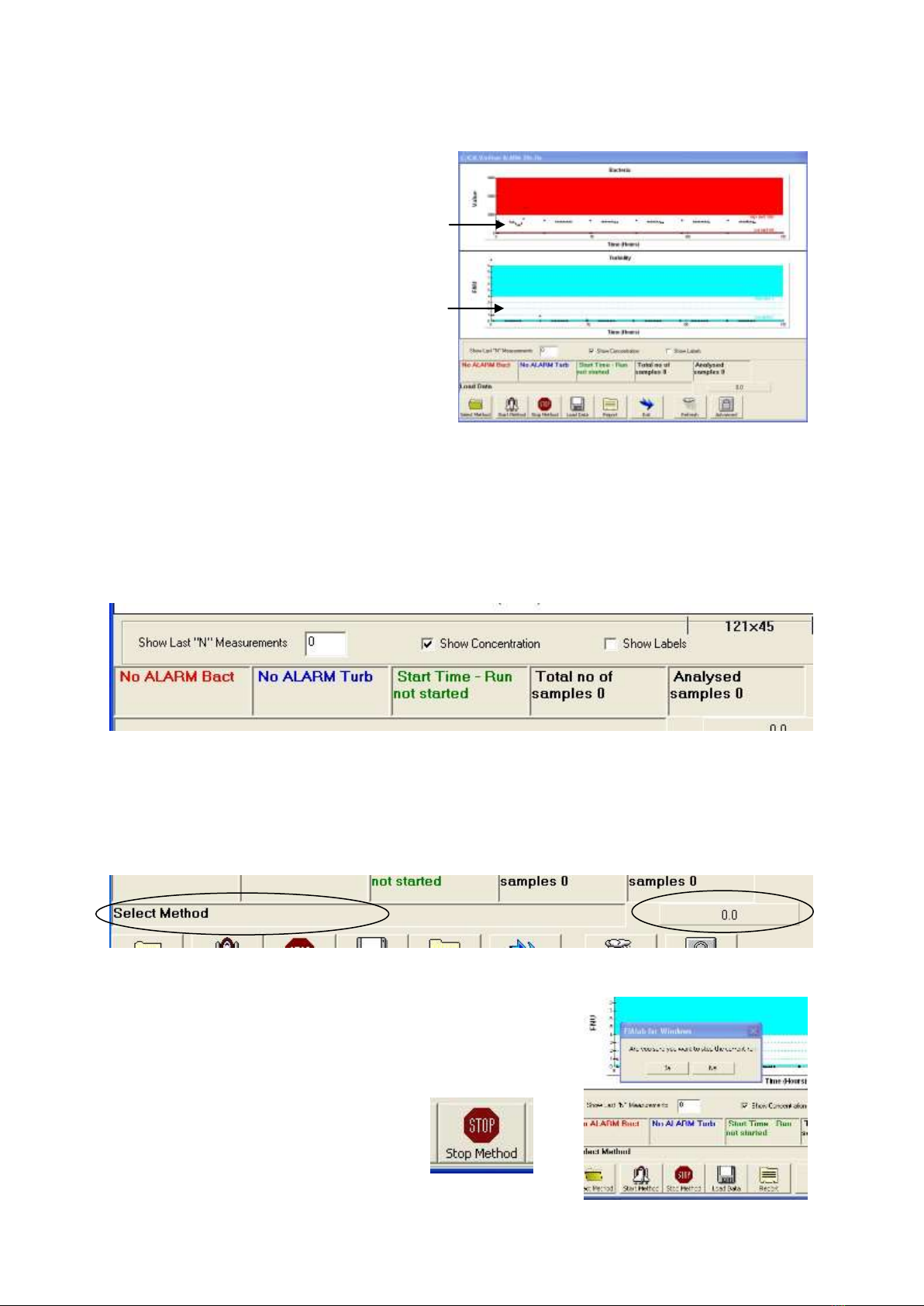

6.2.1 Results Plots.................................................................................................................................... 10

6.2.2 Information Boxes........................................................................................................................... 10

6.2.3 Instrument Run Status ..................................................................................................................... 10

6.2.4 Stop Method .................................................................................................................................... 10

6.2.5 Closing Software ............................................................................................................................. 11

6.2.6 Report File, Results and Copy......................................................................................................... 11

6.2.7 Loading Data from Previous Runs.................................................................................................. 12

6.2.8 Starting a New Run ......................................................................................................................... 12

6.2.9 Audio Alarm.................................................................................................................................... 12

6.2.10 Advanced..................................................................................................................................... 12

7REMOTE WARNING................................................................................................................................ 13

7.1 GSM MODEM SETUP...................................................................................................................................................................... 13

7.2 SMS ALARMS AND COMMANDS..................................................................................................................................................... 13

7.3 LAN REMOTE CONTROL ................................................................................................................................................................ 14

7.4 DIGITAL SIGNALS........................................................................................................................................................................... 15

8MAINTENANCE........................................................................................................................................ 15

8.1 BATCHWISE ROUTINES................................................................................................................................................................... 15

8.2 QUARTERLY ROUTINES .................................................................................................................................................................. 16

8.3 ANNUAL ROUTINES ........................................................................................................................................................................ 16

9INTERPRETATION OF RESULTS......................................................................................................... 18

9.1 METHOD:COLIFORMS P/A (PRESENCE /ABSENCE)........................................................................................................................ 18

9.2 METHOD:TURBIDITY (PARTICLES IN THE SAMPLE)........................................................................................................................ 19

10 TROUBLESHOOTING....................................................................................................................... 19

10.1 TECHNICAL ERRORS ....................................................................................................................................................................... 19

10.1.1 Self Diagnostics .......................................................................................................................... 20

10.2 METHODS /REAGENTS ................................................................................................................................................................... 23

10.3 OTHER............................................................................................................................................................................................ 23

11 APPLICATION NOTE - METHODS................................................................................................. 24

12 QUICK GUIDES AND SUPPLEMENTARY .................................................................................... 25