Collomix Rühr- und Mischgeräte Gmbh Shaker VIBA 15 &VIBA25

D-85080 Gaimersheim

Edition 2.3-05 1

Contents

1. Layout drawings ...................................................................................3

1.1 Machine components ........................................................................... 3

1.2 Variants ............................................................................................... 4

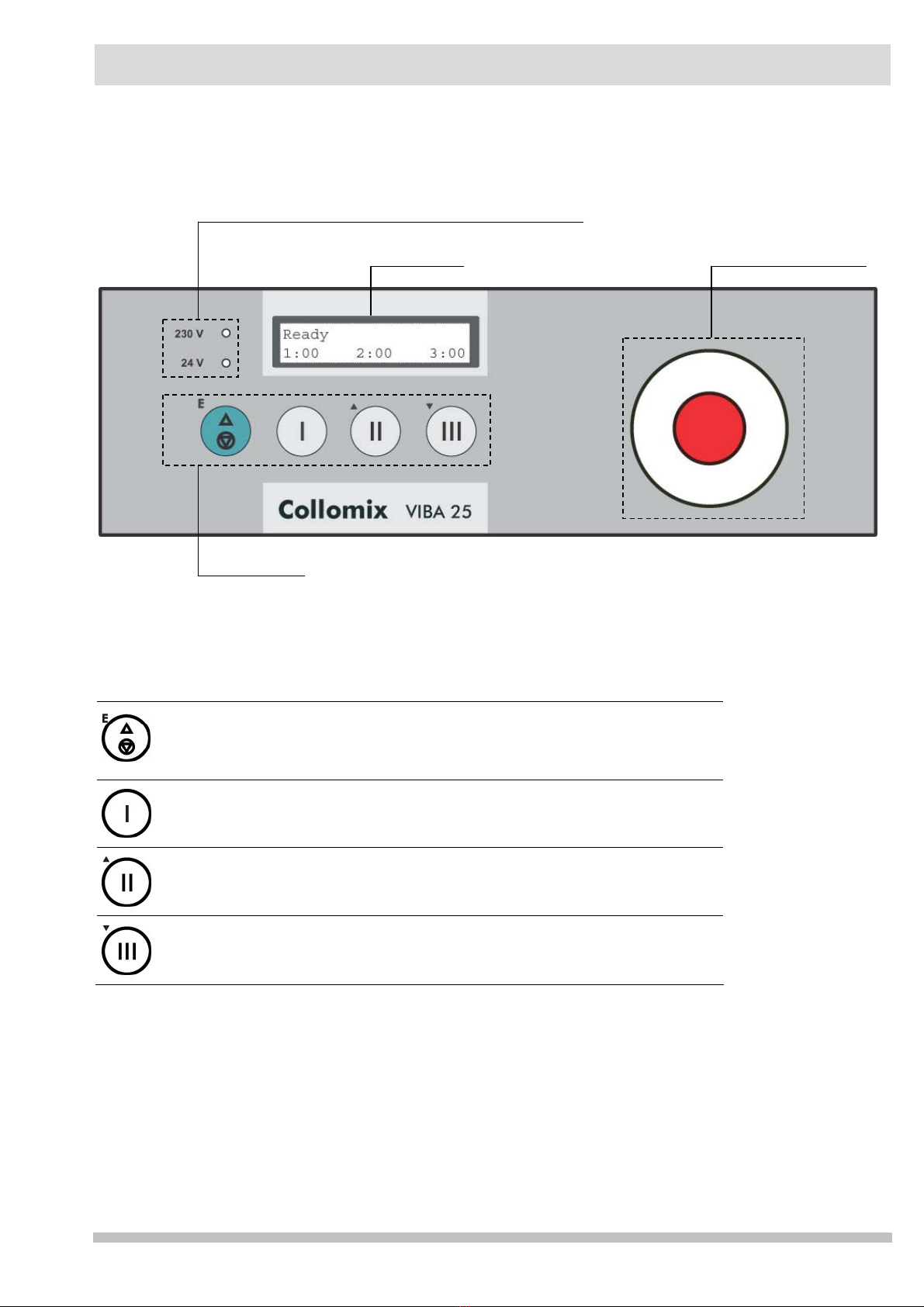

1.3 Operator's controls ............................................................................... 5

2. General information ............................................................................6

2.1 Proper use............................................................................................ 6

2.2 Working principle ................................................................................. 6

3. Safety instructions ................................................................................7

3.1 Safety-relevant components.................................................................. 8

4. Using the machine for the first time ....................................................9

4.1 Installing the machine – Transport notes ............................................... 9

4.2 Removing the transport brace ............................................................... 9

4.3 Fitting the loading shelf and the door handle........................................ 9

4.4 Moving the machine........................................................................... 10

4.5 Manual door release .......................................................................... 10

5. Operation ...........................................................................................11

5.1 Switching on the machine................................................................... 11

5.2 Trial run ............................................................................................. 11

5.3 Loading the container......................................................................... 11

5.4 Starting the mixing cycle..................................................................... 12

5.5 Ending the mixing cycle ...................................................................... 12

5.6 Stand-by ............................................................................................ 12

5.7 Triggering the Emergency Stop function .............................................. 13

5.8 Average mixing cycles ........................................................................ 13

6. Program flow......................................................................................14

6.1 Switching on....................................................................................... 14

6.2 Mixing cycle........................................................................................ 14

7. The service menu................................................................................15

7.1 Activating the service menu ................................................................ 15

7.2 Operator prompting ........................................................................... 16

7.3 Service menu sequence ...................................................................... 17

7.4 Setting the operating parameters........................................................ 18

7.4.1 Switching output function test (TEST OUTPUTS) ............................................... 18

7.4.2 Changing the mixing times (TIME 1 – 3)........................................................... 18

7.4.3 Low/high clamping pressure changeover point (SMALL POT HEIGHT) *only VIBA

25 19

7.4.4 Opening and closing the mixing unit (DC-MOT FREERUN) ............................... 19

7.4.5 Setting the end stop of the mixing unit (DC-MOT ENDPOS).............................. 20

7.4.6 Setting the low clamping pressure (DC-MOT CLAMP LOW) *only VIBA 25 ....... 21

7.4.7 Setting the high clamping pressure (DC-MOT CLAMP HIGH)........................... 22

7.4.8 Switching on the shaker motor (SHAKER MOT)................................................. 23

7.4.9 Saving changes (SAVE TO EPROM) .................................................................. 23

7.4.10 Deactivating the service menu.................................................................. 24