5

1. UNPACKING

Before installing and starting up the equipment, it is

important that you check the box and the state of the

equipment in order to verify that it has not suffered any

damages during its transportation.

Attention: Any claim for damages suffered during

transportation must be presented to the equip-

ment’s distributor together with the packaging

slip or invoice, adding the name of the carrier, within

24 hours from receiving the merchandise.

Take out the equipment and accessories from their

cardboard packaging, removing the corresponding pro-

tections.

Attention: Make sure to properly dispose of any

plastic bags, keeping them out of the reach of

children as they can be dangerous for them.

On the inside you will find (depending on the model):

The water treatment equipment, installation acces-

sories and its documentation.

The materials used in the packaging

are recyclable and

must be discarded in the appropria-

te collection bins or

in the local centre designated for

the recuperation of

waste materials.

This product cannot be discarded

together with other urban waste.

When the equipment’s lifespan comes

to an end, it should be handed

over to the company or centre where

you acquired the device, or in a Recycling

Centre or local centre specialised

in the recycling of materials,

indicating that it has electronic components

and refrigerating gases. The proper collection

and treatment of the unusable devices contributes to

the preservations of natural resources and helps avoid

any potential risks to public health.

2. INTRODUCTION

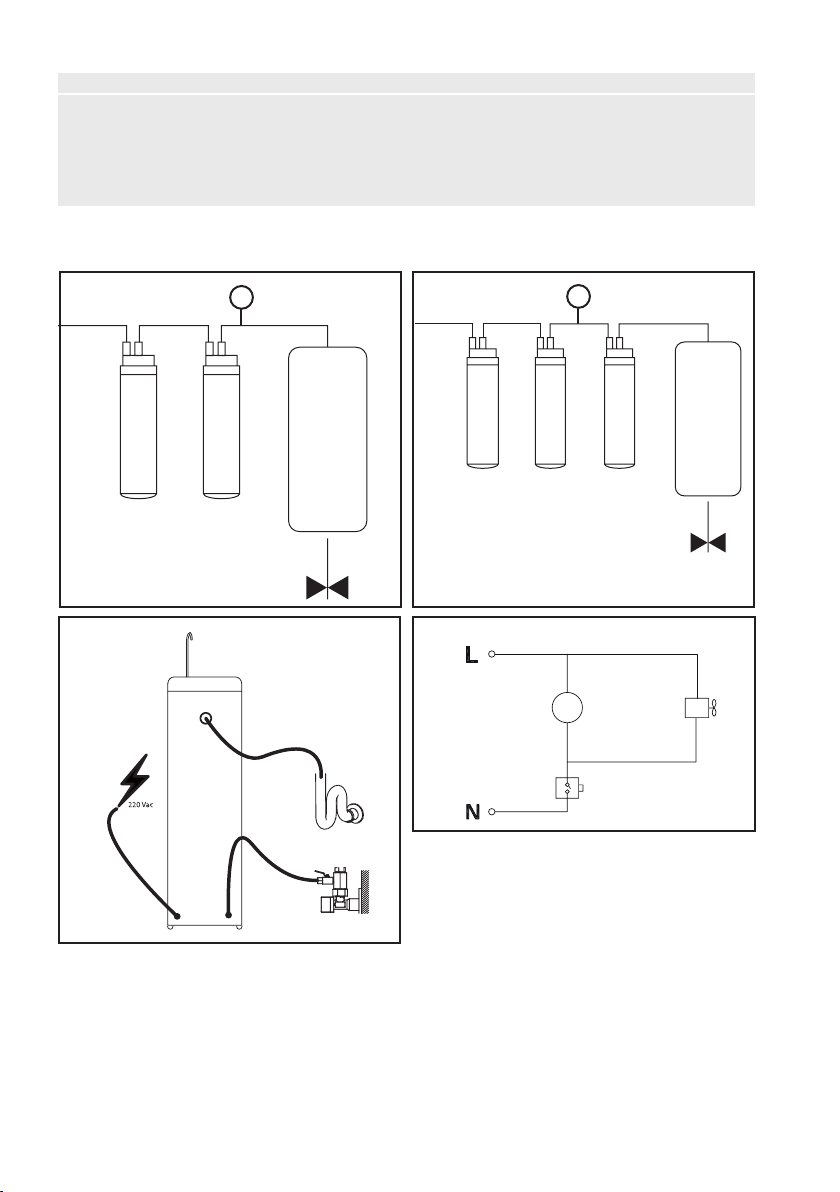

This general manual for Columbia dispensers describes

the characteristics of versions F and UF of the equip-

ment.

F systems include sediment filters and activated carbon

filters. UF systems include sediment filters, activated

carbon filters and an ultrafiltration membrane.

Congratulations. You have acquired one of the best

existing equipment in the market for the treatment of

water for domestic and office use.

This equipment will help you improve the characteris-

tics of your water, putting high quality water at your

disposal.

Your equipment will offer you various benefits and ad-

vantages:

• This is a physical system that does not use nor add

chemical products into the water.

• It offers water of high quality.

• It has a low maintenance cost.

• It ensures high production.

3. THE TYPES OF TREATMENT USED BY

COLUMBIA

Depending on the model, Columbia dispensers equip-

ment

are available with different types of water treatment:

filters and ultrafiltration.

3.1 WHAT IS FILTRATION?

Sediment filters

Filtration is the process of separating suspended solids

in the water by using a porous medium, also called filter.

The water goes through the pores of the filter, but par-

ticles that are larger than the pores of that filter are re-

tained by the filter itself which provides a clearer water.

Columbia dispensers equipment utilises 5 μm filters.

Activated carbon filters

Activated carbon is used to eliminate chloride in water,

and to improve its flavour and smell, as well as to elimi-

nate some organic components thanks to its great

absorbing capacities. Columbia dispensers equipment

utilise granulated carbon.

3.2 WHAT IS ULTRAFILTRATION?

Ultrafiltration is a system used to completely eliminate

all virus and bacteria from the water. Ultrafiltration

membranes have a porosity between 0,1 and 0,001 μm,

and for this reason they are able to retain suspended

solids much better.

4. PRIOR WARNINGS

Attention: Carefully read and safeguard this ma-

nual before installing and starting up the equip-

ment. If you have any doubts regarding the ins-

tallation, use or maintenance of this equipment, get in

touch with the technical assistance service (T.A.S) of

your distributor.

Attention: This equipment does not PRODUCE

POTABLE water. If the water to be treated comes

from a public source (and therefore conforms to

all applicable laws), this equipment will substantially

improve the quality of the water. Otherwise, it will be

necessary to carry out a physical, chemical and bac-

teriological analysis of the water to ensure its proper

purification by using the appropriate techniques and

equipment as needed. This needs to be done BEFORE

THE INSTALLATION of the equipment. Get in touch with

your distributor so that it can advise you with regards

to the appropriate treatment for your situation.

The water treatment equipment requires regular main-

tenance that needs to be carried out by qualified te-

chnical personnel in order to guarantee the quality of

water produced and provided.