© 2016Combat HVAC Limited

All rights reserved. Nopartof this work covered bythe copyrights herein maybereproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without

the written permission of Combat HVAC Limited.

Printed in U.K.

TABLE OF CONTENTS

SECTION 1: Heater Safety...................................................... 2

1.1 Manpower Requirements ............................................. 2

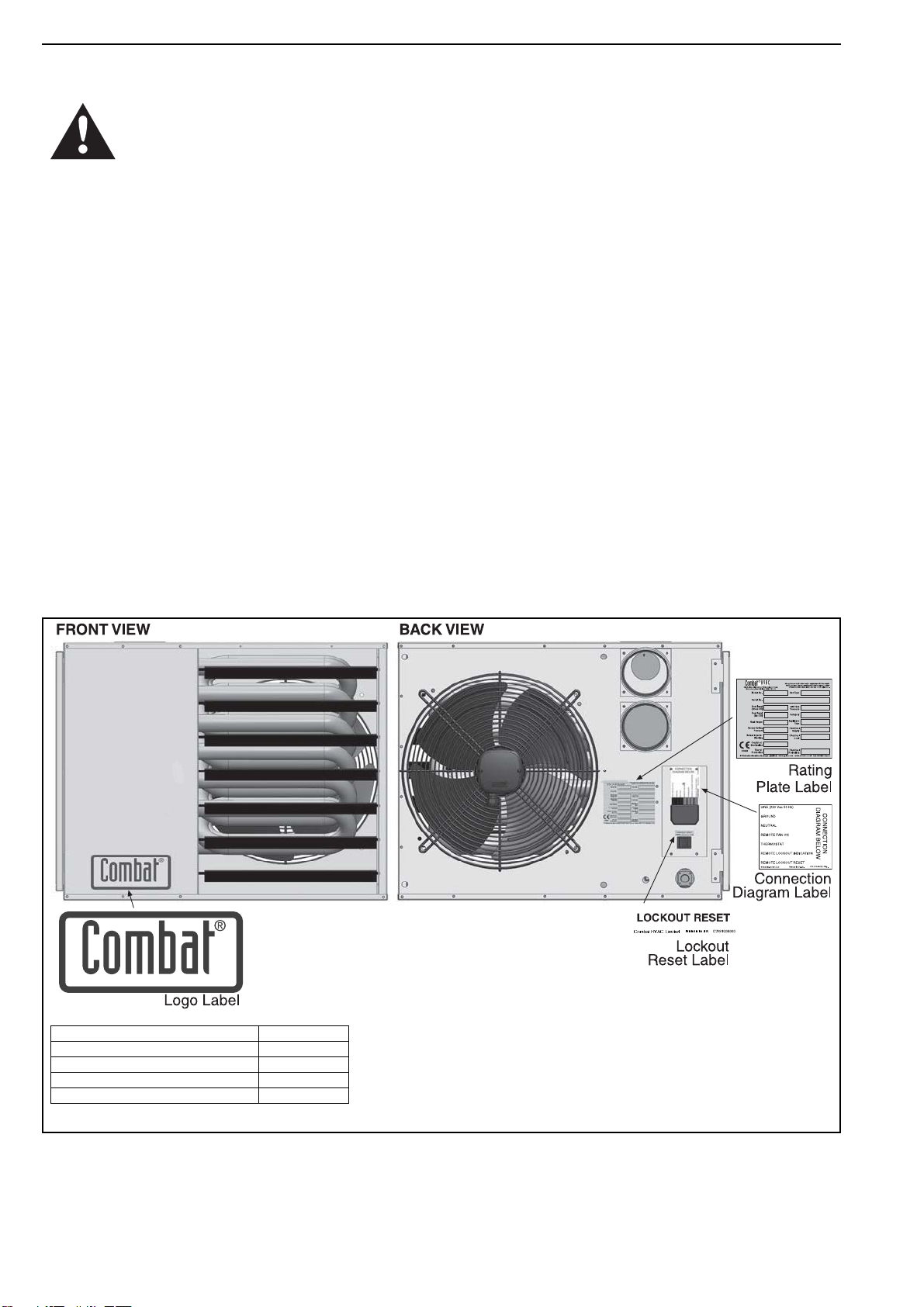

1.2 Safety Labels and Their Placement .............................2

SECTION 2: Installer Responsibility ..................................... 4

2.1 Clearances to Combustibles ........................................ 4

2.2 Corrosive Chemicals.................................................... 4

2.3 National Standards and Applicable Codes .................. 4

SECTION 3: Clearances to Combustibles............................. 5

3.1 Required Clearances to Combustibles......................... 5

SECTION 4: Critcal Considerations ...................................... 7

4.1 Ventilation .................................................................... 7

4.2 Gas Supply .................................................................. 7

4.3 Electrical Supply .......................................................... 7

4.4 Flue.............................................................................. 7

SECTION 5: Specifications .................................................... 8

5.1 CTCUA (All Models) ....................................................8

5.2 General Technical Data Table (All Models) ..................9

5.3 Technical Data Table (All Models)................................ 9

SECTION 6: Heater Installation............................................ 10

6.1 General...................................................................... 10

6.2 Basic Information....................................................... 10

6.3 Location and Suspension .......................................... 10

6.4 Handling .................................................................... 10

6.5 Suspension and Shelf Mounting ................................ 10

6.6 Wall Mounting ............................................................ 10

SECTION 7: Flue Installation ............................................... 13

7. 1 F l ue Installation .......................................................... 13

7.2 Changing Flue and Air Intake Orientation .................. 13

7.3 Type C12, C32 & C62 Appliance..................................... 13

7.4 Type B22 Appliance ..................................................... 13

SECTION 8: Air Supply......................................................... 16

8.1 Room Sealed Installation........................................... 16

8.2 Open Flued Installation.............................................. 16

8.3 Building Ventilation .................................................... 16

SECTION 9: Gas Pipe Work.................................................. 17

9.1 Connections............................................................... 17

SECTION 10: Wiringand Electrical Information................. 19

10.1 Electrical Supply ...................................................... 19

10.2 Remote Controls ...................................................... 19

10.3 CTCUA Wiring Diagram (All Models) ....................... 20

SECTION 11: Commissioning.............................................. 21

11.1 Pre-Commission Checks .......................................... 21

11.2 Gas Supply ............................................................... 21

11.3 Mechanical Checks................................................... 21

11.4 Begin Commissioning............................................... 22

11.5 Co m bustion Testing .................................................. 23

11.6 Turning Off the Heater .............................................. 23

11.7 External Controls ...................................................... 23

11.8 Complete the Commissioning................................... 24

11.9 Instruction to the User .............................................. 24

SECTION 12: User Instructions ........................................... 25

12.1 User Instructions...................................................... 25

12.2 Heater Operation ..................................................... 25

12.3 Common User Controls ...........................................25

12.4 Lighting Instructions................................................. 26

12.5 Simple Fault Finding ................................................ 26

SECTION 13: Servicing.........................................................27

13.1 Servicing Instructions...............................................27

13.2 Burner Maintenance.................................................27

13.3 Fan/Motor Assembly Maintenance ...........................27

13.4 Heat Exchanger Maintenance..................................27

13.5 Gas Control Valve Maintenance ...............................28

13.6 Flue Fan ...................................................................28

13.7 Maintenance Checklist .............................................28

SECTION 14: Conversion Between Gases ..........................30

14.1 General ....................................................................30

14.2 Burner Conversion ...................................................30

14.3 Gas Valves ...............................................................30

SECTION 15: Troubleshooting.............................................31

15.1 General ....................................................................32

15.2 Troubleshooting For Automatic Ignition Burner

Systems....................................................................33

15.3 Troubleshooting for Flame Supervision System .......34

15.4 Troubleshooting for Solenoid Valves ........................34

15.5 Troubleshooting for Main Fan ...................................35

SECTION 16: Removal and Replacement Parts..................36

16.1 Gas Valve .................................................................36

16.2 Ignition Electrode and Flame Probe .........................38

16.3 Flue Fan Vertical Installation (All Models) ................39

16.4 Pressure Switch........................................................40

16.5 Ignition Control .........................................................41

16.6 CTCUA Axial Fan/Guard/Motor Assembly ...............41

16.7 Fan and Limit Thermostats ......................................41