Product Damage Hazard

Do not use heater in area containing

corrosive chemicals.

Refer to appropriate Material Safety Data

Sheets (MSDS).

Failure to follow these instructions can result

in product damage.

To install the heater, as well as the fuel and electrical supplies, in

accordance with applicable specifications and regulations. Combat

HVAC Limited recommends the installer contact a local building

inspector, Fire Oicer or insurance company for guidance.

To use the information given in this manual together with the local and

national regulations to perform the installation.

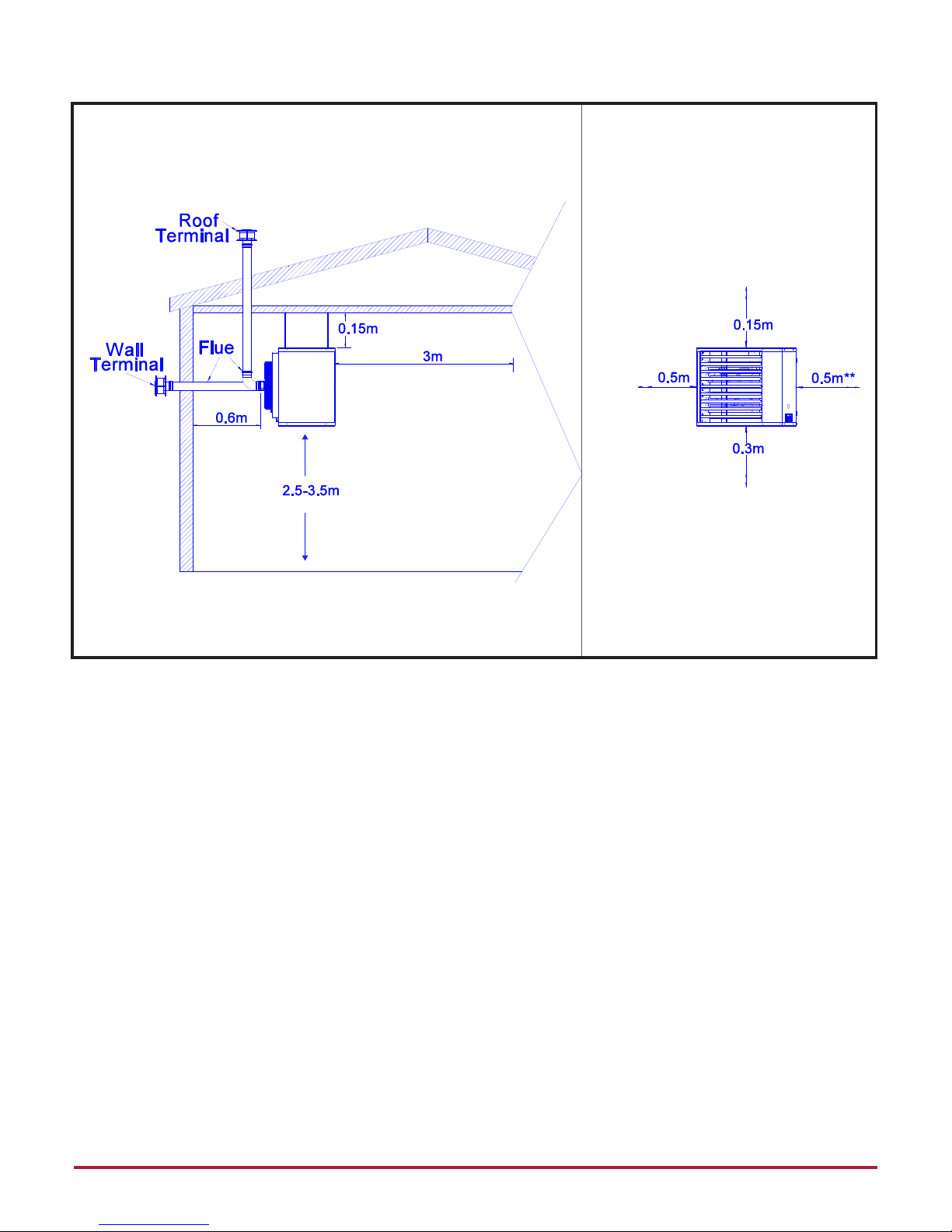

To install the heater in accordance with the clearances to combustibles

of this heater.

To furnish all needed materials not furnished as standard equipment.

To plan the location of supports, flues and air intakes.

To provide access to burners for servicing.

To provide the owner with a copy of this installation, commissioning,

operation and service manual.

To never use heater as support for ladder or other access equipment

and never hang or suspend anything from the heater

To ensure that there is suicient ventilation in the area to comply with

the requirements of all relevant local and national regulations.

To ensure the heater is placed in an approved application.

2.1 Laminated Wall Plate

A laminated wall plate is available for the heater as a permanent

reminder of the safety instructions and the importance of the required

clearances to combustibles. Aix the plate by peeling o the backing of

the adhesive strips on the rear surface and position the plate on a wall

near the heater

A copy of the wall plate is illustrated on the back cover. Know your

model number and installed configuration. The model number and

installed configuration are found on the burner and in the Installation,

Commissioning, Operation and Service Manual. Write the largest

clearance dimensions with permanent ink according to your model

number and configuration in the open spaces on the plate.

2.2 Corrosive Chemicals

Combat HVAC Limited cannot be responsible for ensuring that all

appropriate safety measures are undertaken prior to installation; this

is entirely the responsibility of the installer. It is essential that the

contractor, the sub-contractor, or the owner identifies the presence

of combustible materials, corrosive chemicals or halogenated

hydrocarbons* anywhere on the premises.

* Halogenated Hydrocarbons are a family of chemical compounds

characterized by the presence of halogen elements (fluorine, chlorine,

bromine, etc.). These compounds are frequently used in refrigerants,

cleaning agents, solvents, etc. If these compounds enter the air supply

of the burner, the lifespan of the heater components will be greatly

reduced. Warranty will be invalid if the heater is exposed to halogenated

hydrocarbons.

2.3 National Standards and Applicable Regulations

All appliances must be installed in accordance with the latest revision

of applicable standards and local and national regulations. This refers

also to the electric, gas and venting, flueing and insulation ventilation.

Note: Additional standards for installations in public garages, aircraft

hangars, etc. may be applicable.