1‐818‐841‐5500 10 www.comcoinc.com

Iftheunitdoesnotpressurizewhenyouturniton:

•Istherepowertotheunit?Doesthelightonthepowerswitchilluminate?

Ifnot,checkthepowercordconnectionsatthebackoftheunitandatthepowersource.Check

thefuse.

•Istheairlineconnected?Aretheupstreamvalvesopen?

Checktheinletairsupply.

•Doyouhearairescapingfromtheunitwhenitisturnedon?

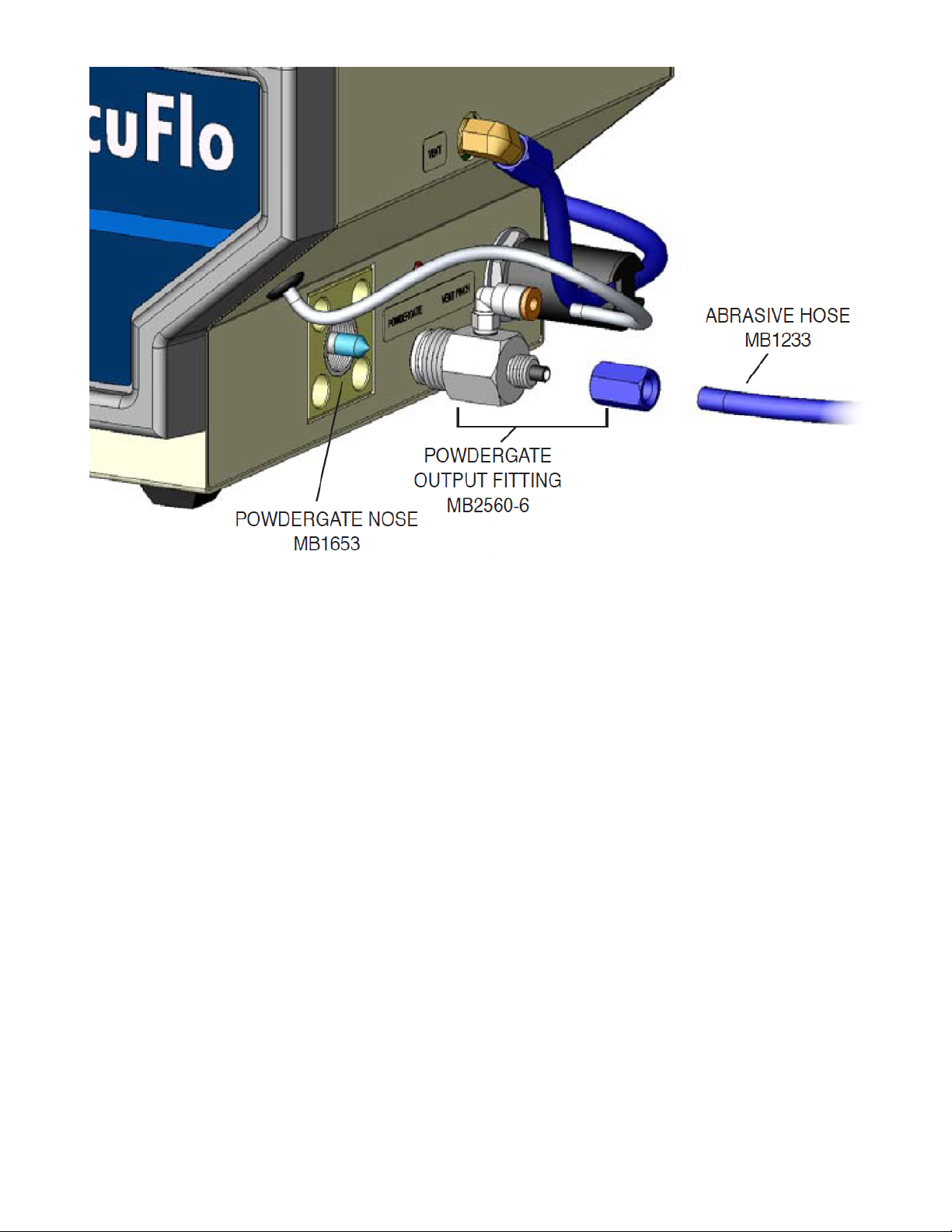

Checkthattheinletair,venthose,andabrasivehoseexitingthePowderGate®valveare

connectedproperly.Seetheset‐upguideonpages4‐5.Makesurethetankcoverissecurely

fastened.

Ifairispassingthroughthenozzle,butnoabrasive;orifthecuttingactiondecreases:

•Isthepowdertankempty?Refill.

•Istheabrasiveinthetankdampandstickingtothewalls?

Replacewithfreshpowder.Checkthatyourairdryerisworkingproperly.

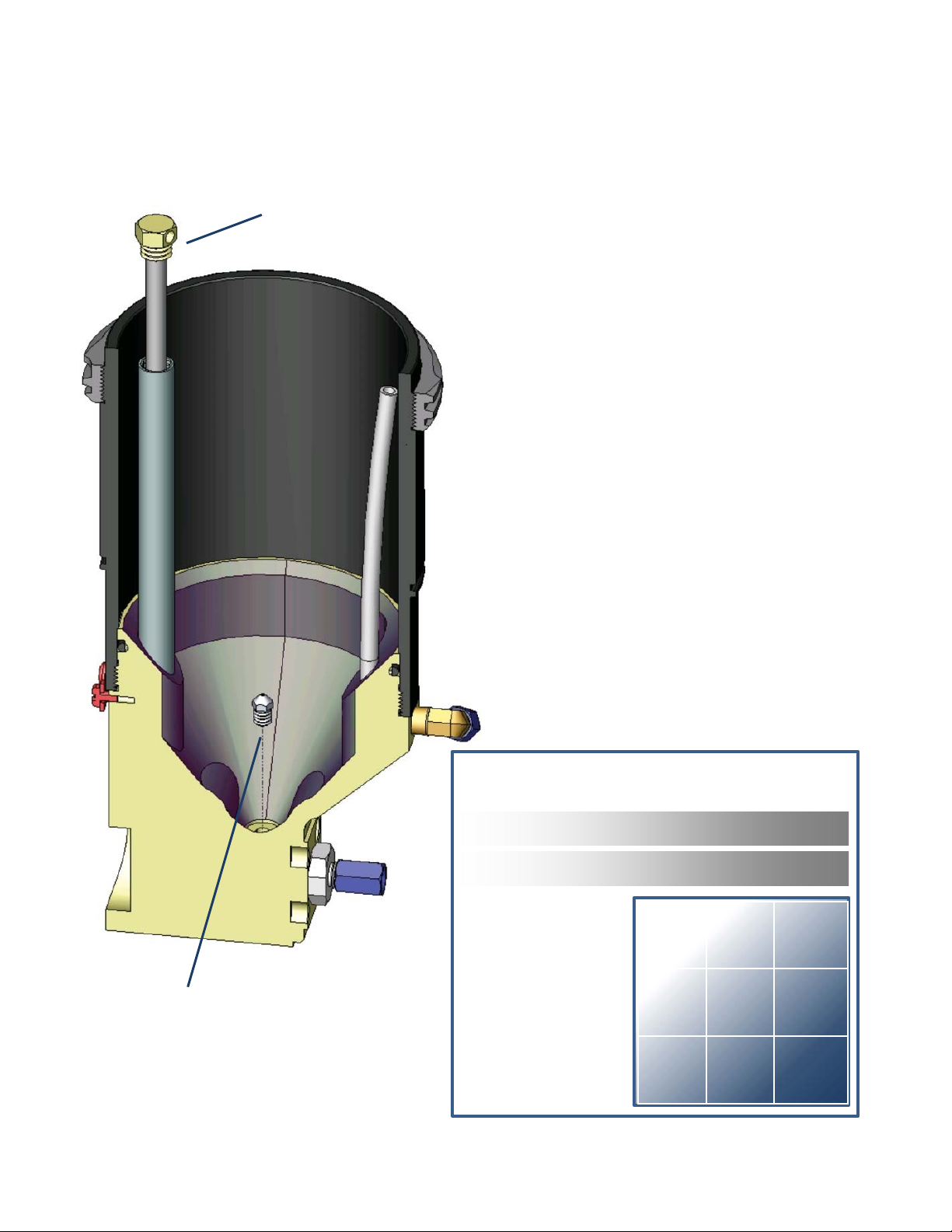

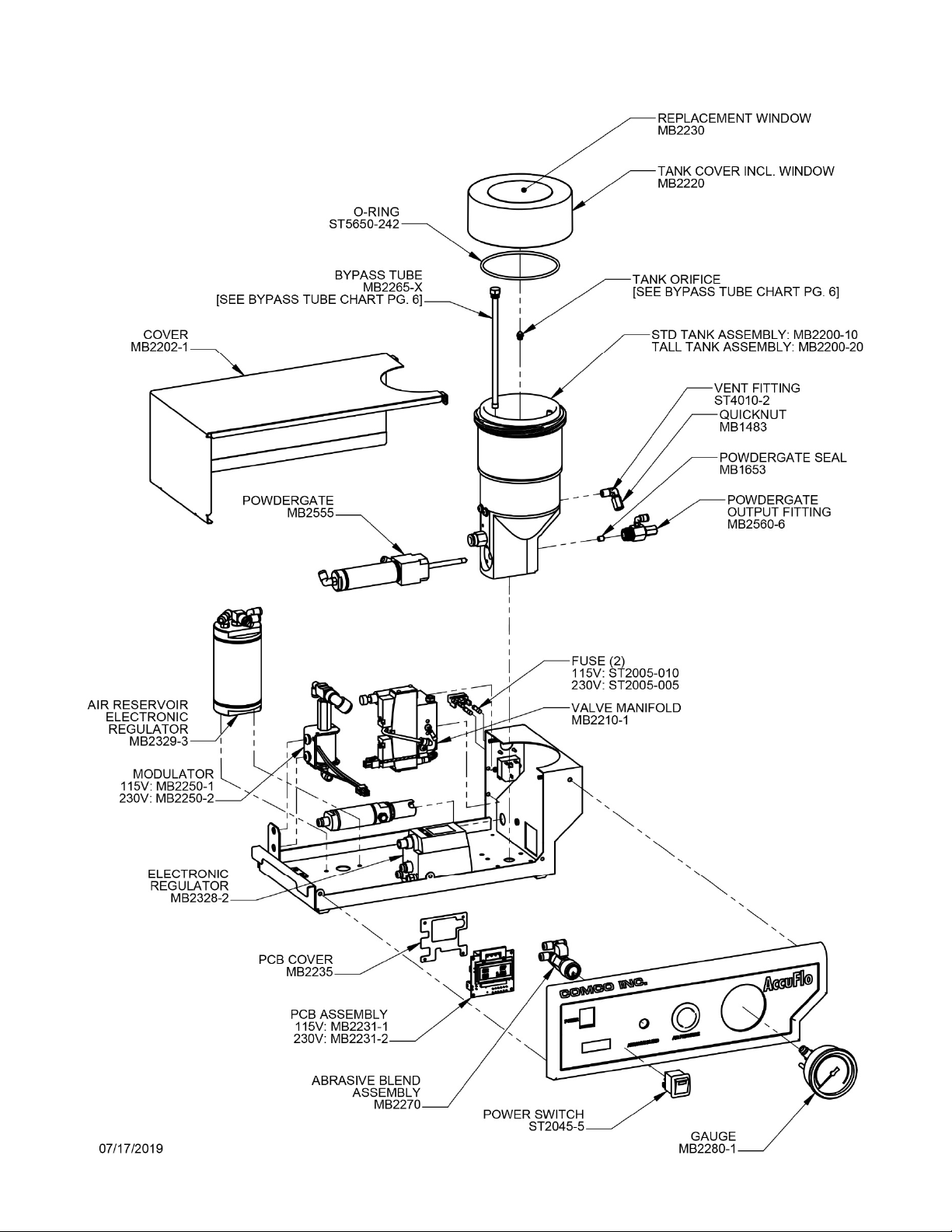

•Isthetankorificeplugged?

Emptypowder,removeorifice,andinspect.Checktoseethatyoursupplierofabrasivepowder

isprovidinghighqualitymaterial.

FordetailsseetheSupportsectiononourwebsite.

•Isyourmodulatorfunctioningproperly?

Youshouldhearabuzzingsoundwhentheblastisactivated.Ifnot,themodulatormayneedto

bereplaced.ForfurtherdetailscontactTechnicalSupport.

Ifnothinghappenswhentheblastisactivated:

•Isthenozzleplugged?Removeandinspect.

•IsthePowderGate®valvefailingtoopen?ContactTechnicalSupport.

IfyoususpectthePowderGate®valveisnotclosingcompletely:

WhenthePowderGate®valvecloses,placeafingerovertheendofthenozzlefor3seconds.

Whenyouremoveyourfinger– isthereasmallpuffofair?Ifso,therearetwopossibilities:

•ThePowderGate®noseiswornandcanbereplacedasdescribedabove.

•Theabrasivemixturemaybetoorich.ReduceAbrasiveBlendadjustmentonfrontpanel,or

checktheBypassTubeChartforaleanermixturetohandleyournozzlesize.

Troubleshooting

Contaminationoftheabrasivepowderfrom

moistureand/oroilisoneofthemost

commonproblemsassociatedwithmicro‐

abrasiveblasting.

Moisturewillcausethepowderto“clump

up,”preventingitfromflowingfreelyfrom

thetank.

Oilintheairsupplywillnotonlyaffect

abrasiveflow,itcanalsocausemajor

componentfailureswithinyourblaster,

resultingincostlyrepairs.

Toavoidmoistureandoilcontamination,run

yourairsupplythroughapositiveairdryer

equippedwithanappropriateoilfilter.

PreventMoistureandOilContamination