Comco Inc. ii Issue Date: January 2009

Table of Contents

The Comco Warranty ............................................................................................iv

Safety Precautions ................................................................................................v

Chapter 1: The DirectFlo DF1400 .............................................................1-1

This chapter introduces you to the basic unit, including its

description, principles of operation, and detail specifications.

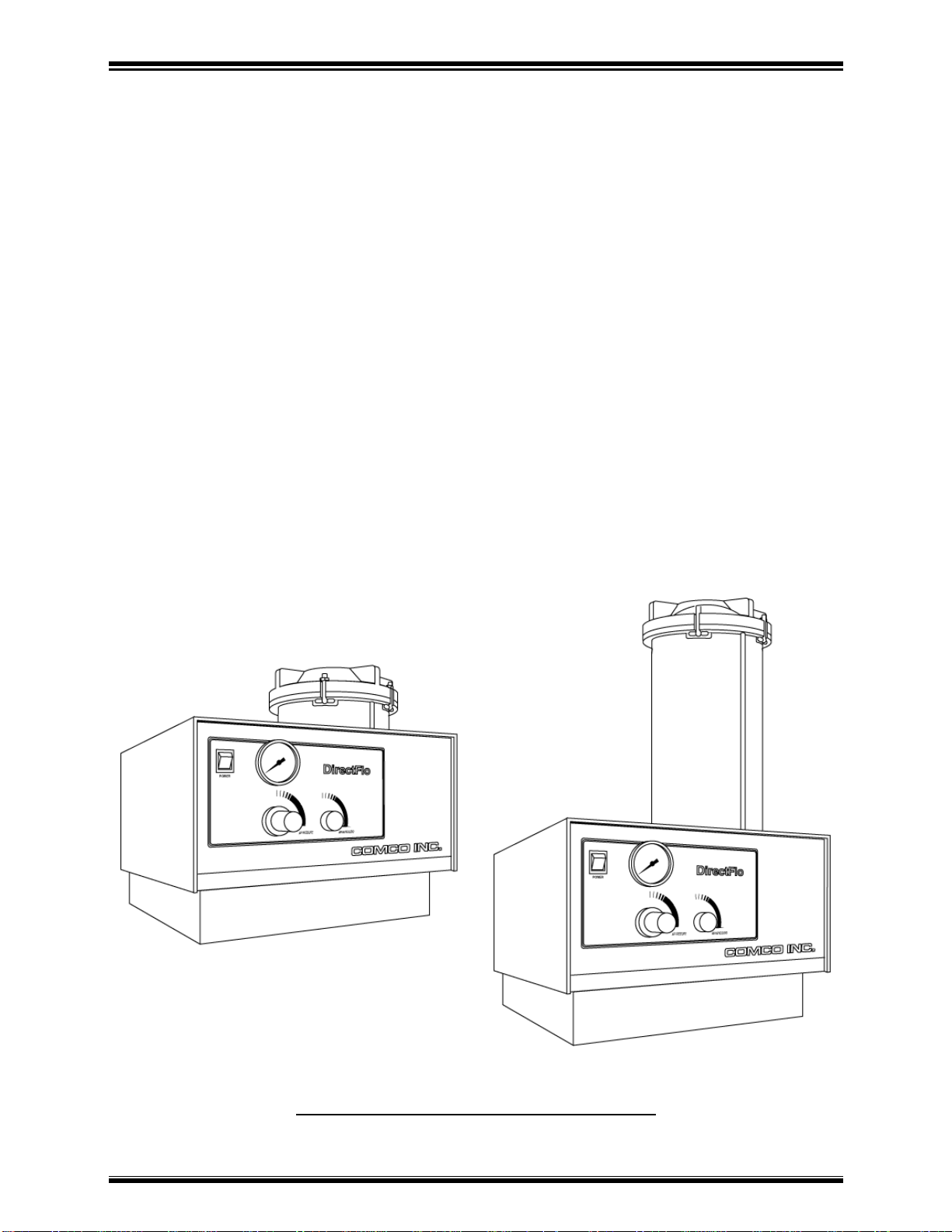

Overview....................................................................................................1-2

Figure 1-1, DirectFlo DF1400.........................................................1-2

How The DirectFlo Works..........................................................................1-3

Figure 1-2, DirectFlo Pressurized...................................................1-3

Figure 1-3, Modulator Open............................................................1-4

Figure 1-4, Modulator Closed.........................................................1-5

Detail Specifications...................................................................................1-6

Chapter 2: Getting Started........................................................................2-1

This chapter tells you what you need to have and what you

need to do to set up the DirectFlo.

The Proper Work Area...............................................................................2-2

Figure 2-1, Micro-abrasive Blasting System Requirements ............2-3

Figure 2-2, DirectFlo Reference Sheet...........................................2-4

What You Received with the DirectFlo.......................................................2-5

Basic Components of the DirectFlo............................................................2-6

Figure 2-3, External Component Locations.....................................2-7

Setup and Test ..........................................................................................2-8

Figure 2-4, Tank Inspection............................................................2-9

Chapter 3: Using the DirectFlo.................................................................3-1

This chapter discusses the selection of key operating

parameters such as abrasives and nozzles; and tells you

how to operate the DirectFlo for maximum efficiency.

Essence of Micro-Abrasive Blasting...........................................................3-2

Table 3-1, Factors Affecting Abrasive Blasting...............................3-3

Abrasive Selection.....................................................................................3-4

Table 3-2, Abrasives and Their Applications...................................3-5

Tank Orifice and Nozzle Selection .............................................................3-6

Table 3-3, Orifice Selection Chart...................................................3-7

Figure 3-1, Changing the Tank Orifice............................................3-7

Figure 3-2, Changing the Nozzle....................................................3-8

Table 3-4, Nozzle Chart..................................................................3-9

General Operation of the DirectFlo ............................................................3-12

Figure 3-3, Filling the Abrasive Tank..............................................3-13

Figure 3-4, Controls and Indicators.................................................3-14